Professional Documents

Culture Documents

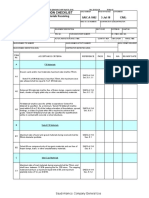

Mounting Plate Installation Checklist

Uploaded by

karthi51289Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mounting Plate Installation Checklist

Uploaded by

karthi51289Copyright:

Available Formats

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.

00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Mounting Plate Installation and Leveling for Pumps SAIC-G-2021 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A. Centrifugal Pumps: See Note 1

All soleplate elevations are to be set in accordance with the construction

drawings. On multiple soleplate installations, one of the soleplates is

chosen as the “reference” soleplate with regard to elevation. This

SAES-G-005

A1 “reference” soleplate is usually the one under the equipment requiring

5.5

“process” connections. API 686 Ch 5 Para 3.9.3.1. For special-purpose

equipment Use Master / precision optical or laser level. API 686 Ch 5

Para 3.9.3.2

Mounting plate jackscrews shall be liberally coated with paste wax or

SAES-G-005

A2 grease to prevent grout adherence. Liquid waxes and oil are not

5.5

permitted. API 686 Ch 5 Para 3.9.1.2

Each individual soleplate level is to be set longitudinally and transversely

to within 42 micrometers per meter (0.0005 in. per ft) with no more than

130 micrometers (0.005 in.) elevation difference between any two points

SAES-G-005

A3 taken on an individual soleplate. In addition, any pair of soleplates (where

5.5

more than one soleplate is used under an individual piece of equipment)

shall be at the same elevation to within 130 micrometers (0.005 in.). API

686 Ch 5 Para 3.9.3.4

Final elevation and level of all soleplates for critical equipment shall be set

with a precision tilting level and precision scale. To balance the length of

sighting distance, the tilting level is to be set near the foundation within a 6 SAES-G-005

A4

m (20-ft) radius of all soleplates. A peg test of the instrument prior to the 5.5

start of the leveling is essential API 686 Ch 5 Para 3.9.3.6 (see Annex I of

API 686).

General-purpose equipment and ASME pump baseplate mounting

surfaces are to be leveled longitudinally and transversely to within 400 SAES-G-005

A5

micrometers per meter (0.005 in. per ft). Refer to Annex D for baseplate 5.5

leveling for horizontal centrifugal pumps.API 686 Ch 5 Para 3.9.4.4.

API pump baseplate mounting surfaces are to be leveled longitudinally

and transversely to within 250 micrometers per meter (0.003 in. per ft). SAES-G-005

A6

This may require removal of equipment to access the machined mounting 5.5

surfaces.API 686 Ch 5 Para 3.9.4.5.

For pumps having a driver rating of 750 kW (1,000 HP) or above the 31-SAMSS-004,

A7 underside of fabricated base plates are constructed with full depth cross Para. 6.3.7 Design

members under all machinery feet,

Saudi Aramco: Company General Use

Baseplates are fully covered by a smooth deck plate. All walking surfaces

are coated with non-slip paint. All baseplates, excluding sub-bases, for 31-SAMSS-004,

A8 Design

permanent installation in onshore facilities are grouted. The grout holes Para. 6.3.9

must be accessible for grouting with the pump and driver mounted.

The outside corner of the base plate in contact with the grout have at least SAES-G-005

A9 Design

50 mm (2 in.) radius in the plan view, (API 610 Para. 6.3.10). 5.5

For offshore installations, the base plate and pedestal support assembly 31-SAMMS-004,

A10

are sufficiently rigid to be mounted without grouting. Para. 6.3.13

Saudi Aramco: Company General Use

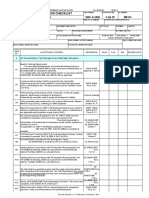

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Mounting Plate Installation and Leveling for Pumps SAIC-G-2021 30-Apr-17 MECH-

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

B. Positive Displacement Pumps: See Note 1

B1 Anchor bolts are not used to fasten machinery to the mounting plates, 31-SAMSS-009,

(API 675 Para. 3.3.5). First Paragraph

All pads for drive train components are machined flat and parrallel and 31-SAMSS-009,

B2

larger than the foot of the mounted equipment., (API 675 Para. 3.3.10). First Paragraph

ITEM No. A1 to A15 of this SAIC to be considered for this part as

B3 SAIC-G-2021

applicable.

