Professional Documents

Culture Documents

Freezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDF

Uploaded by

PrateekOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Freezing and Refrigerated Storage in Fisheries - 8. Calculation of Cold Store Refrigeraion Load PDF

Uploaded by

PrateekCopyright:

Available Formats

3/6/2020 Freezing and refrigerated storage in fisheries - 8.

Calculation of cold store refrigeraion load

8. CALCULATION OF COLD STORE REFRIGERATION

LOAD

8.1 Cold store capacity

A good deal of experience is required to make a correct calculation of a cold store's

refrigeration requirement and this should therefore only be done by a qualified person.

The following calculation is not complete but it serves two purposes. It allows the reader

to make a similar calculation for his own store and thereby obtain an approximate

refrigeration requirement. It also helps the reader to appreciate the number of factors

that have to be taken into account in calculating the heat load and also gives him some

idea of their relative importance.

One important heat load that has been omitted in the calculation is the heat gain due to

solar radiation. This factor depends on a number of conditions which are related to both

the location of the store and its method of construction. In some cases, solar heat load

may not be significant but in other instances, precautions may be necessary to reduce

its effect.

Cold store refrigeration load

Specification

Dimensions 20 m x 10 m × 5 m = 1 000m3

Insulation thickness (0.25 m)

External store surface area (771.5m 2)

Maximum ambient temperature (35C)

Store temperature (-30C)

Load calculation

(1) Insulation heat leak through walls, roof and floor

Conductivity of polystyrene 0.033 0.033 kcal/h mC

Temperature difference between ambient and store 35°C and

-30°C = 65 degC

Thickness of polystyrene = 0.25 m

Surface area of store = 771.5 m 2

Heat leak = 771.5 x 65 × 0.033 ÷ 0.033 = 7422 kcal/h

(2) Air changes

Average of 2.7 air changes in 24 h

Store volume = 1000m 3

Heat gain (35C and 60% R.H. air) 40 kcal/m 3

Air change heat gain = 1000 × 2.7 × 40 ÷ 24 = 4500 kcal/h

(3) Lights (left on during working day)

1000W = 860 kcal/h

(4) Men working

1 man working at -30C gives off 378 kcal/h

2 men working is equivalent to 756 kcal/h

(5) Product load

www.fao.org/3/v3630e/V3630E09.htm#8.1 Cold store capacity 1/3

3/6/2020 Freezing and refrigerated storage in fisheries - 8. Calculation of cold store refrigeraion load

5.5 kcal/kg for fish load at an average temperature of -20C

Fish loaded per day 35 000 kg

Product load = 3500 × 5.5 ÷ 24 = 8020 kcal/h

(6) Fan load

3 × 250W = 644 kcal/h

(7) Defrost heat

1 defrost of 8440 W for 1 h (recovered over 6 h) = 1 209 kcal/h

Total calculated refrigeration load (sum of Items 1 to 7) = 23411

kcal/h

Total refrigeration requirement with allowances 23411 × 24 ÷ 18

= 31215 kcal/h

If a pump is used to circulate refrigerant, the heat equivalent must be added to the

capacity of the refrigeration condensing unit but not to the capacity of the room cooler.

The minimum refrigeration requirement will be when there is only an insulation heat load

and the fans are in operation. In this example, the minimum load corresponds to only

about 25 percent of the capacity of the installed refrigeration plant. This minimum load

factor will vary considerably with the type of store and mode of operation but some

account may have to be taken of this difference between the maximum and minimum

refrigeration requirements. Large cold stores should be operated with a number of

compressors, which can be switched on and off as required. Large compressors may be

fitted with off-loading equipment which allows them to work efficiently on partial loads.

The reliance on one large compressor for a large cold store could be catastrophic in the

event of its failure. In the case of smaller stores it may be that only one compressor is

viable. Other arrangements can be made to cater for the variation in refrigeration

demand. What must not happen is that a large compressor should operate with a low

load and hence operate with a very low suction pressure or stop and start too frequently.

The first condition is bad for the compressor and the second for the electrical

equipment.

8.1 Cold store capacity

There is no method of defining cold store capacity that satisfies the requirements of

everyone concerned with cold storage. Storage capacity based on the weight of produce

that can be stored will depend on the storage density of the products and the method of

storage.

