Professional Documents

Culture Documents

Design (Imperial) 7.23

Uploaded by

Hassan SleemCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design (Imperial) 7.23

Uploaded by

Hassan SleemCopyright:

Available Formats

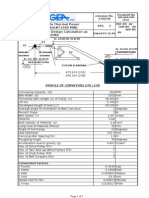

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.

23

Specifier Sheet and Recommendation Summary

05/10/20

Date

6508-B Windmill Way

Wilmington, NC 28405 ###

Ph 910-794-9294 ###

Fax 910-794-9296 Head

Telephone Telefax e-mail www.rulmecacorp.com Head

© Copyright - Rulmeca Corp. Return Run

Go to Design Parameters Tail

Project Name Conveyor Reference Go to Trajectory Sheet belt width

Standard Loading

Standard Loading Conditions:

Conditions 18 in

Conveyor Length (ft) 100 REQUIRED

REQUIRED POWER:

POWER 7.3 HP 24 in

Tonnage Rate (tons/hour) 500 30 in

Belt Speed (fpm) 300 BELT PULL SUMMARY: Force (lbs) 36 in

Material

Material Lift

Lift Height

Height (ft)

(ft) 0.0 Standard Loading Belt Pull 731 42 in

Ambient temperature (°F) Min -10 Extra pull for Hopper (if any) 0 ###

Ambient temperature (°F) Max 100 Extra pull for Slider Bed (if any) 0 Limestone, p

Initial

Initial Velocity

Velocity ofof Material

Material (fpm)

(fpm) 0 Extra pull for Diverter or Tripper (if any) 0 km

Number of Belt Cleaners 1 TOTAL Required Belt Pull (Te): 731 Ashes, coal,

Number of Return Belt Scrapers 0 Bauxite, grou

Length of Skirt Zone (ft) 12 RECOMMENDED OPTIONS: Cement, Port

Depth

Depth of of Mat'l in skirt

Material zoneZone

in Skirt (in) (in) 3 Cement clink

Number of Non-driven Pulleys 4 Clay,

Coal, ceramic

bitum. m

Elev. Above Sea Level (ft) 3300 ft SPECIAL NOTES: Cullet (broken

Go to Design Parameters

Mat'l, friction coeff Limestone, pulv.,dry, 0.128 Minimum allowable belt width for lump size is 12 in Grains,wheat

Bulk Density (pcf) Limestone, crushed, 90 pcf Minimum Acceptable Diameter is 10 in. * Gravel, bank

Size Consist Avg is 50% Max Lump Size Iron Ore,

Max. Lump Size (in) 2 *A smaller pulley diameter may cause belt carcass or fastener damage. Limestone, p

Material Surcharge

Material Angle

Surcharge Angle 25 deg. RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY: Phosphate ro

Belt Width 36 in Power: 7.5HP Models Available: Salt, dry fine,

Belt Carcass Type Fabric Belt Speed: 300 FPM 220, 320, 400, 500, 630

Idler Roll diameter 5 in Face Width: 37.4 in. Wood chips,

CEMA

CEMA Type

Type C

Troughing Idler Spacing 4 ft ###

###

Angle of Wrap** 180 degrees RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY: ###

###

Type of Lagging Full Lagging Power: 5.5 HP/each Models Available: ### Type of Dual D

Type of Take-up Manual Belt Speed: 300 FPM 220, 320, 400, 500

Type of Belt 2 ply, 225 piw Face Width: 37.4 in.

Drive Location Head

Material

Material Flow

Flow Elevating or Horizontal Power savings - 1 shift and 3 shift per day: nest on carry s

Condition of Idlers & Pulleys well maintained (Motorized Pulley compared to exposed motor, gearbox, V-belt conveyor drives) nest on return

Type

Type of

of Dual

Dual Drive, if any

Drive (if any) none Save: 1180 Kw-Hrs/Yr, 1 shift/day or 3541 Kw-Hrs/Yr, 3 shifts/day well mainta

** This parameter is for either single or dual drive arrangement. Save: $94 /Yr, 1 shift/day or $283 /Yr, 3 shifts/day @ $0.08/Kw-Hr ### need

### maintenance

Theoretical

Belt StrengthB(

Special Loading Conditions: Go to Design Parameters Belt Width=

1. ForForhopper

hopper feeder

feeder specify

specify opening

opening dimensions

dimensions below below. 4. Sidewall & Cleated Belt Parameters: piw =

2. For slider bed, specify bed length & type of bed mat'l below. Sidewall & cleat height (in) 0 Belt Strength

3.

3. IfIfbelt

beltisisdriven

drivenon

onreturn

returnrun,

run,specify

specifydrive

drivepulley

pulleylocation

location. Thickness of sidewall (in) 0 ###

4.

