Professional Documents

Culture Documents

Optimization of Ammonia Absorption Using Acid Spray Wet Scrubbers

Uploaded by

Song Nguyen NguyenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of Ammonia Absorption Using Acid Spray Wet Scrubbers

Uploaded by

Song Nguyen NguyenCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/262297103

Optimization of Ammonia Absorption Using Acid Spray Wet Scrubbers

Article in Transactions of the ASABE (American Society of Agricultural and Biological Engineers) · February 2014

DOI: 10.13031/trans.57.10481

CITATIONS READS

14 4,511

3 authors:

Lara Jane Sebuc Hadlocon Roderick Manuzon

The Ohio State University 18 PUBLICATIONS 136 CITATIONS

16 PUBLICATIONS 70 CITATIONS

SEE PROFILE

SEE PROFILE

Lingying W. Zhao

The Ohio State University

75 PUBLICATIONS 409 CITATIONS

SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Pesticide spray drift View project

Modeling fluxes, fate and transport of ammonia emission from egg production and manure management facilities. View project

All content following this page was uploaded by Lara Jane Sebuc Hadlocon on 10 October 2014.

The user has requested enhancement of the downloaded file.

OPTIMIZATION OF AMMONIA ABSORPTION

USING ACID SPRAY WET SCRUBBERS

lục giác bất lợi

L. S. Hadlocon, R. B. Manuzon, L. Y. Zhao

nghịch đảo

ABSTRACT. Packed-bed wet scrubbers are effective for abatement of ammonia (NH3) emissions from animal feeding op-

erations (AFOs) but result in high air resistance. Spray scrubbers generally have relatively low air resistance and high

NH3 removal potential. This study aimed to develop a spray scrubber module (SSM) through optimization of the design

and operating parameters of spray scrubbing for recovering NH3 emissions from the exhaust air streams of animal facili-

ties. The design parameters, including nozzle type, scrubber column size and geometry, and number of stages of the spray

scrubber module, were optimized. Effects of operating parameters such as acid concentration, superficial air velocity,

retention time, and inlet NH3 concentration were quantified. Superficial air velocity adversely affected scrubber perfor-

mance significantly due to its direct relationship with air residence time. The inlet NH3 concentration was inversely pro-

portional to the scrubber efficiency. The SSM was optimized as a hexagonal scrubber column with a diameter of 45.7 cm

(18 in.) equipped with three stages of PJ40 spray nozzles, spraying 1% (w/v) H2SO4 scrubbing liquid counter-current to

the exhaust air stream with superficial gas velocity of 3 to 4 m s-1, equivalent to air retention times of 0.55 to 0.41 s. The

SSM recovered about 91% of the NH3 at an operating liquid pressure of 0.51 MPa, a superficial air velocity of 4 m s-1,

and an inlet NH3 concentration of 30 ppmv when operated with a single stage of spraying. For high inlet NH3 concentra-

tion of 100 and 400 ppmv, the SSM was able to reduce NH3 by 86% and 74%, respectively, when operated at a maximum

pressure of 0.62 MPa with three stages of spray nozzles and a superficial air velocity of 4 m s-1. The pressure drop of the

spray scrubber was mainly caused by the mist eliminator. The total static pressure drop of the SSM was under 15 Pa when

the air velocity ranged from 2 to 4 m s-1. The results of this study demonstrate that acid spray scrubbers could be a very

effective and feasible NH3 mitigation technology for U.S. animal farms.

Keywords. Acid spray wet scrubber, ammonia emissions, ammonia absorption, wet scrubber, nitrogen fertilizer.

A

mmonia (NH3) is associated with both environ- larger than 45 kg within a 24 h period. In recent years, NH3

mental and health impacts (NRC, 2002). It con- has been given serious attention due to its role as a precur-

tributes to the generation of fine particulate mat- sor in the formation of PM2.5, a criteria pollutant regulated

ter of ≤2.5 μm aerodynamic size (PM2.5), eu- through the National Ambient Air Quality Standards

trophication of surface water, formation of haze, and acidi- (NAAQS). Mitigating NH3 emissions is thus important not

fication of the ecosystem (Ndegwa et al., 2008). It has only the protection of human health and the environment

physiological impacts on the respiratory and cardiovascular but also the sustainability of animal agriculture in the U.S.

health of humans, as well as on the reproduction and ener- as animal producers are becoming vulnerable to lawsuits

getic efficiencies of animals in barns (Beker et al., 2004; and new air regulations.

Homidan et al., 2003; WHO, 2005). Animal agriculture Current NH3 abatement strategies include improvement

contributes about 81% of NH3 emissions to the atmosphere, of feed management, housing ventilation, manure storage

corresponding to about 2.4 million tons of NH3 in 2002 management, and treatment of the exhaust air (Melse et al.,

(USEPA, 2004). NH3 is not a regulated air pollutant by the 2009; Ndegwa et al., 2008). Although significant efforts

U.S. Environmental Protection Agency (USEPA) under the have been made to improve housing design, climate condi-

Clean Air Act but is required to be reported under the tions, animal diet, and manure removal and handling sys-

Emergency Planning and Community Right-to-know Act tems (Philippe et al., 2011), mitigation technologies for

(EPCRA) (USEPA, 2009) if the farm-level emission rate is NH3 emissions from the exhaust fans of large AFOs are

still in the development stage. The off-the-shelf NH3

abatement techniques used on European AFOs include bio-

trickling filters, bio-scrubbers, packed-bed acid scrubbers,

Submitted for review in October 2013 as manuscript number SE and water curtains, among which bio-trickling filters

10481; approved for publication by the Structures & Environment

Division of ASABE in February 2014. showed 35% to 90% NH3 removal efficiencies, while acid

The authors are Lara Jane S. Hadlocon, ASABE Member, Graduate packed-bed scrubbers reached 90% to 99% for treatment of

Student, Roderick B. Manuzon, Research Associate, and Lingying inlet NH3 concentrations ranging from 8 to 29 ppmv (Melse

Zhao, ASABE Member, Associate Professor, Department of Food,

Agricultural, and Biological Engineering, The Ohio State University,

and Ogink, 2005).

Columbus, OH 43210-1057. Corresponding author: Lingying Zhao, Packed-bed scrubbers are widely used in Europe for re-

590 Woody Hayes Dr., Columbus, OH; phone: 614-598-8958; phone: duction of NH3 emissions because of their high efficien-

614-292-2366; e-mail: zhao.119@osu.edu.

Transactions of the ASABE

Vol. 57(2): 647-659 © 2014 American Society of Agricultural and Biological Engineers ISSN 2151-0032 DOI 10.13031/trans.57.10481 647

cies. However, this type of scrubber has high air resistance droplets. Figure 1 shows a schematic of the process. Spray

or pressure drop. Packed-bed scrubbers also become easily nozzles are used to generate liquid droplets, which provide

clogged with dust accumulation, which consequently re- surface area for chemical reaction. The spray droplets hit

duces their efficiency. Shah et al. (2008) developed a re- the scrubber walls and form a liquid film, another surface

generating scrubber to reduce NH3 emissions using an end- area for chemical reaction. The greater the surface area for

less polypropylene screen in contact with an alum solution chemical absorption is, the higher the efficiency that can be

that achieved 58% efficiency and a considerable pressure achieved. Spray droplets can either ascend or descend in

drop of approximately 110 Pa. Spray scrubbers are promis- the scrubber column. The majority of larger droplets move

ing as they do not significantly affect the ventilation system down counter-currently against the airflow, while some

due to their low backpressure on fans and the benefit of smaller droplets can be potentially entrained by air flowing

utilizing the effluent as an N fertilizer for crops (Manuzon up. Typically, spray scrubbers operate in a closed loop in

et al., 2007). In the U.S., reports on the use of scrubbers are which the sprayed liquid is collected in a tank and recircu-

limited, and studies are still being conducted on application lated back to the spray nozzles using pumps. Spray scrub-

of wet scrubbers in animal facilities. Manuzon et al. (2007) bers are also equipped with a mist eliminator or demister to

experimentally simulated spray scrubbing operation using a recover entrained droplets, while much finer droplets,

prototype designed for a 0.61 m (24 in.) axial fan. The smaller than the cutoff size of the demister, exit the scrub-

scrubber achieved an NH3 removal efficiency of 35% ±1% ber.

with counter-current single-stage operation using a full- During the process, NH3 is absorbed in the dilute acidic

cone PJ20 nozzle operated at a pressure of 0.62 MPa (90 solution and converted to its reduced form (NH4+) through

psig), an air retention time of 0.2 s or airflow speed of 6.6 m the principle of gas absorption with chemical reaction. The

s-1, and an inlet NH3 concentration of 30 ppmv. A multi- equilibrium reactions for NH3 solubility in acidic solutions

stage scrubbing simulation using three nozzles resulted in are (Melse and Ogink, 2005; Swartz et al., 1999):

scrubber efficiencies of 60% ±1%, 45% ±3%, and 27% H

±2% for inlet NH3 concentrations of 10, 30, and 100 ppmv, NH3( g ) ⇔ NH3( aq ) (1)

respectively, with a backpressure of 27.5 Pa on the fans

(Manuzon et al., 2007). The above simulation of spray k ′f , kr′

scrubbing encountered the following problems: droplet NH3( aq ) + H +aq ⇔ NH 4+ aq Keq

( ) ( )

′ ( ) (2)

interaction (droplet coagulation and breakage), limited ben-

eficial effects of multi-stage scrubbing, air leakage from Equation 1 describes the solubility of NH3 in water,

non-uniform spray coverage, low efficiency, and a narrow where H is the Henry’s law constant, estimated to be 5.33 ×

inlet NH3 concentration range that did not cover many 101 M atm-1 at 298.15 K, which is relatively high compared

practical application conditions. There is therefore a need to other gases such as CO2, CH4, and H2S with H values of

to improve and further optimize spray wet scrubbing tech- 3.47 × 10-2, 1.5 × 10-3, and 1.0 × 10-1 M atm-1, respectively

nology for practical application in animal facilities.

