Professional Documents

Culture Documents

XHHW-2: XLP Insulation, 600 Volts

Uploaded by

NaveedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

XHHW-2: XLP Insulation, 600 Volts

Uploaded by

NaveedCopyright:

Available Formats

XHHW-2

XLP Insulation, 600 Volts

APPLICATION:

1. General purpose wiring for lighting and power - residential, commercial,

industrial buildings in accordance with National Electrical Code, maximum

conductor temperature of 90°C in wet or dry locations, 600 volts, for install-

ation in conduit or other recognized raceways.

2. Suitable for use in low leakage circuits requiring a dielectric constant of 3.5

or less, such as isolated circuits supplying anesthetizing locations per Article

517-160 of the NEC.

3. Suitable for use as low leakage inductive (loop) vehicle detector wire in

accordance with state and municipal requirements.

STANDARDS:

1. Listed by UL as Type XHHW-2 per Standard 44 for Rubber-Insulated Wires and

Cables.

2. Conforms to ICEA S-95-658/NEMA WC70, utilizing Column B thicknesses.

3. Conforms to Federal Specification J-C-30B.

CONSTRUCTION: Annealed copper conductor, XLP thermosetting chem-

ically crosslinked polyethylene insulation, surface printed.

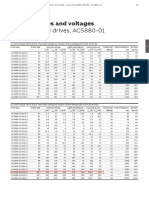

Size Insulation Approx. Wt.

AWG Thick- Nom. Ampacity* lbs/1000 ft

USAWC or No. of ness Diam.

kcmil Strands Mils Inches 75°C 90°C Net

Net Copper

Part #

Stranded

14-01XHHW-2 14 7 30 .14 20 25 18 13

12-01XHHW-2 12 7 30 .16 25 30 27 20

10-01XHHW-2 10 7 30 .18 35 40 40 32

8-01XHHW-2 8 7 45 .24 50 55 66 50

6-01XHHW-2 6 7 45 .28 65 75 96 81

4-01XHHW-2 4 7 45 .32 85 95 145 129

3-01XHHW-2 3 7 45 .35 100 110 182 163

2-01XHHW-2 2 7 45 .38 115 130 225 205

1-01XHHW-2 1 19 55 .44 130 150 290 258

1/0-01XHHW-2 1/0 19 55 .48 150 170 360 326

2/0-01XHHW-2 2/0 19 55 .52 175 195 450 411

3/0-01XHHW-2 3/0 19 55 .58 200 225 555 518

4/0-01XHHW-2 4/0 19 55 .63 230 260 700 653

250-01XHHW-2 250 37 65 .70 255 290 830 772

300-01XHHW-2 300 37 65 .75 285 320 990 926

350-01XHHW-2 350 37 65 .80 310 350 1150 1081

400-01XHHW-2 400 37 65 .85 335 380 1310 1235

500-01XHHW-2 500 37 65 .93 380 430 1620 1544

600-01XHHW-2 600 61 80 1.04 420 475 1980 1853

750-01XHHW-2 750 61 80 1.14 475 535 2445 2316

1000-01XHHW-2 1000 61 80 1.29 545 615 3240 3088

*Ampacity in accordance with NEC for not more than three conductors in raceway at the conductor temperature indicated, in wet or dry locations, 30°C

ambient temperature.

6301 EAST STASSNEY LANE, SUITE 100 2-5

AUSTIN, TEXAS 78744, USA

1-800-880-9473, FAX 512-443-6329, SALES@USAWIRE-CABLE.COM

**A

Specification

XHHW-2

XLP Insulation, 600 Volts

1. SCOPE

1.1 This specification describes single conductor XHHW-2, a general purpose building wire insulated with

crosslinked polyethylene (XLP) intended for lighting and power circuits at 600 volts or less, in residential,

commercial and industrial buildings. The wire may be operated at 90°C maximum continuous conductor tem-

perature in wet or dry locations and is listed by Underwriters Laboratories for use in accordance with Article 310

of the National Electrical Code.

2. APPLICABLE STANDARDS

2.1 The following standards form a part of this specification to the extent specified herein:

2.1.1 Underwriters Laboratories Standard 44 for Rubber-Insulated Wires and Cables.

2.1.2 ICEA Pub. No. S-95-658, NEMA Pub. No. WC70 for Nonshielded Power Cables Rated 2000 Volts or Less.

2.1.3 Federal Specification J-C-30B.

3. CONDUCTORS

3.1 Conductors shall be Class B stranded annealed uncoated copper per UL Standard 44.

4. SEPARATOR

4.1 A suitable separator over the conductor may be used at the option of the manufacturer.

5. INSULATION

5.1 Each conductor shall be insulated with XLP, a crosslinked polyethylene complying with the physical and

electrical requirements of UL Standard 44 for Type XHHW-2.