4. IfIfbelt

belthas

hascleats and/or

cleats sidewalls

and/or showshow

sidewalls dimensions below below.

dimensions Distance between cleats (in) 0 180 degrees

5. IfIf conveyor

5. conveyor has a tripper,

has define

a tripper, tripper

define below below.

tripper Thickness of cleats (in) 0 180 degrees

6. IfIf conveyor

6. conveyor hashasdiverter(s), define

diverter(s), below

define below. Extra Sidewall & Cleat Wt (incl above) 0 200 degrees

1. Hopper Feeder Design Parameters 210 degrees

Hopper opening width (in) 5. Tripper Design Parameters 220 degrees

Hopper opening length (in) Tripper length (ft) 0 240 degrees

Number of Hopper Openings Material lift height on tripper (ft) 0 360 degrees

2. Slider Bed Design Parameters No. of belt cleaners on tripper 0 420 degrees

Slider Bed Length (ft) Length of tripper skirt zone (ft) 0

Type of Slider Bed Material None Depth of material in skirt zone (in) 0

Slider Bed Frictional Coefficient 0 No. of non-driven pulleys on tripper 0

Estimated belt tension, Te (lbs) 0

3. Drive Pulley Location ("return run" drive only) Estimated factor, Ky 0.03

Conveyor Length, tail to drive snub (ft) Bulk Density

Height, top of tail to bottom of drive (ft) 6. Material Diverter (Belt Plow) Ashes, coal,

No. of diverters that work simultaneously Ashes, coal,

Bagasse, 10

file:///conversion/tmp/scratch/475132750.xls, Specifier, Page 1 of 9 05/10/2020 10:18:06

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Model Selector

0 05/10/20

0 Date

0

0

0 0 0 6508-B Windmill Way

Telephone Telefax e-mail Wilmington, NC 28405

Ph 910-794-9294

0 0 Fax 910-794-9296

Project Name Conveyor Reference www.rulmecacorp.com

© Copyright - Rulmeca Corp.

320M

REQUIRED POWER:

REQUIRED POWER 7.3 HP 220M

Select Model 220H

BELT PULL SUMMARY: Force (lbs) 320M 320L

Standard Loading Belt Pull 731 320M

Extra pull for Hopper (if any) 0 Check Radial Load (to prevent internal 320H

Extra pull for Slider Bed (if any) 0 damage to pulley) Force (lbs)

Extra pull for Diverter or Tripper (if any) 0 Maximum Allowable Radial Load 4,496

TOTAL Required Belt Pull (Te): 731 Estimated Maximum Radial Load** 4,001

Selected model is appropriate for estimated radial load.

0

Go to Design Parameters 500H

Check Pulley Diameter

RECOMMENDED OPTIONS (if any): (to prevent belt damage.) 630M

Minimum Acceptable Diameter is 10 in. 630H

Selected Diameter is 12.64 in 800M

Selected diameter is appropriate for specified belt.

SPECIAL NOTES (if any): 0

Minimum allowable belt width for lump size is 12 in Check Maximum Belt Tension (to

Minimum Acceptable Diameter is 10 in. * prevent belt damage) Force (lbs)

Maximum Belt Tension (T1) 2,366

*A smaller pulley diameter may cause belt carcass or fastener damage. Allowable Fabric Belt Tension 8,100

RECOMMENDED "SINGLE DRIVE" MOTORIZED PULLEY: 0

Belt Tension Calculation Summary Force (lbs)

Power: 7.5HP Te, effective belt tension 731

Belt Speed: 300 FPM T2, to prevent belt/pulley slippage 585

Face Width: 37.4 in. T2, to limit belt sag to 2 % 1,635

Models Available: 220, 320, 400, 500, 630 T1, maximum belt tension 2,366

**Measured at Drive A in Dual Drive, if applicable.

Calculation for "Dual Drive on Carry Side" is under construction.

RECOMMENDED "DUAL DRIVE" MOTORIZED PULLEY:

Type of Dual Drive (if any)

Power: 5.5 HP/each

Belt Speed: 300 FPM

Face Width: 37.4 in.

Models Available: 220, 320, 400, 500

Show Location of Drive on Return Ru

Bulk Materials Belt Conveyor Drive Horsepower Calculations, Version 3.1

(based on CEMA manual, 4th Edition)

6740-E Netherlands Drive

Wilmington, NC 28405

Telephone: 910-794-9294

Phone Fax Telefax: 910-794-9296

Customer Name

Conveyor Number

Conveyor Length (ft.) 100

Tonnage Rate (tph) 500 Required Conveyor Drive HP = 7.3 HP

Belt Speed (fpm) 300 37.4 in.

Material Lift Height (ft) 0 RECOMMENDED MOTORIZED PULLEY: Avail. products:

Ambient temp. (deg F) Min -10 7.5HP Model Diam.

Ambient temp. (deg F) Max 100 300 FPM 0 0

Initial Velocity of Material (fpm) 0 TM323 12.64"

Number of Belt Cleaners 1 TM400 15.75"

Number of Belt Plows 0 TM501 19.72"

Length of Skirt (ft) 12 TM631 24.8"

Depth of Matl in skirt zone (in) 3 0 0

Number of Non-driven Pulleys 4 ALTERNATE DUAL DRIVE OPTION:

Belt loaded via chute. 0 5.5 HP/each Avail. products:

300 FPM Model Diam.

TM220 8.5"

Elevation (ft above sea level) 3300 TM321 12.64"

Type of Material Limestone, pulv., dry TM400 15.75"

Belt Width (in) 36 TM501 19.72"

Belt Carcass Type Fabric 0 0

Idler Roll diam (4, 5,6,or 7in) 5 0 0

CEMA Type (A,B,C,D,E) C RECOMMENDED OPTIONS:

Troughing Idler Spacing (ft) 4

Required Belt Pull, Te = 731 lbs SPECIAL NOTES:

Engineering Design Data:

Ai 1.8 lbs Tm 0 lbs Calculated HP to drive conveyor belt: 6.64 HP

Cs 0.128 Tp 78 lbs Drive pulley bearing friction: 0.21 HP

H 0 ft Tpl 0 lbs BHP (Brake HP) at motor: 6.86 HP

Kt 1.59 Tsb 86 lbs Gear loss in Motorized Pulley: 0.44 HP

Kx 0.49 lbs/ft Ttr 0 lbs Calculated HP for Drive Pulley: 7.30 HP

Ky 0.035 Tx 78 lbs Derate for high elevation: 0.00 HP

L 100 ft Tyb 71 lbs Derate for high temp 0 HP

Q 500 tph Tyc 50 lbs Required Motorized Pulley HP: 7.30

Si 4 ft Tym 194 lbs (Note: 60 Hz Motorized Pulley motors have 1.0 Service Factor)

