Professional Documents

Culture Documents

Identification

Uploaded by

varadarajck893Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Identification

Uploaded by

varadarajck893Copyright:

Available Formats

SECTION 23 05 53_MECHANICAL IDENTIFICATION

ATLANTIS THE PALM – AQUAVENTURE EXPANSION PHASE III

DUBAI, UNITED ARAB EMIRATES

Revision History:

0 22-Dec-2019 Issued for Contract MR KH KH

Prepared Checked Approved

Rev. Date Description of Revision

By By By

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

TABLE OF CONTENTS:

PART 1 - GENERAL ................................................................................................................................. 3

1.1 SUMMARY ................................................................................................................................ 3

1.2 RELATED SECTIONS ............................................................................................................... 3

1.3 REFERENCES .......................................................................................................................... 3

1.4 SUBMITTALS ............................................................................................................................ 3

1.5 COORDINATION ....................................................................................................................... 3

PART 2 - PRODUCTS .............................................................................................................................. 4

2.1 EQUIPMENT LABELS ............................................................................................................... 4

2.2 TAGS ......................................................................................................................................... 4

2.3 STENCILS ................................................................................................................................. 4

2.4 SERVICES IDENTIFICATION ................................................................................................... 4

2.5 PIPEWORK IDENFICATION ..................................................................................................... 4

2.6 PIPEWORK IDENTIFICATION .................................................................................................. 5

2.7 IDENTIFICATION OF PLANT .................................................................................................... 6

2.8 ASSET REGISTER .................................................................................................................... 6

2.9 WARNING SIGNS AND LABELS .............................................................................................. 6

2.10 ANCILLARY EQUIPMENT LABELS .......................................................................................... 6

2.11 MOTOR CONTROL CENTERS ................................................................................................. 7

PART 3 - EXECUTION .............................................................................................................................. 8

3.1 INSTALLATION ......................................................................................................................... 8

3.2 EQUIPMENT LABEL INSTALLATION ....................................................................................... 8

3.3 PIPE LABEL INSTALLATION .................................................................................................... 8

3.4 DUCT LABEL INSTALLATION .................................................................................................. 8

3.5 VALVE-TAG INSTALLATION .................................................................................................... 9

3.6 WARNING-TAG INSTALLATION .............................................................................................. 9

END OF SECTION 23 05 53 .................................................................................................................. 9

December 2019 230553 - Mechanical Identification Issued for Contract

Page 2 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

SECTION 23 05 53_MECHANICAL IDENTIFICATION

PART 1 - GENERAL

1.1 SUMMARY

A. This section includes:

1. Nameplates

2. Tags

3. Stencils

4. Pipe Markers

1.2 RELATED SECTIONS

A. 23 2113 - Hydronic Piping

B. 23 3113 - Metal Ducts

C. 23 3116 – Non-Metallic Ducts

1.3 REFERENCES

A. BS 1710: Specification for identification of pipelines and services

B. BS 4800: Schedule of paint colours for building purposes

C. BS 5499: Safety Signs and colours

1.4 SUBMITTALS

A. Contractor to provide the following information as part of a complete and comprehensive technical

submittal:

1. List: Submit list of wording, symbols, letter size, and color coding for mechanical

identification.

2. Submit valve chart and schedule, including valve tag number, location, function, and valve

manufacturer's name and model number.

3. Provide manufacturers catalog literature for each product required.

4. Indicate special procedures, and installation.

5. Record actual locations of tagged valves.

B. Refer to the MEPF General Requirements and Scope of Work document for submittal procedure

and formats

1.5 COORDINATION

A. Coordinate installation of identifying devices with completion of covering and painting of surfaces.

B. Coordinate installation of identifying devices with locations of access panels and doors.

C. Install identifying devices before installing acoustical ceilings and similar concealment.

December 2019 230553 - Mechanical Identification Issued for Contract

Page 3 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

PART 2 - PRODUCTS

2.1 EQUIPMENT LABELS

A. Provide machine-engraved brass, black anodized aluminium or 3-Layer Laminated Plastic

nameplates to identify each major equipment item.

B. Minimum Label Size: Length and width vary for required label content, but not less than 2-1/2 by

3/4 inch (64 by 19 mm).

