Professional Documents

Culture Documents

Workshop Exercise - Steam Distribution and Utilization PDF

Workshop Exercise - Steam Distribution and Utilization PDF

Uploaded by

Carolina SalcedoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Workshop Exercise - Steam Distribution and Utilization PDF

Workshop Exercise - Steam Distribution and Utilization PDF

Uploaded by

Carolina SalcedoCopyright:

Available Formats

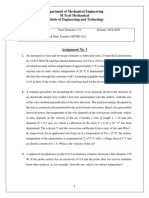

Workshop exercise – Steam Distribution and Utilization

STEAM DISTRIBUTION AND UTILIZATION

A paper plant has an extensive steam network. The steam is generated at a pressure of 10 bar and

the condensate is not recovered. The plant management is planning to generate flash steam (from

the condensate) for use as low pressure process steam and to recover as much steam condensate

as practical.

With the help of the data provided, calculate the following:

1. Quantity of flash steam generated (kg)

2. Annual savings from flash steam recovery in US$/year

3. Annual savings from flash steam recovery and condensate recovery in US$/year

The following data is provided:

Total enthalpy of steam at 10 bars: 672 kCal/kg

Condensate quantity: 1000 kg/hr

Condensate pressure: 10 bar

Cost of steam: US$ 25/ton

Annual operating hours: 8000

Low pressure process steam pressure: 2 bar

(Flash steam pressure)

Sensible heat of condensate at 10 bar: 187.1 kCal/kg

Sensible heat of condensate at 2 bar: 134.4 kCal/kg

Latent heat of steam at 2 bar: 517.5 kCal/kg

Boiler efficiency: 82%

Fuel used in boiler : Furnace oil

GCV of Furnace oil: 10,200 kCal/kg

Specific gravity of furnace oil: 0.92

Condensate temp. when recovered: 950C

Make-up water temperature: 350C

Cost of furnace oil : US$ 350/kiloliter

The following equation is given:

Flash steam generation potential condensate (%) = (S1-S2/L) X 100

Where,

S1 = Sensible heat of condensate at high pressure

S2 = Sensible heat of condensate at low pressure

L = latent heat of steam at low pressure

Energy Efficiency Guide for Industry in Asia – www.energyefficiencyasia.org © UNEP 1

Workshop exercise – Steam Distribution and Utilization

SOLUTION

1. Calculate the quantity of flash steam generated (kg)

Flash steam generation potential condensate (%) = (S1-S2/L) X 100

Where,

S1 = Sensible heat of condensate at 10 bar = 187.1 kCal/kg

S2 = Sensible heat of condensate at 2 bar = 134.4 kCal/kg

L = latent heat of steam at low pressure = 517.5 kCal/kg

= (187.1–134.4) / 517.5

= 0.1018 kg / kg of condensate

Flash steam generated from 1000 kg/hr condensate at 10 bar

= 1000 * 0.1018

= 101.8 kg/hr

2. Calculate the annual savings from flash steam recovery in US$/year

Annual steam savings = 101.8 kg/hr x 8000 hr/yr / 1000 = 814 tons/yr

Equivalent annual steam heat savings = (101.8 kg/hr x 672 kCal/kg) = 68,410 kCal/hr

Annual monetary savings = (814 tons/yr x US$ 25/ton)= US$ 20,350

3. Calculate the annual savings from flash steam recovery and condensate recovery in

US$/year

Condensate available for recovery after flash steam = (1000 kg/hr – 101.8 kg/hr) = 898 kg/hr

Heat recovery potential through condensate recovery

= Mass of condensate x Specific heat of condensate x Temperature difference

= 898 kg/hr x 1 x (95-35)

= 53880 kCal/hr

Heat savings from flash steam recovery and condensate recovery

= (68410 kCal/hr + 53880 kCal/hr) = 122,290 kCal/hr

Annual fuel oil savings

= (heat savings x hours per year) / (boiler efficiency x GCV of fuel)

= (122,290 kCal/hr x 8000 hr/yr) / (0.82 x 10,200 kCal/kg)

= 116,968 kg/yr

= 116,968 / 0.92 = 127,139 liters = 127.1 kiloliters

Annual monetary savings

= 127.1 kiloliters x 350 US$/kl

= 44,485 US$/yr

Energy Efficiency Guide for Industry in Asia – www.energyefficiencyasia.org © UNEP 2

You might also like

- Basic Process IntegrationDocument21 pagesBasic Process IntegrationEloyNo ratings yet

- Pinch Analysis IntroDocument2 pagesPinch Analysis IntroRamakrishna Koushik0% (1)

- Design Fractionating Columns: Entrainment and CapacityDocument6 pagesDesign Fractionating Columns: Entrainment and CapacityVictor VazquezNo ratings yet

