Professional Documents

Culture Documents

So Study of Effect of Different Process Condition On Parameters Needs To Be Carried Out

Uploaded by

zee khanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

So Study of Effect of Different Process Condition On Parameters Needs To Be Carried Out

Uploaded by

zee khanCopyright:

Available Formats

This case study aimed to illustrate application of Taguchi method of experimental

design (TMED) for the development of a new ignition coil for automobiles and also

determined the optimize design parameter for ignition coil.

Although Taguchi method has been employed with great success in experimental

designs for problems with multiple parameters due to its practicality and robustness.

However, it is pertinent to mention that there is no single technique that appears to be

superior in solving different kinds of problem. Improvements are to be expected by

integrating the practical use of the Taguchi method into other optimization approaches

to enhance the efficiency of the optimization process.

In this case study standalone Taguchi method and integration of Taguchi method with

various approaches including numerical simulation, grey relational analysis (GRA i.e. for

factor effect evaluation, multiple criteria decision and solving complicated

interrelationships between multiple factors and variables), principal component analysis

(PCA, i.e. it is a statistical procedure that uses an orthogonal transformation to convert a

set of observations of possibly correlated variables into a set of values of linearly

uncorrelated variables called principal components) and genetic algorithm (GA) are not

linked, used or discussed.

Moreover, herein offline quality controls are employed and online quality controls which

refer to activities that take place during the production stage and includes

measurement, feedback and adjustment, prediction and correction have not been taken

into consideration.

Analysis of variance (ANOVA) is a tool which is a statistical procedure used to test the

degree to which two or more groups vary or differ in an experiment. Here it can be

applied to check the variance of different factors i.e. number of turns in secondary coil

(NTSC),

length of core, magnet material (MM), number of magnets (NOM) and

core material.

There must be a significant factor in above mentioned factors i.e. influential factor.

Other factors also change by altering its value. Here in this study it was not determined.

This factor could be determined by employing ANOVA.

Mathematical models could be developed to describe the influence of the selected

parameters on the performance of ignition coil. This study has also not been undertaken

in this paper. It is well known that process conditions affect some parameters properties

i.e. core material and magnetic material of core i.e. heat treatment process etc. so study

of effect of different process condition on parameters needs to be carried out.

You might also like

- Optimization Under Stochastic Uncertainty: Methods, Control and Random Search MethodsFrom EverandOptimization Under Stochastic Uncertainty: Methods, Control and Random Search MethodsNo ratings yet

- Mathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsFrom EverandMathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsNo ratings yet

- Roughness TaguchiDocument7 pagesRoughness TaguchiAnudatt A. GowdaNo ratings yet

- A Hybrid Approach To Parameter Tuning in Genetic Algorithms: Bo Yuan Marcus GallagherDocument8 pagesA Hybrid Approach To Parameter Tuning in Genetic Algorithms: Bo Yuan Marcus GallagherPraveen Kumar ArjalaNo ratings yet

- International Journal of Advanced Manufacturing TechnologyDocument11 pagesInternational Journal of Advanced Manufacturing TechnologyDiego Andres Diaz CuervoNo ratings yet

- Identification of Catalytic Converter Kinetic Model Using A Genetic Algorithm ApproachDocument35 pagesIdentification of Catalytic Converter Kinetic Model Using A Genetic Algorithm ApproachKoteswara RaoNo ratings yet

- Taguchi TechniqueDocument20 pagesTaguchi TechniqueFunand JoyNo ratings yet

- Design of Experiments Via Taguchi Methods Orthogonal ArraysDocument21 pagesDesign of Experiments Via Taguchi Methods Orthogonal ArraysRohan ViswanathNo ratings yet

- Development of A Variance Prioritized Multiresponse Robust Design Framework For Quality ImprovementDocument17 pagesDevelopment of A Variance Prioritized Multiresponse Robust Design Framework For Quality Improvementaqeel shoukatNo ratings yet

- Application of Multivariate Control Chart For Improvement in Quality of Hotmetal - A Case StudyDocument18 pagesApplication of Multivariate Control Chart For Improvement in Quality of Hotmetal - A Case StudyMohamed HamdyNo ratings yet

- 1999 (C.Y. Nian, W.H. Yang, Y.S. Tarng) Optimization of Turning Operations With Multiple Performance Characteristic PDFDocument7 pages1999 (C.Y. Nian, W.H. Yang, Y.S. Tarng) Optimization of Turning Operations With Multiple Performance Characteristic PDFFikri SiplhoNo ratings yet

