Professional Documents

Culture Documents

New Calculations From Hydrocomp Using Quantitative Relational Elements

Uploaded by

theleepiper8830Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Calculations From Hydrocomp Using Quantitative Relational Elements

Uploaded by

theleepiper8830Copyright:

Available Formats

New calculations from HydroComp using quantitative relational elements

In the hunt for better engineering answers, (for the prescribed pitch distribution of the series).

hydrodynamic codes are evolving with increasing The inflow is described by the nominal effective

complexity. One of the marine industry leaders in wake fraction. As long as the propeller under

hydrodynamic software development and services – consideration matches the foil shape, and

HydroComp, Inc., of Durham, NH USA – is wary of distributions of chord, thickness, camber, and pitch,

this complexity and is developing advanced codes the predictions are reliable. Of course, techniques

with the specific intent of giving highest priority to such as NavCad’s “aligned prediction” can be

reliability, usability, behavior, and cost- applied to improve the accuracy of the prediction,

effectiveness. HydroComp is best known for their albeit still with certain constraints.

empirically based hydrodynamic prediction

software, notably the popular NavCad™ software, Highly complex codes offer the ability to fully

which is now in its 20th year of service. define the three-dimensional surface of the propeller,

including the unique distribution of foil thickness

“Empirical design tools, such as model testing, and camber. These codes, however, are costly both

statistical methods of systematic series, and sea trials in terms of computation time and resources. It is not

– are still the real workhorses of day-to-day uncommon for computation time to exceed 20

quantitative hydrodynamic analysis. I stress the term minutes for a single generation, with hundreds of

‘quantitative’, as most designers are more interested generations required for a complete analysis.

in reliably predicting drag and propeller performance

to select the proper engine, for example, than to HydroComp’s new calculations straddle the ground

tweak the hull form or resolve a flow problem” notes between the wholly empirical and purely numerical.

HydroComp’s technical director, Donald The codes allow for practical global variations that

MacPherson. “Having said that, we acknowledge are not available in statistical methods, such as

that the scope of available statistical methods are arbitrary distributions of chord, thickness, camber,

limited and insufficient for some problems. As a and pitch. It also includes definition of axial and

result, engineers are rightly investigating new codes tangential wake distributions. The characteristics of

to fill this void, but we believe that complex codes the foil itself, such as its shape and lift-drag

are not the universal answer for quantitative coefficient, are prescribed by selecting a foil from

problems.” the calculation library.

Calculation by quantitative relational elements A rapid quantitative performance prediction can be

achieved by taking a common empirically based foil

HydroComp is in the latter stages of a two-year definition, such as the popular NACA 66 mod, and

internal R&D effort to develop a new category of applying it to any set of chord, camber, thickness or

calculation technique that will offer a cost-effective pitch. The following graphic illustrates how a

alternative to complex codes for the prediction of collection of relational elements – or radial slices

bare-hull drag and propeller performance. The codes through the blade – can define the propeller.

are based on what the developers are calling

“quantitative relational elements”. The analytical

basis of “quantitative relational elements” is not

altogether new, but it is implemented in a unique

way to utilize different collections of empirical data

to greatly extend the scope and functionality of these

calculations.

To explain how these calculations work, let’s

consider the performance prediction of a propeller,

and the data required for the calculations. When

calculating performance using systematic series, you

define the propeller by its type (such as the B-

series), number of blades, blade area ratio (which

Figure 1 – Relational element radial slice

defines the outline shape), and pitch-diameter ratio

Likewise, calculation of bare-hull resistance is

achieved in much the same manner, as the hull is

sliced into longitudinal elements, such as sectional

area. This provides greater global definition of the

geometry that you would have with a purely

statistical series (the might use only the prismatic

coefficient, for example, to define the sectional area

curve). Unlike complex codes, you do not have full

three-dimensional definition of the hull surface,

rather you have a practical and meaningful

distribution of the hull’s global shape.

