Professional Documents

Culture Documents

Reel To Reel Printing Line

Uploaded by

Calvawell MuzvondiwaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reel To Reel Printing Line

Uploaded by

Calvawell MuzvondiwaCopyright:

Available Formats

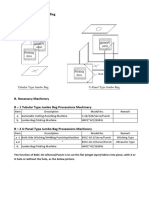

PP/PE WOVEN BAG

P P Woven Bag Rear Processing Machinery

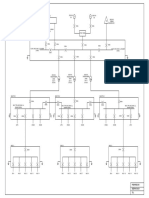

REEL TO REEL PRINTING LINE

New Developed Model Reel To Reel Printing Line

Main Feature:

Model No. NRP-2012/6C

Based on our renowned original Reel To Reel Reel to Reel Printing Method, is the most Imprint Arrangement 6+0, 5+1, 4+2, 3+3 colors combinations

Printing design, which, has been debuted for efficent way for pp woven bag printing

more than a decase now; we have further application, especially when both side

up-grading the desugn by introducing additional imprint required. We can provide 2 to 12

advanced features: colors Reel to Reel Printing Line with

Gear -Box equipped in each printing station, excellent imprint qualityand up to 120

which, can perform online 360 rotation, in meters/minute profuctivity. Our R/R

facilitating the conduct of micro adjustment Printing Line, greatly reduces printing cost

required on individual station imprint-Artwork to the minimal and should be reckoned as,

Registration, under Non-Stop Operation. the best choice on/for corresponding

Enhanced Drying Efficiency for Quickly Drying. process application!

Reel To Reel Printing Line

Model No. NRP-2012/8C

Major Specification of RP serials Optional Equipment

Equipped Gear Box On Each Printing Station, These Gear Box Can Auto Roll Changing System (Unwinding And Rewinding)

360°Online Print Registration While the Machine Is Running.

Corona Treater

Equipped Drying System for Quickly Drying

Automatic Ink Circulation Pump

Diameter of Unwinding Cloth 1200 mm Maximum Applicable

Doctor Blade System

Width of Unwinding Cloth 350-850 mm Applicable

Printing Repeat Length 500-1300 mm

Production Output 120 meters/minute Max.

Reel To Reel Printing Line

Model No. NRP-2012/10C~12C

Imprint Arrangement 5+5, 6+4, 7+3 colors combinations.

11

7 12

8

You might also like

- Single-Pass Textile Printer: Single-Pass Technology Realizes Ultra High Speed PrintingDocument2 pagesSingle-Pass Textile Printer: Single-Pass Technology Realizes Ultra High Speed PrintingAdrian YapNo ratings yet

- Fujifilm Digital Minilab Frontier 550/570/590 Main SpecificationsDocument4 pagesFujifilm Digital Minilab Frontier 550/570/590 Main SpecificationsLa MinNo ratings yet

- Botheven Polypropylene Woven Bags MachinesDocument9 pagesBotheven Polypropylene Woven Bags MachinesCalvawell MuzvondiwaNo ratings yet

- Signage Science and Technology Printer FeaturesDocument2 pagesSignage Science and Technology Printer FeaturesPanji ArihtaNo ratings yet

- The Concept for Technocrats Mind: Integrated Packaging SolutionsDocument8 pagesThe Concept for Technocrats Mind: Integrated Packaging SolutionsTasneem ShaikhNo ratings yet

- Report Alps PDFDocument25 pagesReport Alps PDFRohit SinghNo ratings yet

- Final Layout Plywood1Document1 pageFinal Layout Plywood1Solo MiNo ratings yet

- Rowe RCS4000-RCS6000-RCS8000-RCS9000Document16 pagesRowe RCS4000-RCS6000-RCS8000-RCS9000genisformatNo ratings yet

- Screen ExitsDocument36 pagesScreen Exitsapi-3738703100% (4)

- smartlase-c350hdplus-ds-hq-b1-markem-imajeDocument2 pagessmartlase-c350hdplus-ds-hq-b1-markem-imajeIuri FernandesNo ratings yet

