Professional Documents

Culture Documents

Level Measurement

Uploaded by

T S Ravindra PrasadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Level Measurement

Uploaded by

T S Ravindra PrasadCopyright:

Available Formats

Engineering Encyclopedia

Saudi Aramco DeskTop Standards

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning : The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramco’s employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Instrumentation For additional information on this subject, contact

File Reference: PCI10103 J.L. Sprague on 874-6414

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Content Page

LEVEL MEASUREMENT: PURPOSE, TERMINOLOGY AND

SYMBOLOGY, AND CATEGORIES OF LEVEL MEASUREMENT DEVICES..................... 1

Purpose of Level Measurement ....................................................................................... 1

Point Level Process Measurements...................................................................... 5

Continuous Level Process Measurements ............................................................ 5

Level Measurements in Automatic Tank Gauging Applications........................... 6

Typical Level Control Loops ............................................................................... 6

Terminology and Symbology .......................................................................................... 9

Units of Measure ................................................................................................. 9

Typical Examples of Symbols and Terms .......................................................... 10

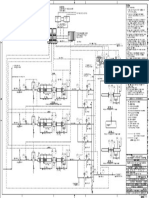

Drawing Symbols .............................................................................................. 11

Influences of Vessel Characteristics................................................................... 12

Example of Calculating Vessel Characteristics .................................................. 13

General Categories of Level Devices............................................................................. 15

Sight.................................................................................................................. 16

Float Type ......................................................................................................... 20

Displacement Type............................................................................................ 23

Force Type ........................................................................................................ 26

Pressure Type .................................................................................................... 28

Electrical Type .................................................................................................. 33

Ultrasonic Type ................................................................................................. 37

Other Types....................................................................................................... 41

Nuclear Type..................................................................................................... 42

SELECTION CRITERIA FOR LEVEL MEASUREMENT DEVICES .................................... 46

An Initial Selection Approach ....................................................................................... 46

Application Characteristics ........................................................................................... 47

Type of application measurements..................................................................... 47

Type of vessel.................................................................................................... 49

Point versus continuous measurement................................................................ 50

Accuracy and span requirements........................................................................ 50

Contacting or non-contacting technology requirements...................................... 51

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Temperature and pressure conditions ................................................................. 51

Maximum and minimum safe heights of process material .................................. 51

Process Operating Conditions........................................................................................ 52

Process material characteristics.......................................................................... 52

Vessel operating conditions ............................................................................... 53

Safety Considerations.................................................................................................... 54

Explosion hazard ............................................................................................... 54

Lethal material measurement ............................................................................. 54

Regulatory requirements.................................................................................... 54

Metallurgy .................................................................................................................... 54

Installation Considerations ............................................................................................ 55

Internal vessel mounting.................................................................................... 55

External cage mounting to vessel or standpipe ................................................... 55

Connection to process taps ................................................................................ 57

Maintenance and Calibration......................................................................................... 58

Compatibility with Existing Process Instrumentation .................................................... 59

Economic Considerations.............................................................................................. 59

Purchase price ................................................................................................... 60

Installation costs................................................................................................ 60

Calibration costs................................................................................................ 60

Training costs.................................................................................................... 60

Maintenance costs ............................................................................................. 60

Spares inventory ................................................................................................ 61

Technical Direction....................................................................................................... 61

Advances in hardware and software................................................................... 61

Point level switch trends .................................................................................... 61

RF admittance versatility ................................................................................... 62

Growing acceptance of HTG ............................................................................. 62

Increasing usage of microwave radar ................................................................. 62

Potential usage of time domain reflectometry .................................................... 62

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

DETERMINING WHETHER PROCESS LEVEL MEASURING

DEVICES MEET APPLICATION REQUIREMENTS ............................................................ 63

Sights............................................................................................................................ 63

Dipstick............................................................................................................. 63

Tubular.............................................................................................................. 64

Reflex Flat Glass ............................................................................................... 65

Transparent Flat Gauge Glass ............................................................................ 71

Float and Tape Devices ................................................................................................. 74

Float Switch ...................................................................................................... 75

Chain or Tape Float Gauge Devices................................................................... 78

Magnetic Type................................................................................................... 82

Displacement Devices ................................................................................................... 84

Simple Displacement Device ............................................................................. 84

Torque Tube Displacers..................................................................................... 90

Hydrostatic Head Devices ............................................................................................. 91

Inferring level measurement from pressure measurement................................... 92

Bubbler Tubes ................................................................................................... 95

Pressure transmitters.......................................................................................... 98

Differential Head Devices................................................................................ 102

Transmitter Range Calculations ....................................................................... 110

Open tank range calculation............................................................................. 112

Open tank with wet leg transmitter range calculation ....................................... 113

Closed tank with dry leg transmitter range calculation ..................................... 116

Closed tank with wet leg transmitter range calculation..................................... 118

Electrical Type............................................................................................................ 121

Capacitance Type Devices............................................................................... 121

Radio Frequency (RF) Admittance .................................................................. 128

Impedance Probes (Resistance Probes) ............................................................ 131

Conductivity Type Devices.............................................................................. 133

Resistance Tape Device ................................................................................... 135

Ultrasonic Type Devices ............................................................................................. 137

Principles......................................................................................................... 137

Design ............................................................................................................. 138

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Performance .................................................................................................... 139

Installation....................................................................................................... 140

Applications .................................................................................................... 140

Nuclear Radiation Devices .......................................................................................... 141

Forced Type................................................................................................................ 143

Load Cells ....................................................................................................... 143

Microwave Radar Devices .......................................................................................... 145

Principles......................................................................................................... 145

Design ............................................................................................................. 147

Performance .................................................................................................... 149

Installation....................................................................................................... 150

Applications .................................................................................................... 153

Level Switch ............................................................................................................... 154