5.2 The average thickness of insulation, for a given conductor size, shall be as specified in UL Standard 44 for Type

XHHW-2. The minimum thickness at any point shall be not less than 90% of the specified average thickness.

The insulation shall be applied tightly to the conductor and shall be free-stripping.

6. IDENTIFICATION

6.1 The wire shall be identified by surface marking indicating manufacturer's identification, conductor size and metal,

voltage rating, UL Symbol and type designation.

7. TESTS

7.1 Wire shall be tested in accordance with the requirements of UL Standard 44 for Type XHHW-2.

8. LABELS

8.1 The wire shall bear the Underwriters Laboratories label for Type XHHW-2.

2-6 6301 EAST STASSNEY LANE, SUITE 100

AUSTIN, TEXAS 78744, USA

1-800-880-9473, FAX 512-443-6329, SALES@USAWIRE-CABLE.COM

You might also like

- Pec PDFDocument22 pagesPec PDFIvan-Jeff Alcantara75% (4)

- Electrical PM Program (By Hanover Risk Solution)Document16 pagesElectrical PM Program (By Hanover Risk Solution)didiekilham100% (2)

- Equipment rental rates and civil works materialsDocument20 pagesEquipment rental rates and civil works materialsKaren Balisacan Segundo Ruiz100% (1)

- 1083fm PDFDocument46 pages1083fm PDFMohamed NaserNo ratings yet

- Electrical Design ProjectDocument12 pagesElectrical Design ProjectClyde Anthony G. BalgosNo ratings yet

- Electical (2 Storey)Document7 pagesElectical (2 Storey)jazmontzNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- 300+ TOP CABLES Objective Type Questions and Answers Electrical Engineering Multiple Choice QuestionsDocument16 pages300+ TOP CABLES Objective Type Questions and Answers Electrical Engineering Multiple Choice QuestionsNaveedNo ratings yet

- Schedule of Loads LPA: Circuit Description LO Va/Lo VA Volts Amps CB Pole Switch NO AT AF S1 S2 S3Document4 pagesSchedule of Loads LPA: Circuit Description LO Va/Lo VA Volts Amps CB Pole Switch NO AT AF S1 S2 S3Samantha BolanteNo ratings yet

- 16 Samss 510Document11 pages16 Samss 510HatemS.MashaGbehNo ratings yet

- Engineering Materials 74 Important MCQ PDFDocument10 pagesEngineering Materials 74 Important MCQ PDFNaveedNo ratings yet

- XHHW 2 PDFDocument2 pagesXHHW 2 PDFSounak RoyNo ratings yet

- XHHW 2 PDFDocument2 pagesXHHW 2 PDFLuis SantiagoNo ratings yet

- XHHW-2 Insulation SpecificationDocument2 pagesXHHW-2 Insulation SpecificationNaveedNo ratings yet

- THHN CuDocument2 pagesTHHN Cujuan pablo castro gallegoNo ratings yet

- THHN CuDocument2 pagesTHHN Cujuan pablo castro gallegoNo ratings yet

- THHNDocument2 pagesTHHNanon-136032No ratings yet

- 2 KV AL Cable Datasheet - Priority CablesDocument1 page2 KV AL Cable Datasheet - Priority CablesVipin KhandelwalNo ratings yet

- Siemens 3TS Type 2 Fuse Protected DOLDocument1 pageSiemens 3TS Type 2 Fuse Protected DOLJitendra SaliNo ratings yet

- ( Update 21 November ) NEW 2023 RF P11 R6 - WS 25 5K RS 27 5K BL Meeting Dom (1) - Updated ProdDocument91 pages( Update 21 November ) NEW 2023 RF P11 R6 - WS 25 5K RS 27 5K BL Meeting Dom (1) - Updated ProdRiza AnimationNo ratings yet

- DSAH0011986Document12 pagesDSAH0011986Mahdi AlizadehNo ratings yet

- OP Signify Juni 23Document8 pagesOP Signify Juni 23Kemas RezaNo ratings yet

- Aluminum XHHW-2 600V, XLPE Insulation: ApplicationDocument1 pageAluminum XHHW-2 600V, XLPE Insulation: ApplicationJuan Rivera DuronNo ratings yet

