Professional Documents

Culture Documents

CONFERENCE Direct Shear Strength Properties of Limestone-Blended PDF

Uploaded by

bagus yosan setiawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CONFERENCE Direct Shear Strength Properties of Limestone-Blended PDF

Uploaded by

bagus yosan setiawanCopyright:

Available Formats

Regional Conference in Civil Engineering (RCCE) 69

The Third International Conference on Civil Engineering Research (ICCER)

August 1st-2nd 2017, Surabaya – Indonesia

Direct Shear Strength Properties of Limestone-Blended

Embankment Materials

Jonathan R. Dungca1*

1

Civil Engineering Department, De La Salle University Manila, 2401 Taft Avenue, 1004 Manila, Philippines

*

Corresponding author: jonathan.dungca@dlsu.edu.ph

Abstract The vast distribution of limestone in the Philippines makes limestone quarrying prevalent resulting

to the accumulation of waste limestone. This opened the idea of utilizing the wastes as embankment materials

which would result to a more economical construction. In order to test the ability of limestone to be an

embankment material, its strength and consolidation parameters are evaluated in different mixed proportions,

at 0%, 20%, 40%, 60% and 100%, with the conventional embankment material using the direct shear test.

Index properties (i.e. specific gravity, Atterberg limits, and maximum and minimum index densities) were

obtained for all the blends in order to produce empirical relationships with the different percentage of

limestone. It was found out that the cohesion increased with the addition of limestone, although there was a

decrease in the internal angle of friction.

Keywords Waste Limestone, Embankment, Direct Shear.

I. INTRODUCTION unbound soil layer by increasing the secant modulus [3].

When high lime contents are used, slab action will

T oday, it is apparent that it is difficult to find quality

develop, and therefore, greater load spreadability of the

pavement layer will result, provided intensive internal

embankment materials especially in isolated island and cracking can be avoided. The lime increases the shear

rural areas in the Philippines. Because of this, there is a strength of the soils.”

need to find an alternative source of embankment

materials that is accessible and is of good quality. II. TESTING MATERIALS

Limestone is a rock which is highly available in the

The limestone that was used in the research came from a

Philippines. In this study, the limestone used is from

limestone quarry in Guimaras Island in the Cntral

Guimaras Island. This island is known to have mining

Philippines. These limestones were considered waste

area of almost 1800 hectares of limestone. With the vast

materials in the limestone quarry, however, have not

amount of limestone in the Philippines and its potential

undergone any treatment. On the other hand, the

to stabilize soil, it was expected that blending this with

conventional embankment material was from a mountain

conventional embankment material will provide strength

quarry in Rizal area.

acceptable as a structural fill.

The waste limestones used were yellowish in color

The main objective of this study is to provide the

and can easily be crushed. On the other hand, the

direct shear strength properties of the blends for

conventional embankment materials used were grayish in

foundation design. By doing so, relationships between

color. For the particle shape, the limestones were sub-

the geotechnical properties and the properties can be

rounded. On the other hand, for the conventional

derived.

embankment material, the particles range from angular to

The usability of a quarry dust limestone powder, a

sub-angular.

by-product of stone crushers, in self-compacting paste

The limestones were blended with the conventional

and concrete applications [1]. These by-products pose

embankment material by replacing the fine aggregates

big problems from aspects such as its disposal,

passing through the No.4 sieve in proportion of 0%,

environmental pollution and health hazards.

20%, 40%, 60%, and 100%. The weights of every size of

In the study Performance of Roadway Embankment on

aggregate passing through sieve no.4 were arithmetically

Lime Waste by Ramer and Wang, 2000, the mechanical

computed based on the grain size distribution curve

and geotechnical properties of a four lane embankment

presented in Figure 1. The corresponding percent weight

which was constructed over an abandoned quarry filled

of the limestone and conventional embankment material

with limestone waste in Plymouth Township,

for every blend is indicated in Table 1.

Montgomery County Pennsylvania was determined[2].

Based on the test results, it was found out that lime waste

is highly compressible, has very low shear strength and

III. TESTING METHODS

cause very large roadway settlements. The result of the

journal varies with this study because of the different A. Index Properties

scenario. In journal, a roadway embankment was placed In order to fully understand the behavior of the

over the limestone waste while this research would blend samples, the geotechnical engineering properties were

together the two materials. While according to Dunlop R. evaluated for the different blends with the following

(1980), “The addition of lime to subbases and bases laboratory tests:

improves the load-spreading ability of the otherwise

Regional Conference in Civil Engineering (RCCE) 70

The Third International Conference on Civil Engineering Research (ICCER)

August 1st-2ndGravity

1 Specific of Solids–(ASTM

2017, Surabaya Indonesia

D 854) kPa and 136.25 kPa. These loads were the approximate

2 Atterberg Limits Test (ASTM D4318 and loads for structural buildings. Two trials were

(ASTMD427) successfully done for each type of specimen. All

3 Maximum Index Density and Unit Weight using specimens were fully saturated so as to simulate worst

Vibratory Table (ASTM D4253) case scenario of the embankments. The relative

4 Minimum Index Density and Unit Weight and compaction used in this study was between 90-95%, the

Calculation of Relative density (ASTM D4254) commonly used relative compaction in the construction

of embankments.

