Professional Documents

Culture Documents

Canned Motor Pump API 685: Technical Data

Uploaded by

nagarajhebbarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Canned Motor Pump API 685: Technical Data

Uploaded by

nagarajhebbarCopyright:

Available Formats

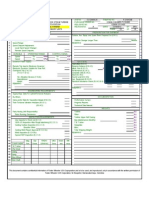

Head-Capacity Envelope

m

50Hz m

500 ft 60Hz 500 ft

1500 1500

1000 1000

700 700

23F

500 25F 26F 500

23F

100 25F 26F 27F 100 22E 23E 24E 25E

300 26E 27E 300

22E 23E 24E 25E 22D 23D 24D 25D

26E 27E 200 26D 200

HEAD

HEAD

22D 23D 24D 25D 23C

26D 22Z 24C 25C 26C

23C 100 100

22Z

Canned Motor Pump

24C 25C 26C 22B 23B

70 24B 70

22B 23B 23A 25B

24B 50 22A 50

25B 24A

22A 23A

10 24A 30 10 30

API 685

1 10 100 1000 m3 /h 1 10 100 1000 m3 /h

10 20 30 50 70 100 200 300 500 700 1000 2000 3000 5000 U.S.gpm 10 20 30 50 70 100 200 300 500 700 1000 2000 3000 5000 U.S.gpm

CAPACITY CAPACITY

Technical Data

Pump Size

(Discharge Nozzle Diameter) 40 mm to 150 mm 11/2" to 6"

Capacity * up to 360 m3/h up to 1600 U.S.gpm

Head up to 220 m up to 720 feet

Motor Rating up to 132 kW up to 180 HP

Design Pressure 40 bar 600 psi

Pumping Temperature up to + 450 o C up to + 840 oF

Insulation Class C

Explosion Protection ATEX Directive (94/9/EC)

* Higher capacities upon request.

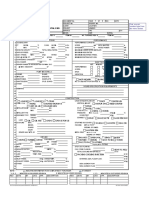

Flange Sizes

Pump Size Suction Nozzle Diameter Discharge Nozzle Diameter

inch mm inch mm

22 2 50 1½ 40

23 3 80 2 50

24A, 24B, 24C 3 80 3 80

24D, 24E 3 80 2 50

25 4 100 3 80

26 6 150 4 100

27 6 150 6 150

Nikkiso-KSB GmbH Telephone: +49 (0) 6181 30010 0 sales@nikkiso-ksb.com

Philipp-Reis-Str. 13 Fax: +49 (0) 6181 30010 99 www.nikkiso-ksb.com

D-63486 Bruchköbel

NKG 2011-2010-02 / KSB 4109.021-10

API 685 Canned Motor Pump

Nikkiso-KSB Canned Motor Pumps that comply with both API 685* and ATEX* is developed for Sleeve (Tungsten Carbide Coated) BEARINGS / SHAFT SLEEVES & Typical Flow Path and Applications

the heavy duty requirments in the refinery and petrochemical industries. Bearing (Carbon Graphite) THRUST WASHERS

Type HN, Type HV

Silicon Carbide Lining Nikkiso-KSB bearings are sliding bearings which

*API 685 : Sealless Centrifugal Pumps for Petroleum, Heavy Duty Chemical, and Gas Industry Services are always provided with lubrication grooves. Fluid at approximately 60 % of discharge pressure is

*ATEX : ATEX Directive ( 94/9/EC ) circulated through the bearings and over the rotor for

The surface of these bearings is lined with a cooling and lubrication and returns through the hollow

silicon carbide of approximate 4mm thickness shaft of suction pressure. Type HN is the basic type and

which is created by conversion of graphite using is suitable for a broad range of clean and nonvolatile

pure silicon. These bearings have a reduced liquids with moderate temperatures.

sensibility to mechanical shocks and chipping Type HV has similar flow path of Type HN, is suitable for

the high viscous liquids (80cp to 200cp).

compared with SiC. Embedded graphite particles

provide emergency lubrication.

