Professional Documents

Culture Documents

Radiograph Interpretation - Welds

Uploaded by

Ravi ShankarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radiograph Interpretation - Welds

Uploaded by

Ravi ShankarCopyright:

Available Formats

Radiograph Interpretation - Welds

WELDING DEFECT

Any irregularity (discontinuity or flaw) in the weld metal, which exceeds the applicable code limit, is

termed as a WELD DEFECT (or Welding Defect). Please note that a discontinuity can be termed as a

defect only when, if it exceeds the specified code limit, hence we can say that every defect present

in a weld metal is a discontinuity but every discontinuity present in the weld metal may not

necessarily be a defect.

Defects may occur due to the following reasons

1. Incorrect welding parameters

2. Inappropriate welding procedures

3. Poor process condition

4. Inappropriate selection of filler metal and parent metal

5. Unskilled welder or welding operator

6. Incorrect job preparation

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

GENERAL WELDING DISCONTINUITIES

1. COLD LAP

2. POROSITY

3. CLUSTERE POROSITY

4. SLAG INCLUSION

5. INCOMPLETE PENETRATION (IP) OR LACK OF PENETRATION (LOP)

6. INCOMPLETE FUSION

7. INTERNAL CONCAVITY OR SUCK BACK

8. INTERNAL OR ROOT UNDERCUT

9. EXTERNAL OR CROWN UNDERCUT

10. OFFSET OR MISMATCH

11. INADEQUATE WELD REINFORCEMENT

12. EXCESS WELD REINFORCEMENT

13. CRACKS

14. TUNGSTEN INCLUSIONS (in TIG Welding only)

15. OXIDE INCLUSIONS (in TIG /GMAW Welding )

16. BURN-THROUGH

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

COLD LAP

Cold lap is a condition where the weld filler metal does not properly fuse with the base metal or the previous weld pass material

(Interpass cold lap). The arc does not melt the base metal sufficiently and causes the slightly molten puddle to flow into the base

material without bonding.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

POROSITY

Porosity is the result of gas entrapment in the solidifying metal. Porosity can take many shapes on a radiograph but often appears

as dark round or irregular spots or specks appearing singularly, in clusters, or in rows. Sometimes, porosity is elongated and may

appear to have a tail. This is the result of gas attempting to escape while the metal is still in a liquid state and is called wormhole

porosity. All porosity is a void in the material and it will have a higher radiographic density than the surrounding area.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

CLUSTER POROSITY

Cluster porosity is caused when flux coated electrodes are contaminated with moisture. The moisture turns into a gas when heated

and becomes trapped in the weld during the welding process. Cluster porosity appear just like regular porosity in the radiograph

but the indications will be grouped close together.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

SLAG INCLUSIONS

Slag inclusions are non-metallic solid material entrapped in weld metal or between weld and base metal. In a radiograph, dark,

jagged asymmetrical shapes within the weld or along the weld joint areas are indicative of slag inclusions.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

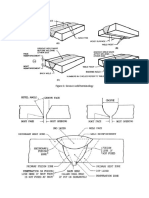

INCOMPLETE PENETRATION (IP) OR LACK OF PENETRATION (LOP)

Incomplete penetration (IP) or lack of penetration (LOP) occurs when the weld metal fails to penetrate the joint. It is one of the

most objectionable weld discontinuities. Lack of penetration allows a natural stress riser from which a crack may propagate. The

appearance on a radiograph is a dark area with well-defined, straight edges that follows the land or root face down the centre of

the weldment.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

INCOMPLETE FUSION

Incomplete fusion is a condition where the weld filler metal does not properly fuse with the base metal. Appearance

on radiograph: usually appears as a dark line or lines oriented in the direction of the weld seam along the weld

preparation or joining area.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

