Professional Documents

Culture Documents

Ky Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDF

Uploaded by

whaywhay whaywhayOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ky Thuat Dieu Khien Tu Dong - Control System Technology-Lab Tutorials PDF

Uploaded by

whaywhay whaywhayCopyright:

Available Formats

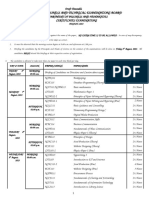

HoChiMinh City University of Technology

Faculty Mechanical of Engineering

Mechatronics Department

Laboratory Tutorial

Control System Technology

(ME2009)

Ho Chi Minh City, Aril 2018

Table of Contents

Laboratory 01: Arduino, Led, Photoelectric Sensor, and Encoder ..................................... 01

Laboratory 02: Control a DC Motor with Arduino.............................................................. 19

Laboratory 03: Sequential Circuit Design Using Relays ..................................................... 33

HoChiMinh City University of Technology Mechatronics Department

HoChiMinh City University of Technology ME2009 - Control System Technology

Faculty Mechanical of Engineering Lab Assignment 1

Mechatronics Department

Arduino, Led, Photoelectric Sensor, and Encoder

1. INTRODUCTION

Arduino (shown in Figure 1) is an open source computer hardware and software company.

It is designed to facilitate interaction with the physical world via sensors while being able to

perform calculations and various functions. Nowadays, Arduino is fast becoming one of the

most popular microcontrollers on the market. Its ease of use, extensive software library and

most importantly, its low cost have come to make it as popular as it is today.

Many projects using the Arduino can be found on http://www.hackaday.com. In order to

start having fun with the Arduino, free software can be found at

http://arduino.cc/en/Main/Software for Macs, Windows and Linux operating systems. This

website also provides tons of easy tutorials for you to start. Tutorials can be found at

http://arduino.cc/en/Tutorial/HomePage.

In this lab, you will become familiar with the Arduino, interact with the other hardware,

e.g. led, Photoelectric Sensor, incremental rotary encoder and some of their applications. You

will learn how to use the Arduino to interface between hardware on the control system Kit 01

board (shown in Figure 2) and software (the code). You will also learn how to use a led

module to display number, detect an object by using Photoelectric Sensor and measure an angle

with an incremental rotary encoder.

2. LAB DEVICES

2.1 Arduino Uno Board

Figure 1. Arduino Uno Board

ME2009 Control system technology 1

HoChiMinh City University of Technology Mechatronics Department

2.2 Control System Kit 01

+ 5V 0V A B Z CLOCK + 5V LATCH DATA 0V +5V 0V OUT

Figure 2. Control System Kit 01

Module No. Device Name Signal

1 Terminal

+5V : (Brown) high voltage of the power supply

0V: (Blue) ground of the power supply

2 Rotary sensor A : (Black) pulse signal of phase A output

B : (White) pulse signal of phase B output

Z : (Orange) pulse signal of phase Z output

+5V : the high voltage of the power supply

0V: the ground of the power supply

3 Led module CLOCK: shift register clock input (SHCP)

LATCH: storage register clock input (STCP)

DATA: serial data input (DS)

+5V : (Red) high voltage of the power supply

4 Photoelectric Sensor 0V: (Green) ground of the power supply

A : (Yellow) Digital output

ME2009 Control system technology 2

HoChiMinh City University of Technology Mechatronics Department

2.3 USB cable

USB 2.0 Type A Male to Type B Male cable used to communicate between PC and Arduino

Uno board.

Figure 3. USB 2.0 Cable Type A Male to Type B

2.4 Wires

Used to connect Arduino Uno board with Control System Kit 01.

Figure 4. Breadboard wires

2.5 Screwdriver

Used to screwing and unscrewing (inserting and removing) screws on the Control System Kit

01.

Figure 5. Flat Tip Screwdriver

ME2009 Control system technology 3

HoChiMinh City University of Technology Mechatronics Department

3. PROCEDURE

3.1 Set up your Arduino Programming Environment

The Arduino programming environment needs to be set up on a machine that you have access

to. It can be a Windows PC, Mac or Linux machine and it can be a laptop or desktop. Get the

latest version free software from the website ( http://arduino.cc/en/Main/Software). You should

choose the Installer (.exe) that installs directly everything you need to use the Arduino Software

(IDE), including the drivers.

When the download finishes, proceed with the installation and please allow the driver

installation process when you get a warning from the operating system. Follow instructions to

finish the installation as shown in Figure 6

Figure 6. Arduino installation process

3.2 Installing Additional Arduino Libraries

Libraries are a collection of code that makes it easy for you to connect to a sensor,

display, module, etc. For example, the Encoder library makes it easy to count pulse output of

the rotary encoder. There are hundreds of additional libraries available on the Internet for

download. To use the additional libraries, you will need to install them.

When you want to add a library manually, you need to download it as a ZIP file and close

all Arduino IDE, expand ZIP file and put in the proper directory (Default is:

ME2009 Control system technology 4

HoChiMinh City University of Technology Mechatronics Department

\Documents\Arduino\libraries). You can find or change the location of your sketchbook folder

at File > Preferences > Sketchbook location (shown in Figure 7)

Figure 7. Location of Arduino library folder

Open Arduino IDE after installing the additional libraries, you can find the installed

library examples in File > Examples > your_library > example_ name

For example, The Basic example of Encoder Library can be found in Figure 8

Figure 8. Open an example of an additional library

ME2009 Control system technology 5

HoChiMinh City University of Technology Mechatronics Department

3.3 Start a new Arduino program

In this first task, we simply connect Arduino board using a USB cable to PC and upload a

simple piece of code to it (shown in Figure 9). Connect Arduino board with USB cable and

USB port on your PC and wait till PC has a device driver for Arduino installed.

Figure 9. Connect Uno board to PC

Choose the icon Arduino on your computer to start a new Arduino program ( Sketch)

and Write a simple program name as Blink as shown in Figure 10. Press Verify button to check

your code.

Figure 10. Make a new sketch

ME2009 Control system technology 6

HoChiMinh City University of Technology Mechatronics Department

Figure 11. Select your Arduino board type Tools>Boards>Arduino UNO

Figure 12. Select your serial port, Tools>Serial Port>COM 7 (COM # depending what

COM port is free during setup)

Click upload button to upload the code to Arduino. Wait until “Done Uploading”

message status appear. The LED should blink and you have successfully installed your

Arduino.

ME2009 Control system technology 7

HoChiMinh City University of Technology Mechatronics Department

3.4 WIRING DIAGRAM AND ELECTRICAL CIRCUIT

+ 5V 0V A B Z CLOCK + 5V LATCH DATA 0V +5V 0V OUT

Figure 13. Uno board and Control System Kit 01 Terminal

Device Name Control System Kit 01 Arduino Uno Board

+5V : (Brown) high voltage of the power

Pin 5V

supply

Pin GND

0V: (Blue) ground of the power supply

Rotary sensor Pin 2

A : (Black) pulse signal of phase A output

Pin 3

B : (White) pulse signal of phase B output

Not use

Z : (Orange) pulse signal of phase Z output

+5V : the high voltage of the power supply Pin 5V

0V: the ground of the power supply Pin GND

Led module CLOCK: shift register clock input (SHCP) Pin 4

LATCH: storage register clock input (STCP) Pin 5

DATA: serial data input (DS) Pin 6

ME2009 Control system technology 8

HoChiMinh City University of Technology Mechatronics Department

+5V : (Red) high voltage of the power supply Pin 5V

Photoelectric

0V: (Green) ground of the power supply Pin GND

Sensor

A : (Yellow) Digital output Pin 8

4. REFERENCE

[1] Arduino.cc, The open-source Arduino Software (IDE), 2018. Available:

http://arduino.cc/en/Main/Software. [Accessed: 1- May- 2018].