Optical Level Devices...................................................................................... 155

DETERMINING THE APPROPRIATE INTERFACE MEASURING

DEVICE FOR A SAUDI ARAMCO APPLICATION............................................................ 157

Definition of Interface................................................................................................. 157

Purpose of Interface Measurement .............................................................................. 157

Role of interface measurement in field separation............................................ 158

Role of interface measurement in crude oil desalters........................................ 159

Units, Terminology, Symbols...................................................................................... 160

General Categories of Interface Measuring Devices .................................................... 160

Displacement Devices ..................................................................................... 160

Capacitive ....................................................................................................... 163

Hydrostatic Head Devices................................................................................ 166

Other Types of Interface Devices..................................................................... 169

Selecting an interface device when emulsions present...................................... 169

DETERMINING WHETHER LEVEL MEASURING DEVICES MEET

AUTOMATIC TANK GAUGING APPLICATION REQUIREMENTS ................................ 172

Purposes of automatic tank gauging ............................................................................ 173

Account for inventory and/or ownership transfer ............................................. 173

Provide effective process operations ................................................................ 173

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Differences between automatic tank gauging and process level measurement.............. 174

Accuracy requirements .................................................................................... 174

Data access intervals........................................................................................ 174

Communication path........................................................................................ 174

Types of data required ..................................................................................... 174

Tank gauging techniques............................................................................................. 175

Level based techniques .................................................................................... 175

Pressure based techniques................................................................................ 175

Combined (hybrid) techniques......................................................................... 176

Tank structure considerations when selecting level measuring devices ........................ 177

Imperfections of tanks ..................................................................................... 177

Fixed versus floating roof tanks ....................................................................... 178

Importance of reference point to level measurement ........................................ 178

Float and Tape Devices ............................................................................................... 179

Principles and design ....................................................................................... 179

Performance .................................................................................................... 181

Installation....................................................................................................... 181

Applications .................................................................................................... 183

Servo Driven Displacers.............................................................................................. 183

Principles and design ....................................................................................... 184

Performance .................................................................................................... 185

Installation....................................................................................................... 185

Applications .................................................................................................... 186

Radar Devices............................................................................................................. 186

Principles and design ....................................................................................... 186

Installation....................................................................................................... 187

Performance and applications .......................................................................... 188

Ultrasonic Devices ...................................................................................................... 189

Installation....................................................................................................... 189

Performance .................................................................................................... 189

Principles and design ....................................................................................... 190

Performance .................................................................................................... 192

Installation....................................................................................................... 193

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Applications .................................................................................................... 195

Closing commentary on automatic tank gauging.............................................. 196

WORK AID 1: RESOURCES USED TO DETERMINE WHETHER LEVEL

MEASUREMENT DEVICES MEET APPLICATION REQUIREMENTS.... 197

Work Aid 1A: Vendor Data Sheets ............................................................................. 197

Work Aid 1B: Saudi Aramco Instrument Specification Sheets .................................... 198

Work Aid 1C: SADP-J-300 (See Course Handout 1.).................................................. 199

Work Aid 1D: SAES-J-300 (See Course Handout 2.).................................................. 200

Work Aid 1E: SADP-J-300 Supplements — Procedures for Calculating

Transmitter Calibration and Range....................................................... 201

WORK AID 2: RESOURCES USED TO DETERMINE THE

APPROPRIATE INTERFACE MEASURING DEVICE

FOR A SAUDI ARAMCO APPLICATION .................................................. 202

Work Aid 2A: Vendor Data Sheets ............................................................................. 202

Work Aid 2B: Saudi Aramco Instrument Specification Sheets .................................... 203

Work Aid 2C: SADP-J-300 (See Course Handout 1.).................................................. 204

Work Aid 2D: SAES-J-300 (See Course Handout 2.).................................................. 205

Work Aid 2E: SADP-J-300 Supplements — Procedures for Calculating

Transmitter Calibration and Range....................................................... 206

WORK AID 3: RESOURCES USED TO DETERMINE WHETHER

LEVEL MEASUREMENT DEVICES MEET TANK

GAUGING APPLICATION REQUIREMENTS............................................ 207

Work Aid 3A: Vendor Data Sheets ............................................................................. 207

Work Aid 3B: Saudi Aramco Instrument Specification Sheets .................................... 208

Work Aid 3C: SADP-J-300 (See Course Handout 1.).................................................. 209

Work Aid 3D: SAES-J-300 (See Course Handout 2.).................................................. 210

Work Aid 3E: 34-SAMMS-318................................................................................... 211

GLOSSARY........................................................................................................................... 212

SPECIFIC GRAVITY: TERMINOLOGY, PURPOSE, EXAMPLES ..................................... 214

Definition of Specific Gravity ..................................................................................... 214

Units, Terminology, and Symbols ............................................................................... 215

Purpose of Specific Gravity Measurement................................................................... 216

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Estimate material composition or value ........................................................... 216

Compare material quantities ............................................................................ 216

General Categories of Level Measuring Devices Used to Measure Specific

Gravity........................................................................................................................ 217

Hydrostatic Head Devices................................................................................ 217

Buoyancy Devices ........................................................................................... 220

Weight of Material Devices ............................................................................. 222

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Table of Figures Page

Figure 1: Level Measurement Definition .................................................................. 1

Figure 2: Oil Separation Example............................................................................. 3

Figure 3: Oil Storage Example ................................................................................. 4

Figure 4: Point Level Control Loop Example ........................................................... 7

Figure 5: Continuous Level Control Example........................................................... 8

Figure 6: Example of Level Symbols and Terms in a P&ID ....................................10

Figure 7: Drawing Symbols and Legends ................................................................11

Figure 8: Same Level, Different Volume.................................................................12

Figure 9: Calculating Vessel Characteristics............................................................13

