Professional Documents

Culture Documents

Gage R & R Analysis Report Gage R & R Analysis Report: Gage R & R Summary Gage R & R Summary

Uploaded by

PRAMODOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gage R & R Analysis Report Gage R & R Analysis Report: Gage R & R Summary Gage R & R Summary

Uploaded by

PRAMODCopyright:

Available Formats

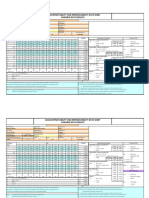

GAGE R & R ANALYSIS REPORT

CUSTOMER: TENNECO GAGE NAME: Digital Vernier Caliper NOMINAL: DATE: 20-Sep-19

PART NO.: 354893 GAGE NO.: VAPL/DVC/01 TOL(+): 0.1 PERFORMED BY: Pramod Nautiyal

CHARACTERISTIC: Dim 4.0 GAGE TYPE: TOL(-): 0.1

APPRAISER A NAME: Vivek PART

1 2 3 4 5 6 7 8 9 10 AVERAGE

1 4.04 4.05 4.08 4.06 4.04 4.03 4.06 4.03 4.02 4.03 4.044

GAGE R & R SUMMARY

TRIAL 2 4.05 4.04 4.07 4.07 4.01 4.04 4.05 4.07 4.03 4.04 4.047

3 4.06 4.05 4.05 4.08 4.04 4.03 4.04 4.05 4.01 4.03 4.044 MEASUREMENT UNIT ANALYSIS

AVERAGE 4.050 4.047 4.067 4.070 4.030 4.033 4.050 4.050 4.020 4.033 XBARA 4.045 REPEATABILITY (EV)

RANGE 0.020 0.010 0.030 0.020 0.030 0.010 0.020 0.040 0.020 0.010 RBARA 0.021 (EQUIPMENT VARIATION): 0.063

REPRODUCIBILITY (AV)

APPRAISER B NAME: Ram Kumar PART (APPRAISER VARIATION): 0.005

1 2 3 4 5 6 7 8 9 10 AVERAGE

R&R

1 4.02 4.08 4.04 4.05 4.04 4.01 4.06 4.01 4.01 4.05 4.037 (REPEATABILITY & REPRODUCIBILITY): 0.063

TRIAL

2 4.01 4.07 4.03 4.06 4.02 4.01 4.06 4.05 4.03 4.04 4.038

3 4.03 4.08 4.06 4.08 4.05 4.02 4.05 4.03 4.01 4.05 4.046 PART VARIATION (PV): 0.061

AVERAGE 4.020 4.077 4.043 4.063 4.037 4.013 4.057 4.030 4.017 4.047 XBARB 4.040 TOTAL VARIATION (TV): 0.088

RANGE 0.020 0.010 0.030 0.030 0.030 0.010 0.010 0.040 0.020 0.010 RBARB 0.021

% PROCESS % TOLERANCE

APPRAISER C NAME: Akash PART VARIATION (TV) VARIATION (TOL)

1 2 3 4 5 6 7 8 9 10 AVERAGE

1 4.02 4.02 4.09 4.02 4.04 4.03 4.08 4.05 4.07 4.01 4.043 % EQUIPMENT VARIATION: 71.54 31.43

TRIAL 2 4.04 4.01 4.08 4.03 4.05 4.03 4.07 4.06 4.05 4.02 4.044 % APPRAISER VARIATION: 5.87 2.58

3 4.02 4.02 4.06 4.01 4.07 4.02 4.08 4.02 4.06 4.01 4.037 % R & R: 71.78 31.54

AVERAGE 4.027 4.017 4.077 4.020 4.053 4.027 4.077 4.043 4.060 4.013 XBARC 4.041 % PART VARIATION: 69.62 30.59

RANGE 0.020 0.010 0.030 0.020 0.030 0.010 0.010 0.040 0.020 0.010 RBARC 0.020 ndc: 1

REPEATABILITY RANGE CONTROL CHART

XBARp 4.032 4.047 4.062 4.051 4.040 4.024 4.061 4.041 4.032 4.031 # PARTS 10 M (FOR EV(K1) = # OF TRIALS)(FOR AV(K2) = # APPR AND G=1)(FOR PV(K3) = # OF PARTS AND G=1)