E-MONITOR Shaft

E-monitor can indicate the axial and

radial rotor position during pump Thrust Washer

operation on an easy-to-read LED (Tungsten Carbide Coated)

Ring

display. Indication can be local or (Using to allow for relative thermal expansion)

remote. Rotation LED for easy Type HQ

startup. The type HQ utilizes a flow through the motor to the

E-monitor is energized by power from vapor zone of the suction vessel. It is for fluid that would

the incoming motor leads and does tend to flush to vapor if returned to impeller eye after

picking up motor heat. The return line is throttled to

not require additional wiring.The maintain high pressure liquid within the motor and also

technical excellence of the E-monitor serves as a vent line normally installed for this type fluid.

makes pump maintenance planable. This type is suitable for fluids with high vapor pressure.

It can avoid expensive motor stator

and winding damage and can prevent

unexpected plant shut down.

TEMPERATURE

MONITORING DEVICE FOR MOTOR WINDING

Insulation class C allows un-cooled operation for fluid temperature Type HR

TEMPERATURE up to 180 °C. Pressure in rotor chamber is the same as discharge

pressure to avoid evaporation and then the flow is

MONITORING DEVICE FOR STATOR LINER / ROTOR LINER returned to the vapor zone of the suction vessel similar

PUMP LIQUID FLANGES to Type HQ. Type HR is suitable for fluids (i.e. liquefied

gases, VCM, hydrocarbons, chlorine) with vapor

HC-N for low eddy-current losses and high

PT100 or PTC Flanges are available for pressure curve that increases steeply.

corrosion resistance.

ANSI/ASME, B16.5 CL300LB RF.

Designed for 4 times Nozzle

Force & Moment from API 685.

ADDITIONAL

TEMPERATURE

MONITORING

Type HS, Type HM

(OPTIONAL)

A clean, compatible flush fluid supply is required and is

constantly recirculated within the motor section to

prevent solids or high vapor pressure liquids from

migrating into the motor chamber. In case of Type HS,

flush fluid loss to the process stream is minimized by

closed clearance bushing between the motor and pump

end. Type HM utilize a mechanical seal for reduced

flush rates. These Types shall be suitable for fluid with

slurries up to 30wt % solids.

BEARINGS

SHAFT SLEEVES &THRUST WASHERS

AUTOMATIC

SECONDARY CONTAINMENT THRUST BALANCE SYSTEM Type HT

In the event of containment shell failure, caused by a This system has engineered to balance the Process fluid is recirculated within the motor section via

foreign object the secondary containment withstands the thrust generated by the pump impellers. Self an auxiliary impeller. The motor housing jacket is

discharge pressure. (Minimum 40bar, 600psi design adjustment allows the Bearing / Thrust provided with series flow to circulating fluid external

pressure with 3 mm corrosion allowance). No containment Washer to function essentially at minimized WEAR RING heat exchanger to maintain cool fluid temperatures

within the motor, to be maintaining an acceptable motor

control required due to E-monitor. Secondary containment thrust load over the entire usable capacity Wear ring material is made from CENTERLINE winding temperature.

monitoring is upon request. range for pumping. Nitronic60 which is SUPPORTED CASING Type HT shall be suitable for hot fluid applications.

nongalling-material. It attains

Minimum 40bar, 600psi design pressure with

extreme low maintenance costs.

3mm corrosion allowance

Centerline supported pump casing shall be used.

Vertical inline type is upon request.

