Professional Documents

Culture Documents

Inorganic Antimicrobial Additive For Concrete Corrosion Control

Uploaded by

sattar12345Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inorganic Antimicrobial Additive For Concrete Corrosion Control

Uploaded by

sattar12345Copyright:

Available Formats

Inorganic Antimicrobial Additive for Concrete Corrosion Control

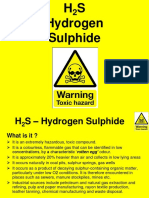

It is known that Hydrogen Sulfide Gas released from wastewater into sewer atmosphere tends to build up

Sulfuric Acid by the activity of Sulfur-Oxidizing Bacteria, Thiobacillus thiooxidans, which causes concrete

corrosion. ZeomightyⓇ-added concrete, by way of suppressing proliferation of the bacteria, can control

build-up of Sulfuric Acid, and thus alleviate this type of concrete corrosion.

<Step 1> Generation of Hydrogen Sulfide in wastewater

SO42- + 2C +2H2O → H2S + 2HCO3-

H2S+2O2→H2SO4

↑ <Step 2> Hydrogen Sulfide is diffused into the gas phase

Sulfur-Oxidizing Bacteria

Badly <Step3> Generation of Sulfuric Acid by the activity of Sulfur-Oxidizing Bacteria

damaged

concrete H2S + 2O2 → H2SO4

Condensed

water

Thiobacillus thiooxidans

H2O Condensation <Step4> Sulfuric Acid reacts with ingredient of concrete, and corrosion progresses

caused by

temperature difference

Water lifted by Ca(OH2)2 + H2SO4 → CaSO4・2H2O

Capillarity

3CaSO4・2H2O + 3CaO・Al2O3 + 26H2O → 3CaO・Al2O3・3CaSO4・32H2O

H2S

Sewer

Sludge

Hume Pipe

Cause of Concrete Corrosion & its mechanism

Ion-exchange Technology Exposure Testing Result

Zeolite Evaluation at the wastewater treatment facility (H2S : 40.7 ppm)

(Carrier)

Ion

Exchange

(Mechanism) Without ZeomightyⓇ With Zeomighty Ⓡ

Sodium Ions Silver & Copper Ions

(Counter Ion) (Active Ingredient) Application

Hume Pipe, Manhole, Box Culvert, other concrete products for sewer,

Physical Properties Ready-mixed concrete and premixed mortar

※ZeomightyⓇ -added concrete can be useful under sewer environments in

Appearance Grayish fine powder which the mean H2S concentration is 50 ppm or below.

Bulk density 0.73 g/cm3

Technology Review & Certification

True specific gravity 2.83

Average particle size 15 μm

Examined & proved under “Construction

Volatility None Technology Review and Certification”

program by JIWET, Japan Institute of

Solubility None Wastewater Engineering Technology.

Directions for Use

Add ZeomightyⓇ at the rate of 1% by weight of the cement used SINANEN ZEOMIC CO., LTD. Marketing Department

when mixing other concrete or mortar components.

4-22, 1-Chome Kaigan, Minato-ku, Tokyo 105-8525, JAPAN

Tel. 81-3-5470-7125 Fax. 81-3-5470-7166

URL http://www.zeomic.co.jp/

You might also like

- Sugar Chem 1Document41 pagesSugar Chem 1shreyNo ratings yet

- BOILERS WATER TREATMENT CHEMISTRYDocument38 pagesBOILERS WATER TREATMENT CHEMISTRYMahmoud MahmoudmNo ratings yet

- Journal of Building Engineering: SciencedirectDocument8 pagesJournal of Building Engineering: Sciencedirectrich jideNo ratings yet

- Boilers Water Treatment: Chemist / Mustafa Ateia MustafaDocument38 pagesBoilers Water Treatment: Chemist / Mustafa Ateia MustafaMakhdoom Ibad HashmiNo ratings yet

- Effect of Silica Fume On The Properties of Concrete: (Ijerat)Document5 pagesEffect of Silica Fume On The Properties of Concrete: (Ijerat)Ohnmar OmNo ratings yet

