Professional Documents

Culture Documents

Industrial Automation Course Outline

Uploaded by

Raihan0 ratings0% found this document useful (0 votes)

77 views2 pagesOriginal Title

Industrial Automation

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

77 views2 pagesIndustrial Automation Course Outline

Uploaded by

RaihanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

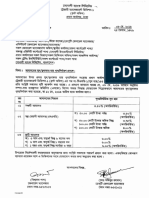

Ideal Automation Technologies

Ideal Design & Engineering

Location:House#40,Road No-9,Nikunja-2,Dhaka. www.idealplc.net Contact- 01832 264 264

Course Introduce: Industrial Automation

Course Duration : 3 Months

Total Class : 30 classes

Class Duration : 2.5 Hours

Total : 75 Hours.

Course Fees- 8000 Tk.

Course Outline: Training Course on Programmable Logic Controllers (PLCs)

v Module 1: Industrial Power Electronics

ÿ For Industrial Purpose Testing & Behavior realize of Capacitor.

ÿ Diode, Triac , Inductor, Solenoid Valve.

ÿ Transistor, MOSFET, SCR , IGBT, Opt coupler , Temperature Controller .

v Module 2: Transformer Design

ÿ Transformer Operation and Behavior.

ÿ Transformer Pre-Design Concept & Theory.

ÿ Transformer test and identify.

ÿ Transformer winding and calculation.

ÿ Final Transformer Design & Output observation.

v Module 3:Manual Control/Driving system

ÿ Operation and Utilize use of Relay , Selector Switch, Push Button Switch, Timer,

Magnetic Contact .

ÿ Practical Hand on Solid State Relay (SSR), Over Load Relay , Phase Failure Relay.

∑ Motor Controlling Project: Relay ,Timer , Magnetic Contact.

ÿ Basic Project of Delay System (Using Timer ).

ÿ Motor Starters : DOL Connection , Star-Delta.

ÿ Reverse Forward Connection, Automation Reverse Forward.

∑ Motor Controlling Project by Solid Sate Relay(SSR), Phase Failure Relay, Overload

Relay

ÿ Motor Starters: DOL Connection, Star-Delta.

ÿ Reverse Forward Connect, Automation Reverse Forward.

v Module4:Industrial Sensor & Application

∑ Sensor Practical Lab Manual

ÿ Sensor Introduce, Type of Sensor.

ÿ Proximity Sensor, Resistance Temperature Detector (RTD).

ÿ PT-100, PT-200, Photo Sensor, Thermocouples, Level Sensor.

ÿ Motion Sensor, Humidity Sensor .

v Module 5: Programmable Logic Controller

Objective: Designing, organizing, and programming the PLC ladder logic project. Describe

functions and uses of Develop PLC program for any industrial process Modify existing PLC

program for more logical use. Select a proper PLC for a certain industrial plant.

∑ PLC Project Design, Programming &Connection:

Programming:

ÿ Siemens Model Logo, S7-200, S7-300.

ÿ Delta: DVP 24ES Series.

ÿ Mitsubishi Model FX1N-60MR., FX1S-30MR-ES/UL

ÿ OMRON SYSMEC CPM1A.

ÿ LG/LS Model Master K 120s,80s.

ÿ Allen Bradley and Untimed S7-200

@@Deliver Minimum 5 PLC Project by each PLC@@

∑ Basic Troubleshooting: Hardware of PLC, Programming & troubleshooting of Siemens-

Logo, S7-200, S7-300. Omron, Mitsubishi, Allan Bradley, LG & Delta PLC Programming.

v Module 6:Variable Frequency Driver (VFD)

ÿ Introduction to AC drives & applications.

ÿ Criteria for drives selection.

ÿ Parameter Programming.

ÿ Designing of drive control panel.

ÿ Communication with PLC Software.

v Module 7: HMI/Touch Screen Programming

ÿ Getting started with HMI.

ÿ Creating applications, creating tags.

ÿ Downloading / uploading programs.

ÿ Creating alarm messages.

ÿ Communication with PLC.