Core attributes

Fundamental criteria for all of the new calculations

are reliability, usability, behavior, and cost- Figure 2 – Irregular waterline offsets through a

effectiveness. Attributes of the calculations can be propeller pocket

summarized as:

One development priority was that all of these new

• Description of hull and propeller codes could be used without special knowledge of

distributions using “elements”. element modeling or unusual manipulation of input

• Predictions are well behaved with no data. Simplifying the distribution data to avoid

unusual results. potential problems, like the propeller pocket

• Any set of data can be applied. No special illustrated above, was an easy compromise for the

knowledge of element modeling is required. developers. “We have always held to the maxim

• Calculation options are limited, and pre-set that, to the best of our ability, we will give you no

where possible. The intent is to remove the answer before giving you the wrong answer” points

need for user “fudge factors”. out Mr. MacPherson, “and sometimes that means

keeping things practical and uncomplicated.”

• Extensive validations fully expose the scope

of the calculations to users.

The bare-hull drag module predicts not just wave-

• Fast calculation times, with most full

making drag, but also viscous drag and thus total

analyses taking less than one minute.

bare-hull drag. Wave-making drag is important only

in so far as it leads to correct prediction of total bare-

Bare-hull drag calculations

hull drag, and extensive effort has been put into

reliable prediction of frictional drag and form factor.

The bare-hull drag module is built upon a novel

The module also provides automatic data checks and

implementation of thin-ship theory. The most well

correlation functions, including viscous effects on

known of the various thin-ship theories is the

wave-making, immersed transom stern, sinkage and

“Michell Integral”, which uses hull offsets to

trim, and pressure drag. These correlation functions

describe the hull. “Early investigations suggested

are automated in the code, and it is important to

that a Michell Integral approach would not be

point out that no special user decisions were made in

suitable for our purposes. The detail afforded by

the creation of these validation calculations.

describing the surface by offsets was canceled by the

practical matter of how irregular changes in offsets,

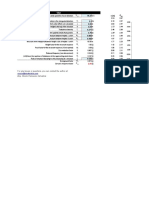

Validation studies were conducted using open

for things like tunnel thrusters or propeller pockets,

published data to provide complete transparency to

caused significant inaccuracies in the calculations.

users. Representative validation plots are shown

So, we simplified the approach and developed a

below, and a full set of validation reports are

comparable linear code that used sectional areas and

available from HydroComp.

their vertical centroid, as well as waterplane

distribution. While this limits the ability to locally

describe the hull geometry, it makes for much more

well-behaved and reliable code. We are also looking

for this to be extensible to ‘not-so-thin’ ships.”

INSEAN 2340 [Free]

the off-design condition. Data exchange is currently

available to both NavCad and HydroComp’s

0.009

0.008

PropCad™ propeller geometric modeling software.

0.007

CT-test

The module can be applied for full wake-adapted

CT, CF, CW

0.006

0.005 CT-calc

0.004 CF-calc design of optimal characteristics or off-design

0.003

0.002

CW-calc analysis of performance and KT-KQ curves. A

0.001 variety of design choices are available, including

0

0 0.1 0.2 0.3 0.4 0.5

different optimal circulation methodologies and tip

Fn or root unloading. Analysis options include foil

characteristics, hub effects, and water properties.

Propeller configurations include both open and

Figure 3 – Prediction of INSEAN 2340 model ducted propellers, with work continuing on counter-

(DTMB 5415 variant); automated correlation rotating propellers.

Wigley [Fixed] “The empirical correlation functions really make the

propeller performance module a ‘fully-baked’

0.009

0.008 propeller design tool.” Comments Mr. MacPherson.

0.007

CT-test

“If a user does not need to explicitly define the foil

CT, CF, CW

0.006

0.005 CT-calc shape and selects a foil from the list, then the tool is

0.004 CF-calc perfectly suited for final design of that particular

0.003 CW-calc

0.002 style of propeller, including pitch and camber

0.001

0.000

distribution. If they do need more local control over

0.0 0.2 0.4 0.6 0.8 1.0 the foil shape, then the module is an ideal pre-

Fn processor for more complex analyses.” The analysis

functions predict a complete set of results including

foil lift and drag, circulation, performance,

Figure 4 – Prediction of Wigley model; no sinkage cavitation, and even blade strength.

and trim correction (for validation)

The empirical correlation functions also extend to

NPL C3 [Free] ducted propeller performance. Part of the R&D tasks

0.014

for the propeller performance module included data

0.012 analysis and fitting of nozzle-propeller thrust ratios,

0.010 CT-test and prediction of the nozzle’s influence on induced

CT, CF, CW

0.008 CT-calc velocity. HydroComp plans to make definition of

0.006 CF-calc

CW-calc

nozzle performance extensible to user-defined data,

0.004

0.002

so that companies can use the module for their own

0.000 custom nozzle shapes.