[2] Instructables.com, Arduino - Blinking Led, 2018. Available:

http://www.instructables.com/id/Arduino-Blinking-LED. [Accessed: 1- May-

2018].

[3] Sunfounder.com, Driving 7-Segment Display by 74HC595, 2016. Available:

https://www.sunfounder.com/learn/rfid-kit-v2-0-for-arduino/lesson-20-driving-7-

segment-display-by-74hc595-rfid-v2-0-for-arduino.html [Accessed: 1- May- 2018].

[4] Howtomechatronics.com, How Rotary Encoder Works and How To Use It with

Arduino, 2016. Available: https://howtomechatronics.com/tutorials/arduino/rotary-

encoder-works-use-arduino/ [Accessed: 1- May- 2018].

ME2009 Control system technology 9

HoChiMinh City University of Technology Mechatronics Department

5. APPENDIX

5.1 Arduino Help

You will find other Arduino functions use them in your sketches at the path Help >

Reference. The structure and use of functions is fully explained.

Figure 14. Arduino IDE Reference

5.2 Sample Solutions: Display number zero “ 0 ” on led module

1. const int clockPin = 4; // clock pin (SHCP) of 74HC595

2. const int latchPin = 5; // latch pin (STCP) of 74HC595

3. const int dataPin = 6; // Data pin (DS) of 74HC595

4. const int sensorPin = 8; // Pin connected Photoelectric Sensor

output

5. // variable

6. int count = 0;

7. int chuctrieu = 0;

8. int trieu = 0;

9. int tramnghin = 0;

10. int chucnghin = 0;

11. int nghin = 0;

12. int tram = 0;

13. int chuc = 0;

14. int donvi = 0;

15. long no_pulse = 1234;

16. long a = 0;

17. int check = 1;

18. void setup()

19. {

20. pinMode(latchPin, OUTPUT);

21. pinMode(dataPin, OUTPUT);

22. pinMode(clockPin, OUTPUT);

23. pinMode(sensorPin, INPUT);

24. }

ME2009 Control system technology 10

HoChiMinh City University of Technology Mechatronics Department

25. void loop()

26. {

27. a = 0;

28. so(a);

29. digitalWrite(latchPin, LOW);

30. digitalWrite(latchPin, HIGH);

31. }

32. void so(int num)

33. {

34. switch (num) {

35. case 0:

36. digitalWrite(dataPin, HIGH); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // dau cham

37. digitalWrite(dataPin, HIGH); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh g

38. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh f

39. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh e

40. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh d

41. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh c

42. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh b

43. digitalWrite(dataPin, LOW); digitalWrite(clockPin, LOW);

digitalWrite(clockPin, HIGH); // canh a

44. break;

45. }

46. }

5.3 Photoelectric Sensor

The DFRobot Adjustable Infrared Sensor Switch is a set of transmitter and receiver in one of

the photoelectric switch sensor. The detection distance can be adjusted according to the

demand. The DFRobot Adjustable Infrared Sensor Switch is small, easy to use, inexpensive,

easy to assemble and can be widely used in a robot to avoid obstacles, interactive media,

industrial assembly line, and many other occasions. The switching signal output differs in

accordance with the obstacles. It remains high when no obstacles and remains low when there

are obstacles. There is also a red led on its back to indicate the sensor status.

Specification:

• Power supply: 5V • Working Current: <100mA

• Adjustable detection range: 3cm - 80cm

• Pin description: • Red - 5V • Green – GND • Yellow - Digital output

ME2009 Control system technology 11

HoChiMinh City University of Technology Mechatronics Department

• Digital output: •"0" - found barrier (~0V) • "1" - no barrier (~4V)

5.4 DFRobot 8 Character x 7 Segment SPI LED Module

Figure 15. LED Module

This is 8 digital bits serial LED display that is controlled using a serial interface. Instead of

using up a dozen-or-so of your microcontroller’s pins to control the LEDs, all you need is one.

You can control all digits, decimal points, the colon, and the apostrophe using SPI interface

which allows more than 2 modules can be serial linked. With Interface Shield For Arduino

module can be plug and play. There are 8 - 74HC595 Shift Register to control the 8 digits 7

segments Led Display.

Figure 16. Connect three LED Module

5.5 The 74HC595 Shift Register

The 74HC595 consists of an 8−bit shift register and a storage register with three−state

parallel outputs. It converts the serial input into parallel output so that you can save IO ports of

an MCU. The 74HC595 is widely used to indicate multipath LEDs and drive multi-bit segment

displays. "Three-state" refers to the fact that you can set the output pins as either high, low or

"high impedance." With data latching, the instant output will not be affected during the shifting;

with data output, you can cascade 74HC595s more easily.

ME2009 Control system technology 12

HoChiMinh City University of Technology Mechatronics Department

The shift register holds what can be thought of

as eight memory locations, each of which can be a 1

or a 0.

To set each of these values on or off, we feed

in the data using the 'Data' and 'Clock' pins of the

chip.

The clock pin needs to receive eight pulses. At

the time of each pulse, if the data pin is high, then a

1 gets pushed into the shift register. Otherwise, it is

a 0. When all eight pulses have been received, then

enabling the 'Latch' pin copies those eight values to

the latch register. This is necessary, otherwise, the Figure 17. The principle of 74HC595

wrong LEDs would flicker as the data was being

loaded into the shift register.

The chip also has an OE (output enable) pin,

this is used to enable or disable the outputs all at

once. You could attach this to a PWM capable

Arduino pin and use 'analogWrite' to control the

brightness of the LEDs. This pin is active low, so we Figure 18. Pin of 74HC595

tie it to GND.

A seven-segment display is a LED module

composed of 8 LEDs. 7 of the LEDs are for

segments of one digit (shown as A to G below) and

the other LED is for the decimal point (shown

as DP below).

Figure 19. Seven- segment Led

Display module

The schematic diagram to use one 74HC595 control one digit 7 segments Led Display

module shown in Figure 20

7-Segment Display 74HC595 SunFounder Uno R3

a Q7

b Q6

c Q5

d Q4

ME2009 Control system technology 13

HoChiMinh City University of Technology Mechatronics Department

e Q3

f Q2

g Q1

DP Q0

VCC 5V

CE, GND GND

SHCP (Clock) 4

STCP (Latch) 5

DS (Data) 6

MR 5V

Figure 20. Connect 74HC595 with one digit 7 segments Led Display and Uno board

Figure 21. Breadboard test

5.6 Rotary Encoder

A rotary encoder, also called a shaft encoder, is an electro-mechanical device that

converts the angular position or motion of a shaft or axle to an analog or digital signal. There

are two main types: absolute and incremental (relative). The output of absolute encoders

indicates the current position of the shaft, making them angle transducers. The output of

ME2009 Control system technology 14

HoChiMinh City University of Technology Mechatronics Department

incremental encoders provides information about the motion of the shaft, which is typically

further processed elsewhere into information such as speed, distance, and position. Rotary

encoders are used in many applications that require precise shaft unlimited rotation—including

industrial controls, robotics, rotating radar platforms.