You might also like

- API 685 BrochureDocument8 pagesAPI 685 BrochureDenar PurnamaNo ratings yet

- Rod Load Calculations and Def Int Ions For Reciprocating Compressor MonitoringDocument4 pagesRod Load Calculations and Def Int Ions For Reciprocating Compressor MonitoringdwightbordelonNo ratings yet

- 41000Document36 pages41000tetiospamNo ratings yet

- API 613 Special Purpose Gear UnitDocument17 pagesAPI 613 Special Purpose Gear UnitMd. Abu Nayeem50% (2)

- A10-A-DOC-VE-068274 - 00 离心泵 设计要求Document14 pagesA10-A-DOC-VE-068274 - 00 离心泵 设计要求zhangNo ratings yet

- Oxygen Pipeline Code of Practice for Steel IndustryDocument17 pagesOxygen Pipeline Code of Practice for Steel Industrysiddhesh_guessNo ratings yet

- VS 6 - FlowserveDocument8 pagesVS 6 - FlowserveJung Jae YualNo ratings yet

- IP 10-4-1 (Reciprocating Process Compressors)Document9 pagesIP 10-4-1 (Reciprocating Process Compressors)luisNo ratings yet

- Effect of Viscosity On PumpsDocument4 pagesEffect of Viscosity On PumpsChemkhiNo ratings yet

- Pulsation Suppression Device Design For Reciprocating CompressorDocument9 pagesPulsation Suppression Device Design For Reciprocating CompressorAlfred LamNo ratings yet

- Customer pipe design and pulsation guidelinesDocument2 pagesCustomer pipe design and pulsation guidelinesdigecaNo ratings yet

- Vertical PumpsDocument16 pagesVertical PumpsAdel ShatlaNo ratings yet

- Exxon IP 10-3-4 Axial Compressors For Air ServiceDocument7 pagesExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaNo ratings yet

- Brochure BEGEMANN BS Pumps-Low ResolutionDocument6 pagesBrochure BEGEMANN BS Pumps-Low ResolutionunknownsaylorNo ratings yet

- FTA157 Piping Plan PosterDocument1 pageFTA157 Piping Plan PosterGloria HamiltonNo ratings yet

- Up-Stream Pumping - Presentation1Document46 pagesUp-Stream Pumping - Presentation1Chozha RajanNo ratings yet

- Gear Pumps & API 676Document2 pagesGear Pumps & API 676Tumu MarakanNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- API 685 Vs API 610Document5 pagesAPI 685 Vs API 610sandeep100% (1)

- Flanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsDocument3 pagesFlanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsHakan ŞahinoğluNo ratings yet

- PT Trieka Aimex Reciprocating Pump Repair ReportDocument18 pagesPT Trieka Aimex Reciprocating Pump Repair ReportAdeImanudinNo ratings yet

- Best High Pressure Equipment & Valve SolutionsDocument8 pagesBest High Pressure Equipment & Valve SolutionsRAVINDR.KNo ratings yet

- Api 685Document12 pagesApi 685Carlos LópezNo ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- Waukesha Knock Index Power CurveDocument1 pageWaukesha Knock Index Power CurveparathasiNo ratings yet

- SIHI Side Channel PumpsDocument7 pagesSIHI Side Channel PumpsChristian VargasNo ratings yet

- Instruction Manual: Dosing Pump MaxroyDocument26 pagesInstruction Manual: Dosing Pump Maxroyenedanielcristian100% (1)

- Pertamina FRP and Ball Valve Specification SheetDocument3 pagesPertamina FRP and Ball Valve Specification Sheetbagus handokoNo ratings yet

- API 682 Seal Selection Process FinalDocument28 pagesAPI 682 Seal Selection Process FinalTasawwur Tahir100% (1)

- Comparación B73.1 Vs ISO 5199Document2 pagesComparación B73.1 Vs ISO 5199AlvialvarezNo ratings yet

- Astm A217-2001 PDFDocument3 pagesAstm A217-2001 PDFMohammed TariqNo ratings yet

- Pages From API Standard 610 Centrifugal PumpsDocument1 pagePages From API Standard 610 Centrifugal PumpsAgustin A.100% (1)

- Mandatory Appendix 9Document2 pagesMandatory Appendix 9Asep DarojatNo ratings yet

- Quick Opening ClosureDocument7 pagesQuick Opening ClosureJayesh SanganiNo ratings yet

- Hot Tapping Modelling EecHotTapDocument2 pagesHot Tapping Modelling EecHotTapParbat SinghNo ratings yet