C. Lettering shall be black on white background, unless expressly specified otherwise.

D. Nameplates for major equipment shall be engraved in lettering 6 mm in height.

E. Uniquely identify such materials using a numbering system similar to that shown on the Drawings

for major equipment items. Uniquely list such materials in the Operating and Maintenance Manual.

F. Attach labels by instant adhesive or stainless steel rivets. Do not mount labels on removable

covers. Attach labels to valves with chromium plated brass chain.

2.2 TAGS

A. Plastic Tags: Laminated three-layer plastic with engraved black letters on light contrasting

background color. Tag size minimum 40 mm diameter.

B. Metal Tags: Brass with stamped letters; tag size minimum 40 mm diameter with smooth edges.

C. Tags to be secured with brass S−hook, and numbered consecutively in line with agreed protocol.

2.3 STENCILS

A. With clean cut symbols and letters of following size:

1. 40-50 mm Outside Diameter of Insulation or Pipe: 8 inch 200 mm long color field, 20 mm

high letters.

2. 65-150 mm Outside Diameter of Insulation or Pipe 300 mm long color field, 30 mm high

letters.

3. 200-250 mm Outside Diameter of Insulation or Pipe: 24 inch 600 mm long color field, 65

mm high letters.

4. Ductwork and Equipment: 65 mm high letters.

2.4 SERVICES IDENTIFICATION

A. Colour: Conform to BS 4800 or agreed equivalent international standard

B. Pipework and ductwork shall be identified by colour bands 150mm. wide or colour triangles of at

least 150mm/side. The bands or triangles shall be applied at termination points, junctions, entries

and exits of plant rooms, walls and ducts, and control points to readily identify the service, but

spacing shall not exceed 4.0 meters.

2.5 PIPEWORK IDENFICATION

A. Colour: Conform to BS 4800 or agreed equivalent international standard

B. Install plastic-laminated labels with permanent adhesive on all pipes and ducts.

C. Lettering size to be at least 38 mm high and the direction of flow shall be indicated by an arrow of

length 3 x diameter of pipe and its insulation.

December 2019 230553 - Mechanical Identification Issued for Contract

Page 4 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

D. Locate labels near points where ducts and pipes enter into concealed spaces and at maximum

intervals of 15 m in each space where ducts are exposed or concealed by removable ceiling

system.

E. Located pipe labels near control devices and each branch connection, excluding short takeoffs for

fixtures and terminal units. Where flow pattern is not obvious, mark each pipe at branch.

F. In addition to the colour bands specified above all pipework shall be legibly marked with black or

white letters to indicate the type of service and the direction of flow, identified as follows or using

the same designations or abbreviations as on the drawings. Text shall also indicate the pipe size,

and an arrow indicating flow direction:

1. High temperature hot water HTHW

2. Medium temperature hot water MTHW

3. Low temperature hot water LTHW

4. Chilled water CHW

5. Condenser water CONDW

6. Steam Steam

7. Condensate Condensate

8. Domestic hot water service HWS

G. Pipes shall have the letters ‘F’ and ‘R’ added to indicate flow and return respectively as

well as directional arrows.

2.6 PIPEWORK IDENTIFICATION

A. Colour: Conform to BS 4800 or agreed equivalent international standard

B. The size of the symbol will depend on the size of the duct and the viewing distance but the

minimum size should not be less than 150mm. length per side. One apex of the triangle shall point

in the direction of airflow.

C. Install plastic-laminated labels with permanent adhesive on all pipes and ducts.

D. Lettering size to be at least 38 mm high and the direction of flow shall be indicated by an arrow of

length 3 x diameter of pipe and its insulation.

E. Locate labels near points where ducts and pipes enter into concealed spaces and at maximum

intervals of 15 m in each space where ducts are exposed or concealed by removable ceiling

system.

F. Located pipe labels near control devices and each branch connection, excluding short takeoffs for

fixtures and terminal units. Where flow pattern is not obvious, mark each pipe at branch.