- Uncertain Parameter Numerical Model Updating According To Variable Modal Test Data in Application of Large Composite Fuselage PanelDocument16 pagesUncertain Parameter Numerical Model Updating According To Variable Modal Test Data in Application of Large Composite Fuselage Paneligomez19No ratings yet

- Taguchi Method Design of Experiments Using Orthogonal ArraysDocument17 pagesTaguchi Method Design of Experiments Using Orthogonal ArraysNatKTh0% (1)

- Expert Systems With Applications: Songtao Zhang, Rickey Dubay, Meaghan CharestDocument9 pagesExpert Systems With Applications: Songtao Zhang, Rickey Dubay, Meaghan CharestBoy RollastinNo ratings yet

- A Study On The Convergence of Multiobjective Evolutionary AlgorithmsDocument18 pagesA Study On The Convergence of Multiobjective Evolutionary AlgorithmsSarvesh GantalaNo ratings yet

- Researchpaper On The Estimation of Variance Components in Gage R R Studies Using Ranges ANOVADocument15 pagesResearchpaper On The Estimation of Variance Components in Gage R R Studies Using Ranges ANOVALuis Fernando Giraldo JaramilloNo ratings yet

- García2008 Article AStudyOnTheUseOfNon-parametricDocument28 pagesGarcía2008 Article AStudyOnTheUseOfNon-parametricGaurav AdakmolNo ratings yet

- Marlin Ch03 Process ControlsDocument47 pagesMarlin Ch03 Process ControlsRagavaaRagavaa100% (1)

- Taguchi MethodDocument8 pagesTaguchi MethodLSARAVANAN91No ratings yet

- AIAA-2000-1437 Validation of Structural Dynamics Models at Los Alamos National LaboratoryDocument15 pagesAIAA-2000-1437 Validation of Structural Dynamics Models at Los Alamos National LaboratoryRomoex R RockNo ratings yet

- Maximum GenerationDocument8 pagesMaximum GenerationDeepak WasgeNo ratings yet

- 0708 0369Document27 pages0708 0369iledinamo1No ratings yet

- Design of ExperimentsDocument4 pagesDesign of Experimentsavinasss1963_3707255No ratings yet

- Process Variability Reduction Through Statistical Process Control For Quality ImprovementDocument11 pagesProcess Variability Reduction Through Statistical Process Control For Quality ImprovementMehul BarotNo ratings yet

- Optimization of Shell and Tube Heat Exchangers Using Modified Genetic AlgorithmDocument10 pagesOptimization of Shell and Tube Heat Exchangers Using Modified Genetic AlgorithmAditya NandanpawarNo ratings yet

- The Principles of Calibrating Traffic Microsimulation Models: Transportation February 2008Document17 pagesThe Principles of Calibrating Traffic Microsimulation Models: Transportation February 2008Andrean MaulanaNo ratings yet

- Design of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiDocument11 pagesDesign of Experiments Via Taguchi Methods - Orthogonal Arrays - ControlsWikiRachel HillNo ratings yet

- Multi-Objective Optimization of The Fiber-Reinforced Composite Injection Molding Process Using Taguchi Method, RSM, and NSGA-IIDocument21 pagesMulti-Objective Optimization of The Fiber-Reinforced Composite Injection Molding Process Using Taguchi Method, RSM, and NSGA-IIClynoesNo ratings yet

- TAGUCHI BRAKE Example FEA PDFDocument9 pagesTAGUCHI BRAKE Example FEA PDFanirudh666No ratings yet

- GuiaDocument22 pagesGuiatruchascorpNo ratings yet

- Model-Based Experimental Screening For DOC Parameter EstimationDocument15 pagesModel-Based Experimental Screening For DOC Parameter EstimationKhairatun NisaNo ratings yet

- Estiamion and ResidualDocument11 pagesEstiamion and Residualanuj1166No ratings yet

- Software Reliability Assessment Modeling and AlgorithmsDocument4 pagesSoftware Reliability Assessment Modeling and AlgorithmsayalewbelayNo ratings yet

- Statistical Statements For Mathematical Methods Synthesis of Automated Measurements Systems For Accuracy IncrementDocument9 pagesStatistical Statements For Mathematical Methods Synthesis of Automated Measurements Systems For Accuracy IncrementReddappa HosurNo ratings yet