Figure 10: Calculating Volume................................................................................14

Figure 11: Dipstick Example ...................................................................................16

Figure 12: Tubular Gauge Glass Example ...............................................................17

Figure 13: Reflex Flat Gauge Glass Example ..........................................................18

Figure 14: Transparent Flat Gauge Glass Example ..................................................19

Figure 15: Magnetic Sight Gauge Example .............................................................20

Figure 16: Magnetic Float Example.........................................................................21

Figure 17: Float Example ........................................................................................22

Figure 18: Float Switch Example ............................................................................23

Figure 19: Torque Tube Displacer...........................................................................24

Figure 20: Servo Type Displacer .............................................................................25

Figure 21: Displacer Switch ....................................................................................26

Figure 22: Compression Type Load Cell Example...................................................27

Figure 23: Suspension System Example ..................................................................28

Figure 24: Diaphragm Box and Continuous Diaphragm...........................................29

Figure 25: Bubbler Tube Example...........................................................................30

Figure 26: Hydrostatic Head Example .....................................................................31

Figure 27: Differential Pressure Example ................................................................32

Figure 28: Hydrostatic Tank Gauging......................................................................33

Figure 29: Capacitance Concept ..............................................................................34

Figure 30: Bare Capacitance Probe..........................................................................35

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Figure 31: Insulated Capacitance.............................................................................35

Figure 32: RF Admittance .......................................................................................36

Figure 33: Conductivity Example............................................................................36

Figure 34: Resistance Sensor Example ....................................................................37

Figure 35: Non-contacting Pulse Type.....................................................................38

Figure 36: Non-invasive Pulse Type........................................................................39

Figure 37: Contacting Continuous Signal Type .......................................................39

Figure 38: Contacting Pulse Wave Signal Type.......................................................40

Figure 39: Microwave Radar Example ....................................................................41

Figure 40: Laser Example .......................................................................................42

Figure 41: Nuclear Level Measurement...................................................................43

Figure 42: Thermal Level Measurement..................................................................44

Figure 43: Frequency of Level Measurement Usage ................................................45

Figure 44: Standpipe Example.................................................................................56

Figure 45: Stillpipe Example ...................................................................................57

Figure 46: Installation References ...........................................................................58

Figure 47: Dipstick Example ...................................................................................63

Figure 48: Tubular Gauge Glass..............................................................................64

Figure 49: Tubular Gauge Glass Application...........................................................65

Figure 50: Reflex Gauge Glass................................................................................66

Figure 51: Reflex Gauge Glass Prisms ....................................................................66

Figure 52: Reflex Gauge Glass Design ....................................................................67

Figure 53: References for Gauge Glass Selection ....................................................69

Figure 54: Reflex Gauge Glass Application.............................................................70

Figure 55: Transparent Flat Gauge Glass.................................................................71

Figure 56: Transparent Flat Gauge Glass Design.....................................................72

Figure 57: Transparent Flat Gauge Glass Concept...................................................72

Figure 58: Separation Example................................................................................74

Figure 59: Float Switch Example ............................................................................75

Figure 60: Float Switch Design ...............................................................................76

Figure 61: References for Float Selection................................................................77

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Figure 62: Float Switch Application........................................................................78

Figure 63: Chain Float Gauge .................................................................................79

Figure 64: Float Example ........................................................................................80

Figure 65: Float Mounting.......................................................................................81

Figure 66: Float Application....................................................................................82

Figure 67: Magnetic Float Example.........................................................................83

Figure 68: Displacement Principles .........................................................................84

Figure 69: Displacement Design..............................................................................85

Figure 70: Displacer Switch Application: Pump Control .........................................88

Figure 71: References for Displacer Selection .........................................................89

Figure 72: Torque Tube Design...............................................................................90

Figure 73: Torque Tube Application: Bottoms Level Measurement.........................91

Figure 74: Example Pressure to Level Measurement ...............................................93

Figure 75: Level in Terms of Pressure .....................................................................95

Figure 76: Bubbler Tube Principles .........................................................................97

Figure 77: Bubbler Tube Application ......................................................................98

Figure 78: Diaphragm Options ................................................................................99

Figure 79: Datum Line ..........................................................................................101

Figure 80: Application: Level Measurement in Storage Vessel..............................102

Figure 81: High Side to Tank Bottom....................................................................103

Figure 82 Connection for Closed Tank...................................................................104

Figure 83: Application Example: Butane Product..................................................108

Figure 84: References for Hydrostatic Head Selection...........................................109

Figure 85: Open Tank Range Calculation..............................................................112

Figure 86: Open Tank Wet Leg Range Calculation................................................114

Figure 87: Closed Tank Dry Leg Range Calculation..............................................117

Figure 88: Closed Tank Wet Leg Range Calculation .............................................119

Figure 89: Capacitance Probe Types......................................................................123

Figure 90: Installation References .........................................................................125

Figure 91: Example Probe Gain Graph ..................................................................126

Figure 92: Application Example: De-watering Tank..............................................127

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Figure 93: References for Electrical Type Device Selection ..................................128

Figure 94: RF Admittance Vectors ........................................................................129

Figure 95: Application: Automatic Well Testing ...................................................131

Figure 96: Impedance Probe Design ......................................................................132

Figure 97: Application: De-watering Tank Level Switch .......................................133

Figure 98: Conductivity Device Design.................................................................134

Figure 99: Application: Water Collection Pot for Crude Stabilizer ........................135

Figure 100: Resistance Tape Design......................................................................136

Figure 101: Resistance Tape in Water Well...........................................................137

Figure 102: Ultrasonic Principles ..........................................................................138

Figure 103: Application: Oily Water Sewer Sump.................................................141

Figure 104: Nuclear Devices .................................................................................142

Figure 105: Load Cell Usage.................................................................................144