Therefore, unless only one product is stored under closely defined conditions, this

definition is obviously unsuitable. It is generally agreed that it is more appropriate to

define storage capacity in terms of the store volume but there are a number of ways in

expressing this value.

Gross volume is the volume of the refrigerated space.

Net volume is the volume that can potentially be used for storage and is the gross

volume less the volume required for coolers, structural requirements, doorways and

other permanent features of the store.

Effective volume is the store space that can actually be utilised for storage and it takes

into account the requirements for passageways, stacking equipment etc.

Gross volume and net volume can easily be defined by devising a simple set of rules for

making these calculations. These store volumes, however, can only give a rough

estimate of storage capacity and their main use may before statistical purposes. The

effective volume can only be calculated for each particular case and to achieve any

degree of accuracy, a drawing of the store layout would be required together with full

details of the storage conditions. Store operators should therefore use general

statements of store capacity with care and when placing an order they would give full

details of the products and the storage operation to enable the supplier to provide a

www.fao.org/3/v3630e/V3630E09.htm#8.1 Cold store capacity 2/3

3/6/2020 Freezing and refrigerated storage in fisheries - 8. Calculation of cold store refrigeraion load

store to suit the operating requirements with the maximum utilisation of the gross

storage volume.

www.fao.org/3/v3630e/V3630E09.htm#8.1 Cold store capacity 3/3

You might also like

- Dvago Brand PlanDocument46 pagesDvago Brand PlanAmeer hamzaaNo ratings yet

- Manual C4 C5Document78 pagesManual C4 C5Leslie Morales75% (4)

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- Solved - The Data in WAGE2.RAW On Working Men Was Used To Estima...Document1 pageSolved - The Data in WAGE2.RAW On Working Men Was Used To Estima...kharismapb0% (1)

- Collection Notes by ClangDocument19 pagesCollection Notes by ClangQuevyn Kohl SurbanNo ratings yet

- Calculation of Cold Store Refrigeration LoadDocument3 pagesCalculation of Cold Store Refrigeration LoadDash HunterNo ratings yet

- Calculation of Cold Store Refrigeration LoadDocument3 pagesCalculation of Cold Store Refrigeration LoadChamara Chinthaka RanasingheNo ratings yet

- Phuong Phap Tinh Tai Theo Phan Mem MistralDocument8 pagesPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987No ratings yet

- IB-187 Fundamentals of Ice Storage ASHRAE Journal PDFDocument7 pagesIB-187 Fundamentals of Ice Storage ASHRAE Journal PDFVietHienNo ratings yet

- Searle Engineers HandbookDocument31 pagesSearle Engineers HandbookDavidB1206No ratings yet

- Potato Cold Storage Load CalculationsDocument3 pagesPotato Cold Storage Load CalculationsSamiYousif100% (1)

- Bigee Refrigerators Freezers User SavingsDocument20 pagesBigee Refrigerators Freezers User SavingsMystic MilanNo ratings yet

- Unit-I: 1.1 Applications and Necessity of RefrigerationDocument21 pagesUnit-I: 1.1 Applications and Necessity of RefrigerationviratNo ratings yet

- Convert Chest Freezer Into A FridgeDocument6 pagesConvert Chest Freezer Into A FridgeelurrakkeroNo ratings yet

- U Uu Uu: by Mark M. Maccracken, P.E., Member AshraeDocument6 pagesU Uu Uu: by Mark M. Maccracken, P.E., Member AshraeHany Elsawy AbdelrahmanNo ratings yet

- Planning of Cold Storage: Produced By: Title: Manual On Meat Cold Store Operation and Management..Document14 pagesPlanning of Cold Storage: Produced By: Title: Manual On Meat Cold Store Operation and Management..DavidB1206No ratings yet

- Paper O.3.8.1Document10 pagesPaper O.3.8.1T M Abir Ahsan Lecturer, MCENo ratings yet

- Ijmet 10 01 065Document7 pagesIjmet 10 01 065IAEME PUBLICATIONNo ratings yet

- MethodologyDocument3 pagesMethodology무제untitledNo ratings yet

- Household Refrigerators and FreezersDocument12 pagesHousehold Refrigerators and FreezersLuis Carlos PardoNo ratings yet

- The Mass Effect of Refrigerant R600a On Household Refrigerator Energy ConsumptionDocument7 pagesThe Mass Effect of Refrigerant R600a On Household Refrigerator Energy ConsumptionEdy MesinNo ratings yet