0.060 APPRAISER A APPRAISER B APPRAISER C 8

UCL-R 0.053 0.053 0.053 0.053 0.053 0.053 0.053 0.053 0.060

0.053 0.053 OP1? 1 d2 2 3

0.060 4 5 6 7 9 10

0.050 LCL-R 0.000 0.000 0.000 0.000 0.000 0.000R - 0.000 0.000 0.050

0.000 0.000 OP2? 1 1 R - 1.410 1.910 2.240 2.480 2.670 2.830 2.960 3.080 3.180

R -

0.050

RBARBAR 0.021

0.040 0.021 0.021 0.021 0.021 0.021OP1 0.021 0.021 0.021 0.021 OP3? 1 2 OP2 1.280 1.810 2.150 2.400 2.600 2.770 2.910 3.020 3.130

OP3

0.040 0.040 UCL-R

XBARBAR 4.042 4.042 4.042 4.042 4.042 4.042UCL-R

4.042 4.042 4.042 4.042 # OPER 3 3 UCL-R

1.230 1.770 2.120 2.380 2.580 2.750 2.890 3.010 3.110

0.030 LCL-R

LCL-R

UCL-XBAR 4.09542 4.09542 4.09542 4.09542 4.09542 4.09542 4.09542 4.09542 0.030

4.09542 4.09542 # TRIALS (M) 3 4 LCL-R

1.210 0.030

1.750 2.110 2.370 2.570 2.740 2.880 3.000 3.100

RBARB RBARB RBARB

0.020

LCL-XBAR 3.98903 3.98903 3.98903 3.98903 3.98903 3.98903 3.98903 3.98903 0.020

3.98903 3.98903 (G) 30.000 G 5 AR 1.190 1.740 2.100 2.360 2.560 2.730 2.870 2.990 3.100

AR 0.020 AR

0.010 d2A(EV)= 1.128 d2(EV)= 1.693 6 1.180 1.730 2.090 2.350 2.560 2.730 2.870 2.990 3.100

0.010 0.010

d2(PV)= 3.180 d2(AV)= 1.910

0.000 0.000 0.000

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

PART APPRAISER AVERAGE CHART

7 1.170 1.730 2.090 2.350 2.550 2.720 2.870 2.990 3.100

COUNT D4 D3 A2 3/d2

APPRAISER ASIZE A2 D3 D4 3/d2 TOLERANCE XDiff (Ro): 0.005 8 1.170 1.720 2.080 2.350 APPRAISER

2.550 2.720 C 2.870 2.980 3.090

APPRAISER B 4.15

3

4.15 2.574 0 2.574 1.772 2 1.88 0 3.268 4.15

2.659 0.2 Rp: 0.038 9 1.160 1.720 2.080 2.340 2.550 2.720 2.860 2.980 3.090

4.1 3 1.023 0 Xavg2.574

- 1.772 1.3604 AV1: 0.000 10 1.160 1.720

4.1 2.080 2.340 2.550 2.720 2.860 2.980 3.090

4 0.729 0 OP1 4.1

2.282 1.457 AV2: 0.000 11 Xavg -

1.160 1.710 2.080 2.340 2.550 2.720 2.860 2.980 Xavg -

3.090

4.05 OP2 4.05 OP3

5 0.577 0 UCL-2.114 4.05

1.29 12 1.150 1.710 2.070 2.340 2.550 2.720 2.850 2.980 3.090

4 XBAR G 13 UCL-

1.150 1.710 2.070 2.340 2.550 2.710 2.850 2.980 UCL-

3.090

4 4

XBAR XBAR

14 1.150 1.710 2.070 2.340 2.540 2.710 2.850 2.980 3.080

3.95 3.95 3.95

15 1.150 1.710 2.070 2.340 2.540 2.710 2.850 2.980 3.080

3.9 3.9 >15 1.128 1.693

3.9 2.059 2.326 2.534 2.704 2.847 2.970 3.078

1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10 1 2 3 4 5 6 7 8 9 10

All calculations are based upon predicting 5.15 sigma (99% of the area under the normal distribution curve).

AV - If a negative value is calculated under the square root sign, the appraiser variation (AV) defaults to zero (0).