Figure 106: FMCW Method..................................................................................146

Figure 107: Radar System Design .........................................................................147

Figure 108: Radar Antennas ..................................................................................148

Figure 109: Floating Roof Tank Installation ..........................................................151

Figure 110: Fixed Roof Tank Installation ..............................................................152

Figure 111: Fully Isolated Mounting .....................................................................153

Figure 112: LPG Application ................................................................................154

Figure 113: Optical Device Design........................................................................156

Figure 114: Interface in Oil Separation Example ...................................................158

Figure 115: Crude Oil Desalting Example .............................................................159

Figure 116: External Displacer Configurations......................................................161

Figure 117: Interface Measurement in Settling Tank .............................................162

Figure 118: Probe Installation ...............................................................................164

Figure 119: Application - Crude Oil Desalter ........................................................165

Figure 120: References for Level Measuring Device Selection for an Interface

Application ............................................................................................166

Figure 121: Hydrostatic Method for Interface Detection........................................167

Figure 122: Multiple D/Ps for Interface Detection .................................................168

Figure 123: Emulsions Presence in Interface .........................................................170

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Figure 124: References for Level Measuring Device Selection for Automatic

Tank Gauging.........................................................................................176

Figure 125: Tank Imperfections That Affect Level Measurement ..........................178

Figure 126: Float in Fixed (Cone) Roof Tank........................................................180

Figure 127: References for Float and Tape Device Installation ..............................182

Figure 128: Servo Driven Displacer ......................................................................183

Figure 129: Servo Driven Displacer Design...........................................................184

Figure 130: References for Servo Driven Displacer Installation.............................185

Figure 131: Tank Radar Operations.......................................................................187

Figure 132: References for Radar Device Installation............................................188

Figure 133: HTG System.......................................................................................190

Figure 134: HTG Calculations...............................................................................191

Figure 135: HTG Measurements ...........................................................................192

Figure 136: Performance References .....................................................................193

Figure 137: References for HTG Installation .........................................................194

Figure 138: HTG Measurement when Vessel is Spherical .....................................195

Saudi Aramco DeskTop Standards

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

LEVEL MEASUREMENT: PURPOSE, TERMINOLOGY AND SYMBOLOGY, AND

CATEGORIES OF LEVEL MEASUREMENT DEVICES

This course module discusses the selection of level measurement devices used to measure

process material levels encountered in Saudi Aramco operations. Process materials requiring

level measurements include liquids, nonmixing (immiscible) liquids, gases, and solids.

The following discussion provides an introductory overview of level measurement in terms of

• the purpose of level measurement,

• terminology and symbology, and

• general categories of level devices.

Purpose of Level Measurement

Level measurement, as used in this course material, is defined as the measurement of an interface

with respect to a reference or datum point (Figure 1). The level measurement occurs between the

two reference points. In Figure 1, the reference points are shown as an upper level reference and

lower level reference.

Upper Reference Point

Level: The Measurement Of

An Interface With Respect

To A Reference Point

Lower Reference Point

Figure 1: Level Measurement Definition

Saudi Aramco DeskTop Standards 1

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

The purpose of level measurement is to provide a measured variable representing the height or

material presence within a vessel. The measured variable is then used in one or more of the

following ways, where the measured variable becomes:

• a local level indication,

• a detection of material presence,

• an input signal to a level control scheme,

• or a measured quantity in hydrocarbon inventory management.

The purpose and importance of level measurement is best illustrated in the following plant

operations, where the level measurement variable is used to:

• control a vessel’s process material level in order to provide satisfactory process

performance, or

• accurately measure a crude oil storage tank’s level in order to calculate

hydrocarbon inventories.

Level measurement is essential to the effective control of a vessel’s process material level. The

level control scheme for a vessel requires a level measurement value. The level measurement

value provides the level control scheme either a quantity, such as a representation of height, or a

logical value, such as the on/off condition of a limit switch that represents the detection of

process material presence.

As an example of the general importance of controlling a vessel’s level for satisfactory process

performance, consider the effects of inadequate level control in a vessel. If the level is too low,

damage to a vessel’s discharge centrifugal pump from cavitation and excessive wear occurs. If

the level is too high, then additional storage capacity will not be available in the vessel to store

unplanned increases in process inlet quantities.

As a more specific example of the role of level measurement in level control, consider the role of

level measurement in a typical spherical three phase oil/gas/water separator (Figure 2). For

separation to occur, a liquid seal must occur in the lower portion of the vessel. The liquid seal

prevents the loss of the gas within the oil. The liquid seal is accomplished through level control,

which in turn is dependent upon a level measurement value.

Saudi Aramco DeskTop Standards 2

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Off Gas

Crude Notch

Oil Off Gas

Crude Oil Water Level HH

LT Weir ~ 2" Below Bottom

Water Of Weir Notch

LC

Crude

Oil

Water Crude

Oil

LT = Level Transmitter

LC = Level Controller

LCV = Level Control Value

Figure 2: Oil Separation Example

Accurate level measurement is also necessary when measuring storage tank levels (Figure 3).

Consider the role of level measurement when calculating the hydrocarbon inventory for a 45.7

meter (150 foot) diameter storage tank. The inventory calculation requires accurate level

measurement values. A level measurement error of 3.2 mm (1/8”) represents 5680 liters (1500

gallons) of a hydrocarbon product. Assuming that the product is crude oil, this represents 35.7

barrels of crude. If the cost of the product is 80 Riyals per barrel, then this could represent over

2800 Riyals worth of inventory that is not properly accounted for.

Saudi Aramco DeskTop Standards 3

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

LI

Level

Indication

Floating Roof Tank

Figure 3: Oil Storage Example

The broad variety of level measurement devices available to accomplish level measurement

makes the level measurement device selection process challenging. Additionally, more than one

level measurement device can be required in a level measurement application, forming a level

measurement system. The intended use for the level measured variable, such as process control

and/or inventory accounting, has a major influence upon the selection of a level measurement

device.