There are many different types of rotary encoders which are classified by either Output

Signal or Sensing Technology. The particular rotary encoder that we will use in the lab

assignment is an incremental rotary encoder and it’s the simplest position sensor to measure

rotation. This rotary encoder is also known as quadrature encoder or relative rotary encoder

and its output is a series of square wave pulses.

Figure 22. Rotary Encoder

How Rotary Encoder Works:

Principle generate the square wave pulses: The encoder has a disk with evenly spaced

contact zones that are connected to the common pin C and two other separate contact pins A

and B, as illustrated below.

Figure 23. The pulse output of the encoder

When the disk will start rotating step by step, the pins A and B will start making contact

with the common pin and the two square wave output signals will be generated accordingly.

ME2009 Control system technology 15

HoChiMinh City University of Technology Mechatronics Department

Any of the two outputs can be used for determining the rotated position if we just count

the pulses of the signal. However, if we want to determine the rotation direction as well, we

need to consider both signals at the same time.

We can notice that the two output signals are displaced at 90 degrees out of phase from

each other. If the encoder is rotating clockwise the output A will be ahead of output B.

So if we count the steps each time the signal changes, from High to Low or from Low

to High, we can notice at that time the two output signals have opposite values. Vice versa, if

the encoder is rotating counterclockwise, the output signals have equal values. So considering

this, we can easily program our controller to read the encoder position and the rotation

direction.

ME2009 Control system technology 16

HoChiMinh City University of Technology Mechatronics Department

HoChiMinh City University of Technology ME2009 - Control System Technology

Faculty Mechanical of Engineering Lab Assignment 1

Mechatronics Department

Arduino – Led – Photoelectric Sensor - Encoder

REPORT

Date:………………… Group:……………… Duration: 5 class hours

Full Name Student ID Signature Grade

Task 1. Check the below answers:

Can you install Arduino IDE successful? Yes No

Can you connect Uno board with PC successful? Yes No

Can you make the Blink program? Yes No

Can you build the Blink program successful? Yes No

Can you upload the Blink program to Uno board? Yes No

Task 2. Modify the Blink program to make the LED flash 5 times (0.5 seconds/time),

pause 2 seconds then flash again.

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

…………………………………………… ………………………………………………..

Task 3. Write a program to display a number 0, 1, 2, 3, 4, 6, 7, 8, 9 on led module.

0% 25% 50% 75% 100%

ME2009 Control system technology 17

HoChiMinh City University of Technology Mechatronics Department

Task 4. Write a program to display a number “123456” on led module.

0% 25% 50% 75% 100%

Task 5. Write a program to display a number “ -123456” on led module.

0% 25% 50% 75% 100%

Task 6. Write a program to detect the Photoelectric Sensor signal

If the Photoelectric Sensor signal is “LOW”, a number “ -123456” is displayed on the

led module,

And if the Photoelectric Sensor signal is “HIGH”, the led module will be OFF.

0% 25% 50% 75% 100%

Task 7. Use Encoder library to get the pulse input of rotary encoder and show the value

on the led module

0% 25% 50% 75% 100%

Task 8. The resolution of the rotary encoder is: ……… pulse/ revolution (PPR)

Task 9. Write a program to display the integer angle (degree) of the rotary encoder. If

Photoelectric Sensor signal is “LOW”, the value will be reset to “00”

0% 25% 50% 75% 100%

Task 10. Write a program to display the real angle (degree) of the rotary encoder. If

Photoelectric Sensor signal is “LOW”, the value will be reset to “00”

0% 25% 50% 75% 100%

ME2009 Control system technology 18

HoChiMinh City University of Technology Mechatronics Department

HoChiMinh City University of Technology ME2009 - Control System Technology

Faculty Mechanical of Engineering Lab Assignment 2

Mechatronics Department

Control a DC Motor with Arduino

1. INTRODUCTION

In lab assignment 1, we have learned how to use Arduino to acquire various types of the

signal from a sensor such as a digital photosensor, potentiometers, incremental rotary encoder.

In this lab assignment, we will turn our attention to actuator control, which is an important part

of an automatic system.

The goal of this lab is to learn how to control a DC servo motor using the Arduino

microcontroller Mega 2560 board (shown in Figure 1) and the L298N Motor Shield driver

(shown in Figure 2). We take a look at some basic techniques for controlling DC motors. We

will use the reading from a rotary encoder attached to the back of the motor as our feedback

signal. We will learn how to design a controller for the motor, and drive the motor to a set-

point.

2. LAB DEVICES

2.1 Arduino Mega 2560 Board

Figure 1. Arduino Mega 2560 Board

ME2009 Control system technology 19

HoChiMinh City University of Technology Mechatronics Department

2.2 DC motor driver

Figure 2. DFRobot 2A Motor Driver Shield

2.3 USB cable

USB 2.0 Type A Male to Type B Male cable used to communicate between PC and Arduino

Mega 2560 board.

Figure 3. USB 2.0 Cable Type A Male to Type B

2.4 Wires

Used to connect Arduino Mega board with Control System Kit 02.

Figure 4. Breadboard wires

2.5 Screwdriver

Used to screwing and unscrewing screws on the Control System Kit 02.

Figure 5. Cross Slot Screwdriver

ME2009 Control system technology 20

HoChiMinh City University of Technology Mechatronics Department

2.6 Control System Kit 02

+5V 0V OUT M+ M- +5V 0V A B +5V KP 0V +5V KI 0V +5V KD 0V

Figure 6. Control System Kit 2

Module No. Device Name Signal

1 Terminal

+5V: high voltage supply for incremental encoder

0V: high voltage supply for incremental encoder

M+: positive power supply for the motor

2 DC Servo Motor

M-: negative power supply for the motor

A: pulse signal of phase A of the encoder

B: pulse signal of phase B of the encoder

+5V : (Red) high voltage of the power supply

Photoelectric

3 0V: (Green) ground of the power supply

Sensor

OUT : (Yellow) Digital output

+5V: the high voltage of the power supply

0V:) ground of the power supply

4 Potentiometers KP: Output of Blue Potentiometer

KI: Output of Yellow Potentiometer

KD: Output of Red Potentiometer

ME2009 Control system technology 21

HoChiMinh City University of Technology Mechatronics Department

3. PROCEDURE

3.1 Set up your Arduino Programming Environment

You should set up the Arduino programming environment and Encoder Library on your PC.

You can review the guideline in Lab assignment 1 to install the software.