(Sander, 1999). The equilibrium constant (K′eq) in equa-

In this work, we aimed to optimize a spray scrubber

tion 2 is equal to the ratio of the rate constants of the for-

module (SSM) for high NH3 absorption efficiency with a

ward and reverse reactions and can be written as:

wider range of exhaust air stream conditions expected in

most AFOs. The specific objectives of this study were to:

(1) optimize the design parameters of an SSM including

selection of appropriate spray nozzle type and operating

pressure, nozzle position, and scrubber diameter and geom-

etry to minimize spray droplet interaction and improve NH3

absorption efficiency; (2) evaluate the effects of operating

parameters and environmental conditions on NH3 removal

performance, including acid concentration of the scrubbing

liquid, superficial air velocity and air retention time, inlet

NH3 concentration, air temperature, and number of spray

stages; (3) quantify the performance of the optimized SSM

for exhaust air streams with both low and high NH3 con-

centrations; and (4) determine the static pressure drop of

the scrubber on fans to assess the feasibility of the scrub-

ber’s application on farms.

MATERIALS AND METHODS

PRINCIPLE OF NH3 ABSORPTION IN

AN ACID SPRAY WET SCRUBBER

In a spray wet scrubber, NH3-laden air reacts counter-

currently with a dilute acidic solution in the form of liquid

Figure 1. Schematic of a typical counter-current spray scrubber.

648 TRANSACTIONS OF THE ASABE

NH +4 (aq ) NH3 concentration (KG), air temperature (T), and number of

′ =

K eq (3) scrubbing stages (G/L). The nozzle operating pressure is

NH 3(aq ) H (aq )

+ also an important parameter, as it directly affects the drop-

let size and distribution, as well as the liquid flow rate.

where [NH4+(aq)], [NH3(aq)], and [H+(aq)] are the concentra- The droplet size is mainly affected by the nozzle type,

tions of each component. The equilibrium constant (K′eq) which is chosen to provide a good balance of liquid flow

can be derived as the reciprocal of the acid dissociation rate and nozzle operating pressure. To study the effect of

constant of NH4+ and has a value of 1.78 × 109 at 25°C, the gas-to-liquid ratio, the scrubber diameter, which direct-

favoring forward reaction (Perrin, 1969). ly affects the gas flow rate, as well as the number of spray

The overall solubility can be expressed in terms of the stages, which is directly related to the liquid flow rate, are

effective Henry’s law constant (H*, M atm-1), as represent- considered. The type of nozzle to be used can also affect

ed by the sum of the dissolved NH3(aq) and protonated this ratio when the nozzle is operated at different pressures.

NH4+(aq), as shown in equation 4 (Swartz et al., 1999): The relative velocity of the droplets with respect to the air-

flow is evaluated by varying air velocity, which significant-

{ NH 3(aq )

+

+ NH 4( }

aq ) = H pNH 3

* ly affects the retention time of air in the scrubber. The mass

transfer coefficient or diffusion rate of NH3 in air can be

= NH3(g ) RTH * (4) evaluated by varying the inlet NH3 concentration and inves-

mặt phân cách tigating its temperature dependence, although the absorp-

( ′ H+

= NH3(g ) H 1 + K eq

) tion is also limited by the effective Henry’s law constant,

which is correlated with the acid concentration in the

where pNH3 is the partial pressure of NH3 (atm), T is the air scrubbing liquid. The scrubber geometry is considered for

temperature (K), and R is the gas constant (atm M-1 K-1). the practical aspects of the design, but it is also reported to

indirectly affect the absorption rate due to its effectiveness

SINGLE-STAGE SCRUBBER PERFORMANCE MODEL in providing better gas-liquid mixing in the scrubber.

A performance model of counter-current gas absorption

in a wet scrubber was developed by Calvert and Englund MULTI-STAGE SCRUBBER PERFORMANCE MODEL

(1984) based on material balance. The model (eq. 5) was The efficiency of a multi-stage scrubber can be estimat-

further generalized by Manuzon et al. (2007) assuming an ed based on the single-stage efficiency using the concept of

empirical relationship for the interfacial area provided by penetration for control devices in series. Assuming that

spray droplets per unit volume of the scrubber: there is no strong interaction among liquid droplets be-

tween stages to cause variation in the scrubbing efficiency

G for each stage (De Nevers, 2000), the efficiency for n-stage

1 − H * scrubbing can be predicted using equation 6:

η = 1− L

(5)

6 RTKG Z N L G n

exp − H * − H *

ηoverall = 1 − (1 − η1− stage ) (6)

3

ΔuD2 G L

where n is the number of stages, ηoverall is the total collec-

where η is the collection efficiency, H* is the effective Hen- tion efficiency of the n stages, and η1-stage is the scrubber

ry’s law constant, G is the moles of air per unit time and efficiency of one stage.

unit tower cross-section (mol air s-1 m-2), L is the molar

flow rate of the NH3-free liquid stream per unit cross- SPRAY SCRUBBER LABORATORY SIMULATION UNIT

sectional area of the tower (mol water s-1 m-2), R is the uni- The spray scrubber laboratory simulation unit used in

versal gas constant (8.314 J mol-1 K-1), T is the absolute air this study is shown in figure 2. It consisted of five sections:

temperature (K), KG is the individual mass transfer coeffi- an air mixing chamber, scrubbing column, spraying system,

cient of NH3 in air (moles NH3 s-1 m-2 Pa-1), ZN is the col- mist eliminator (or demister), and instrumentation. The air

umn length for liquid-gas contact (m), Δu is the relative mixing chamber was used to simulate the exhaust air

velocity between the droplets and the airflow (m s-1), and streams of various animal buildings with different air ve-

D32 is the Sauter mean diameter of spray droplets (m). locities and NH3 concentrations. It was equipped with an

This model is limited to assumptions that the droplet NH3 tank, a transition section for inlet air, a mixing section,

sizes are described only by their mean diameter, the drop- and a ventilation fan. A perforated 0.64 cm pipe was con-

lets have uniform velocity traveling vertically, and the nected to a commercial anhydrous NH3 tank through a

scrubber is operated without recirculation. Sensitivity anal- flow-regulated gas line to deliver different levels of NH3

ysis showed that the main variables that affect scrubber into the chamber. Desired concentrations of NH3 in the air

performance in decreasing order are KG, D32, G/L, Δu, and were achieved by regulating the flow of NH3 into the

ZN (Manuzon et al., 2007). These parameters are both di- chamber. The air mixing chamber was a 40 cm × 40 cm

rectly and indirectly affected by the design parameters of rectangular wooden duct with a length of 91 cm to fully

the scrubber, such as the nozzle type (D32), nozzle position stabilize the airflow before it reached the scrubber. A

(ZN), scrubber diameter (G/L), and scrubber geometry, and 35.6 cm variable-speed axial fan (AT14Z, Aerotech, Inc.,

also by operating parameters such as the acid concentration Mason, Mich.) was used to create airflow resembling the

in the liquid phase (H*), superficial air velocity (Δu), inlet exhaust air stream of a commercial animal facility. The

khan, không ngậm

nước

57(2): 647-659 649

Legend:

Liquid Line Signal Gate Valve P Pressure Gauge

Gas Sampling Line Electrical Wire Pressure Relief Fl Liquid Flow Meter

hình lục giác Valve

Ammonia Line Pump Mixer Fg Gas Flow Meter

Figure 2. Schematic of the laboratory simulation unit for the spray wet scrubbing process.

NH3-laden air was diverted using a 90° elbow toward the relative humidity, as described in the next section. The di-

vertical scrubber column, which had enclosed spray nozzles mensions of the spray column and air mixing chamber and

and liquid pipes. The scrubber column had a starting equiv- static pressure measurement locations in the scrubber are

alent diameter of 35.6 cm and could be easily modified shown in figure 3.

using flange connections to vary the scrubber settings, such

as the number of spray stages, the scrubber column diame- NOZZLE SELECTION AND OPERATING CONDITIONS

ter, and the scrubber geometry. Figure 2 also shows a pho- The choice of appropriate spray nozzles or atomizers is

tograph of the simulation unit with a hexagonal scrubber critical for the optimization of spray scrubber performance.

column installed. The scrubber column can contain a max- The spray used for wet scrubbers can be characterized

imum of three stages of spray nozzles, which are spaced based on its droplet size and concentration, dispersion, ini-

55 cm apart. The position of the nozzle in the scrubber, as tial droplet velocity, spray angle, and spray pattern

well as the spacing between nozzles, was designed to be at (Lefebvre, 1989). The droplet size generated by the atomiz-

least 30.5 cm, which is the spray height of the PJ40 nozzles ers has significant impact on the surface area needed to

used in this study (BETE, 2013). enhance gas-liquid contact for the chemical absorption pro-

The spraying system delivered a prepared solution of di- cess. The total surface area is dictated by the concentration

lute sulfuric acid (H2SO4) into each nozzle stage from a of droplets inside the scrubber column. Dispersion refers to