Because the selection of a level measurement device or system is dependent upon the intended

use of the level measurement variable, the selection process becomes application dependent.

The application itself may require one or more types of level measurements. The level

measurement selection process begins with identifying the type of level measurement that is

required in the application. The types of level measurement encountered in applications can be

broadly categorized as the following:

• Point level process measurements

• Continuous level process measurements

Saudi Aramco DeskTop Standards 4

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

• Level measurements in automatic tank gauging applications

Point Level Process Measurements

Point level process measurements are a type of level measurement used when the level

measurement device or system provides a logical (true or false, on-off) representation of material

presence at some predetermined point(s) within the vessel. Point level process measurements are

also referred to as “point level detections,” or “level set point” measurements. Point level process

measurements often are accomplished through the use of level switches. Each level switch is

installed at a predetermined height or “point level” within the vessel. Uses for point level

measurements include one or both of the following:

• Point level process indication

• Point level process control

Point Level Process Indication provides an indication of process material level at a point within a

vessel. A single point level alarm, such as a vessel level high alarm limit, is an example of point

level process indication.

Point Level Process Control provides the control of a material level between two points in a vessel.

To accomplish point level process control, more than one level switch senses a liquid presence at

two (or more) measured “point levels” in a tank. For example, in a vessel the conditions

controlling level can be dependent upon the level measurement device, such as a switch, sensing

material presence. When the high level switch is on, a discharge pump is turned on, which

lowers the level. When the level drops and activates the lower level limit switch, the pump is

turned off.

An application could require both point level indication and control, hence the phrase “point

level process indication and control.”

Continuous Level Process Measurements

In continuous level process measurements, a level measurement system can provide a numeric

representation of the current position (height) of the process material’s surface. The numeric

value, sometimes expressed in meters or feet, is based upon a proportion of material currently

sensed by the level measurement system. The level is measured continuously between a lower

reference level and an upper reference level. Uses for continuous level measurements include

one or both of the following:

• Continuous level process indication

• Continuous level process control

Saudi Aramco DeskTop Standards 5

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Continuous level process indication provides a continuous numeric indication of level within a

vessel. A numeric indication of level height, such as the liquid level in a non-critical water

storage vessel, is an example of continuous level process indication. In this example, only an

indication of the level is provided because automatic control is not necessary. If it is necessary

to adjust the level, an operator could manually open or close the fill or drain valves.

Continuous level process control provides the control of process material level between two points in

a vessel. For example, in a distillation tower, level control is accomplished by adjusting the flow

through a bottoms valve. A level sensor measures the level between the two reference points.

The level sensor’s signal is sent to a level transmitter, which generates an output signal. The

output signal of the level transmitter is connected as an input signal to a level controller. The

level controller’s output is connected to a bottoms flow valve, which controls the bottoms flow

based on the difference between a known set point and the current process level signal.

An application could require both continuous level indication and control; hence the phrase

“continuous level process indication and control.”

Level Measurements in Automatic Tank Gauging Applications

Although one could argue that level measurements within an automatic tank gauging application

are indeed continuous or point level measurements, an exception to that categorization is made

here. An automatic tank gauging application does not necessarily have as its primary objective

the use of a level measurement quantity as part of a process control scheme. While an objective

of level measurement in automatic tank gauging applications is to measure, as accurately as

possible, the material level within the tank, the level measurement quantity is used calculate

inventory quantities.

Automatic tank gauging systems may also provide temperature and density measurements, which

are necessary for calculating inventories at standard conditions. Therefore, automatic tank

gauging is regarded as not just another form of process level measurement, but as a separate

discipline involving several process measurements. The level measurement aspect of an

automatic tank gauging application, however, does have a major influence on which level

measurement device an engineer selects.

Typical Level Control Loops

Typical level control loops can use, as implied in the previous discussion, a measured variable

from either a point level measurement or continuous level measurement. Thus, the examples that

follow describe a

• typical point level control loop, and a

• typical continuous level control loop.

Saudi Aramco DeskTop Standards 6

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Typical Point Level Control Loop - Point level control is possible using on-off level switches for

controlling the interface level control in an oil and water separator. The oil and water mixture is

separated with the oil removed from the top of the vessel and water drained from the vessel’s

bottom. In this example, the control of level does not require continuous level measurement and

level control. A lower level switch and upper level switch can be used to provide point level

measurements (Figure 4). The two level switches provide input, in the form of on/off values, to

the level control logic in a programmable controller. The level control logic could represent the

condition - “If the lower level switch is on, then the level measurement indicates oil, so close the

valve. If the upper level switch is on, then the level measurement indicates water, so open the

valve.”

The level control logic starts with the interface level between the level switches. When water

reaches the upper level switch, the valve opens. The valve remains open until the lower level

switch indicates oil, then closes. The interface level can then fluctuate between the two level

switches. Because the water is often pumped to a holding tank and recovery system, the level

control logic could also be connected to a pump to turn it on and off when needed.

Oil

High Level

Detection

LS

Control

Interface

Logic

LS

Low Level Water

Detection

Pump

Figure 4: Point Level Control Loop Example

Saudi Aramco DeskTop Standards 7

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Typical Continuous Level Control Loop - A crude oil desalter (Figure 5) illustrates how a continuous

level measurement is used in continuous level control. Before raw crude is refined, it is washed

in a desalter to reduce the crude oil’s salt content. The desalter itself is a long horizontal vessel

containing crude oil and water. The position of where water and crude oil meet is called the

“interface.” The level measurement device used here consists of a level sensing device and a

level transmitter. The position of the interface is measured with a level sensing device. The

level sensing device is able to provide its level transmitter a physical variable, such as a voltage

or displacement, to represent the interface position. The level transmitter sends its signal

representing the position of the interface to the level controller. The interface position must be

closely controlled by the level controller in order for the vessel to have a constant throughput of

crude oil. Because water and oil densities change, the position of the interface changes. The

need to control the interface’s changing position requires a level measurement device that can

accurately and consistently locate the interface.

