Professional Documents

Culture Documents

Cat ELI: Long-Lasting Cooling System Protection For Warm Climates

Uploaded by

arslan0989Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat ELI: Long-Lasting Cooling System Protection For Warm Climates

Uploaded by

arslan0989Copyright:

Available Formats

Cat ELI ®

Extended Life Inhibitor Coolant

™

Concentrate

Long-Lasting Cooling System

Protection for Warm Climates

Cat® ELI™ (Extended Life Inhibitor) is a long-lasting coolant for marine and industrial

engines working in environments that do not experience freezing temperatures. Cat

ELI uses an active protection technology, similar to Cat ELC™, that avoids the problems

experienced with conventional coolants and supplemental coolant additives (SCA) mixed

with water. These types of coolants lay down a coat of inhibitors, such as silicates,

throughout the entire cooling system that slows heat transfer and reduces cooling system

efficiency. Cat ELI works by sending its organic additives only to areas susceptible to

corrosion. This active protection technology delivers superior protection, improved cooling

system efficiency, and is environmentally friendly.

Cat® ELI™

Benefits

Lower Owning and Operating Costs

• Lasts three to six times longer than conventional coolants or commercial

supplemental coolant additives (SCA) mixed with water

• Reduced maintenance costs as a result of less frequent: checks of coolant

health, replacement of inhibitors, and drains/flushes

• Fewer repairs needed due to improved corrosion protection

Maximum Protection

• Uses inhibitors that provide superior protection against pitting and

corrosion for aluminum, brass, copper, iron, steel, etc.

Non-glycol

• Promotes environmental sustainability

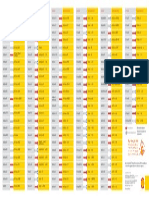

2000 Unsurpassed Protection of Aluminum Components

Aluminum is commonly used in modern diesel engine components

1600 and cooling systems. When supplemental coolant additives (SCA)

Material loss (mg Aluminum/sample)

mixed with water is used as a coolant, significant corrosion of

aluminum components can result.

1200

In testing, Cat ELI demonstrated that it provides significantly

better aluminum protection than two commonly used conventional

800 SCA products. In fact, the Cat ELI showed nearly no aluminum

corrosion at all.

400 Years of Caterpillar field experience with marine and industrial

engines show similar results. Cat ELI is the best protection you can

get for applications where glycol is not desired.

0

Cat® ELI™ Conventional Conventional

SCA #1 SCA #1

Cat® ELI™

Up to Six Times the Life S•O•SSM Fluid Analysis

The protection provided by Cat ELI lasts three to six times longer than that offered Getting the full life of 12,000

by conventional coolants. hours, or more, out of Cat ELI

is possible with the regular

Cat ELC® Extender use of S•O•SSM Fluid Analysis,

the ultimate detection and

The effective life of Cat ELI can be doubled by refreshing its inhibitors with a

diagnostic tool for your

one-time application of Cat ELC® Extender. Added at 6,000 hours of operation, engines.

Cat ELC Extender enables Cat ELI to last up to 12,000 hours (six years) or longer.

When changing coolant, the cooling system must be flushed with clean water.

Cat ELI makes this easy because its active protection doesn’t use the layer of Refer to the Cat Operation and

“goo” found with conventional coolants that can be hard to completely drain Maintenance Manual for the

from the cooling system. recommended intervals of

S•O•S Level 1 Coolant Analysis

(such as every 250 hours).

Level 2 Coolant Analysis

is recommended at least

annually for all Cat engines

and machines.

Conventional SCA

3,000 Hour Life

SCA Every 250 Hours

Cat ELI

12,000 Hour Life or 6 Years**

(whichever comes first)

Cat Extender Every 6,000 Hours*

* Or one-half of the coolant service life

** These coolant change intervals are only possible with annual S•O•SSM

Level 2 coolant sampling and analysis

Cat® ELI™

Typical Characteristics1 Health and Safety

For information on

ASTM Performance Requirements2 ASTM D1384, D2570, D4340 proper use for health,

Color Red safety, and environment,

please refer to the

Recommended Dilution Level3 7.5%

Material Safety Data

Freeze protection Sheet (MSDS). Read

Cat ELI does not provide freeze protection and understand the

MSDS before using this

pH (7.5% solution) 8.5 product. Always observe

Nitrite (7.5% solution) 500 ppm good hygiene measures.

For a copy of the MSDS,

Molybdate (7.5% solution) 530 ppm contact us or visit the

Boiling protection at sea level 100°C, 121°C with 1 bar (15psi) pressure cap web at www.catmsds.com.

1 The values shown are typical values and should not be used as quality control

parameters to either accept or reject product. Specifications are subject to change

without notice.