ANALYSIS: REAPEATABILITY RANGE CHART: ALL RANGES MUST BE WITHIN CONTROL LIMITS. IF ANY RANGE IS BEYOND THE LIMIT, DISCARD THAT DATA AND RECALCULATE THE LIMITS

APPRAISER AVERAGE CHART: AT LEAST 50% DATA SHOULD BE OUT SIDE OF CONTROL LIMITS. IF NOT MEASUREMENT SYSTEM IS NOT CAPABLE FOR MEASURING PART TO PART VARIATION

R&R: IF MS IS USED FOR SPC, CALCULATE R&R AS "% PROCESS VARIATION" OTHERWISE AS "TOLERANCE VARIATION".

R&R<=10%: MS ACCEPTABLE, 10%<R&R<=30%:MS MAY BE ACCEPTED WITH PROPER JUSTIFICATION, R&R>30%: MS NOT ACCEPTABLE, ndc>=5.

You might also like

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument5 pagesGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- Test Report - Milltests-Sample-1Document13 pagesTest Report - Milltests-Sample-1NathanNo ratings yet

- Msa R&RDocument1 pageMsa R&RABHISHEK KUMARNo ratings yet

- GRNR 10pcsDocument12 pagesGRNR 10pcsmadhavansanjayNo ratings yet

- Oil Analysis Report ExplanationDocument2 pagesOil Analysis Report ExplanationFebriyanto FebriyantoNo ratings yet

- Bidders Highest Possible Description Points Comments Points Comments Points Comments Points Comments Points Comments Item. NºDocument2 pagesBidders Highest Possible Description Points Comments Points Comments Points Comments Points Comments Points Comments Item. NºrfriosEPNo ratings yet

- ISU GP 2019 Skate Canada International Judges Details Per SkaterDocument6 pagesISU GP 2019 Skate Canada International Judges Details Per Skaterclareese jamisolaNo ratings yet

- TX IPS - A - 102121Document3 pagesTX IPS - A - 102121ayman belalNo ratings yet

- Engine EvaluationDocument1 pageEngine EvaluationWilson PinacateNo ratings yet

- Nord Drivesystem Motor PDFDocument2 pagesNord Drivesystem Motor PDFJorge Luis Briceño VicuñaNo ratings yet

- E-021 Auxiliary Engine Performance.04Document2 pagesE-021 Auxiliary Engine Performance.04Rizky Sapugungdo100% (1)

- GR&R Variable October 2019 Check - As FoundDocument5 pagesGR&R Variable October 2019 Check - As FoundxharpreetxNo ratings yet

- 2 Turbin 0511 Ob2123174Document1 page2 Turbin 0511 Ob2123174BennyNo ratings yet

- Evinrude E-TEC G2 Flat Rate GuideDocument16 pagesEvinrude E-TEC G2 Flat Rate GuideJason WilliamNo ratings yet

- Charmilles Robofil 190 290P 310P 510P 1-2 Maintenance ManualDocument199 pagesCharmilles Robofil 190 290P 310P 510P 1-2 Maintenance Manualamr amr100% (4)

- Ecr88 Voe95a9920044hDocument527 pagesEcr88 Voe95a9920044hmag86No ratings yet

- Judges Details Per Skater : Capital Indoor StadiumDocument15 pagesJudges Details Per Skater : Capital Indoor StadiumsteemspriteNo ratings yet

- N-1™ and NC-1™ Bridge Plugs and Wireline Adapter Kit: Technical Unit Remedial SystemsDocument6 pagesN-1™ and NC-1™ Bridge Plugs and Wireline Adapter Kit: Technical Unit Remedial SystemsRodolfo Rider67% (3)

- Fs 4041 TG Package, Rev-0Document88 pagesFs 4041 TG Package, Rev-0Othman RejabNo ratings yet

- Altivar 600Document6 pagesAltivar 600RUPESH KUMARNo ratings yet

- Johnson Controls: Software ReleaseDocument2 pagesJohnson Controls: Software ReleaseEstaNo ratings yet

- CRAW Performance Test Info Booklet2013 1Document12 pagesCRAW Performance Test Info Booklet2013 1GabrielaNo ratings yet

- Sae J34-2018Document11 pagesSae J34-2018Vedpal Singh ChoudharyNo ratings yet

- Select One of The Following GRR Situations To Jump To The Acc. Data SheetDocument21 pagesSelect One of The Following GRR Situations To Jump To The Acc. Data SheetisolongNo ratings yet

- Estatus Report King 200Document9 pagesEstatus Report King 200jesus francoNo ratings yet