3.2 Wiring diagram and electrical circuit

Device Name Control System Kit 02 Arduino Mega

+5V: high voltage supply for incremental encoder 5V

0V: high voltage supply for incremental encoder GND

DC Servo Motor

A: pulse signal of phase A of the encoder Pin 2

B: pulse signal of phase B of the encoder Pin 3

+5V : (Red) high voltage of the power supply 5V

Photoelectric Sensor 0V: (Green) ground of the power supply GND

OUT : (Yellow) Digital output Pin 8

+5V: the high voltage of the power supply 5V

0V: the ground of the power supply GND

Potentiometers KP: Output of Blue Potentiometer Pin A0

KI: Output of Yellow Potentiometer Pin A1

KD: Output of Red Potentiometer Pin A2

Device Name Control System Kit 02 Driver shield

M+ : positive power supply for the motor M1 +

DC Servo Motor

M- : negative power supply for the motor M1 -

Arduino Mega Driver shield

Pin 4 Motor 1 Direction control

Pin 5 Motor 1 PWM control

PWM mode

Pin 6 Motor 2 PWM control

Pin 7 Motor 2 Direction control

ME2009 Control system technology 22

HoChiMinh City University of Technology Mechatronics Department

KIT +5V 0V OUT M+ M- +5V 0V A B +5V KP 0V +5V KI 0V +5V KD 0V

+5V GND 8 2 3 A0 A1 A2

MEGA 2560 MEGA 2560

M1+ M1-

Driver Shield

OUT A B

GND (8) (2) (3)

KP KD

(A0) (A2)

KI

(A1)

M1+

M1-

GND

12V

Figure 7. Wiring diagram between Mega 2560 board, a motor shield and the Kit 02

ME2009 Control system technology 23

HoChiMinh City University of Technology Mechatronics Department

3.3 Method control of DC motor

3.3.1 Method control the speed of DC motor

We can control the speed of the DC motor by simply controlling the input voltage to

the motor: If change the value of power supply (12V, 6V, 5V,…) the speed of the motor

will be changed. The most common method of doing that is by using PWM signal.

PWM or pulse width modulation is a technique which allows us to adjust the average

value of the voltage that’s going to the electronic device by turning on and off the power

at a fast rate. The average voltage depends on the duty cycle, or the amount of time the

signal is ON versus the amount of time the signal is OFF in a single period of time.

Figure 8. Pulse with modulation

So depending on the size of the motor, we can simply connect an Arduino PWM output

to the base of a transistor or the gate of a MOSFET and control the speed of the motor by

controlling the PWM output. The low power Arduino PWM signal switches on and off the gate

at the MOSFET through which the high power motor is driven.

3.3.2 Method control the direction of DC motor

For controlling the rotation direction, we just need to inverse the direction of the current

flow through the motor:

- Connect M+ to VDC and M- to GND: motor turn clockwise

- Connect M- to 12VDC and M+to GND: motor turn counterclockwise

ME2009 Control system technology 24

HoChiMinh City University of Technology Mechatronics Department

M+ M+

12V

12V M-

M-

GND GND

Figure 9. Change the rotation direction of the motor

The most common method of doing that is by using an H-Bridge. An H-Bridge circuit

contains four switching elements, transistors or MOSFETs, with the motor at the center

forming an H-like configuration. By activating two particular switches at the same time we can

change the direction of the current flow, thus change the rotation direction of the motor.

Figure 10. H-Bridge circuit

3.3.3 DFRobot 2A Motor L298N Driver Shield

The L298N is a dual H-Bridge motor driver which allows speed and direction control of two

DC motors at the same time. The module can drive DC motors that have voltages between 5

and 35V, with a peak current up to 2A. Using this shield, you can control both the speed and

direction of DC motor using Arduino board.

Code example to change direction and speed of DC motor with the driver shield:

ME2009 Control system technology 25

HoChiMinh City University of Technology Mechatronics Department

// Define pin for Motor

int SPEED1 = 4; // Motor 1 Direction control

int DIR1 = 5; // Motor 1 PWM control

int DIR2 = 6; // Motor 1 PWM control

int SPEED2 = 7; // Motor 1 Direction control

int pwm_value = 0;

void setup() {

pinMode(DIR1, OUTPUT);

pinMode(DIR2, OUTPUT);

}

void loop() {

pwm_value = 100; // PWM value

digitalWrite(M1,HIGH); // change the direction of DC motor

analogWrite(E1, value); //change the speed of DC motor

}

3.4 Determine the position of DC motor

The motor rotation angle will determine by an incremental rotary encoder that integrated

at the end of the motor. As the motor rotates, the encoder also rotates and generates the

square wave pulse output on pins A and B (shown as ) that can be used for determining

the rotated position. We will use Arduino mega board to receive the signal on pins A and

B of the encoder to calculate the position of the motor shaft.

Figure 11. The pulse output of the encoder

Example to get to get pulses of encoder:

// Define pin for Encoder

#include <Encoder.h> // add Encoder Library to the current project

Encoder myEncoder(2,3); // phase A and B of encoder

long motorPos = 0;

void setup() {

Serial.begin(115200); // setup serial

myEncoder.write(0); // reset encoder counter to 0

}

void loop() {

motorPos = myEncoder.read(); // read pulses of encoder

Serial.print("Pulses of encoder: "); // show counter on screen

Serial.println(motorPos);

}

ME2009 Control system technology 26

HoChiMinh City University of Technology Mechatronics Department

3.5 Potentiometer

The Arduino microcontroller can read analog inputs between 0 and 5 V and generate

corresponding integer values. This is accomplished using the analogRead() function. It takes

about 100 microseconds (0.0001 s) to read an analog input, so the maximum reading rate is

about 10,000 times a second. We can use this function to get the analog value of a potentiometer

with the example below:

// Define pin for potentiometer

int POT1 = A0; // select the input pin for the potentiometer

long ADvalue = 0;

void setup() {

Serial.begin(115200); // setup serial

}

void loop() {

ADvalue = analogRead(POT1); // read AD value

Serial.print("Value of Potentiometer 1: "); // show value on screen

Serial.println(ADvalue);

}

3.6 Photoelectric Sensor

The DFRobot Adjustable Infrared Sensor Switch is a set of transmitter and receiver in one of

the photoelectric switch sensor. The switching signal output differs in accordance with the

obstacles. It remains HIGH when no obstacles and remains LOW when there are obstacles.