INTERNAL CONCAVITY OR SUCK BACK

Internal concavity or suck back is a condition where the weld metal has contracted as it cools and has been drawn up into the root

of the weld. On a radiograph it looks similar to a lack of penetration but the line has irregular edges and it is often quite wide in the

centre of the weld image.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

INTERNAL OR ROOT UNDERCUT

Internal or root undercut is an erosion of the base metal next to the root of the weld. In the radiographic image it

appears as a dark irregular line offset from the centerline of the weldment. Undercutting is not as straight edged as

LOP because it does not follow a ground edge.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

EXTERNAL OR CROWN UNDERCUT

External or crown undercut is an erosion of the base metal next to the crown of the weld. In the radiograph, it appears as a dark

irregular line along the outside edge of the weld area.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

OFFSET OR MISMATCH

Offset or mismatch are terms associated with a condition where two pieces being welded together are not properly

aligned. The radiographic image shows a noticeable difference in density between the two pieces. The difference in

density is caused by the difference in material thickness. The dark, straight line is caused by the failure of the weld

metal to fuse with the land area.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

INADEQUATE WELD REINFORCEMENT

Inadequate weld reinforcement is an area of a weld where the thickness of weld metal deposited is less than the

thickness of the base material. It is very easy to determine by radiograph if the weld has inadequate reinforcement,

because the image density in the area of suspected inadequacy will be higher (darker) than the image density of the

surrounding base material.

Prepared By CR Asia – Your Reliable Partner Approved By

CR Asia – Your Reliable Partner

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

EXCESS WELD REINFORCEMENT

Excess weld reinforcement is an area of a weld that has weld metal added in excess of that specified by engineering

drawings and codes. The appearance on a radiograph is a localized, lighter area in the weld. A visual inspection will

easily determine if the weld reinforcement is in excess of that specified by the engineering requirements.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

CRACKS

Cracks can be detected in a radiograph only when they are propagating in a direction that produces a change in

thickness that is parallel to the x-ray beam. Cracks will appear as jagged and often very faint irregular lines. Cracks can

sometimes appear as "tails" on inclusions or porosity.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

TUNGSTEN INCLUSIONS

Tungsten is a brittle and inherently dense material used in the electrode in tungsten inert gas welding. If improper

welding procedures are used, tungsten may be entrapped in the weld. Radiographically, tungsten is more dense than

aluminum or steel, therefore it shows up as a lighter area with a distinct outline on the radiograph.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

OXIDE INCLUSIONS

Oxide inclusions are usually visible on the surface of material being welded (especially aluminum). Oxide inclusions are

less dense than the surrounding material and, therefore, appear as dark irregularly shaped discontinuities in the

radiograph.

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

Radiograph Interpretation - Welds

BURN-THROUGH

Burn-Through results when too much heat causes excessive weld metal to penetrate the weld zone. Often lumps of

metal sag through the weld, creating a thick globular condition on the back of the weld. These globs of metal are

referred to as icicles. On a radiograph, burn-through appears as dark spots, which are often surrounded by light

globular areas (icicles).

Prepared By CR Asia – Your Reliable Partner Approved By

Ravi Shankar Pandey Gireesh Azhakappath

You might also like

- RADIOGRAPHY INTERPRETATION-Rev1Document41 pagesRADIOGRAPHY INTERPRETATION-Rev1OktayKul80% (5)

- MS For Welding ProcedureDocument41 pagesMS For Welding ProcedureDanish mallickNo ratings yet

- IDS 002 Flange FaceDocument1 pageIDS 002 Flange FaceKalanithi GKNo ratings yet

- Cswip 3.1 Question PaperDocument213 pagesCswip 3.1 Question Papersateesh50% (2)

- PLANT DAILY MAINTENANCE SCHEDULEDocument1 pagePLANT DAILY MAINTENANCE SCHEDULERavi ShankarNo ratings yet

- M CHOICE in Ra Để Mang Ve NhaDocument102 pagesM CHOICE in Ra Để Mang Ve NhaDinh Quang NhamNo ratings yet

- Radiography InterpretationDocument13 pagesRadiography InterpretationBhavin SukhadiyaNo ratings yet