The Maximum allowable number of shims under any equipment support 31-SAMSS-009,

B4

foot is five, (API 686, Chapter 7, Para. 5.4.2.1). First Paragraph

Jackscrews are provided for vertical adjustment of base plates on units

31-SAMSS-009,

B5 exceeding 450 kilograms (1000 pounds) in overall weight, (API 675 Para.

First Paragraph

3.3.9).

Pumps with separate drivers are provided with continuous base plates 31-SAMSS-009,

B6

under both the pump and the driver.(API 675 Para 3.3.2) First Paragraph

REMARKS:

NOTES: 1. Complete the API 686 Checklist and attach to this SAIC.

ATTACHMENTS:

ATTACHMENT 1 - API RP 686 MOUNTING PLATE INSTALLATION & LEVELING (PUMPS)

REFERENCE DOCUMENTS:

1. SAES-G-005 -- Centrifugal Pumps, 13 July 2014

2. 31-SAMSS-004 -- Centrifugal Pumps, 19 August 2014

3. 31-SAMSS-009 -- Positive Displacement Pump-Control Volume, 12 November 2013

4. API 686 -- Recommended Practices for Machinery Installation and Installation Design, SECOND EDITION, DECEMBER 2009

5. API 675 -- Positive Displacement Pump-Control Volume, Second Edition

6. API 610 -- Centrifugal Pumps for Petroleum, Heavy Duty Chemical, and Gas Industry Services, 11th Edition-September 2010.

7. SAES-G-006 -- Positive Displacement Pumps - Controlled Volume 12 November 2013

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PIEU - 30-Apr-2017 - REV. 2015.03.00 (Standards Cutoff - March 2015) Rev. 2015.03.00 31-Mar-15

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Mounting Plate Installation and Leveling for Pumps SAIC-G-2021 30-Apr-17 MECH-

ATTACHMENT 1 - API RP 686 MOUNTING PLATE INSTALLATION & LEVELING (PUMPS)

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

You might also like

- Saic G 2002Document32 pagesSaic G 2002jerinNo ratings yet

- SAUDI ARAMCO ACCESS STRUCTURE INSPECTION CHECKLISTDocument17 pagesSAUDI ARAMCO ACCESS STRUCTURE INSPECTION CHECKLISTjerinNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Inspection of Pneumatic Test (Strength & Service) SAIC-A-2021 30-Apr-17 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldDocument2 pagesSaudi Aramco Inspection Checklist: In-Process Welding Inspection (API Tanks) SAIC-W-2086 24-Jul-18 WeldjahaanNo ratings yet

- SAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWDocument27 pagesSAUDI ARAMCO PRESSURE TESTING PROCEDURE REVIEWNaushad AlamNo ratings yet

- Saudi Aramco Test ReportDocument8 pagesSaudi Aramco Test ReportJagdishNo ratings yet

- Aramco Plumbing Interview QuestionsDocument6 pagesAramco Plumbing Interview QuestionsMohanad Suliman100% (1)

- Afghanistan Land Title LteraDocument129 pagesAfghanistan Land Title LterapakphileNo ratings yet

- Saic A 1002Document2 pagesSaic A 1002karthi51289No ratings yet

- 6-Bms & Hvac SystemsDocument41 pages6-Bms & Hvac SystemsHumaid ShaikhNo ratings yet

- Arabian Fal Training Matrix - Non Base Crew UpdateDocument15 pagesArabian Fal Training Matrix - Non Base Crew UpdateastutesureshNo ratings yet

- Saudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Final Reinstatement After Mechanical & Chem Cleaning SAIC-G-2019 30-Apr-17 Mechkarthi51289No ratings yet

- Verify Saudi Aramco Test Equipment SafetyDocument6 pagesVerify Saudi Aramco Test Equipment SafetyEagle SpiritNo ratings yet

- ME430 Air Conditioning Quiz and Exam QuestionsDocument9 pagesME430 Air Conditioning Quiz and Exam Questionskakajssh yhsusuaiwNo ratings yet