- Service Manual 6 Speed Eaton TransmissionDocument84 pagesService Manual 6 Speed Eaton TransmissionPatricio Alejandro Castro LopezNo ratings yet

- Catcm901 PDFDocument32 pagesCatcm901 PDFfjaristizabalNo ratings yet

- Select One of The Following GRR Situations To Jump To The Acc. Data SheetDocument21 pagesSelect One of The Following GRR Situations To Jump To The Acc. Data SheetLa MetalurgicaNo ratings yet

- 1111-1179 Tata Steel BSL Limited ETM-2000-1153Document1 page1111-1179 Tata Steel BSL Limited ETM-2000-1153VikasNo ratings yet

- Example of Full Engine Overhaul ReportDocument90 pagesExample of Full Engine Overhaul ReportCwsNo ratings yet

- Ecr88 Voe74d9920044h E3Document527 pagesEcr88 Voe74d9920044h E3mag86No ratings yet

- SampleDocument5 pagesSampleBlanche DJENo ratings yet

- TEMSADocument88 pagesTEMSAМаксим ШишковNo ratings yet

- Formulas Charts and TablesDocument56 pagesFormulas Charts and TablesRodolfo MendezNo ratings yet

- AE04T&CWI02401 - MV Switchgear and Controlgear - Site Inspection and Test Procedure (IEC)Document10 pagesAE04T&CWI02401 - MV Switchgear and Controlgear - Site Inspection and Test Procedure (IEC)sachin francisNo ratings yet

- 33 - Eaton 4106 5206 Transmission Service Manual PDFDocument90 pages33 - Eaton 4106 5206 Transmission Service Manual PDFSomadbsi100% (1)

- Busch 0872-900-823 R 5 0025-0101 E & 0250 C 0511 PDFDocument20 pagesBusch 0872-900-823 R 5 0025-0101 E & 0250 C 0511 PDFRodolfo M. PortoNo ratings yet

- Formula Draft Kapal (3 Draft) : Table Draft & Displacement 0.745 3.91 Initial Draft 0.815 4.81 Final 0.765 4.345 DraftDocument2 pagesFormula Draft Kapal (3 Draft) : Table Draft & Displacement 0.745 3.91 Initial Draft 0.815 4.81 Final 0.765 4.345 DraftKiki HakikiNo ratings yet

- Crane Monthly InspectionDocument2 pagesCrane Monthly InspectionSwaminathan ThayumanavanNo ratings yet

- Zppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Document1 pageZppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Ahmed ThaerNo ratings yet

- DT 700 I - English-Version1.5Document58 pagesDT 700 I - English-Version1.5Tania EstebanNo ratings yet

- Technical White Paper: Nidec Motor Corporation 2014. All Rights ReservedDocument4 pagesTechnical White Paper: Nidec Motor Corporation 2014. All Rights ReservedfreddyjoertyNo ratings yet

- Manual Transaxle System - M6CF3-1 - 1.6LDocument26 pagesManual Transaxle System - M6CF3-1 - 1.6LmiguelNo ratings yet

- PERFORADORA MODELO Sandvik D75 KSDocument24 pagesPERFORADORA MODELO Sandvik D75 KSJose RebicNo ratings yet

- Cross River GuyDocument13 pagesCross River GuyYARO TERKIMBINo ratings yet

- Data Analysis Techniques For ManagersDocument14 pagesData Analysis Techniques For ManagersSajid hussain awanNo ratings yet

- QSB6.7C Industrial Technical PackageDocument25 pagesQSB6.7C Industrial Technical PackageBui Xuan Duc100% (7)

- Judges Details Per Skater: Capital Indoor StadiumDocument15 pagesJudges Details Per Skater: Capital Indoor StadiumsteemspriteNo ratings yet

- VGT - Service DataDocument15 pagesVGT - Service DataBroCactusNo ratings yet

- B. P. Tapon MolibleDocument16 pagesB. P. Tapon Molibleolger nino100% (1)

- Oloa 58000Document2 pagesOloa 58000Thaer Hamede67% (3)

- Carry OverDocument3 pagesCarry OverAdrian MartinezNo ratings yet

- Basic 5 Pocket - AutoDocument2 pagesBasic 5 Pocket - Autotop 100No ratings yet

- Sae J34-2018Document11 pagesSae J34-2018Gerardo FloresNo ratings yet

- Inline Fans Selections - CrecheDocument1 pageInline Fans Selections - CrecheHARSHANo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Appendix Field Manual For Concrete AnchoringDocument3 pagesAppendix Field Manual For Concrete AnchoringZed BaladrafNo ratings yet