- Manufacturing Execution in Combination With Autonomous Agents Based On SAP and OPC UADocument40 pagesManufacturing Execution in Combination With Autonomous Agents Based On SAP and OPC UASonyAcerNo ratings yet

- Delabeler: Plastic Recycling SystemDocument3 pagesDelabeler: Plastic Recycling SystemFestim RamukaNo ratings yet

- GEA Procomac ECOSpin2 Zero 2015Document2 pagesGEA Procomac ECOSpin2 Zero 2015muhammad arif fakhrudinNo ratings yet

- LabelWorks Brochurep - DF 400 900n PDFDocument6 pagesLabelWorks Brochurep - DF 400 900n PDFsubithk4906No ratings yet

- Xaar 128/80L Xaar 128/40L Xaar 128/80W Xaar 128/40W: Adaptable Printhead With Trouble-Free IntegrationDocument2 pagesXaar 128/80L Xaar 128/40L Xaar 128/80W Xaar 128/40W: Adaptable Printhead With Trouble-Free IntegrationSALISU ABDULWAHEED KOLAWOLENo ratings yet

- Durst RHO 205-8Document11 pagesDurst RHO 205-8andrea.laboratorioNo ratings yet

- Hitachi-Pxr-Series-Users-Manual-313580 2Document11 pagesHitachi-Pxr-Series-Users-Manual-313580 2Lizbeth Ortiz MonroyNo ratings yet

- New Summary Pen TRFRDocument403 pagesNew Summary Pen TRFRDiego de SouzaNo ratings yet

- Daf Technology For Paper Mill Applications: Member of The Safbon GroupDocument4 pagesDaf Technology For Paper Mill Applications: Member of The Safbon GroupYanci JhoeNo ratings yet

- Direct Polyester Printer FP-740S PDFDocument2 pagesDirect Polyester Printer FP-740S PDFCARLOS JOSHUE ORTIZ BOLAÑOSNo ratings yet

- Ricoh Aficio 2020 DDocument6 pagesRicoh Aficio 2020 DlattimroNo ratings yet

- Intertec maquinas para su empresaDocument1 pageIntertec maquinas para su empresaAlberto VELOSA ROANo ratings yet

- Heidelberg SM 74-5 PH L Printing MachineDocument1 pageHeidelberg SM 74-5 PH L Printing MachineService Presse Nouvelle Imprimerie ModerneNo ratings yet

- Deluxe Jet 1320 ENGLISHDocument1 pageDeluxe Jet 1320 ENGLISHlobarriospNo ratings yet

- Pro 8220-8210Document8 pagesPro 8220-8210Claudio OliveroNo ratings yet

- 08.2279 USD2461b (1) Supor EKV BRODocument16 pages08.2279 USD2461b (1) Supor EKV BROMichał KoczorowskiNo ratings yet

- Advidia_CatalogueDocument7 pagesAdvidia_CatalogueinspatiaincNo ratings yet

- Internship Report On HanDocument26 pagesInternship Report On Hanabdulber kedirNo ratings yet

- JLT Series: FlocculatorsDocument2 pagesJLT Series: FlocculatorsCeleynes RTNo ratings yet

- Convenience, control, quality. High-speed printing powerDocument4 pagesConvenience, control, quality. High-speed printing powerCarlos VairinhosNo ratings yet

- iNUKE NU6000DSP: Service ManualDocument45 pagesiNUKE NU6000DSP: Service ManualHerberth BarriosNo ratings yet

- GP Process Pump Brochure en 3Document12 pagesGP Process Pump Brochure en 3Yadir BojacaNo ratings yet

- Rexam Pumps BrochureDocument20 pagesRexam Pumps BrochureAlex SetoNo ratings yet

- Color Printers: Technology Technology Technology Technology Technology TechnologyDocument1 pageColor Printers: Technology Technology Technology Technology Technology TechnologydjokanomcaNo ratings yet

- Service Guide BookDocument152 pagesService Guide BookSupport Biomed100% (1)