2 Exceeds performance requirements for automotive and heavy-duty coolants as

specified by ASTM D3306, D4985, D6210.

3 ELI concentration can be determined using a Brix refractometer, part number 360-0774.

Coolant Maintenance Resources

For in-depth information on coolant maintenance, refer to the Cooling System

Specifications section of the latest version of SEBU6250 – Caterpillar Machine

Fluids Recommendations or SEBU6251 – Caterpillar Commercial Diesel Engine

Fluids Recommendations.

CAT DEALERS DEFINE WORLD-

CLASS PRODUCT SUPPORT.

We offer you the right parts and service

solutions, when and where you need them.

The Cat Dealer network of highly trained

experts keeps your entire fleet up and running

to maximize your equipment investment.

PEHJ0263-02

www.cat.com

© 2014 Caterpillar • All Rights Reserved • Printed in USA

CAT, CATERPILLAR, BUILT FOR IT, their respective logos, “Caterpillar Yellow,” the “Power Edge”trade dress as well as

corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- OB Main ProjectDocument16 pagesOB Main Projectarslan0989No ratings yet

- Mobil Hydraulic Oils Comparison GuideDocument1 pageMobil Hydraulic Oils Comparison Guidearslan0989No ratings yet

- Lubricants For - Cement & MiningDocument2 pagesLubricants For - Cement & Miningarslan0989No ratings yet

- WH Rules ST 1990Document8 pagesWH Rules ST 1990arslan0989No ratings yet

- Get to Know Shell's New Lubricants PortfolioDocument1 pageGet to Know Shell's New Lubricants Portfolioarslan0989100% (1)

- Supply ManagementDocument13 pagesSupply Managementarslan0989No ratings yet

- Mobilgrease XHP™ 220 Series: Lithium Complex GreasesDocument2 pagesMobilgrease XHP™ 220 Series: Lithium Complex Greasesarslan0989No ratings yet

- Data Collection-1Document20 pagesData Collection-1arslan0989No ratings yet

- LCI Sample ReportDocument30 pagesLCI Sample Reportarslan0989No ratings yet

- Partnership DeedDocument4 pagesPartnership DeedAnshumanTripathiNo ratings yet

- Case3 Tesco Supply Management PDFDocument19 pagesCase3 Tesco Supply Management PDFRacing Sangers82% (11)

- Case2 Supply Chain Risk at Unilever PDFDocument16 pagesCase2 Supply Chain Risk at Unilever PDFRacing SangersNo ratings yet

- Strategicmanagementreport EngropolymerandchemicalslimitedDocument29 pagesStrategicmanagementreport Engropolymerandchemicalslimitedarslan0989No ratings yet

- The Family Courts Act, 1964Document12 pagesThe Family Courts Act, 1964arslan0989No ratings yet

- Grammar Fundamentals - Compound, Complex, Simple SentencesDocument3 pagesGrammar Fundamentals - Compound, Complex, Simple Sentencesarslan0989No ratings yet

- SWOT Analysis Strengths: Success CriteriaDocument4 pagesSWOT Analysis Strengths: Success Criteriaarslan0989No ratings yet

- Chain Management Practices. Spoke SystemDocument2 pagesChain Management Practices. Spoke Systemarslan0989No ratings yet

- Chapter 19Document9 pagesChapter 19arslan0989No ratings yet

- Catherine's Confectionaries Business StrategyDocument3 pagesCatherine's Confectionaries Business Strategyarslan0989No ratings yet

- Course Outline OBALDocument7 pagesCourse Outline OBALarslan0989No ratings yet

- Assignment 2: Title: AnalysisDocument5 pagesAssignment 2: Title: Analysisarslan0989No ratings yet

- Operations and Supply Chain Strategy Chapter 2Document23 pagesOperations and Supply Chain Strategy Chapter 2arslan0989No ratings yet

- 7 principles commutation complete concise consideration correctnessDocument8 pages7 principles commutation complete concise consideration correctnessarslan0989No ratings yet

- U.S ConsitutionDocument1 pageU.S Consitutionarslan0989No ratings yet

- Class 15 and 16Document8 pagesClass 15 and 16arslan0989No ratings yet

- NBVNBVNBVDocument4 pagesNBVNBVNBVarslan0989No ratings yet

- Ufone MarketingDocument39 pagesUfone MarketingNauman Rashid71% (7)

- Met A Heuristic SDocument56 pagesMet A Heuristic Sarslan0989No ratings yet

- YO WEAR's Production and Marketing StrategiesDocument13 pagesYO WEAR's Production and Marketing Strategiesarslan0989No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Catalog Fans and Gear Motors For Solid Fuel Heating Systems enDocument112 pagesCatalog Fans and Gear Motors For Solid Fuel Heating Systems ensdfNo ratings yet