G. In addition to the colour bands specified above all pipework shall be legibly marked with black or

white letters to indicate the type of service and the direction of flow, identified as follows or using

the same designations or abbreviations as on the drawings. Text shall also indicate the pipe size,

and an arrow indicating flow direction:

1. Supply air SAD

2. Return air RAD

3. Fresh air FAD

4. Exhaust air EAD

5. Toilet Extract Duct TED

December 2019 230553 - Mechanical Identification Issued for Contract

Page 5 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

6. Smoke Extract Duct SED

7. Kitchen Exhaust KED

H. The colour banding and triangles shall be manufactured from self-adhesive cellulose tape,

laminated with a layer of transparent ethyl cellulose tape. All labels shall be UV resistant.

2.7 IDENTIFICATION OF PLANT

A. Each item of plant and equipment shall be labelled with a traffolyte or metal label indicating its

unique reference code as used in the operating and maintenance documentation.

B. The plant numbering system shall be agreed with the Engineer prior to the commencement of the

Works.

C. The plant numbering system shall be fully compatible with any existing numbering system.

D. All items of plant and equipment shall be provided with a manufacturer’s nameplate indicating the

plant type, reference, serial number, year of manufacturer, performance and electrical data.

E. Pressure vessels which have been hydraulically tested at the manufacturer’s works shall indicate

the test pressure, working pressure and date of test.

2.8 ASSET REGISTER

A. The contractor shall provide an asset register of all plant and equipment in electronic (Microsoft

Excel or Outut from Revit) of all plant and equipment. The register shall include the technical

particulars of the plant and the description shall match the plant labels provided on site.

2.9 WARNING SIGNS AND LABELS

A. Material and Thickness: Multilayer, multicolor, plastic labels for mechanical engraving, 1.6 mm

thick, and having predrilled holes for attachment hardware.

B. Letter Color: White

C. Background Color: Red

D. Minimum Label Size: Length and width vary for required label content, but not less than 64 by 19

mm.

E. Minimum Letter Size: 6.4 mm for name of units if viewing distance is less than 600 mm, 13 mm for

viewing distances up to 1830 mm, and proportionately larger lettering for greater viewing

distances.

F. Fasteners: Stainless-steel rivets or self-tapping screws

G. Adhesive: Contact-type permanent adhesive, compatible with label and with substrate.

H. Duct Label Contents: Include identification of duct service using same designations or

abbreviations as used on Drawings, duct size, and an arrow indicating flow direction.

I. Flow-Direction Arrows: Integral with duct system service lettering to accommodate both directions

or as separate unit on each duct label to indicate flow direction.

J. Lettering Size: At least 38 mm high

2.10 ANCILLARY EQUIPMENT LABELS

A. Tags shall be provided to identify and indicate the function of ancillary equipment such as gauges,

valves (isolating - including whether normally open or closed, balancing, regulating, check and

December 2019 230553 - Mechanical Identification Issued for Contract

Page 6 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

control), strainers, water flow measuring devices, flow switches, balancing and motorized dampers,

fire dampers or other equipment requiring periodic inspection.

B. Brass or black anodized aluminium nameplates to identify each of these items

C. Tags shall be stamped or engraved with 6.4 mm high lettering. The minimum size for labels shall

be 65 mm x 12 mm.

D. Valve-tag schedule shall be included in operation and maintenance data.

2.11 MOTOR CONTROL CENTERS

A. Equipment labels for 400 A or larger Motor Control Centers (MCCs) shall include equipment

designation, manufacturer’s name, type designation or other traceable identification number (to

enable the operator to obtain relevant information from the manufacturer), bus bar rating, fault

level, and duration of fault. Locate labels in a prominent position adjacent to the main switch.

B. Label each way of switchboards, distribution boards and motor control centers with phase and

circuit number.

C. Label motor starters with name and size of load.

D. Provide typed or stenciled schedules, listing circuit number, fuse/mcb rating, and service, for each

switchboard, distribution board and motor control centre. Insert into a plastic sleeve fixed on the

inside of the switchboard door.

E. Provide an as-installed single line drawing of the electrical distribution system, laminated and fixed

in the main switch room.