- Dgen Service GuideDocument99 pagesDgen Service GuideVladimir DimitrovNo ratings yet

- PLASTICS_BROCHURE_2020Document16 pagesPLASTICS_BROCHURE_2020JackNo ratings yet

- Ricoh Pro C7110 BrochureDocument12 pagesRicoh Pro C7110 BrochureAmol PangamNo ratings yet

- Ricoh SP 377Dnwx SP 377Sfnwx: B&W Multifunction Laser PrinterDocument4 pagesRicoh SP 377Dnwx SP 377Sfnwx: B&W Multifunction Laser PrinterFAQMD2No ratings yet

- 2513G UV Flatbed PrinterDocument14 pages2513G UV Flatbed PrinterGuillermo RussoNo ratings yet

- Logistic Management Project for Olivetti MFP DevicesDocument8 pagesLogistic Management Project for Olivetti MFP DevicesfefotroncitoNo ratings yet

- The Printing ProcessDocument22 pagesThe Printing ProcessSteka42No ratings yet

- Filtro de Silica Gel MTraB - 100115620Document1 pageFiltro de Silica Gel MTraB - 100115620Neto JironNo ratings yet

- Headbox Design and Operation GuideDocument43 pagesHeadbox Design and Operation GuideSukallan Dhar89% (9)

- BASF - Pilot Coating CenterDocument4 pagesBASF - Pilot Coating CenterrbucholzNo ratings yet

- Custom Chart - Min Max Average Bps in OutDocument2 pagesCustom Chart - Min Max Average Bps in OutJuan Gabriel Celis SalgueroNo ratings yet

- PTX OpePTX - OpenPrint - Brochure - A4 - ENG-EMEA - f5 - Specs - Pdfnprint Brochure A4 ENG-EMEA f5 SpecsDocument3 pagesPTX OpePTX - OpenPrint - Brochure - A4 - ENG-EMEA - f5 - Specs - Pdfnprint Brochure A4 ENG-EMEA f5 SpecsMohd VasiqNo ratings yet

- Client:: Road GF Roof Beam PlanDocument12 pagesClient:: Road GF Roof Beam Planabhijeet infrastructureNo ratings yet

- 1140 Brochure ENDocument2 pages1140 Brochure ENAnibal Ñaño MontañoNo ratings yet

- Off Gas Drum 115-HPU1-D-007 Psa Off Gas Silencer 115-HPU1-X-003Document1 pageOff Gas Drum 115-HPU1-D-007 Psa Off Gas Silencer 115-HPU1-X-003victor rojasNo ratings yet

- Product Information Ryobi 750GE SeriesDocument8 pagesProduct Information Ryobi 750GE SeriesnzeeNo ratings yet

- Color Printers: Technology Technology Technology Technology TechnologyDocument1 pageColor Printers: Technology Technology Technology Technology TechnologydjokanomcaNo ratings yet

- Reliable dot matrix printers and passbook solutionsDocument16 pagesReliable dot matrix printers and passbook solutionsGilbert TrincheraNo ratings yet

- Profit from the SAP Ecosystem: Business Models, Partnering, Go-to-MarketFrom EverandProfit from the SAP Ecosystem: Business Models, Partnering, Go-to-MarketRating: 3 out of 5 stars3/5 (1)

- Building Successful Partner Channels: Channel Development & Management in the Software IndustryFrom EverandBuilding Successful Partner Channels: Channel Development & Management in the Software IndustryRating: 5 out of 5 stars5/5 (1)

- Guest Cycle1Document20 pagesGuest Cycle1Calvawell MuzvondiwaNo ratings yet

- Guestroom Maintenance InspectionDocument1 pageGuestroom Maintenance InspectionCalvawell MuzvondiwaNo ratings yet

- Individual Guest Registration Form: Accommodation InformationDocument1 pageIndividual Guest Registration Form: Accommodation InformationCalvawell MuzvondiwaNo ratings yet

- Bag Making Machine: Reduce Design Time and Improve Performance For Bag Making ManufacturersDocument27 pagesBag Making Machine: Reduce Design Time and Improve Performance For Bag Making Manufacturershorse0678No ratings yet