Others Training Program:

S/L Course Name Duration Number of Class Course fees

1 Industrial Automation 3 Month 30 8000TK

2 Advance Industrial Automation 3 Month 30 10000TK

3 MATLAB for Engineers 2 Month 25 7000 TK

4 Microcontroller & Robotics system 2 Month 25 6000 TK

5 AutoCAD@ Civil( 2D, 3D) 3 Month 24 5,000 Tk

6 AutoCAD@ Mechanical 2 Month 24 5,000 Tk

7 AutoCAD@ Mechanical 2 Month 24 5,000 Tk

8 Autodesk 3ds Max 2 Month 20 10,000Tk

9 Revit 2017 2 Month 16 8,000 TK

You might also like

- Industrial Automation and Electrical Design Course DetailsDocument10 pagesIndustrial Automation and Electrical Design Course DetailsRaihanNo ratings yet

- Project Report DPM 07202020150504Document45 pagesProject Report DPM 07202020150504Adharsh R nairNo ratings yet

- Government Polytechnic, Jalgaon (0018) : Maharashtra State Board of Technical EducationDocument14 pagesGovernment Polytechnic, Jalgaon (0018) : Maharashtra State Board of Technical EducationRashmi dusaneNo ratings yet

- Automatic escalator control using PLCDocument5 pagesAutomatic escalator control using PLCCarl Justin de Jesus100% (1)

- Mechanic (Embedded Systems and PLC)Document6 pagesMechanic (Embedded Systems and PLC)sbos1100% (1)

- ABHAY KR. GUPTA'S CONTACT AND CAREER DETAILSDocument9 pagesABHAY KR. GUPTA'S CONTACT AND CAREER DETAILSiecnagaNo ratings yet

- Project ProposalDocument8 pagesProject ProposalShafin Al Asad ProticNo ratings yet

- 2171103Document4 pages2171103narayanNo ratings yet

- Object Counter With 7 Segment DisplayDocument86 pagesObject Counter With 7 Segment DisplayShalini AavutiNo ratings yet

- Futuronix Training With Fee Detatil 11Document9 pagesFuturonix Training With Fee Detatil 11arvind_cool05No ratings yet

- Manufacturing Automation (MTS 451) Course OverviewDocument15 pagesManufacturing Automation (MTS 451) Course OverviewKashan Aamir Aamir IshaqNo ratings yet

- Solar Track1 51Document7 pagesSolar Track1 51Srinivasa Reddy Devi ReddyNo ratings yet

- 05Document42 pages05tt_aljobory3911No ratings yet

- A Proposal On The Design and Implementation of An Advanced 8051 Microcontroller Based Trainer ModuleDocument7 pagesA Proposal On The Design and Implementation of An Advanced 8051 Microcontroller Based Trainer ModuleSolomon AkpanNo ratings yet

- Industry Profile:: 1) History of Hem ElectronicsDocument15 pagesIndustry Profile:: 1) History of Hem ElectronicsMahesh Manikrao KumbharNo ratings yet

- Training Report: Bachelor of TechnologyDocument46 pagesTraining Report: Bachelor of TechnologyHelloprojectNo ratings yet

- Summer Internship Program 2012: Course ContentDocument3 pagesSummer Internship Program 2012: Course ContentjungyawarNo ratings yet

- Manoj Kumar: Core Knowledge and Functional Skill AreasDocument4 pagesManoj Kumar: Core Knowledge and Functional Skill AreasMANOJ KUMARNo ratings yet

- Project Report On Robotic ArmDocument28 pagesProject Report On Robotic Armpatel ketan84% (25)

- WK 214modDocument90 pagesWK 214modadusumilliabhishekNo ratings yet

- Mini Project Report Industrial Automation SreekuDocument38 pagesMini Project Report Industrial Automation Sreekusreekumar456No ratings yet

- Automatic Load SheddingDocument4 pagesAutomatic Load SheddingNkechi JoyNo ratings yet

- Syllabus V Sem CS DipDocument25 pagesSyllabus V Sem CS DipSK BeharNo ratings yet

- JournalNX - Automatic Ladle ControlDocument4 pagesJournalNX - Automatic Ladle ControlJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Calendar: Synopsis On DigitalDocument3 pagesCalendar: Synopsis On DigitalSiddharthRawatNo ratings yet

- Institute of Civil and Rural Engineering (Aided) : Basic of PLC Data Sheet of Various ManufacturersDocument13 pagesInstitute of Civil and Rural Engineering (Aided) : Basic of PLC Data Sheet of Various ManufacturersPranil KambleNo ratings yet

- Microcontroller Lab_RB_For CirculationDocument36 pagesMicrocontroller Lab_RB_For Circulationpanave3104No ratings yet