Level Desalted Crude

Transmitter Discharge Pump

LT

Level LC

Control

Crude

Gas/Oil Desalter

Desalter Water Exchanger

Sour Water Stripper

Foul Water Disposal

Figure 5: Continuous Level Control Example

To select a level measurement device, an engineer must first have a familiarity with level

measurement terminology.

Saudi Aramco DeskTop Standards 8

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Terminology and Symbology

This section discusses terminology and symbology topics applicable to level measurement and

level measurement device selection, which include:

• Units of measure

• Examples of terms and symbols

• Drawing symbols

• Influences of vessel characteristics.

Units of Measure

Depending upon the level measurement application, the units of measure are either in distance,

weight, or volume. In continuous level indication and control, the level distance is typically

measured in units of meters (feet), while for smaller tanks the level distance can be measured in

centimeters (inches). The term “head” is also used to represent the measurement of the height of

a process material. When level is inferred from a pressure measurement, the units of measure are

often in either millimeters or inches of water column.

When volume is measured, the units may be in cubic feet, gallons, million gallons, cubic meters,

liters, million liters, and petroleum barrels. In tank gauging and custody transfer operations,

where the concern is accurate measurement of inventory, the units can include weight, such as

kilograms (pounds).

Level measurements, while representing as a height of a liquid surface from a reference (datum)

line, are also used for the following:

• Volume determination

• Weight determination

Volume determination can be calculated from a measurement of level height (distance). For

example, a volume for a cylindrical tank can be determined from a direct measurement of height,

based on the calculation:

Vvolume = Avessel area x L height of process materials

Saudi Aramco DeskTop Standards 9

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Weight determination can be calculated using a direct measurement of level height (distance). For

example, a weight measurement, using a process material’s density, may be determined from a

direct level measurement of height, based on the calculation:

Wweight = Avessel area x L height of process materials x Ddensity

Typical Examples of Symbols and Terms

The most common terms and abbreviations for level measurement devices are “LT” for the level

transmitter, and “LS” for the level switch. An example of how level symbols could appear in a

Process Instrument and Drawing (P&ID) is shown in Figure 6. Refer to Figure 7, which excerpts

level instrument symbols from Saudi Aramco Drawing AC-036950 and an instrument legend

from a typical Saudi Aramco Process Instrument and Drawing (P&ID).

LS

HH HH

LA

100 100

HH

LS

100

HHLL Water 900mm

LE LIT

100 110

Where:

HH = High High

HHLL = High High Liquid Level

LS = Level Switch

Crude Inlet Separator Sphere LA = Level Alarm

LE = Level Element

LIT = Level Indicating Transmitter

Figure 6: Example of Level Symbols and Terms in a P&ID

Saudi Aramco DeskTop Standards 10

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Drawing Symbols

Drawing symbols representing level instruments are shown in Figure 7. The symbols conform to

Saudi Aramco requirements specified in SAES-J-004 (Instrument Symbols and Identification).

Instrument Symbols Instrument Line Symbols

Process Line

Connections to Process or

Mechanical Link or

LG Instrument Supply

Instrument Air Header

Level Gauge Glass Instrument Signal Line

(Pneumatic)

Instrument Signal Line

(Electrical/Electronic)

LT

Instrument Capillary Tube

Level Transmitter

Diff. Pressue Type Electromagnetic or Sonic

Signal (Without Wiring or Tubing)

Instrument Legend

LT LA Level Alarm

LC Level Control

Level Transmitter LE Level Element

Ext. Float/Displ Type

LG Level Gauge Glass

LIC Level Indicating Controller

LS LI Level Indicator

LIT Level Indicating Transmitter

Level Switch LR Level Recorder

Externally Mounted LS Level Switch

001066

LS LT Level Transmitter

LTd Level Transducer

x = Miscellaneous Designations

Multi-Position Level Switch H High

Internally Mounted HH High High

HHH High High High

Abbreviations Outside Of L Low

Instrument Symbol LL Low Low

LL Liquid Level LLL Low Low Low

Figure 7: Drawing Symbols and Legends

Note that the piping symbols for electrical and pneumatic signals as used at Saudi Aramco are

the reverse of instrument society and industry symbol usage.

Saudi Aramco DeskTop Standards 11

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Having seen that level measurements may be expressed in terms of distance, weight, or volume

would lead you to believe that level measurement device selection should be fairly easy.

However, you must also consider the physical characteristics of a vessel when selecting a level

measurement device.

Influences of Vessel Characteristics

The vessel’s characteristics do affect level measurements. Not all vessels are perfect geometric

shapes with easy to calculate volumes. The physical characteristics that can be relevant in level

measurement device selection are:

• Vessel deformations

• Vessel geometries

Vessel deformations can occur during level measurement. Deformations may occur when the

vessel is filled. For example, wall stretching occurs in a crude oil storage tank because of the

increasing hydrostatic pressure on the walls as the vessel fills. While vessel deformations are

beyond the scope of this course module, they must be taken into account when performing a

level measurement. Some level measurement systems provide means for compensating

deformation effects through the use of tank correction tables.

Vessel geometries can include horizontal flat, horizontal elliptical, horizontal spherical, vertical

flat, vertical conical, spherical, and other irregularly shaped vessels. Vessel shape becomes

important when a level measurement is used to infer a volume or mass of process material. This

consideration can be seen in Figure 8 where 3 vessel shapes - each with the same level reading -

nevertheless contain different volumes of liquid.