- 3-4 HD - Api - 617 PDFDocument8 pages3-4 HD - Api - 617 PDFkagasaw023No ratings yet

- Re-Rate Case StudyDocument4 pagesRe-Rate Case StudyA_MosbahNo ratings yet

- PPGJ - MEC - SPC - 013 - BID Specification Centrifugal Pumps ANSI B73.1 B73.2Document26 pagesPPGJ - MEC - SPC - 013 - BID Specification Centrifugal Pumps ANSI B73.1 B73.2Andi HakimNo ratings yet

- PSV Data SheetDocument16 pagesPSV Data SheetYurizki LhzNo ratings yet

- Valvulas STEPLESSDocument10 pagesValvulas STEPLESSHerlin MorenoNo ratings yet

- API vs ANSI Pumps: Key Differences Explained in 40 CharactersDocument9 pagesAPI vs ANSI Pumps: Key Differences Explained in 40 CharactersRogerNo ratings yet

- Low NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFDocument12 pagesLow NPSH & Cases of Vertical Barrel (VS6) Type Pump Selection PDFMuhammad ImranNo ratings yet

- Amarex KRT8041eDocument36 pagesAmarex KRT8041eRui Alves da Silva100% (1)

- Api 611 5Th Edition General " Purpose Steam Turbine Existing TurbineDocument1 pageApi 611 5Th Edition General " Purpose Steam Turbine Existing TurbineAlejandro GilNo ratings yet

- IIT-Intake and Exhaust Manifold DesignDocument28 pagesIIT-Intake and Exhaust Manifold DesignVasudev GuptaNo ratings yet

- API 613 gear units overview for petroleum, chemical industriesDocument8 pagesAPI 613 gear units overview for petroleum, chemical industriesLymePark100% (1)

- EspeyDocument20 pagesEspeyGuillermo Esteban Diaz QuezadaNo ratings yet

- Benefits of HI 14-6 FINAL FULL VERSION PDFDocument8 pagesBenefits of HI 14-6 FINAL FULL VERSION PDF1sympatyagaNo ratings yet

- API Verses Non APIDocument19 pagesAPI Verses Non APIsandeshNo ratings yet

- B Se1 Sew Se2 H ResDocument4 pagesB Se1 Sew Se2 H ResJuan Pablo Palma PizarroNo ratings yet

- Diesel Engine FOR Centrifugal Fire Pumps: SpecificationDocument14 pagesDiesel Engine FOR Centrifugal Fire Pumps: SpecificationlombangrurusNo ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- Retaining Wall - PLANDocument1 pageRetaining Wall - PLANsenvuma edwardNo ratings yet

- Apex B2000 PCB VasDocument1 pageApex B2000 PCB Vasbahattin147No ratings yet

- Lifting Drawings For SS200Document8 pagesLifting Drawings For SS200Amos PaintikNo ratings yet

- Second Floor Framing PlanDocument1 pageSecond Floor Framing PlanDidNo ratings yet

- Setting Out - My 18.07.2020 Original-Layout1 PDFDocument1 pageSetting Out - My 18.07.2020 Original-Layout1 PDFKelum JayasooriyaNo ratings yet

- Yard and Rack Area PipingDocument1 pageYard and Rack Area PipingandredurvalandradeNo ratings yet

- Solidworks Lightweight - Out-Of-Date Print: VentilDocument9 pagesSolidworks Lightweight - Out-Of-Date Print: VentilMaja i Aleksandar JovanovićNo ratings yet

- ADocument1 pageAMary Joy ZamoraNo ratings yet

- Forbes Marshall Arca Pvt. LTDDocument1 pageForbes Marshall Arca Pvt. LTDnagarajhebbarNo ratings yet

- Forged Steel Three Piece Design Ball ValveDocument18 pagesForged Steel Three Piece Design Ball ValvenagarajhebbarNo ratings yet

- Catalogue Actuated Globe & Gate ValvesDocument4 pagesCatalogue Actuated Globe & Gate ValvesnagarajhebbarNo ratings yet