Tac 266 lbs Tyr 21 lbs

Tam 43 lbs V 300 fpm Power savings for 3 shift/day, 50 week/yr operation

Tb 0 lbs Wb 9 lbs/ft (Motorized Pulley compared to gearmotor & V-belt drive)

Tbc 180 lbs Wm 56 lbs/ft Save: 1180 Kw-Hrs/Yr

Te 731 lbs Save: $94/Yr (@ $0.08/Kw-Hr)

file:///conversion/tmp/scratch/475132750.xls, Page 3 of 9 05/10/2020 10:18:06

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Bulk Handling Trajectory Calculator and Plotter

(based on CEMA 5th Edition)

0

0 5/10/20

0 Date 6508-B Windmill Way

0 Wilmington, NC 28405

Ph 910-794-9294

0 0 Fax 910-794-9296

Phone Fax www.rulmecacorp.com

© Copyright - Rulmeca Corp.

Project Name 0 Return to Specifier

Conveyor Ref. 0

System Design Parameters:

Belt Width 36 in Material Trajectory:

Troughing Idler Angle 35° 18

Small Pulley (scale: inches)

15

Diameter Pulley (in) 13.26 in 12

9

Lagging Thickness (in) 0.31 in

6

Belt Speed 300 fpm 3

0

Surcharge

Surcharge Angle (degrees)

Angle 25 deg. -3

Tonnage Rate (TPH) 500 -6

-9

Material Density (pcf) 90

-12

Belt Thickness (in) 0.75

-15

Distance to Chute Plate (in) 24

-18

Angle of Conv. Inclination (deg) 0 -21

Alternate Belt Speed (fpm) 350 -24

-27

-24

-21

-18

-15

-12

-9

-6

-3

0

3

6

9

12

15

18

21

24

27

30

33

36

39

Print This Sheet

Go to Large Pulley Sheet Design Trajectory - red line; Alternate speed - blue.

Go to Overview Sheet 0

Calculated Results:

Calc'd mat'l height at centerline 5 in Mat'l Cross Section at Pulley Face:

Calc'd actual height of C.O.G.* 2 in Small Pulley (scale: inches)

9

Calc'd actual mat'l cross section 84.7 sq ft

CEMA Max Allow. height at center 7 in 6

CEMA Max Height of C.O.G.* 3 in

CEMA Max Allow. cross section 152.6 sq ft 3

0

Note:

This program uses actual C.O.G.* height above -3

-18

-15

-12

-9

-6

-3

12

15

18

top of belt (based on actual cross section) to plot

trajectory. Height of C.O.G. for CEMA

max. allow. cross section is given for ref. only. Design Cross Section - red line; CEMA max allow. - black line.

*C.O.G. = center of gravity of material, shown as ∆ and ∆

file:///conversion/tmp/scratch/475132750.xls, trajectory, Page 4 of 9 05/10/2020 10:18:06

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23 CEMA Rad

Material Cross Section Plotter

CEMA thet

0 5/10/20 CEMA thet

0 Date sin (CEMA

0 cos (CEMA

0 6508-B Windmill Way

Wilmington, NC 28405

0 0 Ph 910-794-9294

Phone Fax Fax 910-794-9296

www.rulmecacorp.com

© Copyright - Rulmeca Corp.

###

Return to Specifier

Reference Name 0 idler

Conveyor Number 0 ###

###

System Design Parameters: Cross Section at Troughing Idler: ###

Tonnage Rate (tph) 500 Narrow Belt (scale: inches) ###

Belt Speed (fpm) 300 ###

15

Bulk Density (lbs/cu ft) 90 ###

Material Surcharge Angle 25 degrees 12 ###

Belt Width 36 in. ###

9

Idler Angle 35 degrees ###

6 ###

R

### e

Plot Wide Belt 3 ### c

o

Material Geometry in Troughing Idler: ### m

CEMA Max. Allow. Cross Section 1.1 sq ft 0 ### m

e

Calculated Cross Section 0.6 sq ft ### n

-3 d Material

Calc'd Xsec/CEMA Xsec 58%

-15

-12

-9

-6

-3

12

15

e

CEMA Standard Edge Distance 2.9 in d

Calculated Edge Distance 6 in Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Calc'd Material Height at Centerline 5.4 in 0 Trapezoida

Total Area

Material Geometry at Pulley Discharge: Trapezoid

Cross Section at Pulley Face:

Calculated Cross Section 0.6 sq ft Trapezoid

Narrow Belt (scale: inches)

Material Height at Centerline 4.4 in Trapezoid

Height of Center of Gravity (A1) 1.8 in 9 Trapezoid

Assumed Edge Distance 3.02 in Surcharge

Calculated Surcharge Angle 33 deg 6 Horiz Proj

CEMA Max. Allow height at center 6.6 in. ###

CEMA Max Height of C.O.G. 2.7 in. 3 2.7 ###

1.80

CEMA Standard Edge Distance 1.44 in ###

0 ###

Note: ###

This program calculates height of actual C.O.G.* -3 ###

-18

-15

-12

-9

-6

-3

12

15

18

by assuming that actual edge distance at pulley ###

face equals 1/2 of actual edge distance in troughed Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

section. Height of C.O.G.* for CEMA maximum ###

allowable cross section pulley face is given for ###

reference only. ###

###

* C.O.G. = center of gravity of material ###

file:///conversion/tmp/scratch/475132750.xls, Page 5 of 9 05/10/2020 10:18:06

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23 CEMA Rad

Material Cross Section Plotter

CEMA thet

0 5/10/20 CEMA thet

0 Date sin (CEMA

0 cos (CEMA

0 6508-B Windmill Way

Wilmington, NC 28405

0 0 Ph 910-794-9294

Phone Fax Fax 910-794-9296

www.rulmecacorp.com

© Copyright - Rulmeca Corp.