- Industrial Refrigeration Energy Saving OpportunitiesDocument15 pagesIndustrial Refrigeration Energy Saving Opportunitiescefa84No ratings yet

- Cooling Load CalculationDocument14 pagesCooling Load CalculationVũ Hằng PhươngNo ratings yet

- Refrigeration Heat Load EstimatingDocument17 pagesRefrigeration Heat Load EstimatingAnonymous 1gbsuaafddNo ratings yet

- Chiller-Plant Energy PerformanceDocument8 pagesChiller-Plant Energy PerformancedaveleyconsNo ratings yet

- Ulf Freezer User Guide PDFDocument17 pagesUlf Freezer User Guide PDFRose Ann RusselNo ratings yet

- 06 24 12 PDFDocument6 pages06 24 12 PDFOla Dorcas DammyNo ratings yet

- By Aaron D'sa Aliakbar Thandlawala Keppler Saldanha Shaun SequeiraDocument13 pagesBy Aaron D'sa Aliakbar Thandlawala Keppler Saldanha Shaun SequeiraAliakbar ThandlawalaNo ratings yet

- Stor ColdstorescasestudyDocument25 pagesStor Coldstorescasestudyตุ๊กตุ้ย ตัวกลมกลมNo ratings yet

- Ice Slurry W Solar Cooling PDFDocument6 pagesIce Slurry W Solar Cooling PDFMattia ParentiNo ratings yet

- Cold Storage PlantDocument32 pagesCold Storage Plantnavalladdha100% (1)

- Calm Ac Frequently Asked Questions About Thermal Energy StorageDocument9 pagesCalm Ac Frequently Asked Questions About Thermal Energy StorageJames LambNo ratings yet

- Energy Efficiency Assumptions and Calculations: Ecofridge, UC Berkeley Typical Refrigerators vs. Phase Change MaterialsDocument3 pagesEnergy Efficiency Assumptions and Calculations: Ecofridge, UC Berkeley Typical Refrigerators vs. Phase Change Materialstoi tu lamNo ratings yet

- CH 06Document11 pagesCH 06lakshmi heat treatmentNo ratings yet

- Thermal Storage With Heat PumpsDocument15 pagesThermal Storage With Heat PumpsIan DaveyNo ratings yet

- Heat RecoveryDocument8 pagesHeat RecoveryPrashantNo ratings yet

- RAC Case StudyDocument11 pagesRAC Case StudyShubham GawdeNo ratings yet

- A8 EnergyconsumptionofanexperimentalcoldstorageDocument7 pagesA8 EnergyconsumptionofanexperimentalcoldstorageLost SoulNo ratings yet

- 2 - Thermal Energy Storage SystemsDocument21 pages2 - Thermal Energy Storage SystemsAbed NaemNo ratings yet

- Air-Conditioning Design Guides-2Document1 pageAir-Conditioning Design Guides-2joshuatamNo ratings yet

- A Case Study of Heat Recovery A Heat Pump in An Inductrial SiteDocument11 pagesA Case Study of Heat Recovery A Heat Pump in An Inductrial SitesaruthanNo ratings yet

- Refrigerated Warehouses: A Case Study of UK Chris SturmanDocument4 pagesRefrigerated Warehouses: A Case Study of UK Chris SturmanHamza KhalidNo ratings yet

- Basic Mechanical EngineeringDocument46 pagesBasic Mechanical EngineeringNguyễn Khánh Tùng100% (1)

- Faculty of Engineering TechnologyDocument11 pagesFaculty of Engineering TechnologyRidzwan IqbalNo ratings yet

- 30gx082 CarrierDocument12 pages30gx082 CarrierRicardoNo ratings yet

- Indoor Pool Application Examples - Load CalculationDocument4 pagesIndoor Pool Application Examples - Load CalculationfireoniceNo ratings yet

- Trane Chiller Plant Admapn014en - 0105Document4 pagesTrane Chiller Plant Admapn014en - 0105a_salehiNo ratings yet

- Design & Construction of LiBr - H2O MachineDocument26 pagesDesign & Construction of LiBr - H2O MachineRana Abdul RehmanNo ratings yet

- Cooling PlantDocument8 pagesCooling PlantMelvin Cotrado100% (1)