- Saic K 4010Document3 pagesSaic K 4010mohamadNo ratings yet

- Paytm E-Ticket for Rajahmundry to Mumbai flightDocument3 pagesPaytm E-Ticket for Rajahmundry to Mumbai flightarunpandey1686100% (1)

- Schedule B - Attachment IVDocument29 pagesSchedule B - Attachment IVAbdul Ahad LoneNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 WeldDocument1 pageSaudi Aramco Inspection Checklist: Review of Procedure For Weld Repair (Plant Piping) SAIC-W-2002 15-Jul-18 Weldm4metzNo ratings yet

- Hydrant Inspection, Testing, and Maintenance SopDocument8 pagesHydrant Inspection, Testing, and Maintenance SopAzamta ZaVrian Rohman100% (1)

- Hydraulic Oil H 22 32 46 68 100 150Document1 pageHydraulic Oil H 22 32 46 68 100 150GTMNo ratings yet

- Technical Spec NK Elevator 1555645582Document115 pagesTechnical Spec NK Elevator 1555645582george_zouridisNo ratings yet

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection ChecklistsureshNo ratings yet

- Saudi Aramco HDPE Liner Inspection PlanDocument10 pagesSaudi Aramco HDPE Liner Inspection PlanJagdishNo ratings yet

- Inspection & Testing Requirements Scope:: Test and Inspection PerDocument1 pageInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinNo ratings yet

- ANSI HI 14.6-2011 Rotodynamic Pumps For Hydraulic Performance Acceptance Tests PDFDocument91 pagesANSI HI 14.6-2011 Rotodynamic Pumps For Hydraulic Performance Acceptance Tests PDFLuis DanielNo ratings yet

- Mechanical Works Sections for Plumbing and Fire FightingDocument239 pagesMechanical Works Sections for Plumbing and Fire FightingmasahinNo ratings yet

- Saic N 2033Document5 pagesSaic N 2033aamirapiNo ratings yet

- Asy Iom MCS PDFDocument140 pagesAsy Iom MCS PDFMohammed IsmailNo ratings yet

- Burj Dubai Sump Pump InstallationDocument6 pagesBurj Dubai Sump Pump InstallationLaura KurniawanNo ratings yet

- 01 Samss 051 PDFDocument13 pages01 Samss 051 PDFnadeem shaikh100% (1)

- Problems With B16.5 and B16.47 Flange StandardsDocument1 pageProblems With B16.5 and B16.47 Flange StandardsManohar SeetharamNo ratings yet

- Saudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbDocument3 pagesSaudi Aramco Inspection Checklist: Gravity Sewer Piping Installation Inspection SAIC-L-2138 25-May-05 PlumbHesham HelalNo ratings yet

- Final Cleanliness InspectionDocument2 pagesFinal Cleanliness Inspectionkarthi51289No ratings yet

- Marafiq Approved Equipments Manufacturer ListDocument2 pagesMarafiq Approved Equipments Manufacturer ListkapsarcNo ratings yet

- Lockout Tagout Program (Short Ver)Document4 pagesLockout Tagout Program (Short Ver)Archana Sooraj100% (1)

- Saudi Aramco PMI Program ReviewDocument18 pagesSaudi Aramco PMI Program ReviewejazNo ratings yet

- Saudi Aramco Office Furniture ProcurementDocument3 pagesSaudi Aramco Office Furniture Procurementmalika_00No ratings yet

- Cold Test & Live Test - LEVEL HT LEVEL 9 NEDocument1 pageCold Test & Live Test - LEVEL HT LEVEL 9 NENathan Emru Dela PeñaNo ratings yet

- 04-DG-Section 4 Sewage Treatment Works-Version 5.0Document24 pages04-DG-Section 4 Sewage Treatment Works-Version 5.0Jamshed AlamNo ratings yet

- Syed Usamn Shah - AY5581 Proposal PDFDocument13 pagesSyed Usamn Shah - AY5581 Proposal PDFusmanNo ratings yet

- Commercial Electric Water Heaters: Instruction ManualDocument20 pagesCommercial Electric Water Heaters: Instruction ManualIonut SomneaNo ratings yet

- Saudi Aramco DWV Piping Inspection PlanDocument3 pagesSaudi Aramco DWV Piping Inspection PlanJahangir AlamNo ratings yet