- IXYS HV MOSFETsDocument17 pagesIXYS HV MOSFETsshahinNo ratings yet

- T-1 Subminiature Lamps: Telephone: 781-935-4442 Fax: 781-938-5867 Engineering Catalog 169Document1 pageT-1 Subminiature Lamps: Telephone: 781-935-4442 Fax: 781-938-5867 Engineering Catalog 169Yacine BàssotiNo ratings yet

- Illustrated Parts Catalog: Figure 50B PAGE 50B-0 DEC.01/14Document3 pagesIllustrated Parts Catalog: Figure 50B PAGE 50B-0 DEC.01/14randoll jamesNo ratings yet

- Technical Data For All PilgersDocument4 pagesTechnical Data For All PilgersTushar PachlangiaNo ratings yet

- Y Three Phase MotorDocument6 pagesY Three Phase MotorVladimir233100% (2)

- JIS-FlangesDocument9 pagesJIS-FlangesIbadullah MominNo ratings yet

- JIS FlangesDocument9 pagesJIS FlangesKhairulUmamNo ratings yet

- KJIN Rockbreaker BrochureDocument8 pagesKJIN Rockbreaker BrochureRC SPARESNo ratings yet

- Plastic Package For TransistorsDocument4 pagesPlastic Package For Transistorsvikram80No ratings yet

- High Speed HRC Fuses - Continued: Fuses, Circuit Breakers & Consumer UnitsDocument1 pageHigh Speed HRC Fuses - Continued: Fuses, Circuit Breakers & Consumer UnitsVasile DumitruNo ratings yet

- Interlocked Armor Power Cable, 5000 VOLTSDocument1 pageInterlocked Armor Power Cable, 5000 VOLTSpedro perezNo ratings yet

- Reboiler Circuit DesignDocument5 pagesReboiler Circuit DesignKamil MarszałekNo ratings yet

- PPRC EstimateDocument2 pagesPPRC EstimateadnansaghirNo ratings yet

- Analyze stock and option trades with MTM valuesDocument3 pagesAnalyze stock and option trades with MTM valuesRounak ChowdhuryNo ratings yet

- Control Transformers: Technical DataDocument2 pagesControl Transformers: Technical DataEngineerOmarNo ratings yet

- Index Quantity Part Number Manufacturer Part NumberDocument3 pagesIndex Quantity Part Number Manufacturer Part NumberNguyễn Văn TâmNo ratings yet

- Brook Comptom Frame Sizes PDFDocument12 pagesBrook Comptom Frame Sizes PDFVictorNo ratings yet

- Koolwal MATERIALDocument2 pagesKoolwal MATERIALSunil KoolwalNo ratings yet

- ABB Cat 580 PDFDocument1 pageABB Cat 580 PDFAnand ParihariNo ratings yet

- Shuttering Boq Tundla Rub & RfoDocument2 pagesShuttering Boq Tundla Rub & RfoAnonymous sfkedkymNo ratings yet

- Client Symbol Series Netqty Netprice Optionty Pe Instrume NT Strikepric E Marketpri CeDocument3 pagesClient Symbol Series Netqty Netprice Optionty Pe Instrume NT Strikepric E Marketpri CeRounak ChowdhuryNo ratings yet

- Copper RWU90 1000V - 40°C XLPE Insulation: Priority Wire & Cable, Little Rock, AR PWC-C-2021Document1 pageCopper RWU90 1000V - 40°C XLPE Insulation: Priority Wire & Cable, Little Rock, AR PWC-C-2021Jaime Ocampo SalgadoNo ratings yet

- DC-DC Converter Spec SheetDocument6 pagesDC-DC Converter Spec SheetSailaja KavinNo ratings yet

- Toque WrenchDocument7 pagesToque WrenchMohammed SibghatullaNo ratings yet

- Steel quantification report for Mahuva construction projectDocument2 pagesSteel quantification report for Mahuva construction projectHarsh BhavsarNo ratings yet

- Altivar Process ATV600 - Protecao de Entrada - en - Mar19Document6 pagesAltivar Process ATV600 - Protecao de Entrada - en - Mar19Luiz Fernando Silva AlvesNo ratings yet

- Stock Qty Model & Serial Wise WSMBRD: Waseem ElectronicsDocument2 pagesStock Qty Model & Serial Wise WSMBRD: Waseem ElectronicsHarry JackNo ratings yet