- DLL - Science 6 - Q2 - W8Document9 pagesDLL - Science 6 - Q2 - W8ABEGAIL BAMBANo ratings yet

- 201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFDocument480 pages201210221219130.laporan Eia Damansara-Shah Alam Elevated Highway-Ukmpakarunding PDFmanimaran75100% (1)

- PUC Splendor+Document1 pagePUC Splendor+Mohit SinglaNo ratings yet

- Hazard Risk Assessment for Earthing WorkDocument10 pagesHazard Risk Assessment for Earthing WorkProjects INTSNo ratings yet

- FLSMIDTH - Wave Grate For The SF Cross-Bar Cooler PDFDocument4 pagesFLSMIDTH - Wave Grate For The SF Cross-Bar Cooler PDFEduart Guerrero100% (1)

- Rattan Lal (Editor) - Soil and Fertilizers-Managing The Environmental Footprint-CRC Press (2020) PDFDocument372 pagesRattan Lal (Editor) - Soil and Fertilizers-Managing The Environmental Footprint-CRC Press (2020) PDFBenhur De la CruzNo ratings yet

- Environmental Value Systems and ModelsDocument14 pagesEnvironmental Value Systems and ModelsMichaella SallesNo ratings yet

- Toleshi WakjiraDocument89 pagesToleshi Wakjirayade ahmedNo ratings yet

- 7 The Design and ConstructionDocument7 pages7 The Design and ConstructionMohammad SuleimanNo ratings yet

- Hydrochemistry and Assessment of Ground Water Quality of Al-ShekhanDocument9 pagesHydrochemistry and Assessment of Ground Water Quality of Al-ShekhanAymen AlsudanyNo ratings yet

- Production Equipment and Facilities Postharvest Equipment and FacilitiesDocument49 pagesProduction Equipment and Facilities Postharvest Equipment and FacilitiesRonel Dimaya CañaNo ratings yet

- Refuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixDocument9 pagesRefuting/Debunking The Claim Made in Quran That Fresh and Salt Water Do Not MixAn Ga50% (6)

- X Minerals Part IiDocument4 pagesX Minerals Part IiShree jegan Kumar B SNo ratings yet

- 3 PBDocument9 pages3 PBDifa Damaryan Al IhsaniNo ratings yet

- Ethno Biology Group One AssignmentDocument8 pagesEthno Biology Group One AssignmentDessalew MeneshaNo ratings yet

- Sds Anti Spatter LiquidDocument8 pagesSds Anti Spatter LiquidHanna HorváthNo ratings yet

- Chapter 7-5: Sludge Treatment and DisposalDocument36 pagesChapter 7-5: Sludge Treatment and DisposalSUWIPHA DAPHANo ratings yet

- Hazardous Waste Storage and LabelingDocument7 pagesHazardous Waste Storage and LabelingavieNo ratings yet

- User Manual Panel Tank FRPDocument7 pagesUser Manual Panel Tank FRPwika mepNo ratings yet

- Bộ Đề 02 - Tham Khảo Avdv Ute 2023Document6 pagesBộ Đề 02 - Tham Khảo Avdv Ute 2023Trân TrầnNo ratings yet

- 4783 Plant Decommissioning Remediation and Redevelopment 508Document5 pages4783 Plant Decommissioning Remediation and Redevelopment 508Humay HamidliNo ratings yet

- NSTP Module 5 Environmental Awareness and ProtectionDocument6 pagesNSTP Module 5 Environmental Awareness and ProtectionFatima DajoyagNo ratings yet

- W9a1 PDFDocument4 pagesW9a1 PDFbosscaptainNo ratings yet

- BSBSUS401 SAT Task 3 Performance Improvement Implementation Ver. 1 2 PDFDocument14 pagesBSBSUS401 SAT Task 3 Performance Improvement Implementation Ver. 1 2 PDFOchaOngNo ratings yet

- Pench Tiger Reserve Buffer Zone PlanDocument293 pagesPench Tiger Reserve Buffer Zone PlanPandit NileshNo ratings yet

- Megacity Padlet ResearchDocument2 pagesMegacity Padlet ResearchSNo ratings yet

- 7-Diversion Head WorksDocument23 pages7-Diversion Head Workswajid malikNo ratings yet

- An Assessment of River Water Quality: The River Tavy Located in The South West of EnglandDocument13 pagesAn Assessment of River Water Quality: The River Tavy Located in The South West of Englandapi-588254617No ratings yet

- Operational Analysis of Green Batching Plant Using Dmaic Tools To Improve Company PerformanceDocument5 pagesOperational Analysis of Green Batching Plant Using Dmaic Tools To Improve Company PerformanceInternational Journal of Innovative Science and Research TechnologyNo ratings yet