Same Level, Different Volume

Figure 8: Same Level, Different Volume

Saudi Aramco DeskTop Standards 12

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Example of Calculating Vessel Characteristics

As an example of how a vessel’s shape relates to level measurement and the subsequently

derived volume, consider the calculation for the volume of a storage vessel. Often volume data

as well as level data is required by various departments. If the storage vessel (Figure 9) is a

cylindrically shaped vessel, such as skimmed oil drum, then the volume calculation can be

complex.

For example, assume the following for the calculation:

• A flat end cylindrical tank

• Tank diameter = 5 feet

• Tank length = 15 feet

• Tank level is currently at 1.5 feet.

The challenge is to calculate the volume of skimmed oil currently in the vessel.

15 ft Length

5 ft

Diameter

Skimmed Oil

Drum Level

At 1.5 ft

Figure 9: Calculating Vessel Characteristics

Saudi Aramco DeskTop Standards 13

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

To begin the volume calculation, you must first know the area of BCDE:

Area BCD = Area ABCD - Area ABD.

Area ABCD’s calculation is based upon:

Area ABCD = (2 ∠DAE°/360°) x area of circle

15 ft Length

5 ft

Diameter

AC = AD = AB = 2.5 ft

EC = Level = 1.5 ft

AE = 1.0 ft

A DAE = cos 1.0 = 66.4Þ

2.5

2.5

1.0 E

D B

1.5

Figure 10: Calculating Volume

The calculation for the volume follows.

Determine the area ABD:

Area ABD = 1.0 x 1.5 x sin ∠DAE°

where sin ∠DAE° requires knowing ∠DAE°.

Since ∠DAE° = cos (1.0/2.5),

then ∠DAE° = 66.42°

Saudi Aramco DeskTop Standards 14

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Calculate area ABD:

Area ABD = 1.0 x 2.5 x sin 66.42°

Area ABD = 1.0 x 2.5 x .916

Area ABD = 2.3 ft2

Calculate area ABCD:

Area ABCD = (2 ∠DAE°/360°) x area of circle

Area ABCD = (2 x 66.42°/360°) x π x (2.5)2

Area ABCD = 7.3 ft2

Calculate the volume:

Area BCD = Area ABCD - Area ABD.

Area BCD = 7.3 ft2 - 2.3 ft2

Area BCD = 5.0 ft2

Volume = Area BCD x 1gal/.1337 ft3 (conversion) x vessel length

Volume = 5.0 ft2 x 1gal/.1337 ft3 x 15 feet

Volume = 560.9 gallons

The volume calculation can become more complex if the vessel is a “bullet” shape with spherical

ends.

Note that if the vessel’s length doubled, one can easily see that the volume doubles. An

important conclusion, then, is that depending upon the vessel’s shape and length, a small level

change can represent a large change in volume. From this example one can observe that a

vessel’s shape can influence level measurement device selection.

General Categories of Level Devices

Of the process measurement devices discussed in the PCI101 course (flow, temperature,

pressure, and level), level measurement applications use the most extensive variety of devices.

The following discussion provides the Saudi Aramco engineer an overview of that extensive

variety. Typical level measurement devices include the following:

• Sight

• Float type

• Displacement type

• Force type

• Pressure type

Saudi Aramco DeskTop Standards 15

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

• Electrical type

• Ultrasonic type

• Microwave radar

• Other types

Sight

Sight level measurement devices primarily are used to give the operator a local visual indication

of the process material’s level. Sight level measurement devices include:

• dip stick

• tubular gauge glass

• reflex flat gauge glass

• transparent flat gauge glass

Dip Stick - The simplest example of a level measurement device is the dip stick. The dip stick

(Figure 11) is a long rod with a graduated scale. The dip stick’s wetted portion of the scale

indicates the height of liquid in the vessel.

Dipstick

Underground

Vessel

Figure 11: Dipstick Example

Saudi Aramco DeskTop Standards 16

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Tubular Gauge Glass - One of the simplest and earliest devices for an above-ground vessel is a

sight glass. One type of sight glass is the tubular gauge glass (Figure 12). A tubular gauge glass

is so named because a tubular glass columnar enclosure is externally connected to a vessel.

Because the tubular glass enclosure acts as a bypass for a liquid, the vessel’s liquid seeks the

same position as the liquid within the glass enclosure. The tubular gauge glass is marked with the

measurement units in either meters or inches.

Liquid

Level

Tubular Gauge

Glass

Figure 12: Tubular Gauge Glass Example

Reflex Flat Gauge Glass - Like the tubular gauge glass, a reflex flat gauge glass (Figure 13) also

uses an enclosure to allow parallel passage of vessel fluids. The enclosure, however, is a metal

chamber with a flat piece of glass clamped on one side of the chamber. The flat piece of glass

contains reflecting prisms to indicate material level. The reflecting prisms make a liquid

material appear dark when it contacts the glass. When liquid material does not make contact with

the reflecting prisms, the glass appears silvery white. Level is then observed as a boundary

between black and white colors.

Saudi Aramco DeskTop Standards 17

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Reflex

Metal Glass

Chamber

Light

Liquid

Light

Liquid

Level

Reflex Flat

Gauge Glass

Figure 13: Reflex Flat Gauge Glass Example

Transparent Flat Gauge Glass - Like the reflex gauge glass, a transparent flat gauge (Figure 14)

glass uses a metal chamber to allow parallel passage of vessel fluids. On each side of metal

chamber, a plain flat glass is clamped. Because light passes through both glasses on each side of

the chamber, the gauge is called a “transparent flat gauge glass.” The transparent flat gauge

glass provides visual indication at one side of the chamber when light is available on the other

side of the chamber. The transparent flat gauge permits observation of liquid color, condition, or

a liquid/gas interface position.