###

Return to Specifier

Reference Name 0 idler

Conveyor Number 0 ###

###

System Design Parameters: ###

Tonnage Rate (tph) 500 Cross Section at Troughing Idler: ###

Belt Speed (fpm) 300 Wide Belt (scale: inches) ###

42

Bulk Density (lbs/cu ft) 90 ###

36

Material Surcharge Angle 25 degrees ###

30

Belt Width 36 in. ###

24

Idler Angle 35 degrees ### R

18 ### e

c

12 ### o

Plot Narrow Belt

### m

6

Material Geometry in Troughing Idler: ### -

m

CEMA Max. Allow. Cross Section 1.1 sq ft 0 ### e

Calculated Cross Section 0.6 sq ft ### n

-6 d

Calc'd Xsec/CEMA Xsec 58% Material

-42

-36

-30

-24

-18

-12

-6

12

18

24

30

36

42

e

CEMA Standard Edge Distance 2.9 in d

Calculated Edge Distance 6 in Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

Calc'd Material Height at Centerline 5.4 in 0

Total Area

Material Geometry at Pulley Discharge: Cross Section at Pulley Face: Trapezoid

Calculated Cross Section 0.6 sq ft Wide Belt (scale: inches) Trapezoid

Material Height at Centerline 4.4 in Trapezoid

18

Height of Center of Gravity (A1) 1.8 in Trapezoid

Assumed Edge Distance 3.02 in 12 Surcharge

Calculated Surcharge Angle 33 deg Horiz Proj

6

CEMA Max. Allow height at center 6.6 in. 2.7 ###

1.80

CEMA Max Height of C.O.G. 2.7 in. 0 ###

CEMA Standard Edge Distance 1.44 in ###

-6 ###

-48

-42

-36

-30

-24

-18

-12

-6

12

18

24

30

36

42

48

Note: ###

This program calculates height of actual C.O.G.* ###

by assuming that actual edge distance at pulley ###

face equals 1/2 of actual edge distance in troughed Legend: Solid Line is CEMA Max. Allowable; Red Line is Calculated.

section. Height of C.O.G.* for CEMA maximum ###

allowable cross section pulley face is given for ###

reference only. ###

###

* C.O.G. = center of gravity of material ###

file:///conversion/tmp/scratch/475132750.xls, Page 6 of 9 05/10/2020 10:18:07

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Design Parameter Summary

0 05/10/20

0 Date

0 6508-B Windmill Way

0 Wilmington, NC 28405

Ph 910-794-9294

0 0 0 Fax 910-794-9296

Telephone Telefax e-mail www.rulmecacorp.com

© Copyright - Rulmeca Corp.

0 0

Project Name Conveyor Reference

Return to Specifier

Power Calculation Summary

Calculated power to drive conveyor belt: 6.6 HP

Drive pulley bearing friction: 0.2 HP

Power at motor: 6.9 HP

Gear loss in motorized pulley: 0.4 HP

Calculated power 7.3 HP

Derate for high elevation 0.0 HP

Derate for high temperature 0.0 HP

Required Power for motorized pulley: 7.3 HP

Symbol Value Definition of Terms

Te 731 lbs Te = effective belt tension at drive.

ang 180 degrees ang = angle of belt wrap around drive pulley(s).

Cw 0.8 Cw = "wrap factor", to determine slack side tension to prevent belt slippage on drive pulley.

T2 1635 lbs. T2 = estimated slack-side tension required to either keep belt from slipping on pulley surface or maintain

trough at allowable sag percentage, whichever is greater.

T1 2366 lbs T1 = Te + T2

T1 + T2 4001 lbs T1 + T2 = Sum of belt forces on drive pulley. NOTE: This is not a vector sum.

T_L Full Lagging T_L = type of lagging specified for drive pulley(s).

Tatype Manual Tatype = type of take-up specified to apply "slack-side tension".

Beltype 2 ply, 225 piw Beltype = type of belt carsass specified.

w 36 in. w = belt width

str 8100 lbs. str = tensile strength of specified belt.

pstr 16 % pstr = percentage of available belt tensile strength used.

btr 3/16 to 7/16 in. btr = thickness range of specified belt

Ai 1.8 lbs Ai = belt tension required to overcome frictional resistance and rotate idlers.

Cs 0.128 Cs = skirtboard friction factor.

H 0 ft H = vertical distance that material is lifted or lowered.

Kt 1.59 Kt = ambient temperature correction factor.

Kx 0.49 lbs/ft Kx = factor to calculate frictional resistance of the idlers and the sliding resistance between belt and idler

rolls.

Ky 0.04 Ky = factor to calculate resistance of belt and resistance of load to flexure as they move over idlers.

L 100 ft L = length of conveyor.

Q 500 tph Q = tons per hour conveyed. Return to Specifier

Si 4 ft Si = troughing idler spacing.

Tac 266 lbs Tac = total of the tensions from conveyor accessories.

