Professional Documents

Culture Documents

Kimat - Mobot Shield User Guide: Description Pin Assignments

Uploaded by

FrederickGabrielRichardExibiaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kimat - Mobot Shield User Guide: Description Pin Assignments

Uploaded by

FrederickGabrielRichardExibiaCopyright:

Available Formats

Kimat – Mobot Shield

User Guide

Revision: v1.2 / 26 March 2018/CDM

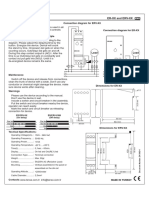

DESCRIPTION Arduino Compatible

The Kimat - Mobile Robot Shield is a compact, Arduino – PIN ASSIGNMENTS

Compatible, motor driver shield with pin headers for IR

sensors, Ultrasonic sensors and a Servo motor. The Kimat Mobot Shield Pin Assigned to

motor driver has 2 individual channels and can Arduino Pin

accommodate a 2 or 4 wheel robot. Each channel can TB6612FNG - PWMA 3

deliver a continuous current of 1.2A (surge up to ~3A). TB6612FNG - AIN1 2

This shield was designed with ease of use in mind: all TB6612FNG - AIN2 4

the essential parts of a mobile robot have been TB6612FNG - PWMB 6

assigned a connector onboard the shield. This greatly TB6612FNG - BIN1 7

simplifies wiring, reduced the number of boards used TB6612FNG - BIN2 5

and the need for soldering is eliminated. The Kimat TB6612FNG - STBY 8

Mobile Robot (Mobot) Shield is designed and made by SERVO – S (via resistor) 9

Layad Circuits Electronics Engineering. IR1 10

IR2 11

IR3 A0

IR4 / T3 (Shared) A1

IR5 / E3 (Shared) A2

T1 12

E1 A3

T2 A4

E2 A5

unused D0

unused D1

unused D13

Labels:

Figure 1: The Kimat Mobile Robot Shield

IRx – are connectors meant for IR line tracing or IR

distance sensors

Tx and Ex – are ultrasonic meant for ultrasonic sensors.

FEATURES and SPECIFICATIONS T refers to the Trigger pin and E refers to the Echo pin.

Integrated motor driver and connectors for a

maximum of 5 IR sensors and maximum of 3 The Arduino pins 2-8 are connected to the TB6612FNG

Ultrasonic Sensors and 1 Servo motor. chip and are not available for other use. All other pins

Motor Driver: TB6612FNG are free. However, the shield has onboard connectors

Number of Channels: 2 for a maximum of 5 IR sensors and a maximum of 3

Max. Motor Voltage = 15V ultrasonic sensors. The last ultrasonic sensor with pins

Max. Continuous Current per Channel =1.2A labeled as T3 and R3, are shared with IR4 and IR5

Max. Surge Current per Channel = 3.6A respectively. Thus, if all 5 IR sensor pins are used, a

Removable Core Driver Board maximum of only 2 ultrasonic sensors may be

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

1

Kimat – Mobot Shield

User Guide

connected. If only 3 IR sensor pins are used, a maximum

of 3 ultrasonic sensors may be installed. There is also

one pin with a current limiting resistor meant for use

with a servo motor.

TERMINAL BLOCKS

There are 3 terminal blocks at the top of the shield.

Terminal Block Label Purpose

(Bottom of PCB)

MOTOR POWER This is the power source of

the motors. If the single

source jumper is installed,

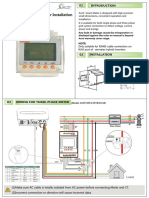

the motor power is derived Figure 2: The Single Source pin header with

from the VIN pin of the microjumper installed

Arduino/Shield

MOTOR A Connector for DC Motor A

MOTOR B Connector for DC Motor B

When using the single power source option, please take

If using 4 wheels, connect the 2 left motors on one note of the following

connector and the other 2 right motors on the other When micro jumper is installed, DO NOT

connector. Therefore, the software for a 2-wheeled and connect anything in the VM terminals!

4-wheeled robot is essentially the same. If external power source is desired, REMOVE

the micro jumper first!

SINGLE POWER SOURCE OPTION Motor voltage must match Arduino Voltage (6-

12V)

The Mobile Robot Shield has a pin header labeled There is a 1A power diode between the DC jack

SINGLE SOURCE with a microjumper provided. If the and VIN pin of the Arduino. This can take in

microcjumper is installed, The Arduino VIN pin and the larger surge current but make sure your motors

Motor Power Supply is connected. This simplifies wiring and Arduino do not exceed 1A continuous

since the user only needs to apply power at the Arduino current. This is not a problem if using the Saleng

DC Jack. The same power is then transferred to the Uno. The Saleng Uno uses a 5A diode instead of

shield via the VIN pin. If the microjumper is not 1A and hence is able to handle small and large

installed, apply power to the motors via the terminal motors and other circuits.

blocks labeled VM / MOTOR POWER.

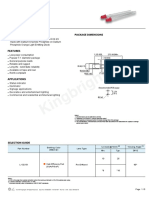

MOTOR POWER CAPACITOR SLOT

If for some reason you need to include a capacitor at

the motor power source line, there is a slot ready made

for this close to the Motor Power terminal block.

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

2

Kimat – Mobot Shield

User Guide

When the shield is installed on top of the

Arduino, the TB6612’s control pins are

effectively connected to the Arduino pins 2-8 as

in the figure below. Do note that the figure

does not show the sensor headers.