114 L feed tank through a magnetically driven pump with a the volume of liquid within the spray given a certain period

rated pressure range of 0 to 0.7 MPa. A pressure relief of time, or the ratio of spray volume to the liquid volume

valve was used to regulate the pressure and liquid flow rate contained in it. This property is also driven by the spray

supplied to the tank. The liquid droplets of known concen- angle, which is the angle formed after the spray is dis-

tration of H2SO4 interacted with the NH3-laden air in coun- charged from the orifice. Good spray dispersion promotes

ter-current mode inside the scrubber column. The cleaner good mixing of the liquid with the surrounding gas, which

exhaust air passed through a commercial mist eliminator helps promote contact; however, the rate of evaporation is

(T-271 vertical flow mist eliminator, Munters Corp., Ft. consequently high. Patternation is another important prop-

Myers, Fla.) made of polypropylene that collected tiny liq- erty that refers to the symmetry of the spray pattern, which

uid droplets entrained by the air. The demister utilized a 9° is necessary for good liquid-gas mixing and process effi-

transition of the airflow to slow down and accumulate en- ciency.

trained droplets and allow them to drain down the inside The two types of spray pattern examined in this study

surfaces of the scrubber. This drainage was recycled back were hollow cone and full cone. Hollow-cone nozzles gen-

to the tank using a recycle pump and was pumped back into erate a ring pattern of spray liquid on the outside of the

the spray nozzles with the feed pump. The entire scrubber cone. This is typically used to gain good penetration and

system was installed with appropriate instrumentations to coverage, and it generates the smallest droplets (Lefebvre,

monitor pH, electrical conductivity, liquid temperature, 1989). Hollow-cone nozzles were also expected to generate

NH3 concentration, pressure drop, and air temperature and droplets that were concentrated closer to the wall. This

650 TRANSACTIONS OF THE ASABE

0.36m -

0.46 m

0.15 m Demister

ΔPs after the

scrubber column or

before demister

0.55 m

Scrubber

2.12 m Column

0.55 m

0.55 m

ΔPs after the

divergence section

0.25 m ΔPs after Total

the elbow Scrubber Axial Air Mixing Entrance Air

ΔPs before ΔPs Fan Chamber Transition

the elbow

0.66 m

0.40 m 0.45 m

0.91 m

Anhydrous

1.82 m 0.81 m 0.30 m 1.10 m 0.42 m NH3 Tank

Note: ΔPs refers to the differential static pressure with respect to ambient static pressure.

Figure 3. Dimensions of the spray scrubber simulation setup and static pressure measurement locations.

would allow some of the droplets to turn into a liquid film fication and produces larger droplets and liquid flow rate

on the wall, thereby lowering the concentration of droplets compared with other PJ nozzles at a given operating pres-

responsible for providing surface area for the chemical re- sure. Therefore, PJ40 was chosen in this study for high NH3

action. A full-cone nozzle produces droplets that occupy concentration applications. In addition, the AAP01 nozzle

the full cone and generally generates much larger droplets (Ikeuchi USA, Inc., West Chester, Ohio) was chosen as the

as compared to a hollow-cone nozzle for a given nozzle hollow-cone counterpart of the PJ40 nozzle, as both noz-

type. zles do not differ much in liquid flow rate at a given pres-

Manuzon et al. (2007) conducted a preliminary analysis sure. The performances of these nozzles in NH3 absorption

of different nozzles for their application in spray scrubbers. were compared to the PJ20 nozzle studied by Manuzon et

Two full-cone nozzles (PJ15 and PJ20) and two hollow- al. (2007) by obtaining the efficiency of each nozzle at var-

cone nozzles (UM300 and L40) were studied, and the re- ying pressure from 0.21 to 0.62 MPa. A summary of the

sults showed that maximum efficiencies of 35% ±1% and characteristics of the nozzles is shown in table 1. There was

31% ±1% were achieved using the PJ20 and L40 nozzles, much preference for using a full-cone nozzle over a hol-

respectively. The increase with pressure in the ratio of liq- low-cone nozzle, but the practical significance associated

uid flow rate to droplet size enhanced the scrubber efficien- with the bigger orifice size of the AAP01 nozzle, which is

cy linearly for all nozzles, but not quite significantly for the beneficial to reduce nozzle clogging, warranted a study of

hollow-cone nozzle L40 nozzle, from which it was con- its performance on NH3 scrubbers.

cluded that hollow-cone nozzles need additional flow to

meet the same performance as full-cone nozzles. The PJ40 MEASUREMENT AND INSTRUMENTATION

nozzle (BETE Fog Nozzle, Inc., Greenfield, Mass.) is part Gas-Phase Measurements

of the same group of full-cone nozzles under the PJ classi- Ammonia concentrations were measured both at the in-

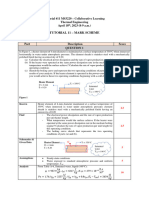

Table 1. Characteristics of the nozzles used for scrubber optimization.

PJ20 Nozzle PJ40 Nozzle AAP01 Nozzle

Operating pressure (MPa) 0.21 0.41 0.62 0.21 0.41 0.62 0.21 0.41 0.62

Spray capacity (L min-1) 0.21 0.31 0.37 0.78 1.00 1.21 0.95 1.24 1.65

Sauter mean diameter (μm) 100 80 74 122 100 90 329 274 250

Spray angle (°) 168 139 137 107 107 112 99 82 87

Spray height (cm) 15.5 30.5 11.4

Orifice diameter (μm) 50 100 200

Spray pattern Full cone Full cone Hollow cone

57(2): 647-659 651

let and outlet ports of the scrubber using a photo-acoustic Liquid conductivity determined the amount of electro-

NH3 analyzer (Chilgard RT NH3 analyzer, MSA, Inc., lytes in the solution; however, it was not specific and re-

Pittsburgh, Pa.) with an accuracy of ±2 ppmv that was cali- sponded both to the scrubbing solution and the byproducts

brated for NH3 in the range of 0 to 100 ppmv for low NH3 of scrubbing, such as (NH4)2SO4. Conductivity was meas-

concentration measurement (<30 ppmv) and in the range of ured with a conductivity probe (CDTX-45P, Omega Engi-

0 to 1000 ppmv for high NH3 concentration measurement neering Inc.) that used a four-electrode system to compen-

(100 to 400 ppmv). The sensor could operate at a tempera- sate for fouling effects. It had an accuracy of ±3% of the

ture range of 0°C to 50°C and relative humidity range of span (±0.1 μS) and a response time of 12 s. It was connect-

0% to 95% and produce 90% of the response within 70 s ed to a separate transmitter (CDTX-45, Omega Engineering

after detecting a step change in the input concentration. Inc.) with 4 to 20 mA output that could display a range of

Sample air was drawn into the photo-acoustic sensor at a conductivity values from 0.0 μS to 2000 mS.

minimum flow rate of 0.75 L min-1 through a particulate Liquid pressure and flow rate were consistently moni-

filter and a solenoid valve. tored. Pressure values were manually read from a liquid-

Temperature and relative humidity (% RH) were meas- filled stainless steel pressure gauges (Fertilizer Dealer Sup-

ured using weatherproof data loggers (HOBO U23 Pro, ply, Anna, Ohio), while liquid flow rate was monitored

U23-001, Onset Computer Corp, Bourne, Mass.) with built- using a polysulfone flowmeter with ±2% F.S. accuracy

in sensors. The accuracies of the temperature and RH sen- (VFA Visi-Float flowmeter, Dwyer Instruments, Inc.,

sors are ±0.21°C from 0°C to 50°C (±0.38°F from 32°F to Michigan City, Ind.).

122°F) and ±2.5% from 10% to 90% RH, respectively.

Both sensors have 90% response within 5 min in air mov- AMMONIA REMOVAL EFFICIENCY

ing at 1 m s-1. The sensors were set to log data every 2 min The scrubber’s ammonia removal efficiencies for the la-

during the field experiment. boratory simulation and the field tests were calculated us-

Air speed was measured periodically using a velocity ing equation 7:

meter (VelociCalc 8345, TSI, Inc., Shoreview, Minn.). The

scrubber column was traversed using the log-Tchebycheff C NH3 ,in − C NH 3 ,out

Efficiency ( % ) = × 100 (7)

method (ASHRAE, 2009). The airflow rate was calculated C NH 3 ,in

by multiplying the average air speed with the cross-

sectional area of the scrubber column. where CNH3,in and CNH3,out are the concentrations of NH3 at

Total static pressure drop caused by the entire scrubber the inlet and outlet ports of the scrubber, respectively.

and by different components of the scrubber was measured

at the locations indicated in figure 3 using a manometer EXPERIMENTAL DESIGN

(Durablock 115-AV, Dwyer Instruments, Inc., Michigan In exploring the effect of different design and operating

City, Ind.). Differential static pressure was determined parameters, one-factor-at-a-time (OFAT) experiments were

across the 90° elbow, divergence section, scrubber column conducted using the high-performing nozzle based on the

with spray, and demister. The pressure drop caused by the nozzle optimization results. Table 2 summarizes the treat-

demister at different air velocities was obtained from the ment factors and the levels that were investigated. The ef-

manufacturer’s specifications for the mist eliminator fects of both design parameters (tests 1 and 2) and operat-