Tam 43 lbs Tam = tension required to accelerate the material continuously as it is fed onto belt.

Tb 0 lbs Tb = tension required to lift or lower the belt.

Tbc 180 lbs Tbc = tension required to overcome belt cleaner drag.

Te 731 lbs Te = effective belt tension at drive.

Tm 0 lbs Tm = tension required to lift or lower conveyed material.

Tp 78 lbs Tp = tension required to overcome resistance of belt to flexure around pulleys and resistance of pulleys to

rotate on their bearings.

Tpl 0 lbs Tpl = tension required to overcome belt plow drag.

Tsb 86 lbs Tsb = tension required to overcome skirtboard drag.

Ttr 0 lbs Ttr = tension required to overcome special loading condition(s.)

Tx 78 lbs Tx = tension required to overcome carrying and return idler friction.

Tyb 71 lbs Tyb = total of tensions due to resistance of belt to flexure as it rides over carrying and return idlers.

Tyc 50 lbs Tyc = tension due to resistance of belt to flexure as it rides over carrying idlers.

Tym 194 lbs Tym = tension due to resistance of material to flexure as it rides over carrying idlers.

Tyr 21 lbs Tyr = tension due to resistance of belt to flexure as it rides over return idlers.

V 300 fpm V = design belt speed.

Wb 9 lbs/ft Wb = weight of belt per unit of length of conveyor.

Wm 56 lbs/ft Wm = weight of material per unit of length of conveyor. Return to Specifier

Sag 2.0% Sag = recommended maximum sag percentage to avoid spillage in troughed section of belt.

Ls 0 Ls = Length of conveyor from tail pulley to Drive snub (for return run drive only)

Hd 0 Hd = Height of conveyor from top of tail pulley to bottom of drive pulley (for return run drive only)

file:///conversion/tmp/scratch/475132750.xls, Design Parameters, Page 7 of 9 05/10/2020 10:18:07

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Bulk Handling Belt Conveyor Terminology

6508-B Windmill Way

Wilmington, NC 28405

Ph 910-794-9294

Fax 910-794-9296

Return to Specifier www.rulmecacorp.com

© Copyright - Rulmeca Corp.

Conveyor Profile

Return to Specifier

Initial Velocity of Material Return to Specifier

Conveyor Cross Section in Skirt Zone Return to Specifier

Belt Conveyor with Tripper Return to Specifier

Hopper Feeder Conveyor Return to Specifier

Cleated Belt with Sidewalls Return to Specifier

Belt Conveyor with Two Diverter(s)

"CEMA" Idler Type Definitions Return to Specifier

(Based on Conveyor Equipment Manufacturers Association Manual)

Belt Width Idler Load Ratings* (lbs)

Idler Type > A B C D E

Idler (deg) > 20 35 45 20 35 45 20 35 45 20 35 45 20 35 45

18 300 300 300 410 410 410 900 900 900 - - - - - -

24 300 300 289 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

30 300 280 270 410 410 410 900 900 900 1200 1200 1200 1800 1800 1800

36 275 256 248 410 410 396 900 837 810 1200 1200 1200 1800 1800 1800

42 - - - 390 363 351 850 791 765 1200 1200 1200 1800 1800 1800

48 - - - 380 353 342 800 744 720 1200 1200 1200 1800 1800 1800

54 - - - - - - 750 698 675 1200 1116 1080 1800 1800 1800

60 - - - - - - 700 650 630 1150 1070 1035 1800 1800 1800

72 - - - - - - - - - 1050 977 945 1800 1800 1800

84 - - - - - - - - - - - - 1800 1674 1620

96 - - - - - - - - - - - - 1750 1628 1575

*These ratings are for three-equal-roll idlers and are based on a 30,000 hour minimum

BU bearing life at 500 RPM. BU bearing life represents the statistical point in hours where

Return to Specifier

a minimum of 90% of the bearings will still be functional with no increase in torque or noise.

Return to Trajectory Plot

Material Surcharge Angle Guide

(Based on Conveyor Equipment Manufacurters Association Manual)

Surcharge Angle of

Description of Material

Angle Repose

Uniform size, very small rounded particles, either very wet or very dry; such as dry silica sand,

5 0 to 19

cement, and wet concrete.

10 20 to 29 Rounded, dry polished particles, of medium weight, such as whole grain and beans.

Irregular, granular or lumpy materials of medium weight, such as anthracite coal, cottonseed

20 30 to 34

meal, and clay.

25 35 to 39 Typical common materials such as bituminous coal, stone, and most ores.

Irregular, stringy, fibrous, interlocking material, such as wood chips, bagasse, and tempered

30 40+

foundry sand.

file:///conversion/tmp/scratch/475132750.xls, Terminology, Page 8 of 9 05/10/2020 10:18:07

Rulmeca Motorized Pulley Power Calculation Program - Standard Version 7.23

Conveyor Height Calculator

Inclined conveyor length (ft) 6508-B Windmill Way

Angle of inclination (degrees) Wilmington, NC 28405

Material lift height (ft) 0.0 Ph 910-794-9294

Fax 910-794-9296

www.rulmecacorp.com

© Copyright - Rulmeca Corp.

file:///conversion/tmp/scratch/475132750.xls, Lift Height, Page 9 of 9 05/10/2020 10:18:07

You might also like

- Loeffler Engineering Group Conveyor Design and Estimating Software Updated 4-13-07Document5 pagesLoeffler Engineering Group Conveyor Design and Estimating Software Updated 4-13-07Luis Matamala MoNo ratings yet