Figure 3: Capacitor slot for the motor power line

Figure 4: Equivalent circuit when shield is installed

Arduino pins 2-8 shall be used as outputs.

If using larger capacitors that do not fit the slot, you Set pin 8 (STBY) as HIGH to enable the motor

may simply install it at the VM terminal block. One driver. A LOW disables the driver.

reason you may need a capacitor is if your motor power Pins 3 (PWMA) and 6(PWMB) are the pins used

source is unable to provide large currents at very short to control the speed of the motors. Applying

time intervals. Exercise caution when selecting the PWM signals via analogWrite() on pins 3 and 6

capacitor voltage rating: because we should not expect controls the speed of the motors. If speed

voltages above 15V at the VM terminals, you may use control is not needed, simply set pins 3 and 6

16V capacitors. However, if your motor voltage is close HIGH using digitalWrite() to keep the motors at

to 15V, higher voltage ratings, such as 25V,35V or 50V, full speed.

is required to account for transients. Pins 2 and 4 control the direction of motor(s) 1

while pins 5 and 7 control the direction of

CODING TIPS motor(s) 2. Follow the table below:

The Mobile Robot Shield is easy to use even without xIN1 xIN2 Motor Reaction

using a library. Follow these pointers in writing your LOW HIGH Move in One Direction

code: HIGH LOW Move in Opposite Direction

LOW LOW Motor Stops

HIGH HIGH Short Break, Motor stops

EXAMPLE CODE WITHOUT LIBRARY

This code demonstrates the basic movements of a

wheeled mobile robot. The code cycles through

forward, backward, left and right movements. If you are

not getting the correct movement, check that your left

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

3

Kimat – Mobot Shield

User Guide

and right motor wirings are consistently wired to xIN1

void motorstop()

and xIN2.

{

digitalWrite(AIN1,LOW);

/* digitalWrite(AIN2,LOW);

* Install right motor(s) on AIN1 & AIN2 digitalWrite(BIN1,LOW);

* Install left motor(s) on BIN1 & BIN2 digitalWrite(BIN2,LOW);

*/ }

#define AIN1 2 void shortbreak()

#define BIN1 7 {

#define AIN2 4 digitalWrite(AIN1,HIGH);

#define BIN2 5 digitalWrite(AIN2,HIGH);

#define PWMA 3 digitalWrite(BIN1,HIGH);

#define PWMB 6 digitalWrite(BIN2,HIGH);

#define STBY 8 }

void speedSetting(byte val)

{ void setup() {

analogWrite(PWMA,val); pinMode(AIN1,OUTPUT);

analogWrite(PWMB,val); pinMode(AIN2,OUTPUT);

} pinMode(BIN1,OUTPUT);

pinMode(BIN2,OUTPUT);

void forward() pinMode(STBY,OUTPUT);

{ digitalWrite(STBY,HIGH);//enable driver

digitalWrite(AIN1,LOW); speedSetting(255); //set to full speed

digitalWrite(AIN2,HIGH); delay(3000); // add 3s delay

digitalWrite(BIN1,LOW); }

digitalWrite(BIN2,HIGH);

}

void loop() {

void backward() forward();delay(600);

{ shortbreak();delay(100);

digitalWrite(AIN1,HIGH); motorstop();delay(2000);

digitalWrite(AIN2,LOW);

digitalWrite(BIN1,HIGH); backward();delay(600);

digitalWrite(BIN2,LOW); shortbreak();delay(100);

} motorstop();delay(2000);

void turnleft() turnleft();delay(1000);

{ shortbreak();delay(100);

digitalWrite(AIN1,LOW); motorstop();delay(2000);

digitalWrite(AIN2,HIGH);

digitalWrite(BIN1,HIGH); turnright();delay(1000);

digitalWrite(BIN2,LOW); shortbreak();delay(100);

} motorstop();delay(2000);

}

void turnright()

{

digitalWrite(AIN1,HIGH);

digitalWrite(AIN2,LOW);

digitalWrite(BIN1,LOW);

digitalWrite(BIN2,HIGH);

}

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

4

Kimat – Mobot Shield

User Guide

LIBRARY void loop()

{

//Use of the drive function which takes as

//arguements the speed

Sparkfun has created a motor driver library compatible //and optional duration. A negative speed will

with the Kimat Mobile Robot Shield. You may download //cause it to go

//backwards. Speed can be from -255 to

it Sparkfuns Github page: //255. Also use of the

//brake function which takes no arguements.

motor1.drive(255,1000);

https://github.com/sparkfun/SparkFun_TB6612FNG_Ar delay(1000);

motor1.drive(-255,1000);

duino_Library motor1.brake();

delay(1000);

Edit the pin assignments of the example code and you //Use of the drive function which takes as

may now test the motor driving functionality of the //arguements the speed

//and optional duration. A negative speed will

shield. Below is an edited version of that example code //cause it to go

//backwards. Speed can be from -255 to

that rotates the motor back and forth. This can be used //255. Also use of the

as a first test and reference code: //brake function which takes no arguements.

motor2.drive(255,1000);

delay(1000);

motor2.drive(-255,1000);

motor2.brake();

#include <SparkFun_TB6612.h> delay(1000);

// Pins for all inputs, keep in mind the PWM defines //Use of brake again.