(Munters, 2006). The total static pressure was calculated ing parameters (tests 3 to 7) on scrubber efficiency were

based on the accumulated pressure drop or gain of each investigated. The scrubber was operated at a superficial air

component. velocity of 5 m s-1 except for test 4, where the air velocity

was varied. The feed pump was operated at a nozzle pres-

Liquid-Phase Measurements sure of 0.62 MPa for tests 1 to 6; for test 7, the pump was

Scrubbing liquid pH was the primary measurement for only operated at 0.55 MPa. The inlet NH3 concentration

the acidity of the solution. It was controlled and monitored was set to 30 ppmv for most tests, except for tests 1 and 5.

using a pH controller and transmitter (PHCN-961, Omega Test 1 had additional runs for an NH3 concentration of

Engineering, Inc., Stamford, Conn.) with a range of -2 to 200 ppmv, while test 5 had varied concentrations at differ-

16 pH and an accuracy of ±0.01 pH. The controller can be ent levels. All experiments were conducted in the laborato-

operated from -10°C to 50°C (14°F to 122°F). The data ry with a room air temperature of 20°C to 25°C and relative

were obtained from the 4 to 20 mA analog output of the humidity of 20% to 70%. One-factor-at-a-time (OFAT)

controller using an Onset data logger. The sensing elec-

trode for pH was an in-line flat-surface electrode (PHE-

5460, Omega Engineering, Inc.) that can be used in appli- Table 2. Summary of treatments and levels.

cations with temperatures of 0°C to 88°C (32°F to 190°F) Test Treatment Levels

1 Scrubber diameter (cm) 35.6, 45.7, 61.0

and up to 100 psig pressure. Due to the exposure of the

2 Scrubber geometry Circle, square, hexagon

probe to acidic conditions, it was calibrated every week. 3 H2SO4 concentration in the 0.0, 0.2, 0.4, 0.6, 0.8, 1

Liquid samples were also brought to the laboratory for sec- scrubbing liquid (% w/v)

ondary pH measurement to ensure accuracy. Measurement 4 Superficial air velocity (m s-1) 2, 3, 4, 5, 5.3

of the pH of these samples was done using a bench-scale 5 Inlet NH3 concentration (ppmv) 10, 20, 30, 50, 80,

100, 200, 300, 400

pH meter (Thermo Fisher Scientific, Hannover Park, Ill.), 6 Air temperature (°C) 12, 23, 30

and the values were compared for precision. 7 Number of spray stages 1, 2, 3

652 TRANSACTIONS OF THE ASABE

experiments were more economical in this study because Table 3. Range and levels of variables in central composite design.

the interaction effects of the experimental factors are rela- Range and Levels

SSM Design and Variables -α -1 0 +1 +α

tively small compared to the main factor effects (Mont-

Single-stage scrubbing for low inlet NH3

gomery, 2001; Qu and Wu, 2005). Although designed ex- Superficial gas velocity (m s-1) 2.6 3 4 5 5.4

periments such as full or fractional factorial experiments Operating liquid pressure (MPa) 0.32 0.34 0.41 0.48 0.51

are preferable to obtain comprehensive effects of factors Three-stage scrubbing for high inlet NH3

and their interactions, OFAT was practical and appropriate Inlet NH3 concentration (ppmv) 100 144 250 356 400

Operating liquid pressure (MPa) 0.50 0.52 0.57 0.62 0.64

in this study for screening factors and isolating their practi-

cal and optimum settings for high scrubber performance. đường kính

Spray scrubber module RESULTS AND DISCUSSION

SSM DEVELOPMENT AND PERFORMANCE TESTS NOZZLE SELECTION AND OPERATING CONDITIONS

The optimized parameters based on the above experi- The performance of the PJ20 nozzle used by Manuzon et

mental factors were used as the design and operating condi- al. (2007) for treating air with an inlet NH3 concentration of

tions of the SSM. The SSM was intended for a wide range 30 ppmv was compared to the performances of the new

of NH3 concentration conditions. The European packed-bed nozzles (PJ40 and AAP01) in this study using a 35.56 cm

scrubbers described by Melse and Orink (2005) were nor- (14 in.) scrubber simulation unit. As shown in figure 4,

mally designed to achieve 90% NH3 removal efficiency. increasing operating pressure improved scrubber efficiency

Because spray scrubbers tend to have lower efficiency in for all nozzles due to increase in liquid flow rate and sub-

comparison with packed-bed scrubbers, especially when sequent increase in liquid-to-gas ratio. An increase in pres-

working with high-speed air streams, the development goal sure also generated smaller droplets, which increased the

for this scrubber was to achieve 80% to 90% of NH3 re- surface area for chemical reaction. The maximum scrubber

moval efficiency. Typical NH3 concentrations observed in efficiency was observed using the PJ40 nozzle with values

mechanically ventilated swine finishing facilities with pit of 70.2% ±3.7%, 59.6% ±2.5%, and 26.1% ±0% at operat-

exhausts are about 2 to 30 ppmv (Aarnink et al., 1995). ing pressures of 0.62, 0.48, and 0.21 MPa, respectively. At

Typical sizes for swine pit fans range from 25.4 to 45.7 cm the highest operating pressure of 0.62 MPa, PJ40 gave the

in diameter. Therefore, a single SSM with simple round highest removal efficiency while PJ20 and AAP01 gave

geometry was used for swine applications. For air streams efficiency values of 53.9% and 49.1%, respectively. Pair-

with large airflow rates and high NH3 concentrations (30 to wise comparisons using Tukey’s HSD test revealed that the

400 ppmv), such as from poultry exhaust fans (Zhao et al., mean performance of PJ40 and PJ20 differed by 15.5%

2008), a scrubber with multiple SSMs is needed. (SE = 6.7%, p = 0.07), while the performances of PJ20 and

Response surface methodology involving a central com- AAP01 did not significantly differ, with mean difference of

posite design was applied to evaluate the performance of 4.8% (SE = 6.8%, p = 0.76). The hollow-cone AAP01 noz-

the SSM designs. For the SSM for swine applications (low zle, which has a liquid flow rate comparable with the PJ40,

ammonia concentrations), the effects of superficial gas ve- did not perform well at higher pressure relative to other

locity and operating liquid pressure on the performance of nozzles and would require additional stages for a compara-

the SSM were quantified using single-stage spray scrub- ble efficiency. However, its large orifice diameter of

bing. The superficial gas velocity was varied to simulate 200 μm made it a practical alternative to the PJ20 nozzle

variable-speed pit fan operation. For the SSM for poultry optimized by Manuzon et al. (2007) to avoid clogging is-

applications (high ammonia concentrations), the response sues possibly caused by dust particles in the exhaust air

surface curve was generated for the effects of ammonia streams of animal buildings. In terms of scrubber efficien-

concentration and operating liquid pressure on the perfor- cy, the full-cone PJ40 was chosen to be the best nozzle for

mance of the SSM using three-stage scrubbing. Because the further optimization of NH3 absorption.

ventilation control of poultry facilities often uses fan stag-

ing, i.e., turning fans on and off, the operating exhaust fans

have relatively constant flow rates but the NH3 concentra-

tions vary due to diurnal and seasonal ventilation rate

changes. Table 3 summarizes the range and levels of the

independent variables for used generating the optimized

curves.

DATA ANALYSIS

The data collected were analyzed by general descriptive

statistical analysis. In studying the effects of the parameters,

three replicate runs were performed for each treatment. The

data were analyzed with JMP 10.0 software (SAS Institute,

Inc., Cary, N.C.) using analysis of variance (ANOVA), anal-

ysis of covariance (ANACOVA), t-tests for paired compari-

sons, and Tukey-Kramer’s honest significant difference

(HSD) for pairwise mean comparisons at 95% confidence

Figure 4. Performance of nozzles with respect to operating pressure

interval. Linear regression analysis was used to fit the model. using a 35.56 cm round scrubber column.

57(2): 647-659 653

EFFECT OF SCRUBBER COLUMN DIAMETER which further atomizes liquid droplets and thus provides

The effect of scrubber column diameter on scrubber per- greater surface area for the absorption process. Flow in

formance was investigated using three different sizes of ducts with more complex geometry, such as non-circular

duct: 35.6, 45.7, and 61.0 cm. The scrubber was operated at ducts, has been an important topic of study in fluid dynam-

constant mean air velocity of 5 m s-1 and constant pressure ics. Jarungthammachote (2010) showed that hexagonal

of 0.62 MPa using the PJ40 nozzle. According to the manu- ducts tend to have higher entropy generation than circular

facturer’s specifications, the cone-shape coverage of the ducts, while Turgut and Sarı (2012) provided experimental

PJ40 nozzle is about 61.0 cm in base diameter and 30.5 cm and numerical data for turbulent flow inside hexagonal

in height. Decreasing the scrubber diameter from 61.0 to ducts that showed 12% to 15% difference in flow charac-

45.7 cm yielded an increase in scrubber efficiency of about teristics between circular ducts and hexagonal ducts under

43% and 23% for inlet NH3 concentrations of 30 and turbulent regime. In terms of reducing flow resistance, the

200 ppmv, respectively, as shown in figure 5. This effect optimal shape is a circle. Bejan (2000) explained that the

might be a result of increased droplet concentration per unit shape of the perimeter affects the flow resistance. As the

volume of the spray tower due to the decrease of the scrub- shape closely approaches round, flow resistance tends to

ber column diameter. Higher droplet concentration had decrease in proportion. While this might be true, the pres-

higher effective surface area for ammonia absorption inside sure drops observed when using the three different geome-

the scrubber and thus resulted in the high scrubber efficien- tries did not show differences, and all averaged 17.4 ±2.5

cy. However, further decreasing the scrubber diameter from Pa. It can be concluded that the hexagonal duct was most