- Troubleshoot Conveyor Belt ProblemsDocument7 pagesTroubleshoot Conveyor Belt Problemssapu11jagat5855No ratings yet

- Conveyor design analysis reportDocument10 pagesConveyor design analysis reportRafael FerreiraNo ratings yet

- Conveyor Chains TsubakiDocument184 pagesConveyor Chains Tsubakitepu msosaNo ratings yet

- Belt Conveyors With Shaft SizingDocument5 pagesBelt Conveyors With Shaft SizingArun Chopra100% (1)

- 5 Power Calculation - BULK HANDLING PDFDocument1 page5 Power Calculation - BULK HANDLING PDFFrank Vega OrtegaNo ratings yet

- Conveyor BrochureDocument6 pagesConveyor BrochuresurachsNo ratings yet

- Design and Analysis of Belt Conveyor Roller ShaftDocument5 pagesDesign and Analysis of Belt Conveyor Roller ShaftGogy100% (1)

- Project: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMADocument7 pagesProject: Vijayawada Thermal Power Station, Stage-IV Unit#7 (500 MW) Subject: Conveyor Design Calculation As Per 5th Edition of CEMASara Lopez100% (8)

- Belt Conveyor Vertical CurvesDocument1 pageBelt Conveyor Vertical CurvesmlacordNo ratings yet

- Belt Conveyor CalculationDocument8 pagesBelt Conveyor CalculationFarrahxviiiNo ratings yet

- Design (Metric) 6.25Document8 pagesDesign (Metric) 6.25Salih Has100% (2)

- Conveyor Dynamic Analysis Case StudyDocument16 pagesConveyor Dynamic Analysis Case StudyarcelitasNo ratings yet

- Designing Hopper Discharge SystemsDocument8 pagesDesigning Hopper Discharge Systemsafzalian_ali5352No ratings yet

- 3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyDocument2 pages3 Date 2 1 0 R e V I S I o N Checked by Checked by Approve DbyidilfitriNo ratings yet

- Discharge Screw Conveyors Design SelectionDocument5 pagesDischarge Screw Conveyors Design SelectionHadid100% (1)

- Belt Turnover Design Using FEADocument20 pagesBelt Turnover Design Using FEAmadhavangceNo ratings yet

- Rational Design of Conveyor ChutesDocument7 pagesRational Design of Conveyor ChutesarsanioseNo ratings yet

- C 100 Conveyor Handbook Low 1 27Document27 pagesC 100 Conveyor Handbook Low 1 27Riki アンドリ كورنياوان50% (2)

- Design Aspects of A Motorised Travelling TripperDocument5 pagesDesign Aspects of A Motorised Travelling Trippercar5lyle100% (1)

- Continuous Ship Unloader Datasheet for Vietnam Coal Power PlantDocument6 pagesContinuous Ship Unloader Datasheet for Vietnam Coal Power PlantCongOanh PHAN100% (1)

- Concepts of Feeder Design and Performance in Relation to Loading Bulk Solids onto Conveyor BeltsDocument24 pagesConcepts of Feeder Design and Performance in Relation to Loading Bulk Solids onto Conveyor BeltsSandi ApriandiNo ratings yet

- Travelling Trippers PDFDocument4 pagesTravelling Trippers PDFkalai0% (1)

- Bins & Feeders in Cement IndustryDocument29 pagesBins & Feeders in Cement IndustryNaelNo ratings yet

- Apex Belting Conveyor HandbookDocument102 pagesApex Belting Conveyor Handbooksasha_seferovic1874No ratings yet

- Design GuideDocument68 pagesDesign GuiderdsrajNo ratings yet

- Belt CalculationDocument61 pagesBelt CalculationtranceinttNo ratings yet

- Motor Selection CalculatorDocument5 pagesMotor Selection Calculatorjay100% (5)

- Konveyör Hesabı 7.24Document9 pagesKonveyör Hesabı 7.24Salih HasNo ratings yet

- Belt Conveyor Design - Apex FennerDocument94 pagesBelt Conveyor Design - Apex Fennerdhangka100% (12)

- Conveyor Screws PDFDocument9 pagesConveyor Screws PDFldavilaluceralNo ratings yet

- Line-by-line conveyor code for material handling parameters and calculationsDocument4 pagesLine-by-line conveyor code for material handling parameters and calculationskmats2No ratings yet

- Selecting The Proper Conveyor Belt: Single Pulley DriveDocument18 pagesSelecting The Proper Conveyor Belt: Single Pulley Drivettr_1983No ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcsjnmanivannan100% (4)

- Conveyor Design CalcDocument6 pagesConveyor Design CalcGregory Nick Toledo VelizNo ratings yet

- The Design of Conveyor PulleysDocument10 pagesThe Design of Conveyor PulleysJam BabNo ratings yet

- Belt Conveyor CalcsDocument3 pagesBelt Conveyor Calcspandu_chemengNo ratings yet

- BELT CONVEYOR - Discharge TrajectoryDocument3 pagesBELT CONVEYOR - Discharge TrajectorySergio Diaz DuarteNo ratings yet

- Belting FormulasDocument1 pageBelting Formulasmanoj-kr-dorai-9476No ratings yet

- Conveyor Idler Standards ExplainedDocument10 pagesConveyor Idler Standards ExplainedObiwan1483100% (1)

- CONVEYOR CALCULATION SHEET DraftDocument24 pagesCONVEYOR CALCULATION SHEET DraftRaghava0% (1)

- Design of Conveyor in Metric UnitsDocument10 pagesDesign of Conveyor in Metric Unitsmuhd.qasimNo ratings yet