December 2019 230553 - Mechanical Identification Issued for Contract

Page 7 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

PART 3 - EXECUTION

3.1 INSTALLATION

A. Clean piping and equipment surfaces of substances that could impair bond of identification

devices, including dirt, oil, grease, release agents, and incompatible primers, paints, and

encapsulate.

B. Install or permanently fasten labels on each major item of mechanical equipment.

C. Locate equipment labels where accessible and visible.

3.2 EQUIPMENT LABEL INSTALLATION

A. Install or permanently fasten labels on each major item of mechanical equipment.

B. Locate equipment labels where accessible and visible.

3.3 PIPE LABEL INSTALLATION

A. Locate pipe labels where piping is exposed or above accessible ceilings in finished spaces;

machine rooms; accessible maintenance spaces such as shafts, tunnels, and plenums; and

exterior exposed locations as follows:

1. Near each valve and control device.

2. Near each branch connection, excluding short takeoffs for fixtures and terminal units.

Where flow pattern is not obvious, mark each pipe at branch.

3. Near penetrations through walls, floors, ceilings, and inaccessible enclosures.

4. At access doors, manholes, and similar access points that permit view of concealed piping.

5. Near major equipment items and other points of origination and termination.

6. Spaced at maximum intervals of 15 m along each run. Reduce intervals to 7.6 m in areas of

congested piping and equipment.

7. On piping above removable acoustical ceilings.

3.4 DUCT LABEL INSTALLATION

A. Locate labels near points where ducts enter into concealed spaces and at maximum intervals of

15 m in each space where ducts are exposed or concealed by removable ceiling system.

1. Near each grille, diffuser and control device.

2. Near each branch connection, excluding short takeoffs for fixtures and terminal units.

Where flow pattern is not obvious, mark each duct branch.

3. Near penetrations through walls, floors, ceilings, and inaccessible enclosures.

4. At access doors, manholes, and similar access points that permit view of concealed

ductwork

5. Near major equipment items and other points of origination and termination.

6. Spaced at maximum intervals of 15 m along each run. Reduce intervals to 7.6 m in areas of

congested ductwork and equipment.

7. On ductwork above removable acoustical ceilings.

December 2019 230553 - Mechanical Identification Issued for Contract

Page 8 of 9 Rev. 0

18-176 ATLANTIS THE PALM, AQUAVENTURE EXPANSION PHASE III

PALM JUMEIRAH, DUBAI, UAE

3.5 VALVE-TAG INSTALLATION

A. Install tags on valves and control devices in piping systems, except check valves; valves within

factory-fabricated equipment units; shutoff valves; faucets; convenience and lawn-watering hose

connections; and HVAC terminal devices and similar roughing-in connections of end-use fixtures

and units. List tagged valves in a valve schedule.

3.6 WARNING-TAG INSTALLATION

A. Write required message on, and attach warning tags to, equipment and other items where

required.

END OF SECTION 23 05 53

December 2019 230553 - Mechanical Identification Issued for Contract

Page 9 of 9 Rev. 0

You might also like

- 26 05 53 Identification For Electrical SystemsDocument3 pages26 05 53 Identification For Electrical SystemskaichosanNo ratings yet

- Pre Employment Health QuestionnaireDocument1 pagePre Employment Health Questionnairevaradarajck893No ratings yet

- Concrete Formwork Removal TimeDocument9 pagesConcrete Formwork Removal TimedrfkamalodeenNo ratings yet

- Oil Filter Cross Reference GuideDocument133 pagesOil Filter Cross Reference GuidePaulo ArrudaNo ratings yet

- Pex SpecsDocument24 pagesPex SpecsYazan TamimiNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- 21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesDocument43 pages21010-BAE-70000-In-SP-0028 Tech Spec For Inst. and Control CablesJignesh BanavaNo ratings yet

- ASTM D1655-20dDocument20 pagesASTM D1655-20dvaradarajck893No ratings yet

- JIG Bulletin-115-EI1584-qualified-equipmentDocument3 pagesJIG Bulletin-115-EI1584-qualified-equipmentvaradarajck893No ratings yet

- P 1-11 Storm Drainage PDFDocument11 pagesP 1-11 Storm Drainage PDFMahmoud GwailyNo ratings yet