- 206 MM CH04 PDFDocument12 pages206 MM CH04 PDFMethodRONo ratings yet

- Golf Well EvDocument10 pagesGolf Well EvJaokNo ratings yet

- Code of Conduct: Sourcing & Supply ChainDocument8 pagesCode of Conduct: Sourcing & Supply ChainPRAMODNo ratings yet

- Not ApplicableDocument1 pageNot ApplicablePRAMODNo ratings yet

- 2017 Excel Calendar Planner 12Document24 pages2017 Excel Calendar Planner 12Jib CollantesNo ratings yet

- Code of Conduct: Sourcing & Supply ChainDocument8 pagesCode of Conduct: Sourcing & Supply ChainPRAMODNo ratings yet

- Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri SatDocument6 pagesSun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri SatPRAMODNo ratings yet

- Setup Approval: S.NO. Tool Operation Cutting Speed Feed Observation RemarksDocument1 pageSetup Approval: S.NO. Tool Operation Cutting Speed Feed Observation RemarksPRAMODNo ratings yet

- Manufacturing Process Chart: Forging Material FG Store CNC Turning-1Document1 pageManufacturing Process Chart: Forging Material FG Store CNC Turning-1PRAMODNo ratings yet

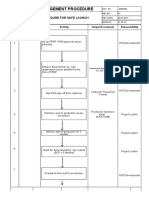

- SAFE LAUNCH ProcedureDocument2 pagesSAFE LAUNCH ProcedurePRAMOD86% (7)

- 2017 Excel Calendar Planner 12Document24 pages2017 Excel Calendar Planner 12Jib CollantesNo ratings yet

- Sun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri SatDocument6 pagesSun Mon Tue Wed Thu Fri Sat Sun Mon Tue Wed Thu Fri SatPRAMODNo ratings yet

- Process Flow Diagram (PFD) : Casting Out Source ProcessDocument1 pageProcess Flow Diagram (PFD) : Casting Out Source ProcessPRAMODNo ratings yet

- Project Training Sheet PDFDocument1 pageProject Training Sheet PDFPRAMODNo ratings yet

- January February March: Business Logo Business NameDocument2 pagesJanuary February March: Business Logo Business NamePRAMODNo ratings yet

- Project Training Sheet PDFDocument1 pageProject Training Sheet PDFPRAMODNo ratings yet

- Project Training Sheet PDFDocument1 pageProject Training Sheet PDFPRAMODNo ratings yet

- Chart PDFDocument1 pageChart PDFPRAMODNo ratings yet

- Team Feasibility Performa Index For Forging PDFDocument1 pageTeam Feasibility Performa Index For Forging PDFPRAMODNo ratings yet

- Program Open Issues Tracking MatrixDocument1 pageProgram Open Issues Tracking MatrixPRAMODNo ratings yet

- Team Feasibility Performa Format PDFDocument1 pageTeam Feasibility Performa Format PDFPRAMODNo ratings yet

- Team Feasibility Performa Index For Forging PDFDocument1 pageTeam Feasibility Performa Index For Forging PDFPRAMODNo ratings yet

- Team Feasibility Performa Index For Forging PDFDocument1 pageTeam Feasibility Performa Index For Forging PDFPRAMODNo ratings yet

- Work Instruction For Operator (English)Document1 pageWork Instruction For Operator (English)PRAMODNo ratings yet

- Not Applicable - Format PDFDocument1 pageNot Applicable - Format PDFPRAMODNo ratings yet

- Chart Time PDFDocument1 pageChart Time PDFPRAMODNo ratings yet

- Timing Chart PDFDocument1 pageTiming Chart PDFPRAMODNo ratings yet

- Apqp Timing Chart PDFDocument1 pageApqp Timing Chart PDFPRAMODNo ratings yet

- Use Na PDFDocument1 pageUse Na PDFPRAMODNo ratings yet

- Not Applicable PDFDocument1 pageNot Applicable PDFPRAMODNo ratings yet

- Use NaDocument1 pageUse NaPRAMODNo ratings yet

- Activity#1: A. Find The Mean, Median and Mode (In Two-Decimal Places) of The Following Set of Data andDocument1 pageActivity#1: A. Find The Mean, Median and Mode (In Two-Decimal Places) of The Following Set of Data andChad MeskersNo ratings yet