45.7 to 35.6 cm reduced the scrubber efficiency by 13% effective in terms of scrubber efficiency. In addition, hex-

and 2% for inlet NH3 concentrations of 30 and 200 ppmv, agonal ducts with planar walls provide a practical ad-

respectively. Further reduction in the scrubber diameter vantage over circular ducts in that they can be packed effi-

likely limited the span of droplets with a large initial re- ciently, with no unused space between them.

lease angle, forced the droplets to hit the scrubber wall to

form a liquid film (also called wall wetting effect), and EFFECT OF SCRUBBING LIQUID ACID CONCENTRATION

caused significant droplet coagulation. This phenomenon Acidity can be quantified by the pH of the solution,

significantly reduced the liquid surface area and therefore which by definition is -log[aH+], where aH+ is the activity of

reduced the scrubber efficiency. The results showed that H+ and is equivalent to [H+] in an aqueous environment. As

maximum efficiencies of 87% (±5%) and 50% (±0%) were expected, the degree of acidity of the scrubbing medium

observed for 30 and 200 ppmv, respectively, when using the greatly enhanced absorption of gas-phase NH3 into the liq-

45.7 cm diameter scrubber given the operating gas velocity. uid phase as a result of greater Henry’s law solubility and

higher chemical reaction rate of NH3 with the acid solution.

EFFECT OF SCRUBBER GEOMETRY Figure 7 illustrates the effect of increasing the H2SO4 con-

The effect of scrubber geometry was studied using three centration on the absorption efficiency of the scrubber for a

different ducts of the same cross-sectional area (922 cm2). constant inlet NH3 concentration of 30 ppmv. Results

The hydraulic diameters or equivalent diameters for each showed that acid concentration had a significant effect on

duct were 35.56, 33.86, and 31.55 cm for the round, hexag- the absorption efficiency of the scrubber [F(5,6) = 68.11,

onal, and square shapes, respectively. Duct shape has a p < 0.11)]. Upon increase of H2SO4 concentration from 0%

significant effect on scrubber efficiency [F(2,3) = to 0.2% (w/v) or equivalently a decrease from pH = 6.12

1.02e+16, p < 0.0001)] with maximum scrubber efficiency (±1.65) to pH = 1.72 (±0.16), scrubber efficiency rapidly

of 63% observed when using the hexagonal duct. The in- increased by 44% (SE = 4%, p = 0.0004). As discussed by

crease in efficiency observed with a duct geometry change Swartz et al. (1999) on the uptake of gas-phase NH3 by

from circular to hexagonal, as shown in figure 6, could be H2SO4 surfaces, at pH > 4 the solubility of NH3 was further

attributed to the increase in turbulence inside the scrubber, limited by its Henry’s law solubility (eq. 1), which caused

Figure 5. Effect of scrubber column diameter on scrubber efficiency Figure 6. Effect of scrubber column shape on scrubber efficiency.

investigated using a round scrubber column.

654 TRANSACTIONS OF THE ASABE

the re-evaporation of NH3 back to gas phase. The increase ear relationship (R2 > 0.98) between absorption efficiency

in [H+] improved the conversion of gaseous NH3 to its liq- and superficial air velocity for each nozzle. Full-cone noz-

uid form by shifting the equilibrium reaction (eq. 2) toward zle PJ40 had a slope of -7.09, while hollow-cone nozzle

NH4+, making it nearly irreversible. This was expected un- AAP01 had a slope of -11.82. PJ40 performed well at high-

der highly acidic conditions at pH < 2. Post-hoc compari- er velocity, with 73% (±0%) efficiency at 5.0 m s-1, while

sons using Tukey’s HSD test revealed that for scrubbing AAP01 produced a mean efficiency of 46% (±1%) at the

liquid with acid concentration above 0.8% (w/v), absorp- same velocity. The expected decrease in scrubber perfor-

tion efficiency started to level off and did not significantly mance was attributed to the decrease in the residence time

change with respect to acidity. or retention time of air in the scrubber column, which di-

Manuzon et al. (2007) observed that efficiencies did not rectly affects the contact time between the gas and liquid

significantly vary above 0.2 N or 1% (w/v) (0.2 to 0.6 N) droplets during the absorption process (Bandyopadhyaya

acid concentration when the maximum gas-carrying capaci- and Biswasa, 2006; Jia et al., 2011; Manuzon et al., 2007).

ty of the acid solution was achieved at a given retention Air residence time is a critical factor for gaseous pollutant

time. It was concluded that the presence of excess acid was scrubbers, where adequate contact time between the scrub-

critical to maintaining the driving force for absorption to bing liquid and gas is needed. It should also be noted that

take place if the scrubbing medium was to be recirculated decreasing the air residence time also means decreasing the

or recycled. This trend was confirmed in this study, and the liquid-to-gas ratio, which could negatively affect the mass

maximum efficiency of 68% (±7%) was observed at 1% transfer from gas to the liquid.

(w/v) H2SO4, which was experimentally equivalent to pH =

1.48. This also revealed that the chemical absorption of EFFECTS OF NH3 CONCENTRATION

NH3 using acidic solution above 1% (w/v) acid was limited AND AIR TEMPERATURE

by the gas-carrying capacity of the scrubbing medium and Figure 9 shows that the effect of NH3 concentration on

not by the concentration of NH3 in air. This was also ob- scrubber efficiency was directly proportional to the natural

served in absorption experiments conducted by Lahav et al. log of NH3 concentration [F(1,27) = 304.29, p = 0.55)].

(2008), who reported that, at pH < ~2.15, NH3 concentra- Scrubber efficiencies ranged from 90% to 34% when the

tion in air is not the rate-limiting parameter during the ab- NH3 concentration varied from 10 to 400 ppmv under nor-

sorption process. Thus, it would be safe to assume at least mal room conditions. The natural log relationship suggest-

1% acid concentration for treating highly concentrated air ed that scrubber efficiency would stabilize at a constant

streams above 30 ppmv. In the subsequent experiments, 1% value as the inlet NH3 concentration is increased further, at

(w/v) H2SO4 was used as the optimized concentration of which point the scrubber is operating at steady-state condi-

acid in the scrubbing medium. Although the presence of tions and the amount of NH3 that the acidic solution can

excess acid is a technical advantage, it should be well con- absorb remains constant given a certain gas-liquid contact

trolled such that it does not exceed the optimized concen- time. Such an effect was due to the decrease in the availa-

tration. A highly acidic solution can be an operational chal- ble sorbent capacity of the liquid, thus lowering the rate of

lenge, as it is highly corrosive and can strongly oxidize absorption (Kiil et al., 1998). This effect could only be

metals. Its exothermic nature when dissolved in water is compensated by increasing the liquid-to-gas ratio, which

also a safety issue in operating the scrubber. It can irritate could be done by decreasing the flow rate of gas into the

eyes and skin as well as damage living tissues. Therefore, scrubber or by increasing the number of spray stages. Even

safety precautions should be observed during scrubber op- though the ventilation rates of animal facilities change di-

eration with acidic effluents. urnally and seasonally as the weather changes, due to the

use of stage ventilation control that operates different num-

EFFECT OF SUPERFICIAL AIR VELOCITY bers of fans at a time, the airflow rate of an individual fan is

As shown in figure 8, there was a significant inverse lin- normally constant as long as the fan is running. Therefore,

Figure 7. Effect of scrubbing liquid acidity (pH) or H2SO4 concentra- Figure 8. Effect of superficial air velocity or gas flow rate on scrubber

tion (% w/v) on NH3 collection efficiency. efficiency using a 35.56 cm round scrubber column.

57(2): 647-659 655

EFFECT OF NUMBER OF STAGES

The effect of the number of stages is shown in fig-

ure 10a. Scrubber efficiency observed from single-stage

scrubbing was 57.4% (±2.8%). Efficiency increased further

to about 89% (±2%) upon increasing the spray stages to

three. The actual results showed very good agreement of

the multi-stage scrubber’s performance with its predicted

performance using penetration calculations from single-

stage scrubbing efficiency (eq. 6). The degree of error be-

tween the actual observation and theoretical calculation

reflects the interaction between the spray stages. Thus, the

results suggested that each stage was behaving inde-

pendently. Compared to the results of the scrubber proto-

type by Manuzon et al. (2007) (fig. 10b), the new scrubber

Figure 9. Effect of inlet NH3 concentration and air temperature on significantly reduced interaction problems and improved

scrubber efficiency using a 35.56 cm round scrubber column.

scrubber efficiency by using a fully optimized scrubber

module to isolate droplet interaction and ensure the opti-

multi-stage scrubbing would be a recommended option for

mized conditions throughout the scrubber column. The

mitigating higher levels of inlet NH3 concentration to pro-

scrubber module has an optimized scrubber diameter, ge-

mote a higher liquid-to-gas ratio.

ometry, column height, spray nozzle, and liquid-to-air flow

Figure 9 also shows the results of a regression analysis

rate ratio. As discussed earlier, increasing the number of

obtained from using the PJ40 nozzle at different air tem-

stages promotes a higher liquid-to-gas ratio sufficient to

peratures. Qualitative observation on the effect of tempera-

improve the absorptive capacity of the scrubbing liquid for

ture did not show an obvious trend for performance in the

a given loading rate of NH3. For a scrubber application that

lower concentration range. Efficiency did not decrease pro-

has a lower concentration of NH3 to be treated, a lesser

portionately for each increase in temperature at fixed inlet

number of stages is sufficient.