0 0.2 0.4 0.6 0.8 1 1.2

Fn

Validation plots are shown below for typical

propeller performance curves. Like validation

Figure 5 – Prediction of NPL C3 model; automated studies for all HydroComp software, all data used to

correlation validate the propeller performance module is taken

from public sources. For example, the Kaplan 4.55

Propeller performance propeller in the 19A nozzle is well documented.

Model DTRC4119 is a three-bladed propeller that is

The propeller performance module utilizes a frequently used for evaluation and validation of

fundamental vortex lattice lifting-line code for propeller flow codes. The range of interest for this

moderately loaded propellers, with a connection to propeller is typically from J = 0.5 to 1.1, and the

empirical data. For example, most lifting-line codes propeller performance module shows excellent

use a generic value for drag coefficient, whereby this results even well away from the design condition

new code allows the user to select from a list of foil (J=0.833). You will note that the validation plot for

types, such as NACA 66 mod, Segmental, and Bi- the DRTC4119 does show the typical reduction in

Circular, to more accurately predict performance in predicted values as it goes from moderately loaded

and approaches the heavily loaded bollard condition correlate the prediction to the known results of a

(low J). However, the new ducted propeller inflow model test. Therefore, one model test can be used to

velocity correlation produces very good results for enhance accuracy for any similar hull or propeller

the Kaplan 19A, even near bollard performance. variant.

0.6 About HydroComp

0.5

Donald MacPherson has been HydroComp’s

0.4

KT technical director since its inception. He is the

KT, 10KQ, KTN

0.3

10KQ author of numerous technical papers and

KTN

KT-calc

presentations on applied hydrodynamics, is

0.2

10KQ-calc Instructor of Naval Architecture at the University of

0.1

KTN-calc

New Hampshire, and is a member of SNAME’s H8

0

Propellers panel.

0 0.2 0.4 0.6 0.8

-0.1

Celebrating its 25th year of operation in 2009,

J

HydroComp provides software and services for the

performance analysis and design of marine vehicles

Fig 6 – Propeller performance, Kaplan 4.55 in 19A to industry, research, academic, and government

nozzle clients. The company is proud to have served over

600 customers from more than 60 countries. For

0.7 more information about the new calculation modules

using quantitative relational elements, please contact

0.6

HydroComp at info@hydrocompinc.com, or through

0.5

their web site at www.hydrocompinc.com.

KT

KT, 10KQ

0.4

10KQ

0.3

KT-calc You can see the new calculations first hand at a

10KQ-calc

number of trade shows and conferences in 2009,

0.2

including SNAME Propeller/Shafting and Annual

0.1

Meeting, National Marine Propeller Association, and

0 METS.

0 0.2 0.4 0.6 0.8 1 1.2

J

Fig 7 – Propeller performance, DTRC 4119

Development plans include aligned prediction

capability

HydroComp has employed a technique called “align

prediction” in its NavCad software for many years.

Future development plans include incorporating this

technique for the new calculation modules.

Aligned prediction offers user the ability to use

quantitative relational element calculations with

specific empirical data, such as model tests, to

further improve the quantitative accuracy of the

prediction. Using an aligned prediction technique is

a simple matter of setting up a hull resistance or

propeller KT-KQ model test with the model’s own

distributive elements. Then, the user can simply

point to the model and allow the calculation to learn

if it needs to add or deduct a small amount to

You might also like

- NavCad PWD Module NA Jul-Aug 14Document1 pageNavCad PWD Module NA Jul-Aug 14theleepiper8830No ratings yet

- Comments On Reliable Prediction Accuracy: A Hydrocomp Technical ReportDocument4 pagesComments On Reliable Prediction Accuracy: A Hydrocomp Technical ReporthaujesNo ratings yet

- Use of Commercial CFD Codes To Enhance Performance Prediction Capabilities For Planning BoatsDocument9 pagesUse of Commercial CFD Codes To Enhance Performance Prediction Capabilities For Planning Boatsgnd100No ratings yet

- Sawaryn 2005Document13 pagesSawaryn 2005AmirhosseinNo ratings yet

- Siemens SW Simulation Driven Ship Design White PaperDocument12 pagesSiemens SW Simulation Driven Ship Design White PaperTip's kNo ratings yet