- Roller ChainsDocument9 pagesRoller ChainsLister NambatacNo ratings yet

- Caltrain Thermite Rail Welding SpecificationsDocument7 pagesCaltrain Thermite Rail Welding SpecificationsPeem'zPlNo ratings yet

- GRP PipeDocument9 pagesGRP Pipesethu1091No ratings yet

- CommercialKitchenHoods PDFDocument8 pagesCommercialKitchenHoods PDFTaha NaeemNo ratings yet

- Fiberglass Piping Engineering Design ManualDocument36 pagesFiberglass Piping Engineering Design ManualdestresscallNo ratings yet

- "Circbase" - Steel Column Circular Base Plate Analysis: Program DescriptionDocument8 pages"Circbase" - Steel Column Circular Base Plate Analysis: Program Descriptionjigarshah21No ratings yet

- Clad-Lined Line PipeDocument21 pagesClad-Lined Line PipeAdvis100% (2)

- 2T X 18.1 Span ELK Hoist Data SheetDocument1 page2T X 18.1 Span ELK Hoist Data SheetNael SwedanNo ratings yet

- LGMG CMT96 Transmission Parts CatalogDocument84 pagesLGMG CMT96 Transmission Parts CatalogShaneNo ratings yet

- Endress+Hauser Flow MeterDocument110 pagesEndress+Hauser Flow Metervaradarajck893No ratings yet

- Repuestos Rexroth-AA4VG90DA2D2-32L PDFDocument36 pagesRepuestos Rexroth-AA4VG90DA2D2-32L PDFRafael RodriguezNo ratings yet

- Section 23 21 00 - Hydronic Valves and SundriesDocument22 pagesSection 23 21 00 - Hydronic Valves and Sundriesvaradarajck893No ratings yet

- Identification For Fire-Suppression Piping and EquipmentDocument5 pagesIdentification For Fire-Suppression Piping and EquipmentAlaa FouaniNo ratings yet

- Identification For Plumbing Piping and EquipmentDocument5 pagesIdentification For Plumbing Piping and EquipmentEN LeedNo ratings yet

- Mechanical IdentificationDocument6 pagesMechanical IdentificationObaidAliKhanNo ratings yet

- SECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesDocument4 pagesSECTION 15075 Mechanical Identification: 1-1/2 Inches 1.9 X 0.75 InchesMunir RasheedNo ratings yet

- Basic Mechanical Materials and MethodsDocument19 pagesBasic Mechanical Materials and MethodsLui TCC BariaNo ratings yet

- Paper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Document7 pagesPaper Supplies Store AT Berkat AL Awamer: Qatar International Islamic Bank (QIIB)Congson JeffNo ratings yet

- Identification For Fire-Suppression Piping andDocument6 pagesIdentification For Fire-Suppression Piping andMohammad SadikNo ratings yet

- Sans 677Document23 pagesSans 677eddy currentNo ratings yet

- NE04 020revpDocument30 pagesNE04 020revpMarlene Yuriserll Ruiz MuñozNo ratings yet

- Part 1 General 1.01 SummaryDocument5 pagesPart 1 General 1.01 Summaryআফজাল -উল ইসলাম নূরNo ratings yet

- Index: CD-3 Piping Design CriteriaDocument18 pagesIndex: CD-3 Piping Design Criteriapaulo_rieloffNo ratings yet

- CR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016Document5 pagesCR Architecture + Design Kroger J717 Indianapolis, IN CR# 516361 May 4, 2016abdullah amanullahNo ratings yet

- Shotcrete Specification SummaryDocument7 pagesShotcrete Specification SummaryJuanPaoloYbañezNo ratings yet

- Electrical Spec.'S Wiring Devices & Methods of Installation 16130-1Document9 pagesElectrical Spec.'S Wiring Devices & Methods of Installation 16130-1Waleed Abd El-HamiedNo ratings yet

- Identification For Fire-Suppression Piping and EquipmentDocument7 pagesIdentification For Fire-Suppression Piping and EquipmentdiribaNo ratings yet

- Section 03 37 13 - ShotcreteDocument7 pagesSection 03 37 13 - ShotcreteWilber Will Huillca Santa CruzNo ratings yet