- Microcontroller Lab_RB_For Circulation (1)Document36 pagesMicrocontroller Lab_RB_For Circulation (1)panave3104No ratings yet

- 03 Development of ScalableDocument15 pages03 Development of ScalableprjpublicationsNo ratings yet

- IRJET-V5I11169Document13 pagesIRJET-V5I11169Sumardi Sadi FT UMTNo ratings yet

- Book With Bookmarks - 7-17-08Document309 pagesBook With Bookmarks - 7-17-08Salah DahouathiNo ratings yet

- Fom MicroprojectDocument9 pagesFom MicroprojectPRABHAVATI TANAJI DESHMUKH100% (1)

- CH - Gopi Chand Civil Engineer: Sri Venkateswara Engineering CollegeDocument48 pagesCH - Gopi Chand Civil Engineer: Sri Venkateswara Engineering CollegeJohneal MatiasNo ratings yet

- Digital Clock Using 8051 Microcontroller With RTCDocument47 pagesDigital Clock Using 8051 Microcontroller With RTCsiddharthNo ratings yet

- A Project Report On: Devi Mahalaxmi Polytechnic College, TitwalaDocument33 pagesA Project Report On: Devi Mahalaxmi Polytechnic College, Titwalaprashant mhatreNo ratings yet

- Resume Vishal Dal ViDocument4 pagesResume Vishal Dal Vibharathks641No ratings yet

- Power Distribution System for Industries Using Real-Time ClockDocument3 pagesPower Distribution System for Industries Using Real-Time Clockdileeppatra100% (1)

- 4 5780930464638307476 PDFDocument28 pages4 5780930464638307476 PDFYihun DesalegnNo ratings yet

- ISA Course Outline R3Document5 pagesISA Course Outline R3Mannu KiruiNo ratings yet

- Microcontroller DecodeDocument99 pagesMicrocontroller Decodewatamo9103No ratings yet

- Power Saving Street LightDocument79 pagesPower Saving Street LightEmilsonu Sam50% (2)

- Proteus Simulation Based Pic ProjectsDocument29 pagesProteus Simulation Based Pic ProjectsSalman MohamedNo ratings yet

- Skills Competition (Mechatronics)Document13 pagesSkills Competition (Mechatronics)Putri Chairany100% (1)

- Mindstorm Engineering Training Profile PDFDocument42 pagesMindstorm Engineering Training Profile PDFmuhammad zubairNo ratings yet

- Practical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11From EverandPractical Embedded Controllers: Design and Troubleshooting with the Motorola 68HC11No ratings yet

- Industrial AutomationDocument4 pagesIndustrial AutomationNarayanan IyerNo ratings yet

- IPS Academy Offers Minor in Robotics EngineeringDocument9 pagesIPS Academy Offers Minor in Robotics EngineeringajayNo ratings yet

- Api I C2Document31 pagesApi I C2mihai37No ratings yet

- RTS SyllabusDocument3 pagesRTS SyllabusthejasNo ratings yet

- Feed-To-Length Application Using MC - Touchprobe For Position LatchingDocument10 pagesFeed-To-Length Application Using MC - Touchprobe For Position LatchingjsofiabeltranNo ratings yet

- Advanced Industrial Automation CourseDocument2 pagesAdvanced Industrial Automation CourseAmaldev ThakurNo ratings yet

- 3361107Document6 pages3361107narayanNo ratings yet

- Sofcon TrainingDocument3 pagesSofcon TrainingDheeraj Sharma0% (1)

- Industrial Automation Using I2c Protocol DocumentationDocument56 pagesIndustrial Automation Using I2c Protocol Documentationsrinithi99No ratings yet

- Sandeep KumarDocument3 pagesSandeep Kumarsandeep151188No ratings yet

- Robotic ManualDocument47 pagesRobotic ManualChhailender Singh BansalNo ratings yet

- New Microsoft Word DocumentDocument10 pagesNew Microsoft Word DocumentTejas KadamNo ratings yet

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- PLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsFrom EverandPLC Programming Using RSLogix 500 & Industrial Applications: Learn ladder logic step by step with real-world applicationsRating: 5 out of 5 stars5/5 (1)

- Intt Rates PDFDocument7 pagesIntt Rates PDFMilon MahmudNo ratings yet

- Sinha power plant written questions solutionDocument14 pagesSinha power plant written questions solutionRaihanNo ratings yet