NH3 concentration. Air temperature is a significant factor

for gas solubility in liquid. Technically, gas solubility in

PERFORMANCE OF OPTIMIZED SCRUBBER MODULE

liquid is dependent on the equilibrium between the gas

An optimized SSM was developed to be able to treat dif-

phase and the liquid phase, which is affected by the Hen-

ferent levels of inlet NH3 concentration. The SSM consists

ry’s law solubility. Increasing air temperature tends to in-

of a 1.65 m tall scrubbing column with a hexagonal geome-

crease the vapor pressure of a gas, which causes distress at

try that has an equivalent diameter of 45.7 cm. It is

the gas-liquid surface interaction, allowing some of the

equipped with three stages of PJ40 spray nozzles operated

dissolved gas to re-evaporate back to the liquid phase.

at about 0.55 to 0.62 MPa. The scrubbing liquid is a dilute

However, statistical analysis through analysis of covariance

sulfuric acid solution with a concentration of at least 1%

(ANACOVA) with air temperature as the covariate variable

(w/v) H2SO4. The optimized air velocity ranged from 3 to

did not show a significant effect of air temperature on effi-

4 m s-1, equivalent to air retention times of 0.55 to 0.41 s.

ciency (p = 0.82) for temperatures ranging from 12°C to

For treating exhaust air streams of animal facilities with

30°C. For this operating temperature range, it was assumed

low airflow rates and low NH3 concentrations (less than

that temperature did not play an important role in the

30 ppmv), such as exhaust air from the pit fans of swine

scrubbing process, which is a favorable conclusion for out-

buildings, the SSM can be simplified to a round geometry

door scrubber operation where inlet air temperature is

with a smaller diameter and fewer spray nozzles. For treat-

among the uncontrollable variables expected in animal fa-

ing exhaust streams with higher airflow rates and high NH3

cilities due to seasonal variation.

concentrations (100 to 400 ppmv), such as the exhaust air

Figure 10. Effect of number of stages on scrubber efficiency using (a) results from this study and (b) results of Manuzon et al. (2007).

656 TRANSACTIONS OF THE ASABE

from poultry facilities, different numbers of SSMs can be reduced to 0.59 MPa, the efficiencies decrease to 85% and

packed together to form large-scale commercial scrubbers 73% given inlet NH3 concentrations of 100 and 400 ppmv,

with more stages of spray nozzles. respectively. At 0.55 MPa, the performance is further re-

duced to 82% and 70% for inlet NH3 concentrations of 100

Single-Stage Scrubber for Low NH3 Concentrations

and 400 ppmv, respectively. Reducing the working pressure

Figure 11 shows the performance of the single-stage

offers practical benefits for the operation and maintenance

scrubber (with round geometry and 35.6 cm in diameter)

of the pump, which runs continuously in the acidic solu-

with respect to two operating parameters: nozzle pressure

tion. The total performance for the three-stage operation

and gas velocity. The performance curve of the optimized

can be fitted by a regression equation:

single-stage scrubber was evaluated with an operating pres-

sure range of 0.32 to 0.51 MPa and air velocity range of η = 55.33P − 0.04C + 56.14 (9)

2.59 to 5.41 m s-1. Based on the performance results, the

scrubber can achieve 91% efficiency at a liquid pressure of where η is the scrubber efficiency (%), P is the nozzle

0.51 MPa and a superficial air velocity of 4.0 m s-1. If the pressure (MPa), and C is the inlet NH3 concentration

air velocity is 3 m s-1, the scrubber efficiency increases to (ppmv). Equation 9 is also consistent with previous findings

about 95% at the same liquid pressure of 0.51 MPa. If the for the effects of operating pressure and NH3 concentration.

performance goal is set to 90% for this velocity, the pump However, it reveals a higher effect of operating pressure on

pressure can be reduced to 0.47 MPa. This reduction in scrubber efficiency at a higher NH3 concentration range

operating pressure has a practical advantage because low- compared to equation 8.

pressure pumps are inexpensive and easy to operate and

maintain. The performance can be mathematically de- STATIC PRESSURE DROP AND AIRFLOW RATE

scribed by a fitted regression equation: Figure 13 shows the differential static pressures of each

scrubber component and of the whole scrubber. The 90°

η = 1.26P − 0.04V + 0.43 (8) elbow did not contribute significantly to the static pressure

drop; instead, it helped regain about 4 to 10 Pa when the air

where η is the scrubber efficiency (%), P is the nozzle velocity changed from 2 to 4 m s-1. The 140% divergence

pressure (MPa), and V is the air velocity (m s-1). Equation 8 section significantly contributed to the static pressure gain

reflects the positive effect of operating pressure (as corre- of about 1.2 to 22.3 Pa for air velocities of 2 to 4 m s-1. The

lated to the droplet size properties and liquid flow rate) and

spray column did not contribute to a measurable pressure

the negative effect of air velocity on scrubber efficiency, drop. The mist eliminator is the greatest contributor of

which are both consistent with earlier findings. pressure drop for the entire scrubber and gave static pres-

Three-Stage Scrubber for High NH3 Concentrations sure drops of 15, 30, and 55 Pa for air velocities of 2, 3, and

Figure 12 shows the surface plot of the three-stage 4 m s-1, respectively. The total pressure drop of the scrub-

scrubber efficiency with respect to inlet NH3 concentration ber was reduced to less than 15 Pa for air velocities less

and nozzle operating pressure. The performance curve of than 4 m s-1 due to static pressure gain from the divergence

the SSM showed that the projected efficiencies were 86% section of the scrubber. The static pressure increase caused

and 74% for inlet NH3 concentrations of 100 and 400 ppmv, by the divergence section helped offset the static pressure

respectively, with an operating pressure of 0.62 MPa and loss caused mainly by the demister; in effect, the total static

superficial air velocity of 4.0 m s-1. If operating pressure is pressure drop of the scrubber was significantly reduced and

Figure 11. Response surface of SSM performance with a single-stage Figure 12. Response surface of SSM performance with three-stage

nozzle operating at different pressures for air streams with low NH3 nozzles operating at different pressures and inlet NH3 concentrations.

concentrations (<30 ppmv) and different air velocities.

57(2): 647-659 657

ized by a hexagonal scrubber column with a diameter of

45.72 cm (18 in.) equipped with three stages of PJ40 spray

nozzles. For air streams with low NH3 concentrations, the

design of the SSM can be simplified to a round scrubber

column with a smaller diameter of 36.0 cm (14 in.) and sin-

gle-stage nozzle operation. The scrubber is operated with 1%

(w/v) H2SO4 scrubbing liquid sprayed counter-current to the

inlet air stream with a superficial gas velocity of 3 to 4 m s-1,

equivalent to air retention times of 0.55 to 0.41 s. The per-

formance of the SSM for a low NH3 concentration of

30 ppmv varied from 91% to 95% at superficial air velocities

of 4.0 and 3.0 m s-1, respectively. For inlet NH3 concentra-

tions of 100 and 400 ppmv, the efficiencies were 86% and

74%, respectively, with an operating pressure of 0.62 MPa

Figure 13. Differential static pressure of the whole scrubber and the and superficial air velocity of 4.0 m s-1. The SSM can be

components of the scrubber with respect to superficial air velocity.

used for commercial scale-up to treat NH3-laden air streams

with high airflow rates.

even lower than that caused by the demister. This level of The pressure drop of the spray scrubber was mainly con-

total static pressure drop is within the capacity of most ag- tributed by the mist eliminator, which was evaluated to be

ricultural axial fans on the U.S. farms, which commonly 15, 30, and 55 Pa for air velocities of 2, 3, 4 m s-1, respec-

encounter static pressures between 0 to 60 Pa (Teitel et al., tively. The scrubber column resulted in a negligible static

2008). The total static pressure drop contributed by this pressure drop. A divergence section of the scrubber con-

spray wet scrubber was also significantly lower than that of tributed to a static pressure increase. The total static pres-

the packed-bed scrubbers reviewed by Melse and Ogink sure drop was under 15 Pa when the air velocity ranged

(2005), which ranged from 50 to 200 Pa, and the regenerat- from 2 to 4 m s-1. The pressure drop was significantly lower

ing scrubber developed by Shah et al. (2008), which had an than that reported for other types of wet scrubbers, which

average pressure drop of 110 Pa. make the spray scrubber feasible for applications on U.S.

animal farms.