- RT Interpretation DefectsDocument12 pagesRT Interpretation Defectsbenergy84No ratings yet

- TR - Smaw NC IDocument59 pagesTR - Smaw NC Imbranzuela_blanquero73% (11)

- Radiographic Film Interpretation - Presentation-1 PDFDocument87 pagesRadiographic Film Interpretation - Presentation-1 PDFvirat virat90% (10)

- Radiography Weld Defects GuideDocument50 pagesRadiography Weld Defects GuideWisüttisäk Peäröön100% (2)

- Weld DefectsDocument47 pagesWeld DefectsPratikNo ratings yet

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- RT Film InterpretationDocument20 pagesRT Film InterpretationMOhammed PatelNo ratings yet

- Radiograph Interpretation (RT Film Interpretation)Document10 pagesRadiograph Interpretation (RT Film Interpretation)Abu HurairaNo ratings yet

- Radiograph Interpretation - WeldsDocument18 pagesRadiograph Interpretation - WeldsRavi ShankarNo ratings yet

- RT Interpretation-SignedDocument7 pagesRT Interpretation-Signedhamdi hamdiNo ratings yet

- S6900QLDocument4 pagesS6900QLmechkashanNo ratings yet

- 002 Ref HSE-S-205-F - Procedure For Everyday Flame Resistant Work Apparel Rev 01 Aug 2012Document15 pages002 Ref HSE-S-205-F - Procedure For Everyday Flame Resistant Work Apparel Rev 01 Aug 2012Ravi ShankarNo ratings yet

- Defect-TrainingDocument16 pagesDefect-TrainingSubhash100% (1)

- API 577 Closed Books Questions AnswersDocument3 pagesAPI 577 Closed Books Questions Answersnikafiq100% (5)

- Welding Defects: Kama L Kama LDocument33 pagesWelding Defects: Kama L Kama LjesycubanNo ratings yet

- Radiographic Film Interpretation GuideDocument5 pagesRadiographic Film Interpretation Guideponnivalavans_994423No ratings yet

- Common weld discontinuities and defects guideDocument28 pagesCommon weld discontinuities and defects guideAmyNo ratings yet

- Repair Welding ProcedureDocument3 pagesRepair Welding Procedurevalararumugams100% (2)

- RADIOGRAPHY FILM INTERPRETATION GUIDEDocument16 pagesRADIOGRAPHY FILM INTERPRETATION GUIDERavindra S. Jivani100% (1)

- Radiographic DefectsDocument20 pagesRadiographic Defectshappysekhon86100% (1)

- NDE Training Guide to Welding Flaw RadiographsDocument40 pagesNDE Training Guide to Welding Flaw Radiographsadam1950100% (1)

- Identification of Weld DiscountinuitiesDocument42 pagesIdentification of Weld DiscountinuitiesAhmed shabanNo ratings yet

- Weld Radio GraphsDocument30 pagesWeld Radio Graphsvenkatesh0% (1)

- Application of Phased Array For Corrosion Resistant Alloy (CRA) WeldsDocument6 pagesApplication of Phased Array For Corrosion Resistant Alloy (CRA) WeldsKevin HuangNo ratings yet

- Radiography PresentationDocument28 pagesRadiography PresentationmqasimqasimNo ratings yet

- Welding Types and Positions and DefectsDocument10 pagesWelding Types and Positions and Defectssam_antony2005No ratings yet

- Radiography TestDocument20 pagesRadiography Testkrishna_pipingNo ratings yet

- Butt Fusion Procedure - r201505 PDFDocument15 pagesButt Fusion Procedure - r201505 PDFTsihatesfaNo ratings yet

- Radiography Weld Defects GuideDocument50 pagesRadiography Weld Defects GuideAdilMunir100% (2)

- Section 4.01 Reliance Dta Refinery Central Planning Manual RJN/CES/CP/4001Document2 pagesSection 4.01 Reliance Dta Refinery Central Planning Manual RJN/CES/CP/4001Ravi ShankarNo ratings yet