- HW 4Document2 pagesHW 4kimyakimya89No ratings yet

- Optimization of Chemical Processes, Second Edition Pág 33Document1 pageOptimization of Chemical Processes, Second Edition Pág 33Cluisantony Jayco DizeNo ratings yet

- 423 Problem Set 1Document2 pages423 Problem Set 1keithcrosley0% (1)

- HW 31 Solutions Spring 2012Document9 pagesHW 31 Solutions Spring 2012rameshaarya99No ratings yet

- AHMT Assignment 01Document2 pagesAHMT Assignment 01shubhamNo ratings yet

- Thermodynamic Analysis of The Soda AshDocument10 pagesThermodynamic Analysis of The Soda AshbenaliNo ratings yet

- Autoflame Emissions CalculatorDocument9 pagesAutoflame Emissions CalculatorLuilio Esparza100% (1)

- TOURTON-páginas-37-124-73-88 PDFDocument16 pagesTOURTON-páginas-37-124-73-88 PDFJesús David González CañasNo ratings yet

- NEW Hybrid Recupurator DSTDocument21 pagesNEW Hybrid Recupurator DSTSubrata DasNo ratings yet

- ThermolysisDocument5 pagesThermolysisJoao MinhoNo ratings yet

- AgitatingDocument24 pagesAgitatingBánh Cuốn Tôm ThịtNo ratings yet

- Astm G 21-15Document6 pagesAstm G 21-15LSPro Sentra Teknologi Polimer100% (1)

- ASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Document7 pagesASTM D974 14 (For Acid and Base Number by Color-Indicator Titration)Fabian Ricardo100% (1)

- Saidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFDocument10 pagesSaidur2010 - Energy, Exergy and Economic Analysis of Industrial Boilers PDFRuben Alejandro Velandia UsugaNo ratings yet

- April 11 Homework Solutions: Mechanical Engineering 375 Heat TransferDocument7 pagesApril 11 Homework Solutions: Mechanical Engineering 375 Heat TransferJeriesPhilipAbedrabboNo ratings yet

- Hysys - Multiple Reactions - StyreneDocument10 pagesHysys - Multiple Reactions - Styrenejenny2409No ratings yet

- Process Component Design PDFDocument3 pagesProcess Component Design PDFWillian MazaNo ratings yet

- Ejemplo DTML Crossflow PDFDocument2 pagesEjemplo DTML Crossflow PDFDaniel González Juárez100% (1)

- Exergetic and Economic Comparison of ORC and Kalina Cycle For Low Temperature Enhanced Geothermal System in BrazilDocument11 pagesExergetic and Economic Comparison of ORC and Kalina Cycle For Low Temperature Enhanced Geothermal System in BrazilJose Jorge FontalvoNo ratings yet

- Solutions Set 6Document19 pagesSolutions Set 6Augustine BrockNo ratings yet

- Hda ProcessDocument53 pagesHda ProcessEmm TeddyNo ratings yet

- Process Dynamics & Control ReportDocument26 pagesProcess Dynamics & Control ReportDonna Joy MallariNo ratings yet

- Chemical Engineering Economics AssignmentDocument2 pagesChemical Engineering Economics AssignmentMisum Ali100% (1)

- F. Huang - Engineering ThermodynamicsDocument52 pagesF. Huang - Engineering ThermodynamicsHectorCabz100% (1)

- Tutorial Problems StatementDocument21 pagesTutorial Problems StatementAbni AbhiNo ratings yet

- Patente Columna York - ScheibelDocument6 pagesPatente Columna York - Scheibeligor1991No ratings yet

- Chemcad: Utility Processes John Edwards, P&I Design LTD January 2015Document19 pagesChemcad: Utility Processes John Edwards, P&I Design LTD January 2015Eng-MustafaHathalAl-SaraiNo ratings yet

- Control Valve Data SheetDocument1 pageControl Valve Data SheetKelly Perez LopezNo ratings yet

- AbsorbtionDocument16 pagesAbsorbtionLuciano EbangNo ratings yet

- Renewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantDocument36 pagesRenewable Energy Resources: Introduction & Economic Analysis of A Gasification PlantfaizanNo ratings yet

- Design and Control of A Methyl Acetate Process Using Carbonylation of Dimethyl EtherDocument18 pagesDesign and Control of A Methyl Acetate Process Using Carbonylation of Dimethyl Ethersheida shNo ratings yet

- AmoniaDocument35 pagesAmonianoelia cossio0% (1)

- CONTROL PLANTA COMPLETA ZhangC TOTAL PDFDocument121 pagesCONTROL PLANTA COMPLETA ZhangC TOTAL PDFemerentiana1No ratings yet