There is also a red led on its back to indicate the sensor status. The signal from the sensor can

be captured by a digital input pin of Arduino with the example below:

// Define Photoelectric Sensor pin

int PHOTO_SENSOR = 8; // select the pin for the Photoelectric Sensor

output

void setup() {

Serial.begin(115200); // setup serial

pinMode(PHOTO_SENSOR, INPUT); // set the digital pin 8 as input

}

void loop() {

if (digitalRead(PHOTO_SENSOR)== LOW)

{

Serial.print("There is a obstacles ");

}

else

{

Serial.print("There is nothing ");

}

}

ME2009 Control system technology 27

HoChiMinh City University of Technology Mechatronics Department

3.7 Control Position of DC motor with P (Proportional) controller

START

Position control

Set: desired_angle = 900 (degree)

Set initial value

current_angle = 0;

err = 0;

pwm_value = 0;

direction = 0;

kp = 50;

Get value from sensor

current_angle = get pulse of encoder and calculate the angle (degree);

Show current_angle to screen

err = desired_angle – current_angle;

pwm_value = kp * err;

direction = 0;

Change motor direction

pwm_value < 0 ? YES pwm_value = abs(pwm_value);

direction = 1;

NO

Validate pwm value

If (pwm_value < 30) then pwm_value = 30;

If (pwm_value > 255) then pwm_value = 255;

Apply control value to motor

Set pwm_value to motor

Set direction to motor

Waitting 100 miliseconds

Figure 12. Flowchart of DC position control with P- controller

ME2009 Control system technology 28

HoChiMinh City University of Technology Mechatronics Department

3.8 Control Speed of DC motor with P (Proportional) controller

START

Speed control

Set desired_speed = 100

(rpm)

Set initial value

current_speed = 0;

err = 0;

pwm_value = 0;

direction = 0;

kp = 50;

Get value from sensor

current_speed = get pulse of encoder and calculate the speed (rpm);

Show current_speed to screen

err = desired_speed – current_speed;

pwm_value = kp * err;

direction = 0;

Change motor direction

pwm_value < 0 ? YES pwm_value = abs(pwm_value);

direction = 1;

NO

Validate pwm value

If (pwm_value < 30) then pwm_value = 30;

If (pwm_value > 255) then pwm_value = 255;

Apply control value to motor

Set pwm_value to motor

Set direction to motor

Waitting 100 miliseconds

Figure 13. Flowchart of DC speed control with P- controller

ME2009 Control system technology 29

HoChiMinh City University of Technology Mechatronics Department

4. REFERENCE

[1] Arduino.cc, The open-source Arduino Software (IDE), 2018. Available:

http://arduino.cc/en/Main/Software. [Accessed: 1- May- 2018].

[2] howtomechatronics.com, Arduino DC Motor Control Tutorial – L298N, 2017.

Available: https://howtomechatronics.com/tutorials/arduino/arduino-dc-motor-

control-tutorial-l298n-pwm-h-bridge/. [Accessed: 7- May- 2018].

[3] www.dfrobot.com, Arduino Motor Shield (L298N), 2017. Available:

https://www.dfrobot.com/wiki/index.php/Arduino_Motor_Shield_(L298N)_(SKU:

DRI0009). [Accessed: 1- May- 2018].

[4] howtomechatronics.com, How Rotary Encoder Works and How To Use It with

Arduino, 2016. Available: https://howtomechatronics.com/tutorials/arduino/rotary-

encoder-works-use-arduino/. [Accessed: 1- May- 2018].

ME2009 Control system technology 30

HoChiMinh City University of Technology Mechatronics Department

HoChiMinh City University of Technology ME2009 - Control System Technology

Faculty Mechanical of Engineering Lab Assignment 2

Mechatronics Department

Control a DC Motor with Arduino

REPORT

Date:………………… Group:……………… Duration: 5 class hours

Full Name Student ID Signature Grade

Task 1. Check the below answers: (0.5 points)

Can you install Arduino IDE successful? Yes No

Can you connect Mega 2560 board with PC successful? Yes No

Can you make Led at Pin 13 on the board flash every 1 second? Yes No

Can you install the Encoder Library successful? Yes No

Can you run the code in section 3.6 Photoelectric Sensor? Yes No

Task 2. Typing and run the example in section 3.5 Potentiometer and answers the

question below (1 point)

Potentiometer to ADC has a minimum ADC value: adc _ max .............

Potentiometer to ADC has a maximum ADC value: adc _ min .............

The resolution of AD convert of Arduino 2560 is n ......... bits

Task 3. Wire program to read signal of A and B channel of the encoder, determine the

resolution of the encoder (1 point)

Number of pulse per round of encoder : res _ encoder ............. (ppr)

Determine the equation to calculate the speed of motor if the Arduino receives pulses

in 100 milliseconds.

speed ........................................................................................ (rpm)

ME2009 Control system technology 31

HoChiMinh City University of Technology Mechatronics Department

speed ........................................................................................ (degree/s)

Task 4. Typing and run the example in section 3.3 Method control of DC motor (1 point)

Can you run the code in section successful? Yes No

Modify your code to add a value 30 to a pwm_value variable every 1 second. If the to

pwm_value > 255, it will be set to 0. (Hint: use For loop and delay function)

0% 25% 50% 75% 100%

Task 5. Use your code in task 4 then modify it to reverse the direction of rotation of motor

as having an obstacle in front of the photoelectric sensor? (1 point)

0% 25% 50% 75% 100%

Task 6. Write a program to change the speed of motor depend on the value ADC of the

potentiometer. As we turn the potentiometer from minimum value to maximum value,

why is the speed of motor changed many times? Please fix this problem? (1 point)

…………………………………………………………………………………………………

…………………………………………………………………………………………………

…………………………………………………………………………………………………

…………………………………………………………………………………………………

…………………………………………………………………………………………………

0% 25% 50% 75% 100%

Task 7. Write a program to control the motor to the angle = 900 (1.5 point)

0% 25% 50% 75% 100%

Task 8. Write a program to control the motor rotate to angle 900 if we put an obstacle in

front of the photoelectric sensor; otherwise, the motor will return to 00 (1.5 points)

0% 25% 50% 75% 100%

Task 9. Write a program to control the speed of motor = 500 rpm (1.5 point)

0% 25% 50% 75% 100%

ME2009 Control system technology 32

HoChiMinh City University of Technology Mechatronics Department

HoChiMinh City University of Technology ME2009 - Control System Technology

Faculty Mechanical of Engineering Lab Assignment 3

Mechatronics Department

Sequential Circuit Design Using Relays

1. INTRODUCTION

A relay is a set of switches that are actuated when electric current passes through a coil of wire.

Nowadays, relays are used quite commonly in industrial applications. Although micro-processor

based controllers are commonly used, using relays as a controller is sometimes a reasonable solution

in sequential processes.

Objectives:

Overview the multi-purpose relay.

Have experience in wiring and testing electrical circuits.

Implement the method of sequential circuit design using relays.

2. EQUIPMENT

2.1 Devices

- 4 multi-purpose relays of 4 poles.

- 5 push buttons (one representing the ON button and the other four

representing sensor signals).

- 4 time-delay relays for time-driven sequence operations.

- 35 connecting coded cables and 1 cable of power plug.

- 2 screw drivers.

ME2009 Control system technology 33

HoChiMinh City University of Technology Mechatronics Department

2.2 Specifications:

a) Electromechanical Relays (EMR): this is a device that uses an electromagnet to provide the force to

close (or open) switch contacts, in other words, an electrically powered switch. When the

electromagnet, called the coil, is energized, it pulls down on the spring-loaded armature. Relay

contacts are described as being one of two kinds: normally open contacts (NO), which are open in

the unenergized state, and normally closed contacts (NC), which are closed in the unenergized state.

By convention, the symbol always depicts the relay in the unenergized state.

For the relay MY4N, pin numbers are assigned as follows

.

b) Push-button switches: these are almost always the momentary type – pressure must be

maintained to keep the switch activated. There are two configurations possible: normally open

(NO) and normally closed (NC).