// must be on PWM pins brake(motor1, motor2);

// the default pins listed are the ones used on the delay(1000);

// Redbot (ROB-12097) with

// the exception of STBY which the Redbot controls }

// with a physical switch

#define AIN1 2

#define BIN1 7 Note that the above is the code for the motor driver

#define AIN2 4 only. If you have connected IR sensors, ultrasonic

#define BIN2 5//8

#define PWMA 3//5 sensors or servo motor, please refer to the individual

#define PWMB 6

#define STBY 8//9 product datasheets. There should also be numerous

references online as these are very common parts for

// these constants are used to allow you to make

//your motor configuration Arduino.

// line up with function names like forward. Value

//can be 1 or -1

const int offsetA = 1;

const int offsetB = 1;

// Initializing motors. The library will allow you

//to initialize as many

// motors as you have memory for. If you are using

//functions like forward

// that take 2 motors as arguements you can either

//write new functions or

// call the function more than once.

Motor motor1 = Motor(AIN1, AIN2, PWMA, offsetA,

STBY);

Motor motor2 = Motor(BIN1, BIN2, PWMB, offsetB,

STBY);

void setup()

{

//Nothing here

}

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

5

Kimat – Mobot Shield

User Guide

/* Hardware notes

* 3 Saleng Trackers on pins headers

SIMPLE LINE TRACING CODE

* I1(left),I2(center) and I3(right)

* Install right motor(s) on AIN1 & AIN2

The following code demonstrates the basic structure of * Install left motor(s) on BIN1 & BIN2

a simple line tracing robot. It uses a Mobile Robot Shield */

with an Uno and 3 Saleng Tracker (by Layad Circuits) // change below to define if line

sensors. // is black on white background or

// white on black background.

A lot of different factors will affect the performance of // These define the sensor value when

// under black and white surface

this code such as: // You may also use the DO and ~DO

Motor specifications // pins of the Saleng Tracker to

Power/Battery performance // change line configuration

Assembly and Build #define BLK LOW // line

Sensors used #define WHT HIGH // background

Thickness of line

#define AIN1 2

Complexity of line route #define BIN1 7

Distance between sensors #define AIN2 4

For better performance, consider: #define BIN2 5

#define PWMA 3

Adding more sensors for better detection of #define PWMB 6

lines and line shape #define STBY 8

Add code to handle different line shapes (e.g. #define SENSOR_L A0

#define SENSOR_C 11

curves, U-turns, crossings)

#define SENSOR_R 10

Improving traction of wheels/floor

Adding automatic speed control code to better byte sensorL, sensorC, sensorR;

handle curves

Add code to for timing motor motion based on void speedSetting(byte val)

motor performance and line shape {

Add PID algorithm for smoother motion analogWrite(PWMA,val);

analogWrite(PWMB,val);

}

/* Hardware Notes:

void forward()

{

digitalWrite(AIN1,LOW);

digitalWrite(AIN2,HIGH);

digitalWrite(BIN1,LOW);

digitalWrite(BIN2,HIGH);

}

void backward()

{

digitalWrite(AIN1,HIGH);

digitalWrite(AIN2,LOW);

Figure 5: Wiring for simple line tracing robot digitalWrite(BIN1,HIGH);

digitalWrite(BIN2,LOW);

}

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

6

Kimat – Mobot Shield

User Guide

void turnleft()

{

digitalWrite(AIN1,LOW);

digitalWrite(AIN2,HIGH);

digitalWrite(BIN1,HIGH);

digitalWrite(BIN2,LOW);

}

void turnright()

{

digitalWrite(AIN1,HIGH);

digitalWrite(AIN2,LOW);

digitalWrite(BIN1,LOW);

digitalWrite(BIN2,HIGH);

}

void motorstop()

{

digitalWrite(AIN1,LOW);

digitalWrite(AIN2,LOW);

digitalWrite(BIN1,LOW);

digitalWrite(BIN2,LOW);

}

void shortbreak()

{

digitalWrite(AIN1,HIGH);

digitalWrite(AIN2,HIGH);

digitalWrite(BIN1,HIGH);

digitalWrite(BIN2,HIGH);

}

void setup() {

pinMode(SENSOR_L,INPUT);

pinMode(SENSOR_C,INPUT);

pinMode(SENSOR_R,INPUT);

pinMode(AIN1,OUTPUT);

pinMode(AIN2,OUTPUT);

pinMode(BIN1,OUTPUT);

pinMode(BIN2,OUTPUT);

pinMode(STBY,OUTPUT);

digitalWrite(STBY,HIGH);//enable driver

//we use a slow speed to avoid

// overshooting lines

// and conserve battery

// full speed = 255

speedSetting(32);

delay(5000); // add 5s delay

Serial.begin(115200);

}

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

7

Kimat – Mobot Shield

User Guide

void loop() {

// read and store all sensors

sensorL = digitalRead(SENSOR_L);

sensorC = digitalRead(SENSOR_C);

sensorR = digitalRead(SENSOR_R);

if(sensorL == BLK && sensorC == BLK && sensorR == BLK)

{

backward(); // assume we overshot line

}

else if(sensorL == WHT && sensorC == BLK && sensorR == BLK)

{

turnleft();

}

else if(sensorL == WHT && sensorC == BLK && sensorR == WHT)

{

// confused! Just move forward

forward();

}

else if(sensorL == BLK && sensorC == BLK && sensorR == WHT)

{

turnright();

}

else if(sensorL == BLK && sensorC == WHT && sensorR == BLK)

{

forward();

}

else if(sensorL == WHT && sensorC == WHT && sensorR == BLK)

{

turnleft();

}

else if(sensorL == WHT && sensorC == WHT && sensorR == WHT)

{

forward();

}

else if(sensorL == BLK && sensorC == WHT && sensorR == WHT)

{

turnright();

}

}

FREQUENTLY ASKED QUESTIONS:

Q: I tried the sample code with the library but my motors turn in just one direction, what is wrong?