- 8020699652bbca665e7a16 79876367 PDFDocument194 pages8020699652bbca665e7a16 79876367 PDFTsehay AmareNo ratings yet

- Inverse Trigonometric FunctionsDocument26 pagesInverse Trigonometric Functionssanskarid94No ratings yet

- Iso TS 21748Document9 pagesIso TS 21748DianaNo ratings yet

- Ch5 MMW BSNDocument17 pagesCh5 MMW BSNManibale SharmaeNo ratings yet

- Lecture 1 Introduction PDFDocument29 pagesLecture 1 Introduction PDFKwokhcNo ratings yet

- An Introduction To Malliavin Calculus With Applications To EconomicsDocument83 pagesAn Introduction To Malliavin Calculus With Applications To EconomicsselivesNo ratings yet

- Parallelism of Statistics and Machine Learning & Logistic Regression Versus Random ForestDocument72 pagesParallelism of Statistics and Machine Learning & Logistic Regression Versus Random Forestvdjohn100% (1)

- Answers To Final-2021Document9 pagesAnswers To Final-2021Enes ErtenNo ratings yet

- Determination of Ethyl Xanthate in Aqueous Solution by High Performance Liquid Chromatography Inductively Coupled Plasma Tandem Mass Spectrometry andDocument16 pagesDetermination of Ethyl Xanthate in Aqueous Solution by High Performance Liquid Chromatography Inductively Coupled Plasma Tandem Mass Spectrometry andxibs2009No ratings yet

- ObjectivesDocument6 pagesObjectivesGravindra Reddy0% (2)

- Probability and StatisticsDocument7 pagesProbability and StatisticsDueñas Mark Anthony G.No ratings yet

- Chapter 15 - Rev PDFDocument26 pagesChapter 15 - Rev PDFalaa al sahmaraniNo ratings yet

- An Introduction To Particle Filters: David Salmond and Neil Gordon Sept 2005Document27 pagesAn Introduction To Particle Filters: David Salmond and Neil Gordon Sept 2005RamaDinakaranNo ratings yet

- Discourse Analysis and Computer AnalysisDocument15 pagesDiscourse Analysis and Computer AnalysistanjasamjaNo ratings yet

- Soalan MPC 1 F2Document4 pagesSoalan MPC 1 F2alan miaNo ratings yet

- BRE4281 - Linear Programming and Applications 2019-20Document28 pagesBRE4281 - Linear Programming and Applications 2019-20Alexander AlexanderNo ratings yet

- Formula SheetDocument4 pagesFormula SheetSteven RaphaelNo ratings yet

- Multiple-Criteria Decision AnalysisDocument12 pagesMultiple-Criteria Decision AnalysisMatheus RochaNo ratings yet

- MathDocument2 pagesMathABDUS SAMADNo ratings yet

- Design of Experiments (SS)Document4 pagesDesign of Experiments (SS)Sudipta SarangiNo ratings yet

- Introduction To Functional Differential Equations, J Hale, Springer, 1993,458s PDFDocument458 pagesIntroduction To Functional Differential Equations, J Hale, Springer, 1993,458s PDFLe Hieu67% (3)

- NSPDEDocument118 pagesNSPDEKamal NikhurpaNo ratings yet

- Graphs of Various FunctionsDocument4 pagesGraphs of Various FunctionsLouis RileyNo ratings yet

- FInancial Derivatives Chance ModelDocument4 pagesFInancial Derivatives Chance Modelharsh guptaNo ratings yet

- Syllabus For B.A./ B.Sc. I, II, IIIDocument21 pagesSyllabus For B.A./ B.Sc. I, II, IIIGuru GuroorNo ratings yet

- Blind Spot AnalysisDocument11 pagesBlind Spot Analysislaxmaiahv212100% (6)

- Skoog - Solucionário Capítulo 10 PDFDocument20 pagesSkoog - Solucionário Capítulo 10 PDFThais Dos SantosNo ratings yet

- EDA Module 7Document3 pagesEDA Module 7Russel MontoroNo ratings yet

- 03 Failure Distribution r1Document8 pages03 Failure Distribution r1Jie Lucas TzaiNo ratings yet