- Solution of Op-Amp Math-2015 NWPGCLDocument1 pageSolution of Op-Amp Math-2015 NWPGCLRaihanNo ratings yet

- Sinha Power Plant Ques.Document2 pagesSinha Power Plant Ques.RaihanNo ratings yet

- MATH Suggestion For EEE EXAMDocument1 pageMATH Suggestion For EEE EXAMAnupam BaruaNo ratings yet

- Kiriti Saha Amit - Proposed Affidavit SampleDocument3 pagesKiriti Saha Amit - Proposed Affidavit SampleRaihanNo ratings yet

- List of Documents Needed For Resident Permit (RP) of FINLAND (Self-Sponsor)Document1 pageList of Documents Needed For Resident Permit (RP) of FINLAND (Self-Sponsor)RaihanNo ratings yet

- Walton exam review for Assistant Manager Techno Service positionDocument3 pagesWalton exam review for Assistant Manager Techno Service positionRaihan0% (1)

- Solution of DPDC-2015 PDFDocument3 pagesSolution of DPDC-2015 PDFRaihanNo ratings yet

- Bcic Recruitment Question 27-06-2014Document3 pagesBcic Recruitment Question 27-06-2014Anonymous XWTgry0% (1)

- NWPGCL For The Post of Assistant Engineer (Electrical)Document3 pagesNWPGCL For The Post of Assistant Engineer (Electrical)Nazmul Hasan100% (4)

- Old graphics versions and pilotsDocument2 pagesOld graphics versions and pilotsRaihanNo ratings yet

- DPDC EEE Objective Question SolveDocument3 pagesDPDC EEE Objective Question SolveRaihanNo ratings yet

- Electrical Design & Drafting (E-CAD) Course OutlineDocument2 pagesElectrical Design & Drafting (E-CAD) Course OutlineRaihanNo ratings yet

- Pvkzwiiav E'B Dig: 5 5 M.Wg. Qwe (M Ú WZ ZVJV, Pvikwc)Document1 pagePvkzwiiav E'B Dig: 5 5 M.Wg. Qwe (M Ú WZ ZVJV, Pvikwc)RaihanNo ratings yet

- 8 English For TodayDocument126 pages8 English For TodayVictor Angel Chan75% (4)

- MCQ English Literature SECURED Raju Ahmed PDFDocument44 pagesMCQ English Literature SECURED Raju Ahmed PDFRaihanNo ratings yet

- BCB High Frequency Exam Vocabulary by Hemal Jamiul HasanDocument68 pagesBCB High Frequency Exam Vocabulary by Hemal Jamiul HasanRaihanNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Ideal Automation Technologies Ideal Design & Engineering: Autocad@ Civil (2D, 3D)Document2 pagesIdeal Automation Technologies Ideal Design & Engineering: Autocad@ Civil (2D, 3D)RaihanNo ratings yet

- 525 MCQ On English Literature (With Option) 2Document73 pages525 MCQ On English Literature (With Option) 2elisia100% (1)

- (By Kusumito) : This Boundary Wall Is A Bone of Contention Between The Two NeighboursDocument4 pages(By Kusumito) : This Boundary Wall Is A Bone of Contention Between The Two NeighboursRaihanNo ratings yet

- A Compilation Ofreli Questions of English Literature by Samad AzadDocument10 pagesA Compilation Ofreli Questions of English Literature by Samad AzadOnnoSaikatNo ratings yet

- Advertisement DNCDocument2 pagesAdvertisement DNCRaihanNo ratings yet

- Physics MCQDocument45 pagesPhysics MCQRaihanNo ratings yet

- List of American and British Spelling Differences: Non-Preferred US Alternative Spellings Are Marked in RedDocument33 pagesList of American and British Spelling Differences: Non-Preferred US Alternative Spellings Are Marked in RedRaihanNo ratings yet

- Hamlet: English LiteratureDocument20 pagesHamlet: English LiteratureRaihanNo ratings yet

- Mvaviy Weávb: Beg-'Kg Köwy Awz Iæz¡C Y© Ga G Iæz¡C Y© Iæz¡C Y©Document6 pagesMvaviy Weávb: Beg-'Kg Köwy Awz Iæz¡C Y© Ga G Iæz¡C Y© Iæz¡C Y©RaihanNo ratings yet

- Oracle Big Data SQL Installation GuideDocument139 pagesOracle Big Data SQL Installation Guidepedro.maldonado.rNo ratings yet