- Rapid CFD Simulation of Internal Combustion EnginesDocument11 pagesRapid CFD Simulation of Internal Combustion EnginesdebelaNo ratings yet

- Bekhit 2018 IOP Conf. Ser. - Mater. Sci. Eng. 400 042004Document12 pagesBekhit 2018 IOP Conf. Ser. - Mater. Sci. Eng. 400 042004ciksunNo ratings yet

- Openwindpower Fixed Foundation: Offshore Wind Turbine AnalysisDocument2 pagesOpenwindpower Fixed Foundation: Offshore Wind Turbine Analysisaayushi doshiNo ratings yet

- Bentley SACS: Offshore Wind Turbine AnalysisDocument2 pagesBentley SACS: Offshore Wind Turbine AnalysisRAM KUMARNo ratings yet

- 3D CFD Modelling of Spillways Practical Feedback On Capabilities and Challenges PDFDocument7 pages3D CFD Modelling of Spillways Practical Feedback On Capabilities and Challenges PDFIsma FajarNo ratings yet

- Anisotropic Grid Adaptation For Rans Simulation of A Fast Manoeuvering Catamaran PDFDocument9 pagesAnisotropic Grid Adaptation For Rans Simulation of A Fast Manoeuvering Catamaran PDFtsaipeterNo ratings yet

- Managing Well CasingDocument18 pagesManaging Well CasingElena Herrera VasquezNo ratings yet

- Calm Water Resistance Prediction of A Container Ship Using Reynolds Averaged Navier Stokes Based SolverDocument6 pagesCalm Water Resistance Prediction of A Container Ship Using Reynolds Averaged Navier Stokes Based SolverShaksNo ratings yet

- Optimized Ship Design Using Heeds & Star-Ccm+Document67 pagesOptimized Ship Design Using Heeds & Star-Ccm+MANABENDRANo ratings yet

- Shape Optimization in Ship Hydrodynamics Using ComputationalDocument18 pagesShape Optimization in Ship Hydrodynamics Using ComputationalFatwa AzamNo ratings yet

- Comparative Investigation of VLM Codes For Joined-WingDocument5 pagesComparative Investigation of VLM Codes For Joined-WingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Marine 2017 18 - Propeller Nozzles DesignDocument13 pagesMarine 2017 18 - Propeller Nozzles DesignMaciej ReichelNo ratings yet

- Etude de Cas STX Coque PDFDocument8 pagesEtude de Cas STX Coque PDFGraham WestbrookNo ratings yet

- Siemens SW Multidisciplinary simulation in the marine industry EBDocument84 pagesSiemens SW Multidisciplinary simulation in the marine industry EBAdhi KusumadjatiNo ratings yet

- 2014 SNH Tahara EtalDocument21 pages2014 SNH Tahara EtalFarid IlhamNo ratings yet

- Solidworks Flow Simulation Instructor Guide: Presenter DateDocument19 pagesSolidworks Flow Simulation Instructor Guide: Presenter DateAndoni Garcia MatxainNo ratings yet

- Parametric Finite Element Model of AIRBUS Engine Pylon With MSC - PatranDocument9 pagesParametric Finite Element Model of AIRBUS Engine Pylon With MSC - Patranventus45No ratings yet

- Speed, power and cost implications for GPU acceleration of Computational Fluid Dynamics on HPC systemsDocument12 pagesSpeed, power and cost implications for GPU acceleration of Computational Fluid Dynamics on HPC systemsbakular.mark675No ratings yet

- Ship Hull Form Design and Optimization Based On CFDDocument9 pagesShip Hull Form Design and Optimization Based On CFDAshley KwambokaNo ratings yet

- Resume Mrunal CFD SGDocument2 pagesResume Mrunal CFD SGMrunal KrishnanNo ratings yet

- Small-Craft Power PredictionsDocument33 pagesSmall-Craft Power PredictionsbourneremembersNo ratings yet

- Jack Up DesignDocument29 pagesJack Up DesignKirti BairathiNo ratings yet

- Advanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessDocument49 pagesAdvanced Fatigue Analysis of Offshore Jacket Tubular Joints: Sesam - 50 Years of SuccessMuraliNo ratings yet