- Installation Practices FOR Cable Raceway Systems: The Okonite CompanyDocument56 pagesInstallation Practices FOR Cable Raceway Systems: The Okonite CompanyharlyganNo ratings yet

- Technical Description PDFDocument40 pagesTechnical Description PDFJonathan HernandezNo ratings yet

- Pdvsa: Engineering Design ManualDocument7 pagesPdvsa: Engineering Design ManualAndresNo ratings yet

- Tech Specs For SS EquipmentDocument53 pagesTech Specs For SS EquipmentYasmin 2021No ratings yet

- Escription Uality Ssurance Ubmittals Pplicable UblicationsDocument5 pagesEscription Uality Ssurance Ubmittals Pplicable UblicationsEdsel Camiguing LoquillanoNo ratings yet

- Rev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidDocument14 pagesRev. NO. Date BY Checked MEI Lead MEI Approval Conoco Revision AA 09/13/00 EJL TD DJ KM MWJ Issued For BidThinh NguyenNo ratings yet

- Irrigation System Specs - Rev.0.1Document26 pagesIrrigation System Specs - Rev.0.1muhammad.civilNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- HVAC Identification GuideDocument91 pagesHVAC Identification GuidekareemNo ratings yet

- SECTION 03230 Post-Tensioned TendonsDocument11 pagesSECTION 03230 Post-Tensioned TendonsMohammed Misbahuddin AsifNo ratings yet

- Plumbing Systems ID MarkingsDocument3 pagesPlumbing Systems ID Markingsabdullah sahibNo ratings yet

- Mechanical IdentificationsDocument2 pagesMechanical Identificationshussam_98No ratings yet

- Method Statement - Installation of Conduits & Fitting - Rev 1Document16 pagesMethod Statement - Installation of Conduits & Fitting - Rev 1Muhammad IrfanNo ratings yet

- DX HVAC and Walk-In Refrigeration Piping ProjectDocument9 pagesDX HVAC and Walk-In Refrigeration Piping ProjectCedel AustriaNo ratings yet

- SECTION 26 05 53 Identification For Electrical SystemsDocument8 pagesSECTION 26 05 53 Identification For Electrical SystemsLuis BaqueNo ratings yet

- CBLCT-3.4 Cable TilesDocument11 pagesCBLCT-3.4 Cable Tilesdhayalasundaram5689No ratings yet

- SECTION 23 31 00 Hvac Ducts and CasingsDocument18 pagesSECTION 23 31 00 Hvac Ducts and CasingshtanhNo ratings yet

- Manufactured Traffic Calming DevicesDocument3 pagesManufactured Traffic Calming DevicesAnees RahmanNo ratings yet

- Hydrotech (SAP) 221214Document16 pagesHydrotech (SAP) 221214Yong QingNo ratings yet

- 16-02 - Fuel-Gas Filter SeparatorsDocument8 pages16-02 - Fuel-Gas Filter SeparatorsFolayemiNo ratings yet

- Rehabilitation of Sawfar Water Transmission Pipe Construction SpecificationsDocument34 pagesRehabilitation of Sawfar Water Transmission Pipe Construction Specificationsayaz hasanNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesDocument2 pagesITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesuddinnadeemNo ratings yet

- Bare Copper & Earthing Accessories SpecificationDocument14 pagesBare Copper & Earthing Accessories SpecificationJayantha SampathNo ratings yet

- Cast Iron Manhole Cover & GratingsDocument4 pagesCast Iron Manhole Cover & GratingsttshareefNo ratings yet

- Technical Specification For Compression Lugs and Links: Ergon Energy Corporation LimitedDocument11 pagesTechnical Specification For Compression Lugs and Links: Ergon Energy Corporation LimitedFadi Mohd ShaherNo ratings yet

- Electrical IdentificationDocument3 pagesElectrical IdentificationMohammed Hussain OMNo ratings yet

- Burried Piping SpecDocument9 pagesBurried Piping Specsada sivaNo ratings yet

- Owner: Project: Location: Group A: Group B: Subject: File No .Document10 pagesOwner: Project: Location: Group A: Group B: Subject: File No .Non Etabas GadnatamNo ratings yet