- SPE 164824 An Adaptive Evolutionary Algorithm For History-MatchingDocument13 pagesSPE 164824 An Adaptive Evolutionary Algorithm For History-MatchingAditya FauzanNo ratings yet

- Taguchi APPDocument14 pagesTaguchi APPAmey VidvansNo ratings yet

- Taguchi MethodDocument22 pagesTaguchi MethodsadanalzoubiNo ratings yet

- Optimizing Injection Moulding Process Conditions Using Multi-Objective AlgorithmsDocument4 pagesOptimizing Injection Moulding Process Conditions Using Multi-Objective Algorithmseduardo_umNo ratings yet

- Supplemental Material D. Montgomery S12-1. Guidelines For Planning ExperimentsDocument9 pagesSupplemental Material D. Montgomery S12-1. Guidelines For Planning ExperimentsRago Ramirez GzzNo ratings yet

- Validation and Updating of FE Models For Structural AnalysisDocument10 pagesValidation and Updating of FE Models For Structural Analysiskiran2381No ratings yet

- Gunay and HinisliogluDocument10 pagesGunay and HinisliogluZriNo ratings yet

- 2004 JQT Woodall Et AlDocument12 pages2004 JQT Woodall Et AlWei WangNo ratings yet

- CASE STUDY 2Document5 pagesCASE STUDY 2vandanavenkat325No ratings yet

- Prediction of ITQ-21 Zeolite Phase Crystallinity: Parametric Versus Non-Parametric StrategiesDocument18 pagesPrediction of ITQ-21 Zeolite Phase Crystallinity: Parametric Versus Non-Parametric StrategiesbaumeslNo ratings yet

- An Introduction To Sensitivity Assessment of Simulation ModelsDocument20 pagesAn Introduction To Sensitivity Assessment of Simulation ModelsEman SalehNo ratings yet

- An Introduction To Genetic AlgorithmsDocument26 pagesAn Introduction To Genetic AlgorithmsSai Pranahita BhaskarapantuluNo ratings yet

- Ijamev4n6spl 01Document6 pagesIjamev4n6spl 01ahmed titoNo ratings yet

- Optimization of Process Parameter Using Theory of ConstraintsDocument5 pagesOptimization of Process Parameter Using Theory of ConstraintsJuanCamiloNo ratings yet

- Estimation of Kinetic Parameters in A Structured Yeast Model Using RegularisationDocument15 pagesEstimation of Kinetic Parameters in A Structured Yeast Model Using RegularisationASimilatrixNo ratings yet

- Calibration Intervals From Variables Data PDFDocument12 pagesCalibration Intervals From Variables Data PDFtomasfbenvenutoNo ratings yet

- Identifying parameters for coupled THM analysisDocument10 pagesIdentifying parameters for coupled THM analysisa4abhirawatNo ratings yet

- Finite Elements in Analysis and Design: A.R. Khoei, Sh. Keshavarz, S.O.R. BiabanakiDocument19 pagesFinite Elements in Analysis and Design: A.R. Khoei, Sh. Keshavarz, S.O.R. Biabanakisinouhe7No ratings yet

- Uncertainty and Sensitivity Analysis of PAT Systems for Crystallization ProcessesDocument2 pagesUncertainty and Sensitivity Analysis of PAT Systems for Crystallization Processesmalmoosawi_1No ratings yet

- Recent Methods For Optimization of Plastic Injection Molding Process - A Retrospective and Literature ReviewDocument15 pagesRecent Methods For Optimization of Plastic Injection Molding Process - A Retrospective and Literature Reviewdanaluca2753No ratings yet

- Establishment of Process Model For Rapid Prototyping Technique (Stereolithography) To Enhance The Part Quality by Taguchi MethodDocument10 pagesEstablishment of Process Model For Rapid Prototyping Technique (Stereolithography) To Enhance The Part Quality by Taguchi MethodmanpreetNo ratings yet

- PMU MaterijaliDocument5 pagesPMU MaterijaliGordana RodićNo ratings yet

- Repeatability and Reproducibility Studies For NonDocument10 pagesRepeatability and Reproducibility Studies For Nonhassen talebNo ratings yet

- Multivariate Process Control Chart For Controlling The False Discovery RateDocument5 pagesMultivariate Process Control Chart For Controlling The False Discovery RateManprita BasumataryNo ratings yet