- Research ProposalDocument9 pagesResearch ProposalSrinivasan Viswanathan100% (1)

- Cable Robot ThesisDocument5 pagesCable Robot ThesisBuyEssaysTulsa100% (2)

- Design AID FOR Continuous Beams: BstractDocument13 pagesDesign AID FOR Continuous Beams: BstractAhmad HazimehNo ratings yet

- XFlow 2018Document6 pagesXFlow 2018Sreeja SunderNo ratings yet

- A Practical System For Hydrodynamic Optimization of Ship Hull FormsDocument7 pagesA Practical System For Hydrodynamic Optimization of Ship Hull FormsSalma SherbazNo ratings yet

- Dynamics and Design Genetic by Algorithm Optimization Coupling Computational Fluid Dynamics and Genetic AlgorithmDocument14 pagesDynamics and Design Genetic by Algorithm Optimization Coupling Computational Fluid Dynamics and Genetic AlgorithmBrian Quintero ArboledaNo ratings yet

- Parametric Study of Airfoil Analysis Using CFD PDFDocument9 pagesParametric Study of Airfoil Analysis Using CFD PDFMr. S. Thiyagu Asst Prof MECHNo ratings yet

- Mixed-Fidelity Design Optimization of Hull Form Using CFD and Potential Flow SolversDocument15 pagesMixed-Fidelity Design Optimization of Hull Form Using CFD and Potential Flow Solversheinz billNo ratings yet

- An Estimation of Motor Yacht Light Displacement Based On Design Parameters Using Computational Intelligence TechniquesDocument14 pagesAn Estimation of Motor Yacht Light Displacement Based On Design Parameters Using Computational Intelligence TechniquesISAI LABORIEN ROMAN RUELASNo ratings yet

- Design Toy Submarine Underwater VehicleDocument8 pagesDesign Toy Submarine Underwater VehicleErickson OngNo ratings yet

- Koelman - Photo - Reengiener - ShipDocument13 pagesKoelman - Photo - Reengiener - ShipMjNo ratings yet

- A Tool For Analysis of Costs On The Manufacturing of The HullDocument7 pagesA Tool For Analysis of Costs On The Manufacturing of The HullCleber001No ratings yet

- Carpenter 2020Document2 pagesCarpenter 2020WICKEY WULANDARINo ratings yet

- Scale Laws Budinger 26688Document17 pagesScale Laws Budinger 26688FLASNo ratings yet

- Resume Mrunal CFDDocument2 pagesResume Mrunal CFDMrunal KrishnanNo ratings yet

- Final Project SummaryDocument6 pagesFinal Project SummaryegemNo ratings yet

- A CFD Suite For Design and Performance PredictionDocument8 pagesA CFD Suite For Design and Performance PredictionAdel AyoubNo ratings yet

- A Parallel Implicit in Compressible FlowDocument33 pagesA Parallel Implicit in Compressible FlowRituraj GautamNo ratings yet

- Encyclopedia of Maritime and Offshore Engineering Hydrodynamic Scale Model Tests For Offshore PDFDocument18 pagesEncyclopedia of Maritime and Offshore Engineering Hydrodynamic Scale Model Tests For Offshore PDFLogical QuestionsNo ratings yet

- Deswik White Paper Pseudoflow ExplainedDocument10 pagesDeswik White Paper Pseudoflow ExplainedKamara100% (1)

- 1998-On The Use of CFD in The Automotive Engine Cooling Fan System DesignDocument12 pages1998-On The Use of CFD in The Automotive Engine Cooling Fan System DesignJianbo JiangNo ratings yet

- A Report On The Papers Presented On High Lift Airfoil SectionsDocument36 pagesA Report On The Papers Presented On High Lift Airfoil SectionsRaja Shekar KalashikamNo ratings yet

- Aerospace Science and Technology: Nicholas J. Peters, Andrew Wissink, John EkaterinarisDocument21 pagesAerospace Science and Technology: Nicholas J. Peters, Andrew Wissink, John EkaterinarisGOVIND SINGH RAWATNo ratings yet

- Wellplan Software: Key ValueDocument4 pagesWellplan Software: Key Valuebyed100% (1)

- PUB-CADFEM Update 2023R1 MBU WBNR-FRDocument81 pagesPUB-CADFEM Update 2023R1 MBU WBNR-FRradhouanhmNo ratings yet