- gems v-3p0 exterior coatings for buried carbon steel pipingDocument14 pagesgems v-3p0 exterior coatings for buried carbon steel pipingMochamad TaufikNo ratings yet

- 2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Document202 pages2B P6 MVCC - RDSS - PGVCL - Infra SBD - Part 2 - TS - Version-2 - 28062022Mrugesh Samsung.m31sNo ratings yet

- Duct For Corrosive Fumes ExhaustDocument8 pagesDuct For Corrosive Fumes ExhaustTS WongNo ratings yet

- Thanh Phong - Ductwork Catalog Ver02Document52 pagesThanh Phong - Ductwork Catalog Ver02Phanhai Kaka100% (1)

- Specifications: Louvers - 08 91 00Document14 pagesSpecifications: Louvers - 08 91 00Persephone KylaNo ratings yet

- Stopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENDocument2 pagesStopac Outer Wrap PE PDS-Stopaq-Outerwrap-PE-V8-ENvaradarajck893No ratings yet

- Tank High Level Shut-Off Valve129-26-Data-Sheet-US - MetricDocument2 pagesTank High Level Shut-Off Valve129-26-Data-Sheet-US - Metricvaradarajck893No ratings yet

- AIRCRAFT REFUELER 8500 Gallons Specification - 8500g - CivilDocument2 pagesAIRCRAFT REFUELER 8500 Gallons Specification - 8500g - Civilvaradarajck893No ratings yet

- AE Bull 030512 Elev Recall Conventional UpdateDocument4 pagesAE Bull 030512 Elev Recall Conventional Updatevaradarajck893No ratings yet

- 15B SketchDocument1 page15B Sketchvaradarajck893No ratings yet

- Fueling Safety Standard Operating ProceduresDocument17 pagesFueling Safety Standard Operating Proceduresvaradarajck893No ratings yet

- 15A SketchDocument1 page15A Sketchvaradarajck893No ratings yet

- Risk Assessment and Safety Analysis For A Jet Fuel Tank Corrosion Recertification OperationDocument10 pagesRisk Assessment and Safety Analysis For A Jet Fuel Tank Corrosion Recertification Operationferdad4realNo ratings yet

- SBM Silo SBM Silo: High Levels High LevelsDocument1 pageSBM Silo SBM Silo: High Levels High LevelsVaradaraj CkNo ratings yet

- Maintenance and Repair of Airfield Apron Rigid PavementsDocument11 pagesMaintenance and Repair of Airfield Apron Rigid Pavementsvaradarajck893No ratings yet

- China For Covid-19Document3 pagesChina For Covid-19varadarajck893No ratings yet

- APP Carbon Grade Chart v6Document1 pageAPP Carbon Grade Chart v6Tashrif YusufNo ratings yet

- Piping Material Specification: Proposed Tank-Farm P R O J E C TDocument2 pagesPiping Material Specification: Proposed Tank-Farm P R O J E C Tvaradarajck893No ratings yet

- 22 56 13 - Solar CollectorsDocument23 pages22 56 13 - Solar Collectorsvaradarajck893No ratings yet

- Rolling Tower Scaffold Evaluation FormDocument1 pageRolling Tower Scaffold Evaluation Formvaradarajck893No ratings yet

- InsulationDocument31 pagesInsulationvaradarajck893No ratings yet

- VibrationDocument13 pagesVibrationvaradarajck893No ratings yet

- Hygienic TankDocument1 pageHygienic Tankvaradarajck893No ratings yet

- QT 2003-RF - Hot Water Boiler Installation and Solar Water Heater Installation PDFDocument3 pagesQT 2003-RF - Hot Water Boiler Installation and Solar Water Heater Installation PDFvaradarajck893No ratings yet

- Domestic Hot Water Calorifiers for Atlantis Palm Aquaventure ExpansionDocument6 pagesDomestic Hot Water Calorifiers for Atlantis Palm Aquaventure Expansionvaradarajck893No ratings yet

- Elec. Eqpt. For MECH. EqptDocument10 pagesElec. Eqpt. For MECH. Eqptvaradarajck893No ratings yet