A: Your power source is unable to provide sufficient current during sudden direction changes. There are 3 solutions:

Use a power source with sufficient current

Add delays in between direction changes to give time for power to stablelize

Add a large capacitor at the VM terminals. You may directly connect it at the VM terminal block

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

8

Kimat – Mobot Shield

User Guide

Q: When the “Single Source” microjumper is installed, do I need power for both Arduino and Shield?

A: NO! You MUST use only one power source when the micro jumper is installed. Apply a voltage acceptable to both

Arduino and motors via the Arduino DC Jack. Note that a 1A diode is in between the Arduino’s DC jack and VIN pin

where the motors are powered from. This diode may be damaged if the total current drawn byt eh motos and Arduino

exceeds this 1A rating. This is not a problem in the Saleng Uno which has a 5A diode instead of 1A.

Q: When the “Single Source” microjumper is installed, can I use the blue VM terminal block to power both Arduino and

Shield?

A: Yes, but beware. While this may solve the problem of the limited 1A rating of the reverse polarity protection diode of

the Arduino, it exposes you to possible hardware faults when you interchange the polarities of the power connected to

VM.

Q: If the microjumper is not installed, how do I power the shield and Arduino?

A: use separate power sources. One for the Arduino via its DC jack or USB port and another power source for the motors

via the VM pin

Q: What power supply / battery voltage is to be used?

A: When microjumper is installed, you need to fulfill the voltage requirements of botht eh Arduino and the Motors. For

example, if you are using 3-9V motors, then you may use 6-9V power source (battery) since the Arduino can operate at

6-12V. The intersection of both motor and Arduino power requirement is 6-9V.

Q: What kind of power supply/battery can be used?

A: Nothing specific since this is mostly dependent on the motor being used. Check the motor voltage required and

current consumption. A good estiamte is to use a power supply that can deliver, and sustain, twice the maximum

current drawn by the motor. For batteries, the battery capacity will determine the running time of the robot. Choose the

highest capacity that is practical.

Q: Can I use power bank?

A: For the Arduino alone (microjumper not installed)? Yes. For both motor and Arduino? It depends. 5V is generally not

sufficient for powering 5V Arduino boards via the DC jack, you may need a step-up DC-DC converter to do so.

Q: Can I use the shield for 4-wheel and 2-wheeled robots?

A: Absolutely! A 4-wheeled robot has the same code as 2-wheeled robot if both left motors are in parallel and

connected to one channel of the driver and the two right motors connected in parallel to the other channel. Just make

sure your combined continuous current does not exceed 1.2A per channel. The common plastic geared DC motors with

yellow gearbox draw some ~250mA, two of these in parallel would mean a current of ~500mA. Thus, you may use these

types of motors, either as 2-wheeled or 4-wheel robots, with the shield.

Q: What powers the shield?

A: Power for the logic circuit of the driver chip is taken from the 5V pin of the Arduino, not from VM or VIN. On the other

hand, the motor(s) are powered from the VM or VIN(microjumper installed).

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

9

Kimat – Mobot Shield

User Guide

Q: Which IO pins are used by the shield?

A: The motor driver section uses pins 2-8. Do not use these pins.

Q: Which IO pins are free?

A: You may use all pins except pins 2-8. There are parallel hole pads for all unused pins, you may installe male or female

pin headers on those pads if you wish so. Note that some pins are used for the sensor header connectors on the shield.

If you are using the headers, then those pins are no longer free. Refer to the Pin Assignment table the IO pins used for

the headers and motor driver.

Q: Can the shield be used as a Sumobot? Line Tracing/ Line Follower robot? Obstacle Avoidance Robot?

A: Of course! We’ve build it for these applications. In fact, almost any mobile-wheeled robot is possible.

Q: Can I use more than 5 digital IR sensors?

A: Yes, you would just need to wire them as in a normal shield. Use the connector pads provided for all unused pins.

There are a total of 13 free pins, that gives you the option to connect up to 13 digital IR sensors!

Q: Will a PID algorithm work for a line tracing application?

A: Yes, use 5 IR sensors or more for a smoother PID algorithm

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

10

Kimat – Mobot Shield

User Guide

IMPORTANT NOTICE

Layad Circuits Electronics Engineering Supplies & Services (Layad Circuits) reserves the right to make corrections, enhancements, improvements and other changes to

its products, services and documentations, and to discontinue any product or service. Buyers or clients should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. Additional terms may apply to the use or sale of Layad Circuits products and services.

Reproduction of significant portions of Layad Circuits information in Layad Circuits datasheets or user guides is permissible only if reproduction is without alteration,

displays the Layad Circuits logo and is accompanied by all associated warranties, conditions, limitations, and notices. Layad Circuits is not responsible or liable for such

reproduced documentation. Information of third parties may be subject to additional restrictions. Resale of Layad Circuits products or services with statements

different from or beyond the parameters stated by Layad Circuits for that product or service voids all express and any implied warranties for the associated Layad

Circuits product or service. Layad Circuits is not responsible or liable for any such statements.