- Turbine Cascade Geometry t106 ProfileDocument9 pagesTurbine Cascade Geometry t106 Profilerabea matoukNo ratings yet

- PBS CRAY RiserSim US WEBDocument4 pagesPBS CRAY RiserSim US WEBkamsNo ratings yet

- Fairway Technical BackgroundDocument7 pagesFairway Technical BackgroundSARCNo ratings yet

- STR 3 2018 Sulcol Program Ang PDFDocument4 pagesSTR 3 2018 Sulcol Program Ang PDFsakthivelg15357No ratings yet

- Small Craft Power PredictionDocument32 pagesSmall Craft Power Predictionaeromexpower2009No ratings yet

- Whitepaper: Engine Intake OptimizationDocument10 pagesWhitepaper: Engine Intake OptimizationgosculptorNo ratings yet

- Introduction To Thruster Design For Submersible Developers PG48 MTR Oct19Document3 pagesIntroduction To Thruster Design For Submersible Developers PG48 MTR Oct19theleepiper8830No ratings yet

- Finding "Green" in The Hydrodynamic Soup With Wake-Adapted PropellersDocument5 pagesFinding "Green" in The Hydrodynamic Soup With Wake-Adapted Propellerstheleepiper8830No ratings yet

- Hydrocomp Software R&D Also Benefit To IndustryDocument1 pageHydrocomp Software R&D Also Benefit To Industrytheleepiper8830No ratings yet

- CAD/CAM Software Feature for Ship Noise Pollution ReductionDocument2 pagesCAD/CAM Software Feature for Ship Noise Pollution Reductiontheleepiper8830No ratings yet

- Electric Motor Efficiency Considerations for UUVsDocument2 pagesElectric Motor Efficiency Considerations for UUVstheleepiper8830No ratings yet

- CAD/CAM Software Feature for Ship Noise Pollution ReductionDocument2 pagesCAD/CAM Software Feature for Ship Noise Pollution Reductiontheleepiper8830No ratings yet

- TNA Oct 2018 Practical Designer-Guided Hull Form OptimizationDocument4 pagesTNA Oct 2018 Practical Designer-Guided Hull Form Optimizationtheleepiper8830No ratings yet

- Introduction To Thruster Design For Submersible Developers PG48 MTR Oct19Document3 pagesIntroduction To Thruster Design For Submersible Developers PG48 MTR Oct19theleepiper8830No ratings yet

- Bollard Pull NavCad MN Dec15Document2 pagesBollard Pull NavCad MN Dec15theleepiper8830100% (1)

- Ship Maintenance Planning With NavCadDocument4 pagesShip Maintenance Planning With NavCadtheleepiper8830No ratings yet

- SoftwareEnablesCloseLookAtTugPower IntlTugOSV MayJun2016 PDFDocument1 pageSoftwareEnablesCloseLookAtTugPower IntlTugOSV MayJun2016 PDFtheleepiper8830No ratings yet

- SoftwareEnablesCloseLookAtTugPower IntlTugOSV MayJun2016Document1 pageSoftwareEnablesCloseLookAtTugPower IntlTugOSV MayJun2016theleepiper8830No ratings yet

- Improvements in CFD Efficiency With RDSO Using NavCad PremiumDocument2 pagesImprovements in CFD Efficiency With RDSO Using NavCad Premiumtheleepiper8830No ratings yet

- HydroComp NavCad ReleasedDocument3 pagesHydroComp NavCad Releasedtheleepiper8830No ratings yet

- New Capabilities For Fast Craft Analysis With HydroComp NavCad 2012Document3 pagesNew Capabilities For Fast Craft Analysis With HydroComp NavCad 2012theleepiper8830No ratings yet

- Squat Effects Pub 2002Document9 pagesSquat Effects Pub 2002theleepiper8830No ratings yet

- Mod Exam Mah PDFDocument3 pagesMod Exam Mah PDFjaja riveraNo ratings yet

- CLASS 12 MATHS Minimum Learning Material KVS Ernakulam PDFDocument83 pagesCLASS 12 MATHS Minimum Learning Material KVS Ernakulam PDFSimha SimhaNo ratings yet

- Chapter 4 - Statistic - PIE CHARTDocument4 pagesChapter 4 - Statistic - PIE CHARTyattie17607No ratings yet