- Roller Chains Design GuidelinesDocument6 pagesRoller Chains Design GuidelinesDrew TwitchNo ratings yet

- Conveyor Tension and Trajectory CalculationDocument8 pagesConveyor Tension and Trajectory CalculationGregory Nick Toledo Veliz50% (2)

- Iso 3684 1990Document8 pagesIso 3684 1990joaquin fuentealba moralesNo ratings yet

- Flexowell - 2013 - EnglischDocument5 pagesFlexowell - 2013 - Englischeduardo_chaban100% (1)

- Screw Conveyors PDFDocument121 pagesScrew Conveyors PDFzackii90No ratings yet

- Slat ConveyorDocument8 pagesSlat ConveyorpkjddjsydNo ratings yet

- Bulk SolidsDocument7 pagesBulk SolidsHafizAB9No ratings yet

- Surface Belt Structure: Cema C & D SeriesDocument8 pagesSurface Belt Structure: Cema C & D SeriesSari Ully SibaraniNo ratings yet

- Material Handling Equipment SteelDocument114 pagesMaterial Handling Equipment SteelZahir Khira100% (1)

- Engineering Inspiration - Brake System Design CalculationsDocument17 pagesEngineering Inspiration - Brake System Design CalculationsManjeet SinghNo ratings yet

- Design Imperial 7.24Document10 pagesDesign Imperial 7.24Pascal CustonNo ratings yet

- Design Imperial 7.30.cleaned (1) .CleanedDocument11 pagesDesign Imperial 7.30.cleaned (1) .Cleanedstephania chavezNo ratings yet

- LongitudinalDocument2 pagesLongitudinalDeddy TambunanNo ratings yet

- LateralDocument2 pagesLateralDeddy TambunanNo ratings yet

- Kruger Ventilation Fan Technical SpecificationsDocument1 pageKruger Ventilation Fan Technical SpecificationsHiei ArshavinNo ratings yet

- System Design Score (For Full Pump and Fluid Level at The Pump) : 68% Grade: CDocument6 pagesSystem Design Score (For Full Pump and Fluid Level at The Pump) : 68% Grade: CMohamed ShafieNo ratings yet

- 5.13 7 8 Lobes 5.7 StagesDocument1 page5.13 7 8 Lobes 5.7 StagesLeonardo BarriosNo ratings yet

- Duct Calculation SheetDocument1 pageDuct Calculation SheetHassan SleemNo ratings yet

- Main Steel Structures First Level Alignment ErectionDocument93 pagesMain Steel Structures First Level Alignment ErectionHassan SleemNo ratings yet

- For The Most Aggressive Conditions: New Total Terrain CoatingDocument2 pagesFor The Most Aggressive Conditions: New Total Terrain CoatingHassan SleemNo ratings yet

- Session 1 Module 2 - Boiler Construction PDFDocument21 pagesSession 1 Module 2 - Boiler Construction PDFtbananoNo ratings yet

- Steam Plant OperationDocument794 pagesSteam Plant Operationgladiatork00793% (14)

- Fire Pump SummaryDocument1 pageFire Pump SummaryHassan SleemNo ratings yet

- Man Power RateDocument2 pagesMan Power RateHassan SleemNo ratings yet

- Pump PowerDocument1 pagePump PowerHassan SleemNo ratings yet

- How Boilers WorkDocument18 pagesHow Boilers Workhozipek5599100% (1)

- Pipe & Fittings Project Installs 500m of Ductile Iron Sewer Pipe Beneath Busy MotorwayDocument1 pagePipe & Fittings Project Installs 500m of Ductile Iron Sewer Pipe Beneath Busy MotorwayHassan SleemNo ratings yet

- Water Sewer Design GuideDocument60 pagesWater Sewer Design GuideJim Lawrence Perea OjedaNo ratings yet

- CyclonesDocument12 pagesCyclonesBilly MoerdaniNo ratings yet

- Pipe & Fittings Water & Sewer: Installation GuideDocument87 pagesPipe & Fittings Water & Sewer: Installation GuideHassan SleemNo ratings yet

- The Hard Way: Advanced Engineering Anchorage SolutionsDocument6 pagesThe Hard Way: Advanced Engineering Anchorage SolutionsHassan SleemNo ratings yet

- Design Scheme for SWTC285 Lifting FrameDocument47 pagesDesign Scheme for SWTC285 Lifting FrameHassan SleemNo ratings yet

- HDD BrochureDocument6 pagesHDD BrochureHassan SleemNo ratings yet

- FITTINGDocument8 pagesFITTINGHassan SleemNo ratings yet

- Dimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesDocument1 pageDimensions (Based On ASME/ANSI B16.9) and Example Weights For Equal TeesHassan SleemNo ratings yet

- Heat Treatment Procedure: Tebbin Plant Quality ControlDocument5 pagesHeat Treatment Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- Cons Tank enDocument27 pagesCons Tank enSujesh Beherain VasudevaNo ratings yet

- NPA MS Office Skills RFQDocument33 pagesNPA MS Office Skills RFQHassan SleemNo ratings yet

- Coal Stockpile Improvements in Indian Power PlantsDocument9 pagesCoal Stockpile Improvements in Indian Power PlantsShashi ShekharNo ratings yet

- KSR Kuebler Transparent Level Gauge Attc 5Document56 pagesKSR Kuebler Transparent Level Gauge Attc 5Hassan Sleem100% (1)

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- Calibration Procedure: 1-PurposeDocument5 pagesCalibration Procedure: 1-PurposeHassan SleemNo ratings yet