ME2009 Control system technology 34

HoChiMinh City University of Technology Mechatronics Department

Time-delay relays: they are control relays that have provisions for a delayed switching action.

Solid-state time-delay relays are used in most newer systems that require delay relays. The delay

in switching is usually adjustable, e.g. the knob is for setting the delay. These units are based on

the delay involved when (1) charging a capacitor or (2) counting high-speed clock pulses with a

digital counter: the higher the count, the longer the delay. The delay may take place when the

coil is energized or when the coil is deenergized. An arrow is used to identify the switching

direction in which the time delay takes place.

For the time-delay relays AH3-3, pin numbers are assigned as follows

3. EXPERIMENTAL CONTENTS

3.1 Time duration: 5 academic periods for each group of 4 students.

3.2 Requirements

3.2.1. Equipment testing

- Supplying AC power to the coil of relays to test their operations. Pay attention to switching

contacts when the coil is energized.

- Supplying AC power to the coil of time-delay relays to test their operations. Pay attention to

LEDs ON and UP when the coil is energized under the effect of timing value.

ME2009 Control system technology 35

HoChiMinh City University of Technology Mechatronics Department

3.2.2. Case study

The figure below illustrates a bending tool with pneumatic drive.

Small bent workpieces can be produced to good advantage without the need for an eccentric or

hydraulic press by using standard commercially available components to create a basic

configuration and pneumatic components to provide the necessary motions in numerous directions.

The illustration shows a bending sequence (from I to IV). The lateral bending jaws can be activated

only after the vertical motion has been completed. The sequence control system thus requires

signals supplied by proximity switches. The finished workpiece must be pushed away from the

bending ram. In the case of full automation, the insertion of a new workpiece blank can be

combined with the ejection of a finished workpiece. This system is described in a diagram as

follows:

Cylinder A

A1

A2

LS1

LS6 LS5

Cylinder B LS2 Cylinder C

LS3 LS4

B1 B2 C2 C1

ME2009 Control system technology 36

HoChiMinh City University of Technology Mechatronics Department

Each pneumatic cylinder is connected through a 4/3 directional valve. Therefore, there are 6

manipulated signals:

A1 = 1: Cylinder A extends.

A2 = 1: Cylinder A retracts.

B1 = 1: Cylinder B extends.

B2 = 1: Cylinder B retracts.

C1 = 1: Cylinder C extends.

C2 = 1: Cylinder C retracts.

Six limit switches are used to detect positions of the cylinders as follows:

LS1 = 1: the cylinder A is at the retracted end position.

LS2 = 1: the cylinder A is at the extended end position

LS3 = 1: the cylinder B is at the retracted end position

LS4 = 1: the cylinder B is at the extended end position

LS5 = 1: the cylinder C is at the retracted end position

LS6 = 1: the cylinder C is at the extended end position

With the diagram above, the sequence operations could be described as:

- Step 1: the cylinder A extends.

- Step 2: then the two cylinders B and C extend together.

- Step 3: when the cylinders B and C reach to the end, they retract at the same time.

- Step 4: when the cylinders B and C are retracted completely, the cylinder A starts

retracting.

The students are required to design the controller for the above system. Note that experimental

results in part 4 need to be completed and submitted to the instructor.

a) Using relays, implement a control circuit to meet the desired sequence in which push-

button switches are used as limit switches.

b) Replace the four push-button switches with four time-delay relays, respectively. Then,

revise the control circuit so that the system operates automatically when the ON button

is the pressed.

3.3 Guidelines of solving problem

3.3.1. Sequential Circuit Design

ME2009 Control system technology 37

HoChiMinh City University of Technology Mechatronics Department

With the statement list above, the system could also be expressed in a Sequential Function Chart

(SFC) as follows

Start

ON

Step 1 Cylinder A extends

LS2

Step 2 Cylinders B & C extend

LS4 & LS6

Step 3 Cylinders B & C retract

LS3 & LS5

Step 4 Cylinder A retracts

LS1

From the SFC, there are four steps operating in sequence. Therefore, the procedure for the design

of an event-driven sequential circuit could be applied. Basic concepts of the design are:

Use of a control relay for each step in the process.

When the process is in a given step. the control relay associated with that step is energized

and all other relays are deenergized each control relay represents a "state" of the

controller.

There is a one-to-one correspondence between steps in the process and states of the

controller, and the step numbers are used to identify the states.

Each state in the controller consists of one rung in the controller ladder diagram.

Assume that the process has three consecutive steps: step i, step j, and step k. The rung in the

ladder diagram that establishes step j in a sequential control circuit has a general form:

ME2009 Control system technology 38

HoChiMinh City University of Technology Mechatronics Department

Where:

Rj

Coil the control relay k, representing State j

Rk

NC contact of the control relay k, terminating State j when the process is in Step k.

Ri

NO contact of the control relay i, informing State j be ready when the process is in

Step i.

Cij

the condition required to move from State i to State j.

Rj

NO contact of the control relay j, self-holding State j.

3.3.2. Relay circuit implementation

Note and mark used pin numbers in the control circuit so that the circuit wiring could be monitored

comfortably. Do wiring for the control circuit in ladder diagram with push-button switches as limit

switches as follows:

R2 Button A

R1

10 2 13 14

R1

5 9

R3 R1 Button B

R2

10 2 7 11 13 14

CRj

5 9

R4 R2 Button C

R3

10 2 7 11 13 14

R3

5 9

Button E R3 Button D

R4

7 11 13 14

R4

5 9

ME2009 Control system technology 39

HoChiMinh City University of Technology Mechatronics Department

4. Experimental results

4.1 Plot the control circuit in ladder diagram with time-delay relays as the transition condition

4.2 Circuit implementation

Using push-button switches

Does not run Incomplete run Work well

Comments: …………………………………………………………………………………………

Using time-delay relays

Does not run Incomplete run Work well

Comments: …………………………………………………………………………………………

Instructor’s name:

Date: Room: Time of report:

Student’s names: Student’s IDs:

………………………………………………………… …………………..

………………………………………………………… …………………..

………………………………………………………… …………………..

………………………………………………………… …………………..

ME2009 Control system technology 40

HoChiMinh City University of Technology Mechatronics Department

REFERENCES:

[1] R.N. Bateson, Introduction to Control System Technology, 7th Edition, Prentice Hall, 2002.

[2] Christopher T. Kilian, Modern Control Technology: Components and Systems, 2nd Edition,

Delmar Thomson Learning, 2001.

Appendices: this lab procedures could be similarly applied to followings:

Example 1:

The drilling, countersinking and chamfering of small workpieces in medium-sized and large

batches are typical work operations in mechanical engineering. It can be well worth while to

develop special devices for these operations. In this example, the workpiece carriers consist of

high-powered pneumatic chucks which are indexed about a horizontal axis with the aid of a rotary

indexing table. Pneumatic pick-and-place units are used for loading and unloading. If the device

is used on a drilling/milling machine with a vertical working spindle, a further working operation

can be carried out in the loading position. A hydraulic cushioning cylinder can be connected up in

parallel to cushion the feed motion.