- Defect TrainingDocument16 pagesDefect Trainingdedikartiwa_dk100% (1)

- Photos of Defects Found in RadiographyDocument14 pagesPhotos of Defects Found in RadiographyKavipriyan KaviNo ratings yet

- Repair WeldsDocument57 pagesRepair WeldsJoseph Jordan Aguilar OndeNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsDanut RusNo ratings yet

- Radiograph Interpretation - WeldsDocument6 pagesRadiograph Interpretation - WeldsPercy Morales RamirezNo ratings yet

- Radiographic Film Interpretation for WeldsDocument193 pagesRadiographic Film Interpretation for WeldsHussain AL-AqilNo ratings yet

- Reliance Industries Limited Line History Sheet For CS Piping Without PWHTDocument1 pageReliance Industries Limited Line History Sheet For CS Piping Without PWHTRavi ShankarNo ratings yet

- Identify Welding Defects & DiscontinuitiesDocument21 pagesIdentify Welding Defects & DiscontinuitiesJoanna AprilNo ratings yet

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocument2 pagesReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNo ratings yet

- Reliance Industries Limited Line History Sheet For Low Alloy Steel PipingDocument2 pagesReliance Industries Limited Line History Sheet For Low Alloy Steel PipingRavi ShankarNo ratings yet

- Welding DefectsDocument15 pagesWelding DefectsAYUSH TRIVEDI100% (1)

- Helpful RT Article and PhotosDocument8 pagesHelpful RT Article and Photosponnivalavans_994423No ratings yet

- Radiograph InterpretationDocument12 pagesRadiograph InterpretationnithingrmeNo ratings yet

- RT Film Identification of Welding DefectsDocument20 pagesRT Film Identification of Welding DefectsMOhammed PatelNo ratings yet

- Flaw TypeDocument8 pagesFlaw TypeTuan Nguyen AnhNo ratings yet

- Incomplete PenetrationDocument2 pagesIncomplete PenetrationBrandon EricksonNo ratings yet

- X Ray InterpretDocument17 pagesX Ray InterpretRavi KasaudhanNo ratings yet

- Defects in Drawing and Bending30 PMFDocument17 pagesDefects in Drawing and Bending30 PMFalan ShajuNo ratings yet

- Radiograph InterpretationDocument9 pagesRadiograph InterpretationCharles OnyechereNo ratings yet

- Radiograph Interpretation - CastingsDocument5 pagesRadiograph Interpretation - CastingshoscriNo ratings yet

- Nondestructive Evaluation Techniques - RadiographyDocument8 pagesNondestructive Evaluation Techniques - RadiographyKaung Myat HtunNo ratings yet

- Radiographic DefectsDocument20 pagesRadiographic DefectsUsman AhmedNo ratings yet

- Radiograph Interpretation - WeldsDocument7 pagesRadiograph Interpretation - WeldsKiky IchanafiNo ratings yet

- Welding DefectDocument14 pagesWelding DefectAfewerk RedaNo ratings yet

- DefectDocument46 pagesDefectZikri Amal bhaktiNo ratings yet

- Weld Testing Methods for Detecting DefectsDocument51 pagesWeld Testing Methods for Detecting DefectsSwapnil Modak100% (1)

- Internal Concavity Undercut Suck BackDocument2 pagesInternal Concavity Undercut Suck Backlram70100% (1)

- Weld TestingDocument47 pagesWeld TestingPraveen SaravanabavaNo ratings yet

- Welding Defect InfoDocument7 pagesWelding Defect Infobriggswill7No ratings yet

- Itp Ec14epDocument1 pageItp Ec14epRavi ShankarNo ratings yet

- 3.1. - Column Tray Manway ChecklistDocument1 page3.1. - Column Tray Manway ChecklistRavi ShankarNo ratings yet

- Doand Dontsfor Polyethylene JointingDocument17 pagesDoand Dontsfor Polyethylene JointingarkadjyothiprakashNo ratings yet