- Literature Review on Concrete MaterialsDocument9 pagesLiterature Review on Concrete MaterialsAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- Hydropath Power PlantDocument25 pagesHydropath Power PlantBoyke Andreas KotoNo ratings yet

- Water Its Treatment Part2Document43 pagesWater Its Treatment Part2netsanet mesfinNo ratings yet

- Study of Properties of Self-Compacting Concrete With Cement Replaced With Aluminum Oxide and Silica FumeDocument10 pagesStudy of Properties of Self-Compacting Concrete With Cement Replaced With Aluminum Oxide and Silica FumeIJRASETPublicationsNo ratings yet

- Effect of GGBS On Corrosion of Rebar in ConcreteDocument9 pagesEffect of GGBS On Corrosion of Rebar in ConcreteSrinivas AyyalasomayajulaNo ratings yet

- UG ReportDocument16 pagesUG ReportMohitNo ratings yet

- 6th Wellbore Integrity Network Meeting Cement Performance in HTHP CO2Document19 pages6th Wellbore Integrity Network Meeting Cement Performance in HTHP CO2Verin MotcheyeNo ratings yet

- Welcome to the Department of Environment Project BriefingDocument66 pagesWelcome to the Department of Environment Project BriefingAdroit ConsultantNo ratings yet

- Topic 2.4 Water Used in Concrete MixDocument18 pagesTopic 2.4 Water Used in Concrete Mix2022449652No ratings yet

- CIB - DC24731Concrete Deterioration Caused by Sulfuric Acid AttackDocument7 pagesCIB - DC24731Concrete Deterioration Caused by Sulfuric Acid Attackm_shahbaghiNo ratings yet

- Causes of Concrete Reinforcement Corrosion and Their RepairDocument124 pagesCauses of Concrete Reinforcement Corrosion and Their RepairPritha DasNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius Dsouza100% (1)

- CHY1701 M2 - Dr. Krishnendu BiswasDocument70 pagesCHY1701 M2 - Dr. Krishnendu Biswaslalithkumaran LNo ratings yet

- Geo Polymer Mix DesignDocument12 pagesGeo Polymer Mix DesignpulendralkNo ratings yet

- Adobe Scan Apr 26, 2021 (6)Document11 pagesAdobe Scan Apr 26, 2021 (6)canusha820No ratings yet

- BFW Chemistry ControlDocument61 pagesBFW Chemistry ControlSteve WanNo ratings yet

- Hardness Removal of Groundwater by Using Optimum Lime-Soda ProcessDocument4 pagesHardness Removal of Groundwater by Using Optimum Lime-Soda Processishaq kazeemNo ratings yet

- Irjet V5i3879 PDFDocument4 pagesIrjet V5i3879 PDFishaq kazeemNo ratings yet

- Eni - E&P Division Produced Water Management Corrosion Connected To Produced WaterDocument35 pagesEni - E&P Division Produced Water Management Corrosion Connected To Produced WaterPabel LemaNo ratings yet

- Water Technology Part 2Document69 pagesWater Technology Part 2ronnie199250% (2)

- Pipeline corrosion management overviewDocument34 pagesPipeline corrosion management overviewAbdul Maabood Hassan AlviNo ratings yet

- GLASSDocument6 pagesGLASSMR. ESHAN GHARPURENo ratings yet

- The effect of sodium hydroxide pH on iron alloy corrosionDocument7 pagesThe effect of sodium hydroxide pH on iron alloy corrosionDevin HardyNo ratings yet

- Carbonation _ Feb_ 2023Document6 pagesCarbonation _ Feb_ 2023Pranjal PriyadarsheeNo ratings yet

- 1 s2.0 S0892687520304842 MainDocument12 pages1 s2.0 S0892687520304842 Mainchaitanya200039No ratings yet

- Use of Steel Slag in Pervious ConcreteDocument11 pagesUse of Steel Slag in Pervious ConcretemargarethsmNo ratings yet

- Water Conditioning Process ExplainedDocument27 pagesWater Conditioning Process ExplainedKamran RanaNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius DsouzaNo ratings yet

- SSC JE Study Material Building MaterialsDocument10 pagesSSC JE Study Material Building MaterialsMohd aslamNo ratings yet