- Arca Index PDFDocument1 pageArca Index PDFnagarajhebbarNo ratings yet

- 1 PDFDocument2 pages1 PDFnagarajhebbarNo ratings yet

- Type 441 - Standard & High Pressure SeriesDocument16 pagesType 441 - Standard & High Pressure SeriesnagarajhebbarNo ratings yet

- Type - 459 - IC - API SeriesDocument20 pagesType - 459 - IC - API SeriesnagarajhebbarNo ratings yet

- BDK DiaphragmDocument8 pagesBDK DiaphragmnagarajhebbarNo ratings yet

- Lubrication Instructions for BallscrewsDocument1 pageLubrication Instructions for BallscrewshollabackcockNo ratings yet

- PEG II CatalogueDocument2 pagesPEG II CataloguenagarajhebbarNo ratings yet

- Stress Analysis Result - L5301 (R4525)Document1 pageStress Analysis Result - L5301 (R4525)nagarajhebbarNo ratings yet

- Air ReceiverDocument1 pageAir ReceivernagarajhebbarNo ratings yet

- Index: Section Description Page No. List NoDocument52 pagesIndex: Section Description Page No. List NonagarajhebbarNo ratings yet

- BDK Globe - Gate ValvesDocument9 pagesBDK Globe - Gate ValvesnagarajhebbarNo ratings yet

- Support Arrow PDFDocument1 pageSupport Arrow PDFnagarajhebbarNo ratings yet

- IntergraphDocument7 pagesIntergraphGokul ShenoyNo ratings yet

- BDK Ball ValveDocument11 pagesBDK Ball ValvenagarajhebbarNo ratings yet

- Wind PDFDocument24 pagesWind PDFnagarajhebbarNo ratings yet

- Valve and pipe isometric diagram legendDocument1 pageValve and pipe isometric diagram legendnagarajhebbarNo ratings yet

- Smartplant License Manager Installation & Setup ChecklistDocument3 pagesSmartplant License Manager Installation & Setup ChecklistnagarajhebbarNo ratings yet

- L00004 & L00005-R0012 PDFDocument1 pageL00004 & L00005-R0012 PDFnagarajhebbarNo ratings yet

- Rack and Rack Start PipingDocument2 pagesRack and Rack Start PipingnagarajhebbarNo ratings yet

- 6163P7-PS &DS - TR13Document1 page6163P7-PS &DS - TR13nagarajhebbarNo ratings yet

- L00001 & L00002 - TR6Document1 pageL00001 & L00002 - TR6nagarajhebbarNo ratings yet

- 6163P7-PS &DS - Tr13aDocument1 page6163P7-PS &DS - Tr13anagarajhebbarNo ratings yet

- 6166P10 - Line L80383-FinalDocument1 page6166P10 - Line L80383-FinalnagarajhebbarNo ratings yet

- L00004 & L00005-R0012Document1 pageL00004 & L00005-R0012nagarajhebbarNo ratings yet

- SIF (C2 Vs ANSYS)Document6 pagesSIF (C2 Vs ANSYS)Rockny2011No ratings yet

- Restraint SummaryDocument18 pagesRestraint SummarynagarajhebbarNo ratings yet

- New Steam Piping On Pipe RackDocument1 pageNew Steam Piping On Pipe RacknagarajhebbarNo ratings yet

- Diaphragma Pump PD20P-X-X-B DatasheetDocument2 pagesDiaphragma Pump PD20P-X-X-B DatasheetsugiantoNo ratings yet

- RRH-Series, Double Acting Hollow Plunger Cylinders: Home Products Industries Projects Downloads Resources ServicesDocument1 pageRRH-Series, Double Acting Hollow Plunger Cylinders: Home Products Industries Projects Downloads Resources ServicesFaisal MuhammadNo ratings yet

- 2006 Ninja® Zx™-6R Parts Diagram: Water PipeDocument2 pages2006 Ninja® Zx™-6R Parts Diagram: Water PipeFer TotoNo ratings yet