- GLA45AMG 156 133 Oil ChangeDocument2 pagesGLA45AMG 156 133 Oil ChangeJoan Callau FuentesNo ratings yet

- OCR Services Corporate BrochureDocument12 pagesOCR Services Corporate BrochureOCR ServicesNo ratings yet

- HP LaserJet 4L - 4P Service ManualDocument306 pagesHP LaserJet 4L - 4P Service ManualimakingtxNo ratings yet

- Scheduling, Preemption and Eviction - KubernetesDocument66 pagesScheduling, Preemption and Eviction - KubernetesFantahun FkadieNo ratings yet

- Compressive Strength of Concrete Drilled CoresDocument1 pageCompressive Strength of Concrete Drilled CoresMd SohagNo ratings yet

- Ts440s Repair FaqDocument17 pagesTs440s Repair FaqboardstNo ratings yet

- Star Control: Operating InstructionsDocument14 pagesStar Control: Operating InstructionsMohamed RaeesNo ratings yet

- KV35S65Document77 pagesKV35S65Gabriel FuentesNo ratings yet

- Submarine Escape Survivability and Rescue MohundroDocument14 pagesSubmarine Escape Survivability and Rescue Mohundroali alvandiNo ratings yet

- C V C V C V C V: Urriculum Itae Urriculum Itae Urriculum Itae Urriculum ItaeDocument1 pageC V C V C V C V: Urriculum Itae Urriculum Itae Urriculum Itae Urriculum ItaeFandrio PermataNo ratings yet

- Neutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Document1 pageNeutral Quick Installation Guide (For Dome CMIP70x2W-28MA) - 20210413Marvin Caballero ZelayaNo ratings yet

- MRD 4400 Receiver Decoder v19Document3 pagesMRD 4400 Receiver Decoder v19Hama AieaNo ratings yet

- ASIC Protocol (Eng)Document7 pagesASIC Protocol (Eng)elroysaaNo ratings yet

- Agor, Sharon M. Curicullum VitaeDocument1 pageAgor, Sharon M. Curicullum Vitaesharon agorNo ratings yet

- Laptop Voltage Requirement and Power Supply DiagramDocument5 pagesLaptop Voltage Requirement and Power Supply Diagrambong bernalbongNo ratings yet

- Project of Electronics SubjectDocument14 pagesProject of Electronics SubjectDarren Troy Lingao MayorNo ratings yet

- Low Noise Amplifier Design by AnsoftDocument17 pagesLow Noise Amplifier Design by AnsoftdieguinkiNo ratings yet

- A Simple Approach To Short Circuit Calculations - EDP1Document48 pagesA Simple Approach To Short Circuit Calculations - EDP1Raul GuerraNo ratings yet

- Hauff ManDocument11 pagesHauff ManMohammad IsmailNo ratings yet

- Trinity Institute of Professional Studies Practical FileDocument33 pagesTrinity Institute of Professional Studies Practical Filekartik aroraNo ratings yet

- Amphenol PCD Terminal Junction Module Milt81714 PDFDocument18 pagesAmphenol PCD Terminal Junction Module Milt81714 PDFramalingamNo ratings yet

- Attach-2 Triconex Technical Product Guide-CompressedDocument39 pagesAttach-2 Triconex Technical Product Guide-Compressedivan_sofyan_aNo ratings yet

- Faça o Download de Vídeo e Áudio Do YouTubeDocument3 pagesFaça o Download de Vídeo e Áudio Do YouTubeBrunoNo ratings yet

- UI - UX Assignment - MadieeDocument4 pagesUI - UX Assignment - Madieeprashastbhardwaj8No ratings yet

- Remote Monitoring & Control of RACON BeaconDocument2 pagesRemote Monitoring & Control of RACON Beacon송현호No ratings yet

- 08 Heffner and Mettrick JDB 4-4Document13 pages08 Heffner and Mettrick JDB 4-4jose ariasNo ratings yet

- Prso KM S - : Durgapur Public SchoolDocument2 pagesPrso KM S - : Durgapur Public SchoolPrasoon Singh RajputNo ratings yet

- How to change net or via name in InnovusDocument8 pagesHow to change net or via name in Innovusvibhash kumarNo ratings yet

- 42 LM 660 SDocument119 pages42 LM 660 SGuy DesbiefNo ratings yet