- Wastewater CharacterizationDocument20 pagesWastewater CharacterizationAnonymous 6RM4Ck100% (1)

- (ENG) Journal-Paint Sludge On IndiaDocument10 pages(ENG) Journal-Paint Sludge On IndiaSoebowo AdjinegoroNo ratings yet

- A Study On Water Absorption and Sorptivity of Geopolymer ConcreteDocument9 pagesA Study On Water Absorption and Sorptivity of Geopolymer ConcreteSajjad AhmadNo ratings yet

- Introduction to Cooling Water Treatment Parameters and IndicesDocument40 pagesIntroduction to Cooling Water Treatment Parameters and IndicessomaniNo ratings yet

- CWT + BWTDocument59 pagesCWT + BWTAfan Miraj100% (1)

- Rilem SMSS 2019Document6 pagesRilem SMSS 2019Iva DespotovicNo ratings yet

- PRC FinalDocument39 pagesPRC FinalvdwakNo ratings yet

- Chem Unit 1Document34 pagesChem Unit 1Ismaeel ShamsiNo ratings yet

- CO2 Corrosion Risks and Mitigation StrategiesDocument15 pagesCO2 Corrosion Risks and Mitigation StrategiesVlassis SarantinosNo ratings yet

- Geopolymer Concrete: Sardar Vallabhbhai Patel Institute of Technology, Vasad Gujarat Technological University AhmedabadDocument43 pagesGeopolymer Concrete: Sardar Vallabhbhai Patel Institute of Technology, Vasad Gujarat Technological University AhmedabadRakesh7770No ratings yet

- An Insight Review On Textile Effluent Treatment Using NanoparticlesDocument33 pagesAn Insight Review On Textile Effluent Treatment Using NanoparticlesRajalakshmiNo ratings yet

- 2 ADocument45 pages2 AShyam SundarNo ratings yet

- Effect of Alccofines and Microsilica on Durability of High Performance ConcreteDocument8 pagesEffect of Alccofines and Microsilica on Durability of High Performance ConcreteAvinash PrajapatiNo ratings yet

- Softening FinalDocument23 pagesSoftening FinalSonali Jahagirdar100% (1)

- KC CottrellDocument47 pagesKC CottrellAnindya Paul Chowdhury100% (1)

- 192 Sample-Chapter PDFDocument39 pages192 Sample-Chapter PDFsenthil4youNo ratings yet

- Inorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyDocument36 pagesInorganic Industries Engineering هيوضعلايرغ تاعانصلا ةسدنه: Dr.: Sameh Araby El-MekawyMohamed AbdelaalNo ratings yet

- 06 - Water - Tech - Revision - PrintDocument58 pages06 - Water - Tech - Revision - PrintLakshmi NarayanNo ratings yet

- Steam Generator PDFDocument27 pagesSteam Generator PDFwaheed2286No ratings yet

- Corrosion of Copper Alloys: Atmospheric Exposure, Temperature, Pollutants & Water CompositionDocument11 pagesCorrosion of Copper Alloys: Atmospheric Exposure, Temperature, Pollutants & Water CompositionAhmed JabirNo ratings yet

- HYDROGEN - Class Notes - JEE MindmapDocument15 pagesHYDROGEN - Class Notes - JEE Mindmapadsaditya24No ratings yet

- 2015 Effect of H2S on the corrosion behavior of pipeline Steels in supercritical and liquid Co2 environmentsDocument12 pages2015 Effect of H2S on the corrosion behavior of pipeline Steels in supercritical and liquid Co2 environmentsRuben CuamatziNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldFrom EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldRating: 3 out of 5 stars3/5 (2)

- Denso Paste S105Document2 pagesDenso Paste S105sattar12345No ratings yet

- Fosroc Expandafoam Closed Cell TDSDocument2 pagesFosroc Expandafoam Closed Cell TDSsattar12345No ratings yet

- Basf Masterpolyheed 8840 TdsDocument2 pagesBasf Masterpolyheed 8840 Tdssattar12345No ratings yet

- Farm Track & Stream Crossing Design GuideDocument2 pagesFarm Track & Stream Crossing Design Guidesattar12345No ratings yet