Buyers and others who are developing systems that incorporate Layad Circuits products (collectively, “Designers”) understand and agree that Designers remain

responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to

assure the safety of Designers' applications and compliance of their applications (and of all Layad Circuits products used in or for Designers’ applications) with all

applicable regulations, laws and other applicable requirements. Designer represents that, with respect to their applications, Designer has all the necessary expertise

to create and implement safeguards that (1) anticipate dangerous consequences of failures, (2) monitor failures and their consequences, and (3) lessen the likelihood

of failures that might cause harm and take appropriate actions. Designer agrees that prior to using or distributing any applications that include Layad Circuits

products, Designer will thoroughly test such applications and the functionality of such Layad Circuits products as used in such applications. Layad Circuits’ provision of

technical, application or other design advice, quality characterization, reliability data or other services or information, including, but not limited to, reference designs

and materials relating to evaluation modules, (collectively, “Layad Circuits Resources”) are intended to assist designers who are developing applications that

incorporate Layad Circuits products; by downloading, accessing or using Layad Circuits Resources in any way, Designer (individually or, if Designer is acting on behalf

of a company, Designer’s company) agrees to use any particular Layad Circuits Resource solely for this purpose and subject to the terms of this Notice.

Layad Circuits' provision of Layad Circuits Resources does not expand or otherwise alter Layad Circuits’ applicable published warranties or warranty disclaimers for

Layad Circuits products, and no additional obligations or liabilities arise from Layad Circuits providing such Layad Circuits Resources.

Layad Circuits reserves the right to make corrections, enhancements, improvements and other changes to its Layad Circuits Resources. Layad Circuits has not

conducted any testing other than that specifically described in the published documentation for a particular Layad Circuits Resource.

NO OTHER LICENSE, EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER LAYAD CIRCUITS INTELLECTUAL PROPERTY RIGHT, AND NO LICENSE TO ANY

TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT OF LAYAD CIRCUITS OR ANY THIRD PARTY IS GRANTED HEREIN, including but not limited to any patent right,

copyright, mask work right, or other intellectual property right relating to any combination, machine, or process in which Layad Circuits products or services are used.

Information regarding or referencing third-party products or services does not constitute a license to use such products or services, or a warranty or endorsement

thereof. Use of Layad Circuits Resources may require a license from a third party under the patents or other intellectual property of the third party, or a license from

Layad Circuits under the patents or other intellectual property of Layad Circuits . Layad Circuits RESOURCES ARE PROVIDED “AS IS” AND WITH ALL FAULTS. LAYAD

CIRCUITS DISCLAIMS ALL OTHER WARRANTIES OR REPRESENTATIONS, EXPRESS OR IMPLIED, REGARDING RESOURCES OR USE THEREOF, INCLUDING BUT NOT LIMITED

TO ACCURACY OR COMPLETENESS, TITLE, ANY EPIDEMIC FAILURE WARRANTY AND ANY IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR

PURPOSE, AND NON-INFRINGEMENT OF ANY THIRD PARTY INTELLECTUAL PROPERTY RIGHTS. LAYAD CIRCUITS SHALL NOT BE LIABLE FOR AND SHALL NOT DEFEND OR

INDEMNIFY DESIGNER AGAINST ANY CLAIM, INCLUDING BUT NOT LIMITED TO ANY INFRINGEMENT CLAIM THAT RELATES TO OR IS BASED ON ANY COMBINATION OF

PRODUCTS EVEN IF DESCRIBED IN LAYAD CIRCUITS RESOURCES OR OTHERWISE. IN NO EVENT SHALL LAYAD CIRCUITS BE LIABLE FOR ANY ACTUAL, DIRECT, SPECIAL,

COLLATERAL, INDIRECT, PUNITIVE, INCIDENTAL, CONSEQUENTIAL OR EXEMPLARY DAMAGES IN CONNECTION WITH OR ARISING OUT OF LAYAD CIRCUITS RESOURCES

OR USE THEREOF, AND REGARDLESS OF WHETHER LAYAD CIRCUITS HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. Unless Layad Circuits has explicitly

designated an individual product as meeting the requirements of a particular industry standard , Layad Circuits is not responsible for any failure to meet such industry

standard requirements. Where Layad Circuits specifically promotes products as facilitating functional safety or as compliant with industry functional safety standards,

such products are intended to help enable customers to design and create their own applications that meet applicable functional safety standards and requirements.

Using products in an application does not by itself establish any safety features in the application. Designers must ensure compliance with safety-related

requirements and standards applicable to their applications. Designer may NOT use any Layad Circuits products in life-critical applications. Life-critical medical

equipment is medical equipment where failure of such equipment would cause serious bodily injury or death (e.g., life support, pacemakers, defibrillators, heart

pumps, neurostimulators, and implantables). Designers agree that it has the necessary expertise to select the product with the appropriate qualification designation

for their applications and that proper product selection is at Designers’ own risk. Designers are solely responsible for compliance with all legal and regulatory

requirements in connection with such selection. Designer will fully indemnify Layad Circuits and its representatives against any damages, costs, losses, and/or

liabilities arising out of Designer’s noncompliance with the terms and provisions of this Notice.

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

11

Kimat – Mobot Shield

User Guide

www.layadcircuits.com Copyright 2017 © Layad Circuits All Rights Reserved

Layad Circuits Electronics Engineering Supplies & Services, B314 Lopez Bldg., Session Rd. cor. Assumption Rd., Baguio City, Philippines

General inquiries: info@layadcircuits.com Sales: sales@layadcircuits.com FB: facebook.com/layadcircuits Mobile: +639164428565

An IMPORTANT NOTICE: at the end of this guide addresses availability, warranty, changes, use in safety-critical applications, intellectual property matters and other

important disclaimers.