ME2009 Control system technology 41

HoChiMinh City University of Technology Mechatronics Department

Example 2:

Certain workpieces tend to deform easily during processing and clamping. In the interests of

accuracy and to prevent deformity, these must be fitted with a temporary clamp sleeve to allow

further processing. This is achieved by using the system shown above, which is partially

automated. The clamp sleeves are first placed into a carrier by hand. The workpiece is then moved

into the clamping position against the stop of the more powerful right-hand cylinder. This is

followed by longitudinal pressing. After this, the stop cylinder retracts again, allowing the feed

cylinder in a second action to push the finished workpiece onto the outward transfer conveyor belt.

The clamp sleeves must be removed again after processing has been completed. The workpieces

are moved by hand from the conveyors to the side setdown area.

ME2009 Control system technology 42

You might also like

- Network Defense 14gDocument36 pagesNetwork Defense 14gBolaji WilliamsNo ratings yet

- Air Brake Work BookDocument47 pagesAir Brake Work BookRudolf Oppermann50% (2)

- Arduino LAB Manual PDFDocument25 pagesArduino LAB Manual PDFjose_mario1128100% (5)

- Module 5 E Comm Internet MarketingDocument25 pagesModule 5 E Comm Internet MarketingJoshua BarracaNo ratings yet

- PowershellDocument133 pagesPowershellganeshNo ratings yet

- Sans 10208-3-2012 PDFDocument35 pagesSans 10208-3-2012 PDFAlexandru Ionuţ PîrvanNo ratings yet

- Electrical SafetyDocument51 pagesElectrical SafetyDIANA QUINONESNo ratings yet

- GCS Troubleshooting&Applications1v0 (3.23.01)Document101 pagesGCS Troubleshooting&Applications1v0 (3.23.01)Jesús A Guerrero MNo ratings yet

- Automatic Color Generation Using AVR MicrocontrollerDocument4 pagesAutomatic Color Generation Using AVR MicrocontrollerInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Microeconomic Theory Basic Principles and Extensions 11th Edition Nicholson Solutions ManualDocument13 pagesMicroeconomic Theory Basic Principles and Extensions 11th Edition Nicholson Solutions Manualdavidnelsonseyjdmpoaz100% (16)

- AR4 Robot ManulDocument289 pagesAR4 Robot ManulMohammad NasutionNo ratings yet

- Brigada Pagbasa Action Plan SY 2021 - 2022Document3 pagesBrigada Pagbasa Action Plan SY 2021 - 2022Jazzele Longno95% (20)

- Home Assignments #3Document2 pagesHome Assignments #3Pham Thanh0% (1)

- Power PneumaticsDocument163 pagesPower PneumaticsMuhammed ElNo ratings yet

- PLCDocument2 pagesPLCDarshan VoraNo ratings yet

- Robust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton RobotDocument6 pagesRobust Fast Terminal SMC With Prescribed Performance For A Wearable Exoskeleton Robotabdelhamid.ghoul93No ratings yet

- 56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFDocument7 pages56 - A Learning Model For 8051 Microcontroller Case Study On Closed Loop DC Motor Speed Control PDFhecirlene vieiraNo ratings yet

- Axm Ref Eng V20110526Document714 pagesAxm Ref Eng V20110526Khoa NguyễnNo ratings yet

- PIC16F877 and CCS-C LanguageDocument83 pagesPIC16F877 and CCS-C Language1726giangNo ratings yet

- Quiz 1 - Battery and Starter - Xem Lại Lần Làm ThửDocument20 pagesQuiz 1 - Battery and Starter - Xem Lại Lần Làm ThửTran Thanh NhanNo ratings yet

- GA Catalogue CA 500 GB 0501Document36 pagesGA Catalogue CA 500 GB 0501adst34No ratings yet

- IpbalanceDocument1 pageIpbalancephuceltnNo ratings yet

- Max31910evkit Max31911evkitDocument13 pagesMax31910evkit Max31911evkitRody GCNo ratings yet

- Simulation of Indirect Field-Oriented Induction Motor Drive SystemDocument12 pagesSimulation of Indirect Field-Oriented Induction Motor Drive SystemThinseepNo ratings yet

- Đề Speaking ban moi nhat PDFDocument237 pagesĐề Speaking ban moi nhat PDFmynsuNo ratings yet

- Es35 SW BrochureDocument4 pagesEs35 SW BrochureThái Trung TàiNo ratings yet

- Chapter 2 Key Elements in Engineering AnalysisDocument35 pagesChapter 2 Key Elements in Engineering AnalysissingNo ratings yet

- Final 222 2009 SolDocument6 pagesFinal 222 2009 SolNapsterNo ratings yet

- Bài Thi Cuối Kỳ Môn Kiến Trúc Máy Tính và Hợp NgữDocument12 pagesBài Thi Cuối Kỳ Môn Kiến Trúc Máy Tính và Hợp NgữTùng LêNo ratings yet

- Giáo Trình LabviewDocument54 pagesGiáo Trình LabviewXuan Chiem0% (1)

- Chapter 8 ProblemsDocument21 pagesChapter 8 Problemskhrid3100% (2)

- RM3100 Breakout Board Sales SheetDocument2 pagesRM3100 Breakout Board Sales Sheetkostya_4524No ratings yet

- THIẾT KẾ MÁY ÉP PHUN NHỰADocument34 pagesTHIẾT KẾ MÁY ÉP PHUN NHỰAThienNo ratings yet

- Problems: Analysis and Design of Machine ElementsDocument6 pagesProblems: Analysis and Design of Machine Elementszangue billy jamesNo ratings yet

- Flame SensorDocument6 pagesFlame SensorGst Agung Ngrh ArjayaNo ratings yet

- Hướng dẫn kết nối board plc FK3UDocument7 pagesHướng dẫn kết nối board plc FK3UHiệp Trần100% (1)

- Analysis of Bush Bearing Using Ansys 11Document5 pagesAnalysis of Bush Bearing Using Ansys 11engineersaabNo ratings yet

- (BS 1041-5-1989) - Temperature Measurement. Guide To Selection and Use of Radiation Pyrometers PDFDocument42 pages(BS 1041-5-1989) - Temperature Measurement. Guide To Selection and Use of Radiation Pyrometers PDFAnonymous Y833nLdDNo ratings yet

- Kte 5000LTDocument110 pagesKte 5000LTzalomxisNo ratings yet

- BTL Chude 1Document2 pagesBTL Chude 1Tom DangNo ratings yet

- MCNPDocument42 pagesMCNPRuly GumilarNo ratings yet

- Ejercicios Del Tema 1 y Tema 2 - Estatica Beer Jhonson 9edDocument11 pagesEjercicios Del Tema 1 y Tema 2 - Estatica Beer Jhonson 9edJean Pierre MoralesNo ratings yet

- Fundamentals of Control Systems Fundamentals of Control SystemsDocument60 pagesFundamentals of Control Systems Fundamentals of Control SystemsĐỗ Ngọc CẩnNo ratings yet

- RainBird AutoCAD LegendDocument3 pagesRainBird AutoCAD LegendFlop ArghNo ratings yet

- Technician A Technician BDocument14 pagesTechnician A Technician BBikay Nguyen100% (1)