- Negotiation of Hotel Management AgreementsDocument14 pagesNegotiation of Hotel Management AgreementsCalvawell MuzvondiwaNo ratings yet

- Guiding Notes To Financial ProjectionsDocument2 pagesGuiding Notes To Financial ProjectionsCalvawell MuzvondiwaNo ratings yet

- A. Two Kind of Jumbo Bag: Printing AreaDocument3 pagesA. Two Kind of Jumbo Bag: Printing AreaCalvawell MuzvondiwaNo ratings yet

- Test No.: 012 008 B2 StencilDocument2 pagesTest No.: 012 008 B2 StencilCalvawell Muzvondiwa100% (7)

- Grain Bag Manufacturing Feasibility StudyDocument53 pagesGrain Bag Manufacturing Feasibility StudyCalvawell MuzvondiwaNo ratings yet

- Project FormulasDocument14 pagesProject FormulasCalvawell MuzvondiwaNo ratings yet

- Flexo Packaging Financial Projections - For ReviewDocument75 pagesFlexo Packaging Financial Projections - For ReviewCalvawell MuzvondiwaNo ratings yet

- Crazy Crepes Final 1Document56 pagesCrazy Crepes Final 1Mika SouhNo ratings yet

- Manual Printing LineDocument1 pageManual Printing LineCalvawell MuzvondiwaNo ratings yet

- Manufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersDocument1 pageManufacturing of Woven Jumbo Bag Flexible Intermediate Bulk ContainersCalvawell MuzvondiwaNo ratings yet

- Application For Customary Land RightsDocument2 pagesApplication For Customary Land RightsCalvawell Muzvondiwa100% (1)

- Equatoria - Final BPDocument27 pagesEquatoria - Final BPCalvawell MuzvondiwaNo ratings yet

- Meals and MealsDocument51 pagesMeals and MealsCalvawell MuzvondiwaNo ratings yet

- Hospitality BusinessDocument70 pagesHospitality BusinessCalvawell MuzvondiwaNo ratings yet

- Hotel Accounting StandardsDocument38 pagesHotel Accounting StandardsCalvawell Muzvondiwa100% (1)

- Dart Rules: The GamesDocument1 pageDart Rules: The GamesCalvawell MuzvondiwaNo ratings yet

- 1 All Scratch Recipes FINALDocument103 pages1 All Scratch Recipes FINALCalvawell MuzvondiwaNo ratings yet

- Wcms 203969Document40 pagesWcms 203969Raj PresentationistNo ratings yet

- Application For Customary Land RightsDocument2 pagesApplication For Customary Land RightsCalvawell Muzvondiwa100% (1)

- 2017-Botswana Business Application Form - JennyDocument1 page2017-Botswana Business Application Form - JennyCalvawell MuzvondiwaNo ratings yet

- Salary Payment Demand Letter To Cutee Inn DirectorsDocument1 pageSalary Payment Demand Letter To Cutee Inn DirectorsCalvawell MuzvondiwaNo ratings yet

- Science 4 Term 1 Revision: 90 Questions - Good LuckDocument12 pagesScience 4 Term 1 Revision: 90 Questions - Good LuckCalvawell MuzvondiwaNo ratings yet

- Apply for SME Grant in BotswanaDocument4 pagesApply for SME Grant in BotswanaCalvawell MuzvondiwaNo ratings yet

- Dart ReglerDocument12 pagesDart ReglerCalvawell MuzvondiwaNo ratings yet

- Ch.2 Case and Duct SystemDocument11 pagesCh.2 Case and Duct Systemcpt.ghostNo ratings yet

- Villamor Test - 2 PDFDocument18 pagesVillamor Test - 2 PDFLocrian IonianNo ratings yet

- Transfer Case MP 3023Document103 pagesTransfer Case MP 3023jackson vivasNo ratings yet

- Katalog Single Split Packaged AC 2015-2016 PanasonicDocument32 pagesKatalog Single Split Packaged AC 2015-2016 Panasonicdoris0% (1)