- RAC Case StudyDocument11 pagesRAC Case StudyshubhamNo ratings yet

- Energy Storage SystemDocument10 pagesEnergy Storage Systemcif johnnyNo ratings yet

- CoolFlex Application Report - KW Per RackDocument6 pagesCoolFlex Application Report - KW Per RackmajortayNo ratings yet

- Design of Cold Storage: R.D. Verma and S.C. SarmaDocument7 pagesDesign of Cold Storage: R.D. Verma and S.C. SarmaChristopher Lennon Dela CruzNo ratings yet

- CH Hiller e Energ Gy Effic Ciency Y: Info Ormatio On Pap Per - 2 22Document6 pagesCH Hiller e Energ Gy Effic Ciency Y: Info Ormatio On Pap Per - 2 22mattiturboNo ratings yet

- HVACDocument29 pagesHVACimranakhtarNo ratings yet

- Pracassign11 12Document2 pagesPracassign11 12Jatin KishoreNo ratings yet

- Refits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5From EverandRefits, More Ways to Make Your Boat Better.: Cruising Boats, How to Select, Equip and Maintain, #5Rating: 3 out of 5 stars3/5 (1)

- Sustainable Retail RefrigerationFrom EverandSustainable Retail RefrigerationJudith A. EvansRating: 5 out of 5 stars5/5 (1)

- Refrigerator Revelations: A User's Guide to Operation and MaintenanceFrom EverandRefrigerator Revelations: A User's Guide to Operation and MaintenanceNo ratings yet

- Circular GeMDocument2 pagesCircular GeMPrateekNo ratings yet

- LT-HT LP Feb-2022 W.E.F. 25.02. 2022Document5 pagesLT-HT LP Feb-2022 W.E.F. 25.02. 2022PrateekNo ratings yet

- Construction Cost IndicesDocument40 pagesConstruction Cost IndicesPrateek100% (1)

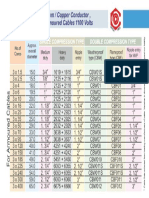

- Three Core Aluminum Copper Conductor, XLPE Insulated, Armoured Cables 1100 VoltsDocument1 pageThree Core Aluminum Copper Conductor, XLPE Insulated, Armoured Cables 1100 VoltsPrateekNo ratings yet

- IRC 58 - Plain Jointed Rigid Pavements Design HighwaysDocument61 pagesIRC 58 - Plain Jointed Rigid Pavements Design HighwaysPrateekNo ratings yet

- Domestic Project List Price 180 Mtrs W.E.F. 04.07.2019Document1 pageDomestic Project List Price 180 Mtrs W.E.F. 04.07.2019PrateekNo ratings yet

- Short Circuit Current Calculation (Base KVA Method)Document16 pagesShort Circuit Current Calculation (Base KVA Method)PrateekNo ratings yet

- 601 02 003A.25022005.1 Annex-FDocument29 pages601 02 003A.25022005.1 Annex-FPrateekNo ratings yet

- Area NeedDocument3 pagesArea NeedPrateekNo ratings yet

- Annexure - J: Extracts From Arema Manual For Railway Engineering - Part IDocument6 pagesAnnexure - J: Extracts From Arema Manual For Railway Engineering - Part IPrateekNo ratings yet

- Annexure - I: Extracts From Uic Code 776.3Document14 pagesAnnexure - I: Extracts From Uic Code 776.3PrateekNo ratings yet

- Design Considerations For Aircraft BridgesDocument8 pagesDesign Considerations For Aircraft BridgesPrateekNo ratings yet

- Annexure - I: Extracts From Uic Code 776.3Document14 pagesAnnexure - I: Extracts From Uic Code 776.3PrateekNo ratings yet

- Trane Sintesis Air-Cooled Chillers: Chillers That Give You ChoicesDocument2 pagesTrane Sintesis Air-Cooled Chillers: Chillers That Give You ChoicesPrateekNo ratings yet

- HVAC ParametersDocument5 pagesHVAC ParametersPrateekNo ratings yet

- Ascend™ Air-Cooled Chillers: An Unbeatable Combination of High-Energy Efficiency and Quiet PerformanceDocument2 pagesAscend™ Air-Cooled Chillers: An Unbeatable Combination of High-Energy Efficiency and Quiet PerformancePrateekNo ratings yet