- Ansi Pipe ScheduleDocument1 pageAnsi Pipe ScheduleRameshBMNo ratings yet

- Ansi Pipe ScheduleDocument1 pageAnsi Pipe ScheduleRameshBMNo ratings yet

- % Manpower Planned VS UtilizedDocument1 page% Manpower Planned VS UtilizedRavi ShankarNo ratings yet

- DPPR 200519 Utility+etpDocument1 pageDPPR 200519 Utility+etpRavi ShankarNo ratings yet

- DPPR 210519 Utility+etpDocument1 pageDPPR 210519 Utility+etpRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- Maintaining Plant OperationsDocument1 pageMaintaining Plant OperationsRavi ShankarNo ratings yet

- DPPR 220519 Utility+etpDocument1 pageDPPR 220519 Utility+etpRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS UtilizedDocument1 page% Manpower Planned VS UtilizedRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- PLANT DAILY MAINTENANCE SCHEDULEDocument1 pagePLANT DAILY MAINTENANCE SCHEDULERavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS Utilized: HT ST RT IN SCDocument1 page% Manpower Planned VS Utilized: HT ST RT IN SCRavi ShankarNo ratings yet

- % Manpower Planned VS UtilizedDocument1 page% Manpower Planned VS UtilizedRavi ShankarNo ratings yet

- Daily plant maintenance schedule and manpower reportDocument1 pageDaily plant maintenance schedule and manpower reportRavi ShankarNo ratings yet

- 3 Hours / 70 Marks: Seat NoDocument3 pages3 Hours / 70 Marks: Seat NoDivya ChandewarNo ratings yet

- Technology Vocational Livelihood: Shielded Metal Arc WeldingDocument9 pagesTechnology Vocational Livelihood: Shielded Metal Arc WeldingjonquintanoNo ratings yet

- Practice 6 - Questions - CSWIPDocument12 pagesPractice 6 - Questions - CSWIPravichandran0506No ratings yet

- Storage and Handling Recommandations ConsumableDocument20 pagesStorage and Handling Recommandations ConsumableTakul ThongyooNo ratings yet

- CSWIP-WI-6!92!11th Edition September 2011Document16 pagesCSWIP-WI-6!92!11th Edition September 2011JiminYoo0419No ratings yet

- Cranes & Heavy Lifting Equipment: Product LiteratureDocument33 pagesCranes & Heavy Lifting Equipment: Product LiteraturebvbarcNo ratings yet

- Properties of Fusion WeldsDocument34 pagesProperties of Fusion WeldsUmesh AryaNo ratings yet

- Erection MethodologyDocument30 pagesErection MethodologyravindraNo ratings yet

- Moment Resisting Frames - Part1Document95 pagesMoment Resisting Frames - Part1peterpaulwNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet

- Follow HereDocument18 pagesFollow HereAkram Alhaddad100% (1)

- K To 12 Basic Education Curriculum (Final)Document9 pagesK To 12 Basic Education Curriculum (Final)Lyn VallesNo ratings yet

- Defects and Discontinuities in WeldsDocument78 pagesDefects and Discontinuities in WeldsjswldeepNo ratings yet

- Unitror Welding ElectrodeDocument3 pagesUnitror Welding ElectrodeSergei KurpishNo ratings yet

- Paper 10Document8 pagesPaper 10Kani Al BazirNo ratings yet

- Welding Defects Guide: Causes and PreventionDocument63 pagesWelding Defects Guide: Causes and PreventionKhalid HafezNo ratings yet

- Cracks in Welds: Paper PresentationDocument19 pagesCracks in Welds: Paper PresentationJigar Mevada100% (1)

- Testing and inspection of weld joints guideDocument64 pagesTesting and inspection of weld joints guideyashNo ratings yet

- Tekken en Acero Weldonx 1300Document8 pagesTekken en Acero Weldonx 1300nestor leonardonNo ratings yet

- Guia Practica Eleccion AporteDocument26 pagesGuia Practica Eleccion AporteNegrito RosarinoNo ratings yet