- 1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WaterDocument10 pages1 Liquid-Liquid Equilibrium For The Ternary System Methanol + Acrylonitrile + WatersandraesiqNo ratings yet

- Ejercicios de Balance de Materia PDFDocument88 pagesEjercicios de Balance de Materia PDFMichelleNo ratings yet

- Kinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystDocument8 pagesKinetics of The Selective Hydrogenation of Phenol To Cyclohexanone Over A Pd-Alumina CatalystTaylor PennaNo ratings yet

- Exercise BM With Chemical ReactionDocument2 pagesExercise BM With Chemical ReactionSergio Rugerio TorresNo ratings yet

- Dry Centrifugal Col Lector - PPT by Hitarth MIHS-IsTARDocument25 pagesDry Centrifugal Col Lector - PPT by Hitarth MIHS-IsTARHM04100% (1)

- Solution Thermodynamics 2020Document49 pagesSolution Thermodynamics 2020Esha ChohanNo ratings yet

- Trimming Nox From Furnaces - Rev3Document6 pagesTrimming Nox From Furnaces - Rev3Deepika UmlaniNo ratings yet

- Iit MumbaiDocument2 pagesIit Mumbaivijaya025No ratings yet

- CSTR in SeriesDocument6 pagesCSTR in SeriesMuqarrabin Hairul AnuarNo ratings yet

- Church 1951Document8 pagesChurch 1951Evan DulayNo ratings yet

- Modeling A Crude Vacuum System With Preheat TrainDocument6 pagesModeling A Crude Vacuum System With Preheat TrainELTIPAZONo ratings yet

- Optimization of The Acetone Plant Using CHEMCADDocument24 pagesOptimization of The Acetone Plant Using CHEMCADshahed IasirNo ratings yet

- Mutli Component DistillationDocument13 pagesMutli Component Distillationramantal5No ratings yet

- Tutorial Topic 2 2020 RevisedDocument3 pagesTutorial Topic 2 2020 RevisedTara PillayNo ratings yet

- HW 5Document8 pagesHW 5Anonymous AjrDxGNo ratings yet

- ATD RAnkin Assignment-2011Document3 pagesATD RAnkin Assignment-2011Yuvraj SinghNo ratings yet

- Applied Thermodynamics Exam 2018 Wirh SolutionsDocument9 pagesApplied Thermodynamics Exam 2018 Wirh SolutionsFarouk BassaNo ratings yet

- Agave Bagasse Biorefinery - Processing and Perspectives PDFDocument19 pagesAgave Bagasse Biorefinery - Processing and Perspectives PDFMeyerling RandfordNo ratings yet

- Pinch TechnologyDocument38 pagesPinch TechnologyPankaj VermaNo ratings yet

- Flue Gas Condenser: More Than Years Proven QualityDocument2 pagesFlue Gas Condenser: More Than Years Proven QualityemadNo ratings yet

- Lab 1 Heat of FusionDocument3 pagesLab 1 Heat of FusionAaron DaCostaNo ratings yet

- Che516 Lecture NotesDocument69 pagesChe516 Lecture NotesifiokNo ratings yet

- Tutorial 9 Solutions 1Document5 pagesTutorial 9 Solutions 1Henry TranNo ratings yet

- Lab 4 SimulationDocument8 pagesLab 4 SimulationaziziNo ratings yet

- Energy Management Tutorial SolutionsDocument9 pagesEnergy Management Tutorial SolutionsLucas LentzNo ratings yet

- Boiler EconomyDocument64 pagesBoiler EconomyKhurram ShahzadNo ratings yet

- Calculation of Boiler EfficiencyDocument43 pagesCalculation of Boiler EfficiencyTamer Abd ElrasoulNo ratings yet

- Operating Envelopes For Centrifugal Pumps: Problem StatementDocument9 pagesOperating Envelopes For Centrifugal Pumps: Problem StatementChang Chee HongNo ratings yet

- Questionnaires 2019-2020 PDFDocument15 pagesQuestionnaires 2019-2020 PDFChang Chee HongNo ratings yet

- Lewatit Monoplus TP 260: Product InformationDocument5 pagesLewatit Monoplus TP 260: Product InformationChang Chee HongNo ratings yet

- Wound Filter Cartridges Versus Meltblown CartridgesDocument2 pagesWound Filter Cartridges Versus Meltblown CartridgesChang Chee HongNo ratings yet

- Basics of DeionizationDocument4 pagesBasics of DeionizationChang Chee HongNo ratings yet

- Palm Oil Note 1Document88 pagesPalm Oil Note 1Chang Chee Hong89% (9)

- DryerDocument55 pagesDryerDana Guerrero67% (3)

- Production of High-Basicity PACDocument20 pagesProduction of High-Basicity PACChang Chee HongNo ratings yet