- Geometric Design of Linkages J Michael 27006480Document2 pagesGeometric Design of Linkages J Michael 27006480warekarNo ratings yet

- Physics MYP Questions 3Document14 pagesPhysics MYP Questions 3shikhaNo ratings yet

- Adilet Imambekov - Strongly Correlated Phenomena With Ultracold Atomic GasesDocument200 pagesAdilet Imambekov - Strongly Correlated Phenomena With Ultracold Atomic GasesItama23No ratings yet

- Tabulation of Error Function Values PDFDocument1 pageTabulation of Error Function Values PDFReyes DanaeNo ratings yet

- PaythonDocument45 pagesPaythonKajal KachrooNo ratings yet

- Reservoir Simulation BasicsDocument11 pagesReservoir Simulation Basicsoliver_34No ratings yet

- Control and energy management of a pumping systemDocument16 pagesControl and energy management of a pumping systemhassenbbNo ratings yet

- Mathematics for Business Students Worksheet No. 7 SolutionDocument6 pagesMathematics for Business Students Worksheet No. 7 Solutionahmed wahshaNo ratings yet

- 2022 General Math Exam P1 ResponseDocument24 pages2022 General Math Exam P1 ResponsesamNo ratings yet

- DC Motor N GeneratorDocument23 pagesDC Motor N GeneratorGilbert SihombingNo ratings yet

- Malvern Usp 429Document237 pagesMalvern Usp 429Dimitris PapamatthaiakisNo ratings yet

- Oracle Datatypes: Data Types For Oracle 8 To Oracle 11gDocument9 pagesOracle Datatypes: Data Types For Oracle 8 To Oracle 11gRathish KumarNo ratings yet

- SF-2200H Operating ManualDocument36 pagesSF-2200H Operating ManualuripssNo ratings yet

- A Review of Scroll Expander Geometries and Their PerformanceDocument23 pagesA Review of Scroll Expander Geometries and Their PerformancePedro ferreiraNo ratings yet

- 10 Questions for Stephen Hawking about the UniverseDocument2 pages10 Questions for Stephen Hawking about the UniverseYihuan ZouNo ratings yet

- Notes 8Document45 pagesNotes 8---No ratings yet

- DTE MCQ QUESTION BANK ON DIGITAL ELECTRONICS GATESDocument29 pagesDTE MCQ QUESTION BANK ON DIGITAL ELECTRONICS GATESAmal NairNo ratings yet

- The Basis of GlottochronologyDocument16 pagesThe Basis of GlottochronologyEky SyahrudinNo ratings yet

- Chain Product Quotient Rules 277qagsDocument7 pagesChain Product Quotient Rules 277qagsRobert JoeNo ratings yet

- Cpa Review School of The Philippines Management Advisory Services Quantitative Methods TheoryDocument19 pagesCpa Review School of The Philippines Management Advisory Services Quantitative Methods TheoryAdèity TVNo ratings yet

- Dynamic Response Factor As Per As 1170.2Document2 pagesDynamic Response Factor As Per As 1170.2Zarna ModiNo ratings yet

- EE719 Tutorial Assigment 1Document24 pagesEE719 Tutorial Assigment 1Siddhesh SharmaNo ratings yet

- Grade 3 Grand Finals Contest Problems: Chọn câu trả lời đúngDocument2 pagesGrade 3 Grand Finals Contest Problems: Chọn câu trả lời đúngHoa NguyễnNo ratings yet

- (-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice AnotherDocument4 pages(-/2 Points) SCALCET8 2.7.JIT.003.MI.: Details My Notes Ask Your Teacher Practice Anotherbilal5202050No ratings yet

- Baseband Shaping for Data TransmissionDocument60 pagesBaseband Shaping for Data Transmissionrahul guptaNo ratings yet

- Determining Beta Factor For A 2N2222 TransistorDocument2 pagesDetermining Beta Factor For A 2N2222 TransistorJuan Carlos Morales ParraNo ratings yet

- (Ggplot2 Data Visualization) Alboukadel Kassambara - Guide To Create Beautiful Graphics in R-STHDA (2013) PDFDocument238 pages(Ggplot2 Data Visualization) Alboukadel Kassambara - Guide To Create Beautiful Graphics in R-STHDA (2013) PDFGrasiela SantanaNo ratings yet