- Laboratory Manual: Ho Chi Minh City University of Technology Faculty of Computer Science & EngineeringDocument8 pagesLaboratory Manual: Ho Chi Minh City University of Technology Faculty of Computer Science & EngineeringHuy Minh HoàngNo ratings yet

- DE2 Pin AssignmentsDocument8 pagesDE2 Pin Assignmentstuandt5No ratings yet

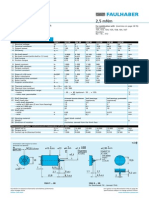

- Faulhaber DatasheetDocument5 pagesFaulhaber DatasheetMuhammad SharifNo ratings yet

- CNC Lathe Concept Turn 250 enDocument6 pagesCNC Lathe Concept Turn 250 enjose2525No ratings yet

- DE2 SchematicDocument24 pagesDE2 Schematictqminh1990No ratings yet

- Newton Cotes in MATLABDocument2 pagesNewton Cotes in MATLABVicky Lavinia IINo ratings yet

- C++ Project: BombermanDocument10 pagesC++ Project: BombermanTsepo ShataNo ratings yet

- 1582887084-UI - 01 - 12. MechanismsDocument6 pages1582887084-UI - 01 - 12. MechanismsGeorgiana LazarNo ratings yet

- Total AutoDocument49 pagesTotal Automoba funnyNo ratings yet

- DC Motor With Encoder Manual (1.1 W)Document7 pagesDC Motor With Encoder Manual (1.1 W)Saad NajibNo ratings yet

- Stair Climbing Wheel ChairDocument4 pagesStair Climbing Wheel ChairMukesh KhairnarNo ratings yet

- Solutions Chapter 5 (WǪ) PDFDocument34 pagesSolutions Chapter 5 (WǪ) PDF黃羿傑No ratings yet

- Structure Question BankDocument16 pagesStructure Question BankMinh Ngọc LêNo ratings yet

- 5.control of Manipulator by CPM2 Series PLCDocument5 pages5.control of Manipulator by CPM2 Series PLCIlija Petkovic0% (1)

- HUST PPT Template 2022 Blue 16x9Document13 pagesHUST PPT Template 2022 Blue 16x9Đằng ĐinhNo ratings yet

- DLD Lab#01Document6 pagesDLD Lab#01Zoya KhanNo ratings yet

- Exam 2004Document20 pagesExam 2004kib6707No ratings yet

- Giai Tich 2 Nam2017 Nhom 6Document3 pagesGiai Tich 2 Nam2017 Nhom 6huongNo ratings yet

- Employee Salary Prediction SlidesDocument21 pagesEmployee Salary Prediction SlidesrushipanchalNo ratings yet

- PDF 3136325f4d616e75616cDocument234 pagesPDF 3136325f4d616e75616coprea vasileNo ratings yet

- MTTCNDocument296 pagesMTTCNCarlosNo ratings yet

- Me2009 - Control System Technology Lab Assignment 1: Hochiminh City University of Technology Mechatronics DepartmentDocument18 pagesMe2009 - Control System Technology Lab Assignment 1: Hochiminh City University of Technology Mechatronics DepartmentThanh HiếuNo ratings yet

- ME2010 - Control System Technology Lab Assignment 1Document18 pagesME2010 - Control System Technology Lab Assignment 1Tăng Gia LạcNo ratings yet

- Screenshot 2024-03-28 at 2.50.29 AMDocument17 pagesScreenshot 2024-03-28 at 2.50.29 AMrr1974aaNo ratings yet

- Final QBDocument15 pagesFinal QBShubham Anil KambleNo ratings yet

- Walmart Vs AmazonDocument188 pagesWalmart Vs AmazonRYENA111No ratings yet

- Verburg, Babette Linnet, Bjørn - The Black Box of Netflix - A Qualitative Study of Consumers Perception of Netflix and Its Recommendation SystemDocument116 pagesVerburg, Babette Linnet, Bjørn - The Black Box of Netflix - A Qualitative Study of Consumers Perception of Netflix and Its Recommendation SystemMarcos CurvelloNo ratings yet

- Professional Communication Skills For Engineers: DR Atul Aman SaslDocument13 pagesProfessional Communication Skills For Engineers: DR Atul Aman SaslRishi JhaNo ratings yet

- Institute of Aeronautical Engineering (Autonomous) : Electronics and Communication EngineeringDocument32 pagesInstitute of Aeronautical Engineering (Autonomous) : Electronics and Communication EngineeringMano Har100% (1)

- CT13005 FullLine BrochureDocument6 pagesCT13005 FullLine BrochureJuve De la CruzNo ratings yet

- 11.2.4.4 Packet Tracer - Configuring Port Forwarding On A Linksys Router InstructionsDocument2 pages11.2.4.4 Packet Tracer - Configuring Port Forwarding On A Linksys Router InstructionsLiyanNo ratings yet

- B737-200 L3 ATA 23 Communications (Full)Document130 pagesB737-200 L3 ATA 23 Communications (Full)Belisario Sergio Llacchas rodasNo ratings yet

- Business Certificate Timetable August 2023 Draft Edited 1 1pdf 1686898228811Document3 pagesBusiness Certificate Timetable August 2023 Draft Edited 1 1pdf 1686898228811Sada DahonestNo ratings yet

- P PQT QuestionsDocument20 pagesP PQT Questionsbarathi subburamNo ratings yet

- Ch2 - Auditing IT Governance Controls - FOR UPLOADDocument46 pagesCh2 - Auditing IT Governance Controls - FOR UPLOADGonzalo Jr. RualesNo ratings yet

- Business Conduct PolicyDocument19 pagesBusiness Conduct PolicySarah Mae De Los ReyesNo ratings yet

- Rainwater Harvesting: Model-Based Design EvaluationDocument12 pagesRainwater Harvesting: Model-Based Design EvaluationOliver AbordoNo ratings yet

- A Failure Mode and Effect Analysis FMEA-based ApprDocument12 pagesA Failure Mode and Effect Analysis FMEA-based ApprTrần Thanh TiếnNo ratings yet

- Simran KaurDocument8 pagesSimran KaurgarvitNo ratings yet

- We Plan... We Deliver... : Integrated Urban Development & Infrastructure ConsultantsDocument19 pagesWe Plan... We Deliver... : Integrated Urban Development & Infrastructure ConsultantsSenthilKumaranDNo ratings yet

- A Review On EEG Based Epileptic Seizures Detection Using Deep Learning TechniquesDocument8 pagesA Review On EEG Based Epileptic Seizures Detection Using Deep Learning TechniquesWorld FactsNo ratings yet

- Variance and Standard DeviationDocument17 pagesVariance and Standard DeviationPuja GahatrajNo ratings yet

- Slim and Symmetrical. Every Presentation Will Command AttentionDocument2 pagesSlim and Symmetrical. Every Presentation Will Command AttentionraviezsoftNo ratings yet

- GXV Operations Vignettes PDFDocument28 pagesGXV Operations Vignettes PDFTitoGhioNo ratings yet

- Half-Life Valve Software'sDocument6 pagesHalf-Life Valve Software'sdavid alonsoNo ratings yet