- Forged Steel Flanges SpecificationDocument25 pagesForged Steel Flanges SpecificationAwais CheemaNo ratings yet

- Satip P 121 01 Rev 7 MPDocument7 pagesSatip P 121 01 Rev 7 MPmohamedqcNo ratings yet

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- SATIP-K-001-11 - AC Split Systems DX TypeDocument3 pagesSATIP-K-001-11 - AC Split Systems DX TypeRAMAKRISHNANo ratings yet

- Sa 7918 2Document2 pagesSa 7918 2junaid ShahNo ratings yet

- Contractor Pre-QualificationDocument4 pagesContractor Pre-QualificationRajesh DhakeNo ratings yet

- Sale and Purchase Agreement (Land and Building)Document22 pagesSale and Purchase Agreement (Land and Building)Eda Edayu AnuarNo ratings yet

- Saic LPT 2006Document12 pagesSaic LPT 2006jerinNo ratings yet

- HydrantDocument18 pagesHydrantMehul PatelNo ratings yet

- Mining & Civil Product Catalogue 2021Document56 pagesMining & Civil Product Catalogue 2021Robert NormanNo ratings yet

- Plumbing Refresher CourseDocument44 pagesPlumbing Refresher CourseRomyr0% (1)

- Workers Accommodation HSES Plan Chapter 56 Rev.06.APPDocument29 pagesWorkers Accommodation HSES Plan Chapter 56 Rev.06.APPsaranya anandNo ratings yet

- Saudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbDocument2 pagesSaudi Aramco Inspection Checklist: Vent Piping Connection SAIC-S-4041 18-May-05 PlumbUzair AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Mounting Plate Installation and Leveling For Pumps SAIC-G-2021 25-May-05 Mechqazi12No ratings yet

- Saudi Aramco Tank Inspection ChecklistDocument12 pagesSaudi Aramco Tank Inspection ChecklistMd ShariqueNo ratings yet

- Saic D 2025Document10 pagesSaic D 2025jerinNo ratings yet

- Saudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechDocument23 pagesSaudi Aramco Inspection Checklist: Preliminary / Final Alignment of Pump & Driver SAIC-G-2022 29-Dec-16 MechAbdul HafeezNo ratings yet

- Saudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Post-Application Insp of Intumescent Fireproofing Mat'l SAIC-B-2008 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument13 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 InstDocument17 pagesSaudi Aramco Inspection Checklist: Fire Alarm System - Pre-Commissioning Inspection SAIC-B-6108 3-Jul-18 Instkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: In-Process Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2007 3-Jul-18 Mechkarthi51289No ratings yet

- SAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTDocument4 pagesSAUDI ARAMCO ID/PIEU INSPECTION CHECKLISTkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Pre-Application Insp of Intumescent Fireproofing Mat'ls SAIC-B-2006 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 CivilDocument2 pagesSaudi Aramco Inspection Checklist: Concrete Fireproofing Final Inspection SAIC-B-1004 3-Jul-18 Civilkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 MechDocument3 pagesSaudi Aramco Inspection Checklist: Inspection of Leaks For Tightness Testing SAIC-A-2024 3-Jul-18 Mechkarthi51289100% (1)

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization of Pneumatic Test (Strength & Service) SAIC-A-2020 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 MechDocument4 pagesSaudi Aramco Inspection Checklist: Pressurization For Bubble Leak Test (Using Air, Inert Gas) SAIC-A-2023 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 MechDocument2 pagesSaudi Aramco Inspection Checklist: Pre-Test Inspection of API Tanks SAIC-A-2026 3-Jul-18 Mechkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 MechDocument1 pageSaudi Aramco Inspection Checklist: Depressurization & Disposal of Hydrotest Water SAIC-A-2017 3-Jul-18 Mechkarthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- Saic A 1007Document2 pagesSaic A 1007karthi51289No ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saic A 2016Document1 pageSaic A 2016karthi51289No ratings yet

- SAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSDocument2 pagesSAUDI ARAMCO INSPECTION CHECKLIST FOR PRESSURE VESSELSkarthi51289No ratings yet