- Depletion Mode N CH MosfetsDocument1 pageDepletion Mode N CH MosfetsscribddderNo ratings yet

- XHHW-2: 1. DescriptionDocument2 pagesXHHW-2: 1. DescriptionPreditec PeruNo ratings yet

- 110 1 WZDocument2 pages110 1 WZAyman MufarehNo ratings yet

- SC and SW Series Specifications: Magnetic Contactors and StartersDocument5 pagesSC and SW Series Specifications: Magnetic Contactors and StartersMohsin LatifNo ratings yet

- Load Schedule:Power PanelDocument1 pageLoad Schedule:Power Panelshaira novesterasNo ratings yet

- Actual Data Produksi 230203Document33 pagesActual Data Produksi 230203sandrafortuna39No ratings yet

- Acs580 p18Document1 pageAcs580 p18NovyNo ratings yet

- Katalog Komposisi Lengkap New VersionDocument8 pagesKatalog Komposisi Lengkap New VersionSontani PurnamaNo ratings yet

- Packing List CB10000039Document7 pagesPacking List CB10000039TarunNo ratings yet

- 8 - 17Document6 pages8 - 17Muhammad Usman GhaniNo ratings yet

- ABB Cat 880 PDFDocument1 pageABB Cat 880 PDFAnand ParihariNo ratings yet

- Magnetic Contactors and Starters SpecificationsDocument8 pagesMagnetic Contactors and Starters SpecificationsSyed Abrar HussainNo ratings yet

- SIMpull XHHW 2 Copper WireDocument3 pagesSIMpull XHHW 2 Copper Wireanton baskoroNo ratings yet

- Bảng Tính CS QuạtDocument6 pagesBảng Tính CS QuạtPhúc NgọcNo ratings yet

- Zener Diode Voltage Specifications and Data SheetDocument4 pagesZener Diode Voltage Specifications and Data SheetPanagiotis PanagosNo ratings yet

- Arrancadores General ElectricDocument1 pageArrancadores General ElectricFernando AguíñagaNo ratings yet

- 600V AL Photovoltaic PV Cable - Priority CablesDocument1 page600V AL Photovoltaic PV Cable - Priority CablesVipin KhandelwalNo ratings yet

- Direct on line starters 400 V - 80 kA - Long starting (heavy duty) start - upDocument1 pageDirect on line starters 400 V - 80 kA - Long starting (heavy duty) start - upIto SalvadorNo ratings yet

- Engine Parameters ChartDocument1 pageEngine Parameters ChartCalandrasReyCalandrasreyNo ratings yet

- AC107Document1 pageAC107sruNo ratings yet

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedNo ratings yet

- FTC470XET TGH en PDFDocument84 pagesFTC470XET TGH en PDFNaveedNo ratings yet

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedNo ratings yet

- MOH Approved Projects List & Medical City DecreesDocument4 pagesMOH Approved Projects List & Medical City DecreesNaveedNo ratings yet

- ATICS-DIO-Operation TKA en PDFDocument4 pagesATICS-DIO-Operation TKA en PDFNaveedNo ratings yet

- ATICS-DIO TGH enDocument100 pagesATICS-DIO TGH enNaveedNo ratings yet

- ATiCS Praxis PPT en 20110308Document12 pagesATiCS Praxis PPT en 20110308NaveedNo ratings yet

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedNo ratings yet

- EDS151 DB enDocument4 pagesEDS151 DB enNaveedNo ratings yet

- CDocument10 pagesCNaveedNo ratings yet

- Title Sheets Dallah Submittal PDFDocument1 pageTitle Sheets Dallah Submittal PDFNaveedNo ratings yet

- Control System 32 Important MCQDocument7 pagesControl System 32 Important MCQDINESHNo ratings yet

- Network and Transmission Lines 100 MCQDocument21 pagesNetwork and Transmission Lines 100 MCQNandakumar ReddyNo ratings yet

- Analog and Power Electronics Important MCQ PDF: All Exam Review AddaDocument12 pagesAnalog and Power Electronics Important MCQ PDF: All Exam Review AddaNoor AhmedNo ratings yet

- ATICS-DIO-Operation TKA en PDFDocument4 pagesATICS-DIO-Operation TKA en PDFNaveedNo ratings yet

- Functional Safety PROSP en 20101102Document4 pagesFunctional Safety PROSP en 20101102NaveedNo ratings yet