Based on the results of the optimization study, acid

CONCLUSIONS spray scrubbing was found to be an effective and feasible

An acid SSM was developed and optimized to resolve NH3 mitigation technology for a wider range of application

issues such as spray interaction and low NH3 removal effi- scenarios anticipated at different animal facilities.

ciencies encountered by Manuzon et al. (2007) during pre-

liminary simulation of spray NH3 scrubbing for air streams ACKNOWLEDGEMENTS

from animal facilities. The design and operating parameters This project was supported by National Research Initia-

of the scrubber that directly affect NH3 absorption efficien- tive Competitive Grant No. 2008-55112-1876 from the

cy were optimized. The PJ40 (full-cone) nozzle was identi- USDA Cooperative State Research, Education, and Exten-

fied as the best performing nozzle through the simulation sion Service Air Quality Program. The authors acknow-

study, especially for air streams with high NH3 concentra- ledge the help and support provided by Mr. Carl Cooper,

tions. The optimized scrubber diameter was 45.7 cm, while Mr. Alan Yost, and Mr. Jared Felder of the Department of

a hexagonal geometry was found to be the most effective Food, Agricultural, and Biological Engineering of The

scrubber column design. Operating parameters including Ohio State University.

acid concentration, superficial air velocity, inlet NH3 con-

centration, and air temperature were investigated for their

effects on scrubber performance. A 1% (w/v) H2SO4 solu- REFERENCES

tion, with an equivalent pH of 1.46 (±0.05), was verified as Aarnink, A. J., Keen, A., Metz, J. H., Speelman, L., & Verstegen,

the optimized scrubbing liquid. Superficial air velocity ad- M. W. (1995). Ammonia emission patterns during the growing

versely affected scrubber performance significantly due to periods of pigs housed on partially slatted floors. J. Agric. Eng.

its direct relationship with air residence time or contact Res., 62(2), 105-116. http://dx.doi.org/10.1006/jaer.1995.1069.

time between the gas and the liquid droplets. The scrubber ASHRAE. (2009). Chapter 21: Duct design. In HVAC Systems and

efficiency was observed to be inversely proportional to the Equipment. Atlanta, Ga.: ASHRAE.

Bandyopadhyaya, A., & Biswasa, M. N. (2006). Prediction of the

natural log of the inlet concentration. Typical indoor air

removal efficiency of a novel two-stage hybrid scrubber for flue

temperatures did not play an important role in the scrub- gas desulfurization. Chem. Eng. and Tech., 29(1), 130-145.

bing process. Based on theoretical analysis and experi- http://dx.doi.org/10.1002/ceat.200500160.

mental simulation, increasing the number of scrubbing Bejan, A. (2000). Shape and Structure, from Engineering to Nature.

stages enhanced the absorptive capacity of the SSM, espe- Cambridge, U.K.: Cambridge University Press.

cially for recovering high levels of NH3. Beker, A., Vanhooser, S. L., Swartzlander, J. H., & Teeter, R. G.

Performance of the SSM was quantified for both low and (2004). Atmospheric ammonia concentration effects on broiler

high NH3 concentration applications. For air streams with growth and performance. J. Appl. Poultry Res., 13(1), 5-9.

high NH3 concentrations, the design of the SSM is character- BETE. (2013). PJ fine atomization. Greenfield, Mass.: BETE Fog

658 TRANSACTIONS OF THE ASABE

Nozzle, Inc. Retrieved from www.bete.com/pdfs/BETE_PJ.pdf. NRC. (2002). Air Emissions from Animal Feeding Operations:

Calvert, S., & Englund, H. M. (1984). Handbook of Air Pollution Current Knowledge, Future Needs. Washington, D.C.: National

Technology. Hoboken, N.J.: John Wiley and Sons. Research Council.

De Nevers, N. (2000). Air Pollution Control Engineering. 2nd ed. Perrin, D. (1969). Dissociation Constants of Inorganic Acids and

New York, N.Y.: McGraw-Hill. Bases in Aqueous Solution. London, U.K.: Butterworths.

Homidan, A. A., Robertson, J. F., & Petchey, A. M. (2003). Review Philippe, F. X., Cabaraux, J. F., & Nicks, B. (2011). Ammonia

of the effect of ammonia and dust concentrations on broiler emissions from pig houses: Influencing factors and mitigation

performance. World’s Poultry Sci. J., 59(3), 340-349. techniques. Agric., Ecosyst. and Environ., 141(3-4), 245-260.

http://dx.doi.org/10.1079/WPS20030021. http://dx.doi.org/10.1016/j.agee.2011.03.012.

Jarungthammachote, S. (2010). Entropy generation analysis for Qu, X., & Wu, C. F. (2005). One-factor-at-a-time designs of

fully developed laminar convection in hexagonal duct subjected resolution V. J. Stat. Planning and Inference, 131(2), 407-416.

to constant heat flux. Energy, 35(12), 5374-5379. Sander, R. (1999). Compilation of Henry’s law constants for

http://dx.doi.org/10.1016/j.energy.2010.07.020. inorganic and organic species of potential importance in

Jia, Y., Zhong, Q., Fan, X., Chen, Q., & Sun, H. (2011). Modeling environmental chemistry. Mainz, Germany: Max Planck

of ammonia-based wet flue gas desulfurization in the spray Institute of Chemistry. Retrieved from

scrubber. Korean J. Chem. Eng., 28(4), 1058-1064. www.ceset.unicamp.br/~mariaacm/ST405/Lei%2520de%2520H

http://dx.doi.org/10.1007/s11814-010-0472-4. enry.pdf.

Kiil, S., Michelsen, M. L., & Dam-Johansen, K. (1998). Shah, S. B., Westerman, P. W., Munilla, R. D., Adcock, M. E., &

Experimental investigation and modeling of a wet flue gas Baughman, G. R. (2008). Design and evaluation of a

desulfurization pilot plant. Ind. and Eng. Chem. Res., 37(7), regenerating scrubber for reducing animal house emissions.

2792-2806. http://dx.doi.org/10.1021/ie9709446. Trans. ASABE, 51(1), 243-250. http://dx.doi.org/doi:

Lahav, O., Mor, T., Heber, A. J., Molchanov, S., Ramirez, J. C., Li, 10.13031/2013.24217.

C., & Broday, D. M. (2008). A new approach for minimizing Swartz, E., Shi, Q., Davidovits, P., Jayne, J. T., Worsnop, D. R., &

ammonia emissions from poultry houses. Water Air and Soil Kolb, C. E. (1999). Uptake of gas-phase ammonia: 2. Uptake by

Pollution, 191(1-4), 183-197. http://dx.doi.org/10.1007/s11270- sulfuric acid surfaces. J. Physical Chem. A, 103(44), 8824-8833.

008-9616-0. http://dx.doi.org/10.1021/jp991697h.

Lefebvre, A. H. (1989). Atomization and Sprays. New York, N.Y.: Teitel, M., Levi, A., Zhao, Y., Barak, M., Bar-lev, E., & Shmuel, D.

Hemisphere Publishing. (2008). Energy saving in agricultural buildings through fan

Manuzon, R. B., Zhao, L. Y., Keener, H. M., & Darr, M. J. (2007). motor control by variable-frequency drives. Energy and

A prototype acid spray scrubber for absorbing ammonia Buildings, 40(6), 953-960.

emissions from exhaust fans of animal buildings. Trans. ASABE, http://dx.doi.org/10.1016/j.enbuild.2007.07.010.

50(4), 1395-1407. http://dx.doi.org/10.13031/2013.23628. Turgut, O., & Sarı, M. (2012). Experimental and numerical study of

Melse, R. W., & Ogink, N. W. (2005). Air scrubbing techniques for turbulent flow and heat transfer inside hexagonal duct. Heat and

ammonia and odor reduction at livestock operations: Review of Mass Transfer, 49(4), 543-554.

on-farm research in the Netherlands. Trans. ASAE, 48(6), 2303- http://dx.doi.org/10.1007/s00231-012-1101-z.

2303. http://dx.doi.org/10.13031/2013.20094. USEPA. (2004). National Emission Inventory: Ammonia emissions

Melse, R. W., Ogink, N. W., & Rulkens, W. H. (2009). Air from animal husbandry operations. Draft report. Washington,

treatment techniques for abatement of emissions from intensive D.C.: U.S. Environmental Protection Agency. Retrieved from

livestock production. Open Agric. J., 3(1), 6-12. www.epa.gov/ttnchie1/ap42/ch09/related/nh3inventorydraft_jan

http://dx.doi.org/10.2174/1874331500903010006. 2004.pdf.

Montgomery, D. (2001). Design and Analysis of Experiments. USEPA. (2009). Emergency Planning and Community Right-To-

Hoboken, N.J.: John Wiley and Sons. Know Act (EPCRA). Washington, D.C.: U.S. Environmental

Munters. (2006). DV 270 Droplet separator (Mist eliminator). Ft. Protection Agency. Retrieved from

Myers, Fla.: Munters Corp. Retrieved from www.epa.gov/agriculture/lcra.html.

www.munters.com/upload/Related%20product%20files/DV%2 WHO. (2005). Air quality and health. Geneva, Switzerland: World

0270.pdf. Health Organization. Retrieved from

Ndegwa, P. M., Hristov, A. N., Arogo, J., & Sheffield, R. E. (2008). www.who.int/mediacentre/factsheets/fs313/en/.

A review of ammonia emission mitigation techniques for Zhao, L. Y., Manuzon, R., Darr, M., Keener, H., Heber, A. J., & Ni,

concentrated animal feeding operations. Biosystems Eng., J. Q. (2008). Ammonia emissions from a commercial poultry

100(4), 453-469. manure composting facility. In Proc. Intl. Livestock

http://dx.doi.org/10.1016/j.biosystemseng.2008.05.010. Environment Symposium (ILES VIII). St. Joseph, Mich. ASABE.