- Bird Guard Specifications 2004Document1 pageBird Guard Specifications 2004sattar12345No ratings yet

- TD VSL Multistrand-EcDocument1 pageTD VSL Multistrand-Ecsattar12345No ratings yet

- PN060511Document1 pagePN060511sattar12345No ratings yet

- PBB0310 Butyl Sealant TapeDocument1 pagePBB0310 Butyl Sealant Tapesattar12345No ratings yet

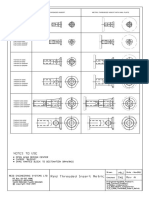

- Reid Threaded Insert MetricDocument1 pageReid Threaded Insert Metricsattar12345No ratings yet

- Denso PasteDocument2 pagesDenso Pastesattar12345No ratings yet

- Ux FlyDocument2 pagesUx FlyRonal SolisNo ratings yet

- DensoHi TackPrimerDocument2 pagesDensoHi TackPrimersattar12345No ratings yet

- Sika Fume - PDSDocument3 pagesSika Fume - PDSAnonymous 8HrGcpcKNo ratings yet

- Plate SizeDocument1 pagePlate Sizesattar12345No ratings yet

- Bridges: Data SheetDocument2 pagesBridges: Data Sheetsattar12345No ratings yet

- Flooring: Sika® Technology and Concepts For Flooring and CoatingDocument56 pagesFlooring: Sika® Technology and Concepts For Flooring and Coatingsattar12345No ratings yet

- Applications: TYPE: RutileDocument1 pageApplications: TYPE: Rutilesattar12345No ratings yet

- Jakob Rope Systems Catalogue Webnet n2 EnglishDocument84 pagesJakob Rope Systems Catalogue Webnet n2 EnglishakajsiNo ratings yet

- Sika Concrete Repair & Protection To en 1504 Brochure NZ 0614Document56 pagesSika Concrete Repair & Protection To en 1504 Brochure NZ 0614Gandhi HammoudNo ratings yet

- Bituthene® 5000: Product Data SheetDocument3 pagesBituthene® 5000: Product Data Sheetsattar12345No ratings yet

- Sika Ferrogard 903 Concrete Corrosion Inhibitor Brochure 0415 NZDocument8 pagesSika Ferrogard 903 Concrete Corrosion Inhibitor Brochure 0415 NZamitNo ratings yet

- Primacorelw-71 en PDFDocument2 pagesPrimacorelw-71 en PDFsattar12345No ratings yet

- Specification For Lighting Columns: NotesDocument9 pagesSpecification For Lighting Columns: Notessattar12345No ratings yet

- Primacorelw-71 en PDFDocument2 pagesPrimacorelw-71 en PDFsattar12345No ratings yet

- Welding Consumables: PRODUCT CATALOGUE - Australia & New ZealandDocument230 pagesWelding Consumables: PRODUCT CATALOGUE - Australia & New Zealandtristanxp80No ratings yet

- SF 70W PDFDocument8 pagesSF 70W PDFsattar12345No ratings yet

- Innershield NR-203 Ni PDFDocument2 pagesInnershield NR-203 Ni PDFsattar12345No ratings yet

- Superarc LA-75: Conformances Key FeaturesDocument2 pagesSuperarc LA-75: Conformances Key Featuressattar12345No ratings yet

- Atlas Specialty Metals: Stainless Steel Wire & BarDocument29 pagesAtlas Specialty Metals: Stainless Steel Wire & Barsattar12345No ratings yet

- Latosov 2017Document8 pagesLatosov 2017kos basukiNo ratings yet

- H2S AwarenessDocument13 pagesH2S AwarenessDedy SulistyoNo ratings yet

- Calibrate MSA ALTAIR 2X Single Gas DetectorDocument10 pagesCalibrate MSA ALTAIR 2X Single Gas DetectorMANIVASAGANNo ratings yet

- SA-924-2 Red PrintDocument2 pagesSA-924-2 Red PrintAbdus SamadNo ratings yet

- Environment (Air) Purifying PlantsDocument52 pagesEnvironment (Air) Purifying Plantss kdNo ratings yet