Saudi Aramco DeskTop Standards 18

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Transparent

Glasses

Liquid

Light

Liquid

Level

Transparent Flat

Gauge Glass

Figure 14: Transparent Flat Gauge Glass Example

Magnetic Sight Gauge - In certain applications, where the process fluid is very corrosive or at a

high pressure, a gauge glass would not be acceptable. The risk from glass breakage would have

harmful consequences. In those applications, a magnetic sight gauge (Figure 15) is acceptable.

A magnetic gauge uses brightly colored wafers to indicate the level position. As the magnetic

float within the gauge travels with the liquid, the magnetically coupled float flips over the wafers

to provide an indication of the level.

Saudi Aramco DeskTop Standards 19

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Level

Vessel

Indicating

Standpipe

Wafers

Magnet

Float

Figure 15: Magnetic Sight Gauge Example

Float Type

Float type devices consist of an element called a float, which contacts and follows the surface of

a liquid. An external readout device can be connected to the float to provide local indication of

the level within the vessel. Types of float type devices include:

• magnetic float,

• float and tape, and

• float switches.

Magnetic Float - A magnetic float device (Figure 16) contains a magnet within the float. As the

liquid surface position changes, a corresponding change in float position occurs. The float itself

is magnetically coupled to a tape within a internal pipe. The tape senses the float changes in

level. Because the tape has a connection to a level indicator, the tape’s movement is converted

to a level indication.

Saudi Aramco DeskTop Standards 20

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Magnets Process

Level

Figure 16: Magnetic Float Example

Float and Tape - Generally, float and tape devices use a float resting on the surface of a liquid

(Figure 17). The float is restricted by guide wires or rods so that the float can only move in an

up or down direction. A cable is attached to the float. The cable is also routed through pulley

assemblies and attached to an external readout device. The external readout device, called a

gauge head assembly, provides local level indication.

Saudi Aramco DeskTop Standards 21

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Float

Gauge Head

Assembly

Float (External

Guide Readout)

Wires

Figure 17: Float Example

Float Switch - Float switches (Figure 18), like float and tape devices, employ a float element that

rests on the liquid surface. As the float element reaches a predetermined point level, a switch

actuating element causes a relay to actuate (that is, open or close). The switch mechanism itself

is used to provide high or low level alarm conditions or point level detection.

Saudi Aramco DeskTop Standards 22

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Float Switch

Float

High Level

Low Level

Figure 18: Float Switch Example

Displacement Type

Displacement type devices differ from float type devices in that they do not float on the surface,

but are partially immersed in the vessel’s liquid. Displacer type devices are usually contained

within a chamber that is external to the vessel. Inside the external chamber is a float-like

element called the displacer. The displacer remains in a relatively fixed position and experiences

very little observable movement. Although the displacer remains in a relatively fixed position,

the buoyancy forces acting upon the displacer are measurable. The buoyancy forces displace or

change the apparent weight of the displacer. The changing buoyancy forces of a changing level

are thus converted to a level measurement. Types of displacers used in Saudi Aramco level

measurements include the following:

• torque tube displacer,

• servo type displacer, and

• displacer switches.

Torque Tube - A torque tube displacer (Figure 19) is so named because torque due to buoyancy

forces acting upon the displacement element are used to infer a level measurement. At the top of

the torque tube chamber, the displacer’s buoyancy force is measured by a torque arm assembly.

As the level in the tank changes, the level in the external chamber changes. As the level

changes, the buoyant forces placed upon the displacer changes. Although the small movement

on the displacer appears insignificant to an observer, the small movement produces a torque that

can be measured and converted to a level measurement.

Saudi Aramco DeskTop Standards 23

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Torque

External

Tube

Displacer

Chamber

Local

Indication

Device

Displacer

Liquid

Level

Figure 19: Torque Tube Displacer

Servo type displacer is so named because a displacer element continually follows the liquid level

through the use of level sensing technology that includes servo motors and precision balancing

mechanisms. The servo type displacer uses precision transducers and microprocessor technology

to provide highly accurate level measurements. The servo type displacer is mounted at the top of

the tank. The servo type displacer is also referred to as a “servo gauge” or “servo driven

displacer.” Servo type displacers are usually intended for automatic tank gauging applications.

Saudi Aramco DeskTop Standards 24

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Servo Motor

Inside Enclosure

Servo

Type

Displacer

Displacer

Level

Figure 20: Servo Type Displacer

Displacer switch - A displacer switch (Figure 21) employs one or more displacer float-like

elements, which are typically held in place by a spring. As the level changes, the changing

buoyancy forces act upon the float-like elements. As the buoyancy forces are sensed by the

displacer switch’s sensors, the switches actuate. Like the float switch, the switch actuation is

used to provide high or low level alarm conditions or point level measurement and control.

A displacer switch can be used in complex process level detections, such as a foaming or an

agitated liquid level application that otherwise would not suitable for a float switch. Because one

or more float-like elements can be employed in one displacer switch device, the displacer switch

also provides a way to start and stop a series of pumps based upon the detected level.

Saudi Aramco DeskTop Standards 25

Engineering Encyclopedia Instrumentation

Determining Appropriate Level Measuring

Systems For Saudi Aramco Applications

Displacer Switch

Displacers

High Level

Low Level

Figure 21: Displacer Switch

Force Type

Level measurement devices that can detect pressure exerted against a sensor are called force type

devices. Force type devices are more frequently called “load cell” weighing devices. Load cells

are on occasion used in level measurements of dry, dusty solids or hazardous, toxic liquids. The

purpose of level measurement devices is to determine the amount of material in the vessel. Load

cells are the direct measurement of the mass of the material. When reverting from mass

measurement to level, the specific gravity of the material must be known. If the size varies, the