- The Crew 2Document4 pagesThe Crew 2SteveNoirNo ratings yet

- UNDERTAKINGSDocument6 pagesUNDERTAKINGSBrian ByarsNo ratings yet

- Case Honda 350 CB H'nessDocument11 pagesCase Honda 350 CB H'nessRajesh JayakumarNo ratings yet

- Xarmy1862 - Army of Northern Virginia Reports v2 PDFDocument603 pagesXarmy1862 - Army of Northern Virginia Reports v2 PDFDongelxNo ratings yet

- Pitch TemplateDocument16 pagesPitch TemplateAnna Shin Yee YapNo ratings yet

- Mahatranscom - in - PDF - LLR English Marathi Que Bank OrientDocument17 pagesMahatranscom - in - PDF - LLR English Marathi Que Bank OrientRaymond HickmanNo ratings yet

- MPhil PhyEdup To 15-12-13Document8 pagesMPhil PhyEdup To 15-12-13rameshbajiyaNo ratings yet

- Brockport Physical Fitness Test for Youths with Disabilities (BPFTDocument2 pagesBrockport Physical Fitness Test for Youths with Disabilities (BPFTNasri100% (1)

- CA Database June 2012Document229 pagesCA Database June 2012CelebAutosNo ratings yet

- Sistema de FrenosDocument110 pagesSistema de Frenoszaka_czNo ratings yet

- Anson Favorite Mazda Rx-7Document2 pagesAnson Favorite Mazda Rx-7Efistein Archymedes NagaNo ratings yet

- 105th VSGA Amateur Championship PreviewDocument14 pages105th VSGA Amateur Championship PreviewTom JacobsNo ratings yet

- Student List SC, ST, OBC For The Session 2019-20Document8 pagesStudent List SC, ST, OBC For The Session 2019-20Rishav KumarNo ratings yet

- Pinewood FinalsDocument2 pagesPinewood FinalsPack 3322 LeadersNo ratings yet

- Medial Epicondylitis (Golfer's Elbow) What Is Medial Epicondylitis?Document4 pagesMedial Epicondylitis (Golfer's Elbow) What Is Medial Epicondylitis?Kalamegam RamasamiNo ratings yet

- Performance Checklist Handwashing DON E Scor E NOT Done 2 1 3 1 2 2 3Document1 pagePerformance Checklist Handwashing DON E Scor E NOT Done 2 1 3 1 2 2 3Mhel MGNo ratings yet

- LotsDocument9 pagesLotsCesar Antonio Espinoza RojasNo ratings yet

- SoftcamDocument16 pagesSoftcameduardoNo ratings yet

- Fundamental of Diesel EngineDocument23 pagesFundamental of Diesel EngineAyah Nofa PutraNo ratings yet

- Arnold SchawarzeneggerDocument2 pagesArnold SchawarzeneggerFarcas Ioan PaulNo ratings yet

- Phys CH3Document39 pagesPhys CH3dockmom4No ratings yet

- FIFA 2014 World Cup Sports MarketingDocument80 pagesFIFA 2014 World Cup Sports MarketingAnjaliThakkarNo ratings yet

- OCS Packing ListDocument5 pagesOCS Packing ListcrowthwNo ratings yet

- Natural Remedies For FibroidsDocument2 pagesNatural Remedies For Fibroidsafm2026No ratings yet

- Uwi Sports Day 2020 ResultsDocument6 pagesUwi Sports Day 2020 ResultsRonaldo FergusonNo ratings yet

- 2005 RockShox WartungshandbuchDocument99 pages2005 RockShox Wartungshandbuchpsagnes3142No ratings yet

- Design and Fabrication of Two Wheeled Self Balancing Scooter - 3rd ReviewDocument6 pagesDesign and Fabrication of Two Wheeled Self Balancing Scooter - 3rd ReviewKuldeep PatelNo ratings yet

- Manual Motor Mack 675Document4 pagesManual Motor Mack 675Jeferson Forero Rubio75% (12)

- Single Convoluted Firestone Air SpringsDocument2 pagesSingle Convoluted Firestone Air SpringsMROstop.comNo ratings yet

- Master The Art of Texas Holdem With Calculatem Pro PDFDocument2 pagesMaster The Art of Texas Holdem With Calculatem Pro PDFGelu BugnaruNo ratings yet