- Technical Note 128 - Formaldehyde (HCHO) Sensor in RAE Systems Instruments - 02 14 PDFDocument2 pagesTechnical Note 128 - Formaldehyde (HCHO) Sensor in RAE Systems Instruments - 02 14 PDFRdw PartaNo ratings yet

- Environmental Impacts, Attributes, and Feasibility Criteria: Chapter 8Document19 pagesEnvironmental Impacts, Attributes, and Feasibility Criteria: Chapter 8crresoso957No ratings yet

- Imvic Tests (Indole, Methyl Red, Voges-Proskauer, Citrate) + and H SDocument4 pagesImvic Tests (Indole, Methyl Red, Voges-Proskauer, Citrate) + and H Srandiey john abelleraNo ratings yet

- Miscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CaloriesDocument32 pagesMiscellaneous Information: R 1.987 Cal/mole°k 8.314 J/mole°K Absolute Zero - 273.15°C 1 Joule 0.239 CalorieswastequestNo ratings yet

- Detecting Bacterial Contamination in WaterDocument17 pagesDetecting Bacterial Contamination in WaterShashank100% (2)

- (Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Document125 pages(Topics in Chemical Engineering) Lanny D. Schmidt - The Engineering of Chemical Reactions (2004, Oxford University Press, USA)Diego FernandoNo ratings yet

- Utilization of Aspen Hysys SimulationDocument6 pagesUtilization of Aspen Hysys SimulationKhuram MaqsoodNo ratings yet

- Environmental, Health, and Safety Guidelines For Petroleum RefiningDocument35 pagesEnvironmental, Health, and Safety Guidelines For Petroleum RefiningMuhammad Maulana RizkiNo ratings yet

- BASF-MBS Broschuere MasterSeal 7000CR en LY18Document2 pagesBASF-MBS Broschuere MasterSeal 7000CR en LY18Amar WadoodNo ratings yet

- IP30 Doctor Test - Flow ChartDocument1 pageIP30 Doctor Test - Flow ChartHayateNo ratings yet

- Oil and Gas Hazard Sheet ListDocument396 pagesOil and Gas Hazard Sheet Listghada gattouch100% (1)

- Industry AbbreviationsDocument39 pagesIndustry Abbreviationsrafik1995No ratings yet

- 2019 (Process) Dielectric Barrier DischargeDocument8 pages2019 (Process) Dielectric Barrier DischargeKin Wai CheahNo ratings yet

- Honeywell E3Point - QuickStart GuideDocument2 pagesHoneywell E3Point - QuickStart GuideCam DennisNo ratings yet

- Case Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve BodyDocument12 pagesCase Study on Sulfide Stress Corrosion Cracking of an A216-WCC Wellhead Flow Control Valve Bodypinkan25No ratings yet

- Crowcon Gas DetectionDocument61 pagesCrowcon Gas Detectionpmotc100% (1)

- 092702b Gaseous Fuel SpecsDocument9 pages092702b Gaseous Fuel SpecsManish patelNo ratings yet

- Crude Oil Assay ManualDocument41 pagesCrude Oil Assay Manualman45039No ratings yet

- D4952 1630083-1Document3 pagesD4952 1630083-1Asep TheaNo ratings yet

- DLG Fluids WS (Presentation) PDFDocument75 pagesDLG Fluids WS (Presentation) PDFMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Alternatives For Sulphate Treatment in Municipal WatersDocument87 pagesAlternatives For Sulphate Treatment in Municipal WatersMiguel De La HozNo ratings yet

- SDS-Graferex - Lubricant-AdditiveDocument6 pagesSDS-Graferex - Lubricant-AdditiveCanchindoNo ratings yet

- GEOLOGY The Wellsite GuideDocument138 pagesGEOLOGY The Wellsite GuideHéctor Eduardo Gallardo GutiérrezNo ratings yet

- General Information Saudi Aramco Work Permit ReceiverDocument4 pagesGeneral Information Saudi Aramco Work Permit Receiverjohn samuelNo ratings yet

- Rod Pump - Failure.analysisDocument109 pagesRod Pump - Failure.analysisvibhutiNo ratings yet