- Chlor AlkaliDocument178 pagesChlor AlkaliChang Chee Hong100% (1)

- Refinery Process Design Notes - For IITGDocument193 pagesRefinery Process Design Notes - For IITGLakshmi Devineni100% (3)

- Ventilation: Ref: Chemical Process Safety, DA Crowl Et AlDocument8 pagesVentilation: Ref: Chemical Process Safety, DA Crowl Et AlChang Chee HongNo ratings yet

- Pid Control 15 1 2007Document69 pagesPid Control 15 1 2007Chang Chee HongNo ratings yet

- To Find Out The Viscosity of A Given Liquid Using Red Wood ViscometerDocument3 pagesTo Find Out The Viscosity of A Given Liquid Using Red Wood ViscometerApoorva SinghNo ratings yet

- Terminal Unit Performance and Control (Expansion Tank) : Dr. Samah E. HatabDocument15 pagesTerminal Unit Performance and Control (Expansion Tank) : Dr. Samah E. HatabLulu PixNo ratings yet

- Prista - Lista Metode Acreditate PDFDocument12 pagesPrista - Lista Metode Acreditate PDFCorina StanculescuNo ratings yet

- 8HL.18.1 Lewis Acids and BasesDocument19 pages8HL.18.1 Lewis Acids and BasesJesus carbonoNo ratings yet

- Atomic StructureDocument13 pagesAtomic StructureAlvin K ThomasNo ratings yet

- Notes On EnzymologyDocument23 pagesNotes On EnzymologyCalvin Yeow-kuan ChongNo ratings yet

- Bestway Cement Limited ChakwalDocument42 pagesBestway Cement Limited Chakwaltarehman7595No ratings yet

- 2SS Lecture 8Document26 pages2SS Lecture 8Nur FiqalbiNo ratings yet

- Mathematical Modeling of Chemical ProcessesDocument43 pagesMathematical Modeling of Chemical ProcessesInnocent ShetaanNo ratings yet

- GEA WS Wine-BrochureDocument52 pagesGEA WS Wine-BrochurePhan Thi Thuy100% (1)

- ForgingDocument37 pagesForgingchris mushunjeNo ratings yet

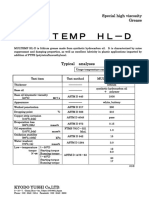

- Multemp HL-DDocument1 pageMultemp HL-DVishal AmleNo ratings yet

- Student Handout: Making A Crystal Garden - Chemistry and ArtDocument2 pagesStudent Handout: Making A Crystal Garden - Chemistry and ArtYT ChongNo ratings yet

- OMFDocument16 pagesOMFDuy AnhNo ratings yet

- Bitustick XLDocument2 pagesBitustick XLganmosesNo ratings yet

- CY101-Inorganic Quiz-Questions-FinalDocument8 pagesCY101-Inorganic Quiz-Questions-FinalPravat Kumar SahooNo ratings yet

- TDS - Starproof WF AC-800Document1 pageTDS - Starproof WF AC-800EssamNo ratings yet

- CSE331&CSE20331 Tutorial 1& FeedbackDocument22 pagesCSE331&CSE20331 Tutorial 1& FeedbackHenry TangNo ratings yet

- CHAPTER 8 - WATER AND FLARE SYSTEM Edit MOSH 211220Document27 pagesCHAPTER 8 - WATER AND FLARE SYSTEM Edit MOSH 211220subash1111111No ratings yet

- Astm A 615 PDFDocument6 pagesAstm A 615 PDFVo Hong Kiet0% (1)

- Bilirubin Jendrassik-Gróf FSDocument2 pagesBilirubin Jendrassik-Gróf FSErika Kusuma DaruNo ratings yet

- A Review On Stability Indicating HPLC Method DevelopmentDocument19 pagesA Review On Stability Indicating HPLC Method DevelopmentppiccoliniNo ratings yet

- Direct From: 2Nd Quarter 2019Document22 pagesDirect From: 2Nd Quarter 2019JeanNo ratings yet

- Orbu SPC 44 0 22Document98 pagesOrbu SPC 44 0 22geverett2765No ratings yet

- Project Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterDocument11 pagesProject Oxhydroelectric Effect Procedure and Apparatus To Extract Electric Energy From WaterFrancesco Paolo TuccinardiNo ratings yet

- Final Chapter 1 and 2Document26 pagesFinal Chapter 1 and 2Val LlameloNo ratings yet

- Flare System: Types, Segregation, Tips, PurgeDocument14 pagesFlare System: Types, Segregation, Tips, PurgeNicon PaulNo ratings yet

- Kami Export - ALEXA CADENA - GizmoCellEnergySE A & BDocument5 pagesKami Export - ALEXA CADENA - GizmoCellEnergySE A & BALEXA CADENANo ratings yet