12

You might also like

- Internet of Things (Iot) Using Nicerf Lora1276Document17 pagesInternet of Things (Iot) Using Nicerf Lora1276Henry Elvis Inga CcennchoNo ratings yet

- Connector Industry: A Profile of the European Connector Industry - Market Prospects to 1999From EverandConnector Industry: A Profile of the European Connector Industry - Market Prospects to 1999No ratings yet

- 1 19115823Document8 pages1 19115823Netaji PatraNo ratings yet

- Manual Air Band ReceiverDocument8 pagesManual Air Band Receiverdp500100% (1)

- Vutron Building DocsDocument7 pagesVutron Building DocsStani-Slav JanáčNo ratings yet

- Tu510a enDocument28 pagesTu510a enmenale libayeNo ratings yet

- AL3353Document15 pagesAL3353JonathanTaclindoNo ratings yet

- Ascon KM3Document40 pagesAscon KM3Juan Carlos Abarca SereñoNo ratings yet

- Assignment Automatic Drilling MachineDocument6 pagesAssignment Automatic Drilling MachineSumit KambleNo ratings yet

- S H Microelectronics Corp.: AM OPDocument12 pagesS H Microelectronics Corp.: AM OPagcauchiNo ratings yet

- SOLN D ALL ANTENNAs W 2-RRU31-1900 2-4X2 X4 Combiners NO 800 CDMA RevADocument10 pagesSOLN D ALL ANTENNAs W 2-RRU31-1900 2-4X2 X4 Combiners NO 800 CDMA RevASidahmed ZaouiNo ratings yet

- (Top View) : High Performance Boost Led ControllerDocument15 pages(Top View) : High Performance Boost Led ControllerJavier Mendoza CastroNo ratings yet

- Micom P130C: Directional Time-Overcurrent and Frequency Protection Device P130C/En In/ B22Document6 pagesMicom P130C: Directional Time-Overcurrent and Frequency Protection Device P130C/En In/ B22MarcNo ratings yet

- MC#1 Turret-WS Manual1Document25 pagesMC#1 Turret-WS Manual1prithwirajroyNo ratings yet

- Honeywell 51-52-33-134 - B5M8T2Document9 pagesHoneywell 51-52-33-134 - B5M8T2Anonymous NwnJNONo ratings yet

- BIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyDocument10 pagesBIT3251 BIT3251 BIT3251 BIT3251 應用指南 應用指南 應用指南 應用指南: Beyond Innovation TechnologyHamza AbbasiNo ratings yet

- Analog Input RTPDocument8 pagesAnalog Input RTPAlaa MohammedNo ratings yet

- Quad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsDocument20 pagesQuad High-Side Gate Driver For Automotive Applications: Description Features and BenefitsTuấn NeoNo ratings yet

- Basic Wiring Diagram - Delta VFD-V Series User MaDocument1 pageBasic Wiring Diagram - Delta VFD-V Series User MaPhan Thanh BảoNo ratings yet

- D D D D D D D D D: DescriptionDocument10 pagesD D D D D D D D D: DescriptionRenzo Arredondo PradaNo ratings yet

- SM Minarcmig 170-180 V1.0.EnDocument23 pagesSM Minarcmig 170-180 V1.0.EnDiego ArgañarazNo ratings yet

- Integrated Mariner Premium: Product InformationDocument3 pagesIntegrated Mariner Premium: Product InformationAbdulaziz AlrawiNo ratings yet

- Sensitive Triacs: (0.8 A To 8 A)Document9 pagesSensitive Triacs: (0.8 A To 8 A)Leonel MartinezNo ratings yet

- TMUX1208 5-V Bidirectional 8:1, 1-Channel Multiplexer: 1 Features 3 DescriptionDocument33 pagesTMUX1208 5-V Bidirectional 8:1, 1-Channel Multiplexer: 1 Features 3 Descriptionkishore_bulli6666No ratings yet

- Fx32a Users Manual EngDocument4 pagesFx32a Users Manual EngSerg100% (1)

- Iw1710-01 For 12V@1.5A Adapter DesignDocument17 pagesIw1710-01 For 12V@1.5A Adapter DesignИван АлексиевNo ratings yet

- Er-Xx and Erv-Xx Timer RelaysDocument1 pageEr-Xx and Erv-Xx Timer RelayszainahmedscribdNo ratings yet

- YOLICO YD101 ModBusDocument33 pagesYOLICO YD101 ModBusryndra01No ratings yet

- Fx32a Manual en R20160602Document4 pagesFx32a Manual en R20160602Khiareddine KadhemNo ratings yet

- 433aschematic PDFDocument1 page433aschematic PDFCarlos Vasquez100% (1)

- Dual Driver v2Document5 pagesDual Driver v2Jorge JuniorNo ratings yet

- Acrel Meter Installation Three PhaseDocument4 pagesAcrel Meter Installation Three PhasehardaniNo ratings yet

- XE125 Product BriefDocument19 pagesXE125 Product BriefCem VardarNo ratings yet

- Westermo Ds Ibex-Rt-630 2112 en RevdDocument4 pagesWestermo Ds Ibex-Rt-630 2112 en RevdJuan PerezNo ratings yet