- Cold Room Calculator: Mobile App For iOS & AndroidDocument2 pagesCold Room Calculator: Mobile App For iOS & AndroidPrateekNo ratings yet

- Capacitor Selection ChartDocument1 pageCapacitor Selection ChartPrateekNo ratings yet

- Space Required For Substation and EquipmentDocument16 pagesSpace Required For Substation and EquipmentPrateek100% (1)

- Cable Ampacity and SC RatingDocument3 pagesCable Ampacity and SC RatingPrateekNo ratings yet

- Marketing 3rd Quarter ReviewerDocument10 pagesMarketing 3rd Quarter ReviewerJohn Cris BuanNo ratings yet

- Regulatory Aspects and Quality Controls of Polymer-Based Parenteral Long-Acting Drug Products How Challenging Is Approving CopiesDocument24 pagesRegulatory Aspects and Quality Controls of Polymer-Based Parenteral Long-Acting Drug Products How Challenging Is Approving CopiesChaojun JiangNo ratings yet

- Pakistan's Investment Climate: The Way ForwardDocument9 pagesPakistan's Investment Climate: The Way ForwardInstitute of Policy StudiesNo ratings yet

- Test Certificate: Upvc Fittings To Bs en 1401 LPO Ref: 352004218 DN Number: 33458977Document9 pagesTest Certificate: Upvc Fittings To Bs en 1401 LPO Ref: 352004218 DN Number: 33458977Karlo Sam DiegoNo ratings yet

- Solved Determine The Combined Present Value As of December 31 2018Document1 pageSolved Determine The Combined Present Value As of December 31 2018Anbu jaromiaNo ratings yet

- Schengen VisaDocument4 pagesSchengen Visajannuchary1637No ratings yet

- HTML BackgroundsDocument5 pagesHTML Backgroundsrc.david.florendoNo ratings yet

- Battle Ship LabDocument1 pageBattle Ship Labapi-276688928No ratings yet

- Injection Wafer DatashtDocument2 pagesInjection Wafer DatashtMisael RamírezNo ratings yet

- Fiat Ducato 1st - x250 - Training ManualDocument187 pagesFiat Ducato 1st - x250 - Training Manualfragma84100% (1)

- SCS 3142 Module #1 Rev1Document40 pagesSCS 3142 Module #1 Rev1Wahid ZakiNo ratings yet

- DocumentsDocument135 pagesDocumentsupsc.bengalNo ratings yet

- Error AnalysisDocument6 pagesError Analysisagbas20026896No ratings yet

- 12 796 and 798 Update - Jeff - 20nov18Document17 pages12 796 and 798 Update - Jeff - 20nov18tatiana100% (1)

- Fas - Ul.p.3.005 Zic-4aDocument4 pagesFas - Ul.p.3.005 Zic-4aShashish AshuNo ratings yet

- Ticketmaster Member Services - Print ReceiptDocument1 pageTicketmaster Member Services - Print Receipt8768263No ratings yet

- Worcester MT20 Wired Timer Installation and Servicing InstructionsDocument12 pagesWorcester MT20 Wired Timer Installation and Servicing InstructionspabloNo ratings yet

- Fundamentals of Electric Circuits Basic ConceptsDocument15 pagesFundamentals of Electric Circuits Basic ConceptsThiruppathy KesavanNo ratings yet

- BVOC HM Syllabus With Final ChangesDocument58 pagesBVOC HM Syllabus With Final ChangesGovind SharmaNo ratings yet

- Q4 HOPE 2 - Module 5Document10 pagesQ4 HOPE 2 - Module 5May Ann GodezanoNo ratings yet

- Electronic Theses and Dissertations (Etds)Document208 pagesElectronic Theses and Dissertations (Etds)jasimnddNo ratings yet

- LR24A-SR Datasheet En-Gb PDFDocument3 pagesLR24A-SR Datasheet En-Gb PDFmikegalvezNo ratings yet

- Itcooling hb32 629-1347 804-805Document2 pagesItcooling hb32 629-1347 804-805Erdinc KlimaNo ratings yet

- Datasheet Hitachi Content Software For FileDocument4 pagesDatasheet Hitachi Content Software For FileHung Do MinhNo ratings yet

- DM163Document21 pagesDM163Marco OBNo ratings yet

- Automatic Account Determination (MM-FI)Document19 pagesAutomatic Account Determination (MM-FI)Ankit BudheNo ratings yet