- ANOVA Gauge R&RDocument3 pagesANOVA Gauge R&Rmia farrow100% (1)

- On The Pareto Optimum Sensitivity Analysis in Multicriteria OptimizationDocument23 pagesOn The Pareto Optimum Sensitivity Analysis in Multicriteria Optimizationdtn2008No ratings yet

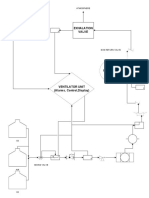

- Ventilator Assignment PDFDocument1 pageVentilator Assignment PDFzee khanNo ratings yet

- Technical Specifications For Pressure Swing Adsorption (PSA) Oxygen PlantsDocument5 pagesTechnical Specifications For Pressure Swing Adsorption (PSA) Oxygen Plantszee khanNo ratings yet

- WHO 2019 nCoV Oxygen - Sources 2020.1 Eng PDFDocument6 pagesWHO 2019 nCoV Oxygen - Sources 2020.1 Eng PDFkkaranagNo ratings yet

- WHO 2019 nCoV Oxygen - Sources 2020.1 Eng PDFDocument6 pagesWHO 2019 nCoV Oxygen - Sources 2020.1 Eng PDFkkaranagNo ratings yet

- Brian-Morrison Design For ExcelenceDocument42 pagesBrian-Morrison Design For ExcelencemstevkaNo ratings yet

- Assignment Fast PDFDocument1 pageAssignment Fast PDFzee khanNo ratings yet

- For Class Felexible ManufacturingDocument20 pagesFor Class Felexible Manufacturingzee khanNo ratings yet

- Assignment QRMDocument2 pagesAssignment QRMzee khanNo ratings yet

- Bom Psa 4 TanksDocument1 pageBom Psa 4 Tankszee khanNo ratings yet

- Function Analysis Diagram PDFDocument1 pageFunction Analysis Diagram PDFzee khanNo ratings yet

- Cycle Time Calculation-Unit - 15 - Flexible - Manufacturing - Systems PDFDocument38 pagesCycle Time Calculation-Unit - 15 - Flexible - Manufacturing - Systems PDFzainikamal1975No ratings yet

- Assignment Fad PDFDocument1 pageAssignment Fad PDFzee khanNo ratings yet

- PDF For Successive ApproximationDocument28 pagesPDF For Successive ApproximationNeekitaGuptaNo ratings yet

- FlexDocument1 pageFlexzee khanNo ratings yet

- Assignment (Submission On Friday 23rd December 2019) - 2Document1 pageAssignment (Submission On Friday 23rd December 2019) - 2zee khanNo ratings yet

- ..... Numarical Analaysis PDFDocument69 pages..... Numarical Analaysis PDFtarunNo ratings yet

- Hollier Method ExampleDocument1 pageHollier Method Examplezee khanNo ratings yet

- Lec 25-27 FMS 29 Oct 2019Document45 pagesLec 25-27 FMS 29 Oct 2019zee khanNo ratings yet

- Matlab Q 1 PDFDocument1 pageMatlab Q 1 PDFzee khanNo ratings yet

- Matlab Q 1 PDFDocument1 pageMatlab Q 1 PDFzee khanNo ratings yet

- PDF For Successive ApproximationDocument28 pagesPDF For Successive ApproximationNeekitaGuptaNo ratings yet

- For Class Felexible ManufacturingDocument20 pagesFor Class Felexible Manufacturingzee khanNo ratings yet

- Matlab Q 1 PDFDocument1 pageMatlab Q 1 PDFzee khanNo ratings yet

- An Investigation in To The AMT ImplementDocument14 pagesAn Investigation in To The AMT Implementzee khanNo ratings yet

- ..... Numarical Analaysis PDFDocument69 pages..... Numarical Analaysis PDFtarunNo ratings yet

- Cycle Time Calculation-Unit - 15 - Flexible - Manufacturing - Systems PDFDocument38 pagesCycle Time Calculation-Unit - 15 - Flexible - Manufacturing - Systems PDFzainikamal1975No ratings yet

- Matlab Q 1 PDFDocument1 pageMatlab Q 1 PDFzee khanNo ratings yet

- Langranges Interpolation MethodDocument51 pagesLangranges Interpolation Methodzee khanNo ratings yet

- Numerical IntegrationDocument8 pagesNumerical Integrationzee khanNo ratings yet