- Hydrostatic Test Procedure: 1. ScopeDocument5 pagesHydrostatic Test Procedure: 1. ScopeHassan SleemNo ratings yet

- Heat Treatment Procedure2Document2 pagesHeat Treatment Procedure2Hassan SleemNo ratings yet

- Handling of Welding Consumables ProcedureDocument3 pagesHandling of Welding Consumables ProcedureHassan SleemNo ratings yet

- Handling of Welding Consumables ProcedureDocument3 pagesHandling of Welding Consumables ProcedureHassan SleemNo ratings yet

- Heat Treatment Procedure: Tebbin Plant Quality ControlDocument5 pagesHeat Treatment Procedure: Tebbin Plant Quality ControlHassan SleemNo ratings yet

- DoME Report (009 & 019)Document9 pagesDoME Report (009 & 019)Muhammad WaleedNo ratings yet

- Operacion de Sistemas Power Shift - D4EDocument6 pagesOperacion de Sistemas Power Shift - D4ERenato LicettiNo ratings yet

- Amarok 2011 8-Speed Automatic Gearbox 0CMDocument69 pagesAmarok 2011 8-Speed Automatic Gearbox 0CMManuel Gonzales0% (1)

- Twin Clutch TransmissionDocument237 pagesTwin Clutch TransmissionAkash Mankar100% (1)

- Shimano RD M593 Rear DerailleurDocument1 pageShimano RD M593 Rear DerailleurBaris SozuakNo ratings yet

- 590 Super R 695 Super R: Section 17 - Torque ConvertersDocument12 pages590 Super R 695 Super R: Section 17 - Torque ConvertersTeknik MakinaNo ratings yet

- Seminar Report Final AzharDocument37 pagesSeminar Report Final AzharManjeet SinghNo ratings yet

- Honda Px4bDocument101 pagesHonda Px4bRoberto Perez100% (1)

- MD-II TutorialDocument4 pagesMD-II TutorialRohan KolapeNo ratings yet

- CHRYSLER A500 (40RH, 42RH, 40RE, 42RE, 44RE) : 4 SPEED RWD & 4WD (Hydraulic & Electronic Control)Document6 pagesCHRYSLER A500 (40RH, 42RH, 40RE, 42RE, 44RE) : 4 SPEED RWD & 4WD (Hydraulic & Electronic Control)Miguel GuzmanNo ratings yet

- ATF LubricantDocument35 pagesATF LubricantTung NguyenNo ratings yet

- Classification and Applications of GearsDocument20 pagesClassification and Applications of GearsnirmalkrNo ratings yet

- Chrysler 62TE: FWD 6 SpeedDocument6 pagesChrysler 62TE: FWD 6 SpeedLucas MullerNo ratings yet

- Dsi M78 6-Speed Automatic Transmission GeneralDocument30 pagesDsi M78 6-Speed Automatic Transmission GeneralMarcos Diogenes100% (1)

- Mechanical Power TransmissionDocument26 pagesMechanical Power TransmissionVinoth KumarNo ratings yet

- Daewoo 8140le RepairDocument9 pagesDaewoo 8140le RepairwurikeNo ratings yet

- Misuse Service Brake TTT D8R-TDocument10 pagesMisuse Service Brake TTT D8R-TGendon Arkana100% (1)

- Terminals of Ecm: E4 E5 E6 E7 E8Document3 pagesTerminals of Ecm: E4 E5 E6 E7 E8luisNo ratings yet

- Factsheet - Rear Axle Rt2310Hv: Features and BenefitsDocument2 pagesFactsheet - Rear Axle Rt2310Hv: Features and BenefitsJoãoPauloSouzaNo ratings yet

- ZF6HP26 6R60 PDFDocument8 pagesZF6HP26 6R60 PDFDaniel NavasNo ratings yet

- ZF 6hp19 ZF 6hp26 ZF 6hp32 Repair ZF 6hp19 ZF 6hp26 ZF 6hp32 Repair Manual ManualDocument2 pagesZF 6hp19 ZF 6hp26 ZF 6hp32 Repair ZF 6hp19 ZF 6hp26 ZF 6hp32 Repair Manual ManualArda Billy2429% (7)

- 6141-Article Text PDF-9899-1-10-20130718 PDFDocument15 pages6141-Article Text PDF-9899-1-10-20130718 PDFGroup-IV ADAM 2019-20No ratings yet

- 307 Automatic TransmissionTransaxleDocument113 pages307 Automatic TransmissionTransaxleNoureddine MerabtiNo ratings yet

- 6000 Powershift Transmission 4 Speed 0077Document62 pages6000 Powershift Transmission 4 Speed 0077Héctor Medina100% (1)

- 16 S 251 WSK-4130 065 212Document112 pages16 S 251 WSK-4130 065 212Ricardo Luna100% (2)

- Conversiones de Reductores de Velocidad PDFDocument1 pageConversiones de Reductores de Velocidad PDFGrupo Alsa100% (1)

- AT2011 Nissan To ToyotaDocument138 pagesAT2011 Nissan To ToyotaTransmisiones Guero100% (2)

- 6-Speed MTDocument34 pages6-Speed MTJijo MercyNo ratings yet

- TM 9-1807 STUDEBAKER US6 AND US6X4 POWER TRAIN, CHASSIS AND BODYDocument199 pagesTM 9-1807 STUDEBAKER US6 AND US6X4 POWER TRAIN, CHASSIS AND BODYAdvocate100% (4)

- Kinematics Lab Manual GuideDocument18 pagesKinematics Lab Manual Guideshailendra_236No ratings yet