- BMW E39Document11 pagesBMW E39lukas.ulinskasNo ratings yet

- 2-Hw Descr OMSN R4.3-5Document100 pages2-Hw Descr OMSN R4.3-5znesroNo ratings yet

- L-132XID (Ver 18A)Document5 pagesL-132XID (Ver 18A)yafix34669No ratings yet

- ADR111EDocument14 pagesADR111Etapas_jituNo ratings yet

- Separate Construction With Cylindrical 16-Dia. Body: List of ModelsDocument17 pagesSeparate Construction With Cylindrical 16-Dia. Body: List of Modelskasim leeNo ratings yet

- Linear Scale ManualDocument19 pagesLinear Scale ManualImran NisarNo ratings yet

- K8050 - IR ReceiverDocument20 pagesK8050 - IR ReceiverAnonymous Af4ORJNo ratings yet

- TIDUE531 10-kW, Bidirectional Three-Phase Three-Level (T-Type) Inverter and PFCDocument94 pagesTIDUE531 10-kW, Bidirectional Three-Phase Three-Level (T-Type) Inverter and PFCvituvxiaomi redmi5plusNo ratings yet

- srv25 4Document9 pagessrv25 4Aditya SrivatsavNo ratings yet

- Voltage Regulator Ic AP3968 DatasheetDocument15 pagesVoltage Regulator Ic AP3968 Datasheetkanthkk100% (1)

- 06 236179 001 - ScreenDocument14 pages06 236179 001 - ScreenJUAN DAVID GARCIA MAHECHANo ratings yet

- Music Playing Tesla CoilDocument1 pageMusic Playing Tesla CoilPéricles RangelNo ratings yet

- A005R820021-Wiring Diagrams and Component LocationsDocument747 pagesA005R820021-Wiring Diagrams and Component LocationswaggcasNo ratings yet

- Speed Dome InstaDocument2 pagesSpeed Dome InstaJoy Son100% (1)

- Features: EL5202, EL5203Document14 pagesFeatures: EL5202, EL5203Евгений ИвановNo ratings yet

- Atmel 44050 Cortex M7 Microcontroller SAM E70 XPLD Xplained User GuideDocument58 pagesAtmel 44050 Cortex M7 Microcontroller SAM E70 XPLD Xplained User Guidedomenico_leuzziNo ratings yet

- Dell Inspiron 15 5567 BAL20 LA-D801P Rev 1.0 (A00) SchematicsDocument61 pagesDell Inspiron 15 5567 BAL20 LA-D801P Rev 1.0 (A00) SchematicsFreddy CachumbaNo ratings yet

- Dell Inspiron 15 5567 5767 Compall LA-D801P R1.0-OutputDocument61 pagesDell Inspiron 15 5567 5767 Compall LA-D801P R1.0-OutputriyasNo ratings yet

- DRT2-D32SL (-1) /DRT2 - D32SLH (-1) DRT2 - D32ML (-1) DRT2 - D16ta (-1) DRT2-MD16S (-1) Drt2-Ros16s 3G3MV-PDRT2/3G3RV-PDRT2 Itnc-Eis01-Drm/epx01-DrmDocument237 pagesDRT2-D32SL (-1) /DRT2 - D32SLH (-1) DRT2 - D32ML (-1) DRT2 - D16ta (-1) DRT2-MD16S (-1) Drt2-Ros16s 3G3MV-PDRT2/3G3RV-PDRT2 Itnc-Eis01-Drm/epx01-DrmSergio Eu CaNo ratings yet

- Hh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdDocument3 pagesHh-Ard-3P Elevator Automatic Rescue Device: Xi'An Uplift Parts Co.,LtdRebecca DangNo ratings yet

- USB-FBLMCB User's ManualDocument19 pagesUSB-FBLMCB User's ManualZeljko Krivokuca100% (1)

- 3RK19030AB00 Datasheet enDocument4 pages3RK19030AB00 Datasheet enSal TargarienNo ratings yet

- FVD Englishcatalog 20220922Document6 pagesFVD Englishcatalog 20220922NATHANEASTBOUNDNo ratings yet

- AL8805 Description Pin Assignments: Not Recommended For New Design USE ORDocument18 pagesAL8805 Description Pin Assignments: Not Recommended For New Design USE ORlakshmananNo ratings yet

- Assembly Features: Removable Terminals GreenDocument3 pagesAssembly Features: Removable Terminals GreenЕсет ДаулетжанNo ratings yet

- FIELD 01 2023 AxCmpDocument1 pageFIELD 01 2023 AxCmpAwadhiNo ratings yet

- Irlb8314Pbf: Application V 30 V R Max 2.4 M 3.2 QG 40 NC I 171 A I 130ADocument8 pagesIrlb8314Pbf: Application V 30 V R Max 2.4 M 3.2 QG 40 NC I 171 A I 130AJosè Miguel López RodriguezNo ratings yet

- Chapter Sixteen: Organization Change and DevelopmentDocument17 pagesChapter Sixteen: Organization Change and DevelopmentJAKANNo ratings yet

- AgendaDocument10 pagesAgendaMHASKE SVPMEnggNo ratings yet

- ASME Y14.5 2009 Vs 2018 Comparison ChartDocument1 pageASME Y14.5 2009 Vs 2018 Comparison ChartShiban TripathyNo ratings yet

- College For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityDocument2 pagesCollege For Research and Technology of Cabanatuan: Del Pilar ST., Cabanatuan CityLove JcwNo ratings yet