- Katalog Promo PC200-8 Okt 2020Document6 pagesKatalog Promo PC200-8 Okt 2020ariy yuli styawanNo ratings yet

- Case Study:Iron Pillar Near Qutub Minar: Ji .'1, FJF,) .'1, (Document1 pageCase Study:Iron Pillar Near Qutub Minar: Ji .'1, FJF,) .'1, (Maina SharmaNo ratings yet

- 2216 0280 Iee 40 01 E14Document18 pages2216 0280 Iee 40 01 E14Lal NandaniNo ratings yet

- Customer Feedback Form: To Send Your Feedback See Over The Page..Document2 pagesCustomer Feedback Form: To Send Your Feedback See Over The Page..sangho jeongNo ratings yet

- Everyday English Vocabulary PDFDocument2 pagesEveryday English Vocabulary PDFSamantha0% (1)

- Controller Tuning Methods for Process ControlDocument17 pagesController Tuning Methods for Process ControltrshaaaNo ratings yet

- 2019 ACS101 Academic Skills Students MaterialDocument90 pages2019 ACS101 Academic Skills Students MaterialSONAM TSHERING100% (2)

- Silo Design1Document20 pagesSilo Design1Sasikumar JothiNo ratings yet

- Power BI Performance Tips and TechniquesDocument27 pagesPower BI Performance Tips and TechniquesClaudio Santander HernándezNo ratings yet

- PTTI Presentation Prepared at STEVTADocument35 pagesPTTI Presentation Prepared at STEVTAkhalidhussainrazaNo ratings yet

- BiologyDocument6 pagesBiologySuraj KumarNo ratings yet

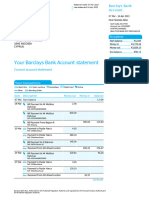

- Barclays Bank UPDATEDocument32 pagesBarclays Bank UPDATEAbdul wahidNo ratings yet

- DNV Otg - 02 Floating Liquefied Gas Terminals - tcm4-460301Document128 pagesDNV Otg - 02 Floating Liquefied Gas Terminals - tcm4-460301Jeril PhilipNo ratings yet

- DFX9000 Repair Manual PDFDocument223 pagesDFX9000 Repair Manual PDFRams ANo ratings yet

- Module 2 - Individual BehaviourDocument187 pagesModule 2 - Individual BehaviourBiswajeet DashNo ratings yet

- Module 4 - Contemp World - BSA2Document7 pagesModule 4 - Contemp World - BSA2Marian AntipoloNo ratings yet

- CCP403Document18 pagesCCP403api-3849444100% (1)

- The Roots and Method of Phenomenological RealismDocument133 pagesThe Roots and Method of Phenomenological RealismYuri OberlaenderNo ratings yet

- Argosy Trading Co tackles promotions and seasonality with Demand Solutions forecastingDocument2 pagesArgosy Trading Co tackles promotions and seasonality with Demand Solutions forecastingdhruvgoel1No ratings yet

- Perbandingan Harga LaptopDocument5 pagesPerbandingan Harga Laptopgihe purnamaNo ratings yet

- TLE 6 Q4 WK8 MultimediaPresentation v0.1Document7 pagesTLE 6 Q4 WK8 MultimediaPresentation v0.1Christian Vincent Tampus AliñoNo ratings yet

- Tir A9 14 PDFDocument99 pagesTir A9 14 PDFGino Tironi100% (7)

- Skyline Skylites - Unit SkylightsDocument2 pagesSkyline Skylites - Unit SkylightskdpmansiNo ratings yet

- Vision IAS CSP21T30S FLT6Document39 pagesVision IAS CSP21T30S FLT6AvanishNo ratings yet

- Minilab SpecsDocument5 pagesMinilab SpecsFrancisco DesiderioNo ratings yet

- Modul 8 SMM - 2Document12 pagesModul 8 SMM - 2Irvin Richard WinataNo ratings yet

- Physical Preparation of The Modern Elite Football PlayerDocument8 pagesPhysical Preparation of The Modern Elite Football PlayerKamil SochaNo ratings yet

- LogicDocument6 pagesLogicpppppiiiiiNo ratings yet

- Digital Scent TechnologyDocument13 pagesDigital Scent TechnologyRahul Maravi0% (1)

- Accident Investigation, Reporting and Analysis: Safety Engineering and Management For MEDocument38 pagesAccident Investigation, Reporting and Analysis: Safety Engineering and Management For MEAndre De VillaNo ratings yet