- VocabularyDocument3 pagesVocabularyvaradarajck893No ratings yet

- Project Management GlossaryDocument9 pagesProject Management GlossaryMushtaq MalikNo ratings yet

- Project Management Professional HandbookDocument42 pagesProject Management Professional HandbookMirco SpagnoloNo ratings yet

- Build Program: Hydraulic Fluid Power B.VDocument12 pagesBuild Program: Hydraulic Fluid Power B.Vrakhikishore143No ratings yet

- A.C. Motors: Figure 5a - Exploded View of A.C. 3-Phase Induction MotorDocument6 pagesA.C. Motors: Figure 5a - Exploded View of A.C. 3-Phase Induction MotorJB 1922No ratings yet

- Bearing Puller 1Document10 pagesBearing Puller 1Ashna WaseemNo ratings yet

- 13 Afco - BV01 SeriesDocument5 pages13 Afco - BV01 Seriesafie pio pioNo ratings yet

- Structural Engineer's Handbook for Steel DesignDocument209 pagesStructural Engineer's Handbook for Steel DesignAnkur JainNo ratings yet

- Full Tilt Feller PDFDocument13 pagesFull Tilt Feller PDFViniciusCamargosNo ratings yet

- Katalog Pesawat #Rev3Document13 pagesKatalog Pesawat #Rev3Wataru Ardhy MizunoNo ratings yet

- Compact GM 80 vacuum cleanerDocument2 pagesCompact GM 80 vacuum cleanertylerdurdaneNo ratings yet

- Chapter 52 - Spread Sheet of Calculations Structural Design of Flexible Conduits Part 636 STR Eng - NEH June 2005Document51 pagesChapter 52 - Spread Sheet of Calculations Structural Design of Flexible Conduits Part 636 STR Eng - NEH June 2005Andri DoemeriNo ratings yet

- Butterfly Single-Head Machine Parts BookDocument30 pagesButterfly Single-Head Machine Parts BookCambridge GTNo ratings yet

- Resource: Sheepshank SheepshankDocument3 pagesResource: Sheepshank SheepshankKeanu100% (1)

- UTE Beam ContinuationDocument14 pagesUTE Beam ContinuationmichaelNo ratings yet

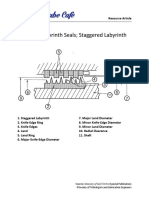

- Typical Labyrinth Seals Staggered Labyrinth: Resource ArticleDocument2 pagesTypical Labyrinth Seals Staggered Labyrinth: Resource ArticleKanchana WeerasingheNo ratings yet

- Analysis of Doubly Reinforced Concrete BeamDocument4 pagesAnalysis of Doubly Reinforced Concrete BeamAnton_Young_1962No ratings yet

- Electro-Polished Detachable Battery Unit For Easy CleaningDocument2 pagesElectro-Polished Detachable Battery Unit For Easy CleaningIker BasqueAdventureNo ratings yet

- JK Cement EngDocument20 pagesJK Cement EngAlvaroNo ratings yet

- SpecialtyDocument16 pagesSpecialtyarduanaNo ratings yet

- Other Projects - Ut3Document7 pagesOther Projects - Ut3api-261139685No ratings yet

- Standard Specification For Woven Wire Test Sieve Cloth and Test Sieves ASTM E11 - 15Document1 pageStandard Specification For Woven Wire Test Sieve Cloth and Test Sieves ASTM E11 - 15yuliaNo ratings yet

- (STD SCG 006 r1) Standard Self Closing Balustrade GateDocument1 page(STD SCG 006 r1) Standard Self Closing Balustrade GateAdi SantosoNo ratings yet

- Series W706 Ags Butterfly Valves (300 Psi/2065 Kpa) : Product DescriptionDocument6 pagesSeries W706 Ags Butterfly Valves (300 Psi/2065 Kpa) : Product DescriptionTushar LanjekarNo ratings yet

- Series F GEN-3 - 2019 - V7 - 1Document6 pagesSeries F GEN-3 - 2019 - V7 - 1Prathamesh Pradeep MashilkarNo ratings yet

- Secure and stable lowering with DLHV valveDocument2 pagesSecure and stable lowering with DLHV valveEdwing GuerreroNo ratings yet