- Experiment No 2 Flame TestDocument2 pagesExperiment No 2 Flame TestBalangNo ratings yet

- Tinnitus Assessment Thi ScoringDocument4 pagesTinnitus Assessment Thi ScoringbssNo ratings yet

- Chapter 5 Discrete Probalitity Dsitributions - Jaggia4e - PPTDocument66 pagesChapter 5 Discrete Probalitity Dsitributions - Jaggia4e - PPTpeter shlomoNo ratings yet

- PuzzlesDocument9 pagesPuzzlespraveen_1288No ratings yet

- Sedimentologi - Transport Dan Pengendapan Sedimen Silisiklastik PDFDocument45 pagesSedimentologi - Transport Dan Pengendapan Sedimen Silisiklastik PDFIndah LestariNo ratings yet

- ICETEMS-18 Abstract Book PDFDocument152 pagesICETEMS-18 Abstract Book PDFJAMILNo ratings yet

- Bid Documents 2022Document17 pagesBid Documents 2022Arlene VillarosaNo ratings yet

- PMT Class XI Chemistry Atomic StructureDocument39 pagesPMT Class XI Chemistry Atomic StructureAurobinda MaharanaNo ratings yet

- Luningetal2005 - SiluriansourcerocksandpetroleumplayJordanDocument32 pagesLuningetal2005 - SiluriansourcerocksandpetroleumplayJordanMary DNo ratings yet

- NCERT Solutions Class 7 Science Chapter 15 LightDocument5 pagesNCERT Solutions Class 7 Science Chapter 15 LightJAI PRAJEN PRO HACKERNo ratings yet

- Reformation of Moral Philosophy and Its Foundation in Seerah of The Prophet MuhammadDocument15 pagesReformation of Moral Philosophy and Its Foundation in Seerah of The Prophet MuhammadMuhammad Idrees LashariNo ratings yet

- Best Practice To Measure Physical Progress of An EPC ProjectDocument5 pagesBest Practice To Measure Physical Progress of An EPC ProjectShimelash Kassahun100% (1)

- Qualtrics Survey Software PostDocument13 pagesQualtrics Survey Software Postapi-283622630No ratings yet

- Sponge ColoringDocument3 pagesSponge ColoringMavel Madih KumchuNo ratings yet

- Argumentative EssayDocument8 pagesArgumentative Essayapi-272949288No ratings yet

- Nursing Philosophy PaperDocument6 pagesNursing Philosophy PaperDanielle AalderinkNo ratings yet

- Water Laboratory - Pasig City HallDocument18 pagesWater Laboratory - Pasig City HallLloid LauretaNo ratings yet

- Nucleic Acids WorksheetDocument4 pagesNucleic Acids WorksheetNatalie PembertonNo ratings yet

- Lebanese Medical LSK - pdf2Document96 pagesLebanese Medical LSK - pdf2Alaor LopesNo ratings yet

- (Short Term) (Explain The Nursing Diagnosis)Document1 page(Short Term) (Explain The Nursing Diagnosis)Angel MayNo ratings yet

- Report of PDA Test Pile T29Document20 pagesReport of PDA Test Pile T29bertaNo ratings yet

- OrgMan - Week 5 - Tools in Business DecisionDocument13 pagesOrgMan - Week 5 - Tools in Business DecisionSilfa De la CruzNo ratings yet

- Daylight Factor - Wikipedia, The Free EncyclopediaDocument2 pagesDaylight Factor - Wikipedia, The Free EncyclopediadasaNo ratings yet

- News Drama: Reporter For A DayDocument4 pagesNews Drama: Reporter For A DayDavi BruderNo ratings yet

- Hero Found: The Greatest POW Escape of the Vietnam WarFrom EverandHero Found: The Greatest POW Escape of the Vietnam WarRating: 4 out of 5 stars4/5 (19)

- The Fabric of Civilization: How Textiles Made the WorldFrom EverandThe Fabric of Civilization: How Textiles Made the WorldRating: 4.5 out of 5 stars4.5/5 (58)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaFrom EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNo ratings yet

- The End of Craving: Recovering the Lost Wisdom of Eating WellFrom EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellRating: 4.5 out of 5 stars4.5/5 (81)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Sully: The Untold Story Behind the Miracle on the HudsonFrom EverandSully: The Untold Story Behind the Miracle on the HudsonRating: 4 out of 5 stars4/5 (103)

- Pale Blue Dot: A Vision of the Human Future in SpaceFrom EverandPale Blue Dot: A Vision of the Human Future in SpaceRating: 4.5 out of 5 stars4.5/5 (588)

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationFrom EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationRating: 4.5 out of 5 stars4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (122)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4 out of 5 stars4/5 (5)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerFrom EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerRating: 4.5 out of 5 stars4.5/5 (54)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- The Weather Machine: A Journey Inside the ForecastFrom EverandThe Weather Machine: A Journey Inside the ForecastRating: 3.5 out of 5 stars3.5/5 (31)

- Mini Farming: Self-Sufficiency on 1/4 AcreFrom EverandMini Farming: Self-Sufficiency on 1/4 AcreRating: 4 out of 5 stars4/5 (76)

- Packing for Mars: The Curious Science of Life in the VoidFrom EverandPacking for Mars: The Curious Science of Life in the VoidRating: 4 out of 5 stars4/5 (1395)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureFrom EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureRating: 5 out of 5 stars5/5 (125)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachFrom EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachRating: 4.5 out of 5 stars4.5/5 (27)