- Fluid Flow Theory Energy LossesDocument6 pagesFluid Flow Theory Energy LossesAlexander MugabeNo ratings yet

- MSS SP-135 2010Document13 pagesMSS SP-135 2010Francisco Javier Zúñiga Montiel100% (1)

- Measuring Volume Flow Rate Using Venturi MeterDocument4 pagesMeasuring Volume Flow Rate Using Venturi Meterlya AhmedNo ratings yet

- Válvula ContrabalanceDocument16 pagesVálvula ContrabalanceMauricio Ariel H. Orellana100% (1)

- Tubing & FittingsDocument10 pagesTubing & FittingsKent Martin D. CartagenaNo ratings yet

- Grundfos Hydro Diesel Fire Pump Sets Data BookletDocument24 pagesGrundfos Hydro Diesel Fire Pump Sets Data BookletAnca OpreaNo ratings yet

- Recording Parameters C-2650Document13 pagesRecording Parameters C-2650adi SaputraNo ratings yet

- Commissioning Circulating Pumps at 600MW Power PlantDocument15 pagesCommissioning Circulating Pumps at 600MW Power Plantrohit_me083No ratings yet

- Booster PumpDocument2 pagesBooster PumpNghiaNo ratings yet

- Especificaciones de Valvulas Normas APIDocument2 pagesEspecificaciones de Valvulas Normas APIÀngel Rodriguez0% (1)

- Hydraulic Pump PDFDocument1,568 pagesHydraulic Pump PDFIbrahim AwadNo ratings yet

- Project Datasheet for Echo Compressor Bleed RingDocument6 pagesProject Datasheet for Echo Compressor Bleed RingTamyizudin Kodri100% (1)

- Bending Machine CRC Evans Centurion 06 20Document4 pagesBending Machine CRC Evans Centurion 06 20bharathaninNo ratings yet

- External engine water pump and fresh water pump detailsDocument4 pagesExternal engine water pump and fresh water pump detailsFarshaaad HkNo ratings yet

- Caterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BDH) Service Repair Manual (BDH00001 and Up) PDFDocument26 pagesCaterpillar Cat 301.8 Mini Hydraulic Excavator (Prefix BDH) Service Repair Manual (BDH00001 and Up) PDFfkdmma20% (5)

- Angle-Seat Externally Operated Valve Type AV210A - AV210H: Data SheetDocument16 pagesAngle-Seat Externally Operated Valve Type AV210A - AV210H: Data SheetAnderengNo ratings yet

- Booster Pump and Ejector GuideDocument8 pagesBooster Pump and Ejector Guidegmurali2kNo ratings yet

- Device Summary EnglishDocument14 pagesDevice Summary Englishكاظم محمدNo ratings yet

- D160610-Appendix ConfirmedDocument8 pagesD160610-Appendix ConfirmedNguyễn Đức CườngNo ratings yet

- SECTION 1.0 - Tech Spec - Scope of WorkDocument1 pageSECTION 1.0 - Tech Spec - Scope of WorkBiggie ColdAngelNo ratings yet

- Asme Pipe Wall ThicknessDocument3 pagesAsme Pipe Wall ThicknessYoke ShuNo ratings yet

- PSV ManualDocument55 pagesPSV Manualioan.tsiamisNo ratings yet

- Data SheetDocument1 pageData Sheetjozef shamsNo ratings yet

- Adobe Scan 25 Dec 202Document1 pageAdobe Scan 25 Dec 202Jimit ShahNo ratings yet

- Power Plant Engineering 1Document15 pagesPower Plant Engineering 1Anushree GhoshNo ratings yet

- Oil and Gas Processing Systems: Offshore Standard DNV-OS-E201Document51 pagesOil and Gas Processing Systems: Offshore Standard DNV-OS-E201TIZIANO CIVIDINONo ratings yet

- Bachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersDocument10 pagesBachelor of Technology (Civil) - Level 05 Cex 5231 - Mechanics of Fluids - Year 2015/2016 Assignment 06 - Suggested AnswersMufeesNo ratings yet