57(2): 647-659 659

V i e w p u b l i c a t i o n s t a t s

You might also like

- Spray Scrubber Simulation Setup and Static Pressure Measurement LocationsDocument14 pagesSpray Scrubber Simulation Setup and Static Pressure Measurement LocationsAhmad Anas Nagoor GunnyNo ratings yet

- Evaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988Document8 pagesEvaluation of The NH Removal Efficiency of An Aci-Wageningen University and Research 184988exergy 33No ratings yet

- Production of Ammonium Sulfate Fertilizer Using Acid Spray Wet ScrubbersDocument12 pagesProduction of Ammonium Sulfate Fertilizer Using Acid Spray Wet ScrubbersTyokNo ratings yet

- Production of Ammonium Sulfate Fertilizer Using Acid Spray Wet ScrubbersDocument11 pagesProduction of Ammonium Sulfate Fertilizer Using Acid Spray Wet ScrubbersgiraulNo ratings yet

- ASABE2010 Poster PerformanceComparison Spray Packed 1009484Document1 pageASABE2010 Poster PerformanceComparison Spray Packed 1009484Yahya KhanNo ratings yet

- Using Poultry Litter Derived Biochar As Litter Amendment To Cont 2016Document8 pagesUsing Poultry Litter Derived Biochar As Litter Amendment To Cont 2016EveAriNo ratings yet

- Performance Compliance and Reliability of Waste STDocument11 pagesPerformance Compliance and Reliability of Waste STLouis LuizNo ratings yet

- Radiation Physics and ChemistryDocument6 pagesRadiation Physics and ChemistryCamila Gomes MeloNo ratings yet

- Bioresource Technology: J. Bousek, D. Scroccaro, Jan Sima, Norbert Weissenbacher, W. FuchsDocument8 pagesBioresource Technology: J. Bousek, D. Scroccaro, Jan Sima, Norbert Weissenbacher, W. FuchsManuel CorredorNo ratings yet

- Groundwater Arsenic Remediation: Treatment Technology and Scale UPFrom EverandGroundwater Arsenic Remediation: Treatment Technology and Scale UPNo ratings yet

- ReviewPaperonindustrialwastewatertreatmentprocesses PDFDocument19 pagesReviewPaperonindustrialwastewatertreatmentprocesses PDFPrathamesh KanganeNo ratings yet

- 1 s2.0 S0960852413004458 MainDocument6 pages1 s2.0 S0960852413004458 MainANIL SINGHNo ratings yet

- Deoliveira 2018Document10 pagesDeoliveira 2018Marwen EsselmiNo ratings yet

- Ammonia Exposure and Hazard Assessment For Selected Household Cleaning Product UsesDocument11 pagesAmmonia Exposure and Hazard Assessment For Selected Household Cleaning Product UsesShitta AspendiraNo ratings yet

- Assessment of The Impacts of Aromatic VOC Emissions and Yields of SOA On SOA Concentrations With The Air Quality Model RAMS-CMAQ OKDocument11 pagesAssessment of The Impacts of Aromatic VOC Emissions and Yields of SOA On SOA Concentrations With The Air Quality Model RAMS-CMAQ OKabhiy7No ratings yet

- Journal of Loss Prevention in The Process Industries: Wei Tan, Huang Du, Liyan Liu, Tong Su, Xuanya LiuDocument11 pagesJournal of Loss Prevention in The Process Industries: Wei Tan, Huang Du, Liyan Liu, Tong Su, Xuanya Liuabril garciaNo ratings yet

- Nitrogen-Removal Efficiency in An Upflow PartiallyDocument10 pagesNitrogen-Removal Efficiency in An Upflow PartiallyCristiam MercadoNo ratings yet

- 1 s2.0 S1876107023004674 Main - OptDocument20 pages1 s2.0 S1876107023004674 Main - OptDani Puji UtomoNo ratings yet

- Measuring Concentrations of Ammonia in Ambient Air or Exhaust Air Stream Using Acid TrapsDocument8 pagesMeasuring Concentrations of Ammonia in Ambient Air or Exhaust Air Stream Using Acid TrapsGaniyuNo ratings yet

- A High-Efficiency, Low-Bias Method For Extracting Particulate Matter From Filter and Impactor Substrates - Bein and Wexler - 2014Document9 pagesA High-Efficiency, Low-Bias Method For Extracting Particulate Matter From Filter and Impactor Substrates - Bein and Wexler - 2014sikhpointNo ratings yet

- DynamicAdsorptionModelingPaper ResearchgateDocument35 pagesDynamicAdsorptionModelingPaper ResearchgateDiana CarvajalNo ratings yet

- VVVVVVV ImpppppppppppppppppDocument5 pagesVVVVVVV ImpppppppppppppppppbandayNo ratings yet

- Assessment of Clogging Effects On Lateral Hydraulics Proposing A Monitoring and Detection ProtocolDocument12 pagesAssessment of Clogging Effects On Lateral Hydraulics Proposing A Monitoring and Detection ProtocolTrian TeeNo ratings yet

- Pish Gar 2017Document10 pagesPish Gar 2017Nazario HuarachiNo ratings yet

- Performance of Air Cleaners For Removing Multiple Volatile Organic Compounds in Indoor AirDocument15 pagesPerformance of Air Cleaners For Removing Multiple Volatile Organic Compounds in Indoor AirClifford Allen CooperNo ratings yet

- Modeling and Computational Fluid Dynamic Simulation of AcetaminophenDocument11 pagesModeling and Computational Fluid Dynamic Simulation of AcetaminophenUma SureshNo ratings yet

- Chemosphere: Hua-Se Ou, Chao-Hai Wei, Ce-Hui Mo, Hai-Zhen Wu, Yuan Ren, Chun-Hua FengDocument7 pagesChemosphere: Hua-Se Ou, Chao-Hai Wei, Ce-Hui Mo, Hai-Zhen Wu, Yuan Ren, Chun-Hua FengKarenRosioMoreiraCruzNo ratings yet

- Effect Depth Pressure PDFDocument6 pagesEffect Depth Pressure PDFBijay ThapaNo ratings yet

- AerationDocument10 pagesAerationbndrprdnaNo ratings yet

- Ammonia Removalfromaqueoussolutionsusinghollow FiberDocument8 pagesAmmonia Removalfromaqueoussolutionsusinghollow FiberSilvia Rahmi EkasariNo ratings yet

- Studies On Biogas Production by Anaerobic Process Using Agroindustrial WastesDocument11 pagesStudies On Biogas Production by Anaerobic Process Using Agroindustrial Wastestera novaNo ratings yet

- Optimization of Reverse Osmosis Desalination SysteDocument22 pagesOptimization of Reverse Osmosis Desalination SysteYesid Tapiero MartínezNo ratings yet

- Comparison of Ozonation, Photolysis, Photocatalysis and Photoelectrocatalysis Methods For Wastewater DecolorizationDocument8 pagesComparison of Ozonation, Photolysis, Photocatalysis and Photoelectrocatalysis Methods For Wastewater DecolorizationOllafNo ratings yet

- PLT Acidifier Dosage Impacts On Ammonia Concentrations NCSU PaperDocument21 pagesPLT Acidifier Dosage Impacts On Ammonia Concentrations NCSU PaperJhovan Meurer PotrichNo ratings yet

- Development of The Yeast and Lactic Acid Bacteria Co-Culture Agent For Atmospheric Ammonia Removing - Genomic Features and On-Site ApplicationsDocument9 pagesDevelopment of The Yeast and Lactic Acid Bacteria Co-Culture Agent For Atmospheric Ammonia Removing - Genomic Features and On-Site ApplicationsHamid MatariNo ratings yet

- Chemosphere: Ant On Puga, Emilio Rosales, Maria Angeles Sanrom An, Marta PazosDocument9 pagesChemosphere: Ant On Puga, Emilio Rosales, Maria Angeles Sanrom An, Marta PazosEcNo ratings yet

- Best PaperDocument19 pagesBest Paperhemant sadafaleNo ratings yet

- Design of A Two-Step Pulsed Pressure-SwiDocument17 pagesDesign of A Two-Step Pulsed Pressure-SwiJAy RastaNo ratings yet

- 1 s2.0 S2352186419305802 MainDocument10 pages1 s2.0 S2352186419305802 MainJoan Clotet GarciaNo ratings yet

- Air Pollution Prediction by Using An Artificial Neural Network ModelDocument15 pagesAir Pollution Prediction by Using An Artificial Neural Network ModelQian Jun AngNo ratings yet

- Paper 8-InglesDocument16 pagesPaper 8-InglesEvelynNo ratings yet

- Ecotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonDocument6 pagesEcotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonLintang Noor FitriaNo ratings yet

- 1 s2.0 S0043135418300460 MainDocument10 pages1 s2.0 S0043135418300460 MainFABIAN BUSTOSNo ratings yet

- Acoustic Stim SPE31129Document8 pagesAcoustic Stim SPE31129fudvariNo ratings yet

- Journal of Environmental Management: D. Bravo, F.J. Alvarez-Hornos, J.M. Penya-Roja, P. San-Valero, C. Gabald OnDocument3 pagesJournal of Environmental Management: D. Bravo, F.J. Alvarez-Hornos, J.M. Penya-Roja, P. San-Valero, C. Gabald OnMichaelNo ratings yet

- Coagulation ProcessDocument9 pagesCoagulation Processvijay kumarNo ratings yet

- Bioresource Technology: Chao Qi, Jinnan Wang, Yaohua LinDocument10 pagesBioresource Technology: Chao Qi, Jinnan Wang, Yaohua LinMariaM RuizNo ratings yet

- Modelling The Release of Nitrogen From ControlledDocument9 pagesModelling The Release of Nitrogen From ControlledEngr. Babar AzeemNo ratings yet

- Surfactant Effects On A-Factors in Aeration Systems: Diego Rosso, Michael K. StenstromDocument8 pagesSurfactant Effects On A-Factors in Aeration Systems: Diego Rosso, Michael K. StenstromNicole FelicianoNo ratings yet