- E420 S1100 Fact SheetDocument7 pagesE420 S1100 Fact Sheetiskandarn_el5735No ratings yet

- Lecture 10Document19 pagesLecture 10Sara AlwehrNo ratings yet

- Luftwaffe Night Fighter Control MethodsDocument17 pagesLuftwaffe Night Fighter Control MethodsKIRU SILVIU100% (3)

- ACS Appl. Energy Mater. 5 (2022) 367-379 PDFDocument13 pagesACS Appl. Energy Mater. 5 (2022) 367-379 PDFEdgar QuintanillaNo ratings yet

- Fine ArtsDocument12 pagesFine Artsatul prajapatiNo ratings yet

- FF4 58 Service Manual ERQU40E3HUSDocument20 pagesFF4 58 Service Manual ERQU40E3HUSCarmen Adriana Garcia MendozaNo ratings yet

- VIVI Ref Part 2 PDFDocument111 pagesVIVI Ref Part 2 PDFAaron OliverNo ratings yet

- Paracetamol GuideDocument3 pagesParacetamol GuideJanine SantosNo ratings yet

- DR 38312-011Document33 pagesDR 38312-011Julio Csar da SilvaNo ratings yet

- (MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesDocument15 pages(MT 6322 - MYCO VIRO LAB) Unit 7 Laboratory Diagnosis For Negative-Sense (-) ssRNA VirusesAbbas MaghazehiNo ratings yet

- Just-in-Time and Lean Production Systems: Professor AhmadiDocument29 pagesJust-in-Time and Lean Production Systems: Professor AhmadiawaisjinnahNo ratings yet

- Budget-of-Work-General Biology 1Document2 pagesBudget-of-Work-General Biology 1joei ArqueroNo ratings yet

- Cuban Puerco Asado - Petit PorciniDocument2 pagesCuban Puerco Asado - Petit PorciniDra. Carmen DittelNo ratings yet

- Intermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingDocument4 pagesIntermittent Fasting Facts and Myths: Metabolic Benefits of Intermittent FastingIJAR JOURNALNo ratings yet

- GY HM 100 Service ManualDocument36 pagesGY HM 100 Service Manualvideoengr100% (1)

- Conceptual SLDDocument1 pageConceptual SLDakhilNo ratings yet

- Flaxseed Paper PublishedDocument4 pagesFlaxseed Paper PublishedValentina GarzonNo ratings yet

- Viral Skin Infections Caused by Herpesviridae and PoxviridaeDocument55 pagesViral Skin Infections Caused by Herpesviridae and PoxviridaeGita RizkiNo ratings yet

- Real-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshDocument8 pagesReal-Time Reservoir Operation For Irrigation: P. P. Mujumdar and T. S. V. RameshGetachew BekeleNo ratings yet

- Pump CommissioningDocument1 pagePump CommissioningMD SAMANNo ratings yet

- Amplifiers and OscillatorsDocument109 pagesAmplifiers and OscillatorsAdilNo ratings yet

- Steven Churchill, Jack Reynolds (Eds.) - Jean-Paul Sartre - Key Concepts-Routledge (2014)Document257 pagesSteven Churchill, Jack Reynolds (Eds.) - Jean-Paul Sartre - Key Concepts-Routledge (2014)Leonardo Grana100% (3)

- S6000-Operation-Manual SkyliftDocument50 pagesS6000-Operation-Manual SkyliftSetiawan Tuhu basukiNo ratings yet

- Rohail Hassan: ObjectiveDocument3 pagesRohail Hassan: ObjectiveNoumanKhanNo ratings yet

- Behavior of Connected and Unconnected Back-to-Back Walls For Bridge ApproachesDocument10 pagesBehavior of Connected and Unconnected Back-to-Back Walls For Bridge Approachessalar salarNo ratings yet

- Telangana Govt T-PRIDE Scheme GuidelinesDocument90 pagesTelangana Govt T-PRIDE Scheme GuidelinesitzprasuNo ratings yet