- FTC470XET TGH en PDFDocument84 pagesFTC470XET TGH en PDFNaveedNo ratings yet

- IR145YDocument3 pagesIR145YAndy Kong KingNo ratings yet

- IRDH275 DB en PDFDocument4 pagesIRDH275 DB en PDFNaveedNo ratings yet

- Transformer - Datasheet - NFPA (American) PDFDocument4 pagesTransformer - Datasheet - NFPA (American) PDFNaveedNo ratings yet

- IR1575 DB enDocument3 pagesIR1575 DB enNaveedNo ratings yet

- Neca Nacma 120 Track ChangesDocument43 pagesNeca Nacma 120 Track ChangesAhmed H. HassanNo ratings yet

- Ir1575 PDFDocument3 pagesIr1575 PDFNaveedNo ratings yet

- 107TD47 DB enDocument6 pages107TD47 DB enNaveedNo ratings yet

- SimpliPhi Battery Wiring GuideDocument16 pagesSimpliPhi Battery Wiring GuideMaksym KlymenkoNo ratings yet

- Jonelc Indutrial Complex SCVDDocument17 pagesJonelc Indutrial Complex SCVDCarl Patrick PondivillaNo ratings yet

- Electric Distribution Systems GuidelinesDocument42 pagesElectric Distribution Systems GuidelinesahmedengNo ratings yet

- CA General Notes ApprovedDocument6 pagesCA General Notes ApprovedSal ShamNo ratings yet

- AVT 4235 - Wire and Wireless CommunicationDocument39 pagesAVT 4235 - Wire and Wireless CommunicationLey Martinez FaylognaNo ratings yet

- Utilities Systems Flashcards QuizletDocument59 pagesUtilities Systems Flashcards QuizletRonielle MercadoNo ratings yet

- PC1 532Document147 pagesPC1 532bharatsehgal00@gmail.comNo ratings yet

- Ampacity of ConductorsDocument8 pagesAmpacity of ConductorsAriel DimacaliNo ratings yet

- 14 Samss 531Document23 pages14 Samss 531HatemS.MashaGbehNo ratings yet

- RehabilitatioSB Session Hall Tile WorksDocument64 pagesRehabilitatioSB Session Hall Tile WorksAnthony DelarosaNo ratings yet

- Ramos DLP Lesson1Document10 pagesRamos DLP Lesson1Irah kabilingNo ratings yet

- Grand Central Terminal Mep Handbook 180323Document84 pagesGrand Central Terminal Mep Handbook 180323Pete A100% (1)

- Project Cost Estimate (CARPORT) PDFDocument4 pagesProject Cost Estimate (CARPORT) PDFJMike P. FernandezNo ratings yet

- Technical Specifications - Simple Written FormatDocument13 pagesTechnical Specifications - Simple Written FormatBianca SamaleaNo ratings yet

- PEC Closed Door 8Document9 pagesPEC Closed Door 8Essej OrtsacNo ratings yet

- This Site: Load Schedule and AnalysisDocument1 pageThis Site: Load Schedule and AnalysisRyan De GuzmanNo ratings yet

- Back of The House Monitoring Central Bloc SEDA HOTEL: SEPTEMBER 18, 2019Document21 pagesBack of The House Monitoring Central Bloc SEDA HOTEL: SEPTEMBER 18, 2019Charles NunezNo ratings yet

- Csu-Xu9 24vkq (Premium Inv) Start-Up ChecklistDocument8 pagesCsu-Xu9 24vkq (Premium Inv) Start-Up ChecklistBernar D Bo SanchezNo ratings yet

- Catalogo Cable FestonDocument16 pagesCatalogo Cable FestonJesús AlvaradoNo ratings yet

- Powerflex 4 User Manual - ANTECHDocument108 pagesPowerflex 4 User Manual - ANTECHOG100% (1)

- 3000 Series Electronic Quick Install Guide: Important Safety InstructionsDocument18 pages3000 Series Electronic Quick Install Guide: Important Safety InstructionsPepe Queño MtzNo ratings yet

- PNL LP: General NotesDocument1 pagePNL LP: General NotesEDRICK ESPARRAGUERRANo ratings yet

- Philippine Electrical Code #5Document116 pagesPhilippine Electrical Code #5Jeffrey AlimarioNo ratings yet

- CABLE Southwire Extracto 600 V, Cu, EPR, XLPE, XHH Untitled1Document8 pagesCABLE Southwire Extracto 600 V, Cu, EPR, XLPE, XHH Untitled1Hector RiveraNo ratings yet