B. Sample Preparation The three conditions considered for this test were the

The samples that were used for the consolidation and following: Unconsolidated Undrained (UU),

direct shear tests were done by means of moist tamping Consolidated Undrained (CU) and Consolidated Drained

method. This is a procedure that was suggested by Chao (CD). For the Undrained test the rate of shearing was

(2008) that can successfully provide a uniform sample 1.25 mm/min which was derived from Soil Properties:

for oedometer testing[4]. In this procedure the addition Testing Measurement and Evaluation (Liu and Evett,

of water is divided into two parts since it is difficult to 1990) . The book suggests a shearing rate of 0.05 in/min

compact the sample in its fully saturated state. The first which is approximately 1.25mm/min when converted to

part is adding the amount of water that allows the sample metric. For the drained test, the rate of loading used was

to attain optimum moisture content. And the second half determined through the formula, Time of Failure (tf) =

is added before the start of the test to make it fully 50t50, t50 was obtained using the square-root-of-time

saturated. method. The time of consolidation used for the study was

The two main requirements in the sample preparation 3 hours.

are to prepare them at 90% to 95% relative density and

to make sure that the sample is fully saturated. To attain IV. TEST RESULTS

a relative density in this range, series of trials was

The geotechnical properties of the five blends

needed in order to attain the right amount of compaction

were investigated and used to obtain different empirical

relationships. The summary of the values are shown in

Table 3.

A. Specific Gravity

Experiments show that 100% limestone has a specific

gravity of 2.63 which is within the range of 2.58 - 2.65

for carbonate materials [1]. On the other hand, for the

0% limestone, the specific gravity is 2.89 which is in the

range of typical values for silty soils [5]. With the

increasing amount of limestone, there is a decreasing

value which can be attributed to the mineralogical

component of the sample.

Figure 1. Grain Size Distribution Curve A polynomial equation in the second degree which can

estimate specific gravity for different limestone content

is derived as shown in Equation (1).

Table 1. Comparison of two methods in training of

OHL-CBPNN Gs = 0.00003(LC)2 - 0.0054(LC) + 2.8827 (1)

Corresponding % of Corresponding % where;

Limestone Passing Conventional Gs= specific gravity of solids;

No.4 Sieve Embankment and LC= limestone content in %.

Material Passing

No.4 Sieve B. Minimum and Maximum Index Densities

0 100% The control blend shows the highest value for both the

20% 80% ρdmin and ρdmax which is due to the weight of the

40% 60% particles. The control blend has higher specific gravity

60% 40% which means that it is heavier as compared to the

100% 0% limestone.

From these values, the emax and emin were computed

exerted for every layer of soil both for the preparation of as shown in Table 2. Among the five samples, the control

sample for consolidation and direct shear test. Moreover, blend, 0% limestone, is the densest while the 100%

the saturation of the sample was also checked after every limestone has the largest void ratio.

test to make sure that the sample was is in its saturated

state.

C. Direct Shear Test

The direct shear test had a total of 90 trials. There were

three varying normal loads for the test: 81.75 kPa, 109

Regional Conference in Civil Engineering (RCCE) 71

The Third International Conference on Civil Engineering Research (ICCER)

August 1st-2nd 2017, Surabaya – Indonesia content from UU,CU and CD tests are shown in Figures

Table2. Maximum and Minimum Void Ratios

Limestone Table 3. Summary of the Index Properties

emax emin

Content (%)

0 0.69 0.32

20 0.74 0.37 ρdmin

Limestone Specific

ρdmax (g/cm

40 0.87 0.43 Content Gravity

(g/cm3) 3

)

LL PL PI

60 0.93 0.48 (%) (Gs)

100 1.20 0.76

100 2.63 1.49 1.19 19.70 15.11 4.59

60 2.67 1.81 1.38 17.29 14.42 2.87

The maximum and minimum void ratios are affected 40 2.71 1.89 1.45 15.82 13.13 2.68

by several factors such as the grain size, grain shape, 20 2.77 2.03 1.59 14.20 12.07 2.12

0 2.89 2.18 1.71 13.73 11.84 1.89

nature of the distribution curve and the fine contents [5].

Since there is a grain size distribution followed as 2, 3 and 4, respectively.

specified in the methodology, the samples used can be

defined as a well-graded sample. The fines content for

both the 0% limestone and 100% limestone are equal in

proportion. The main factor affecting the void ratio of

the blends is the grain shape. Because of the range of the

angularity of the particles, lesser spaces are left thus

resulting to a lesser void ratio.

Equations (2) and (3) were derived to estimate the

maximum and minimum void ratios in terms of

limestone content, respectively.

emax = 0.00002(LC)2 + 0.0031(LC) + 0.6874 (2)

emin = 0.00004(LC)2 + 0.0006(LC) + 0.3331 (3)

Figure 2. Cohesion vs Limestone Content from

where;

Unconsolidated Undrained test

emax = maximum void ratio;

emin = minimum void ratio;

and LC = limestone content in %.

C. Atterberg Limits

It shows the amount of limestone increases, the LL and

PL increases its values as well. The control blend has

a very low PI which is equal to 1,89. On the other hand,

for the 100% limestone, PI is equal to 4.59. A limestone

filler has a plasticity index generally under 4 [6]. 100%

limestone can be classified as low plastic while the

control blend, 20%, 40% and 60% are classified as

slightly plastic. The control blend is expected to have a

low value of PI since it is a cohesionless type of soil.

Equations (4), (5), and (6) were derived to estimate the

liquid limit, plastic limit and plasticity index in terms of Figure3. Cohesion versus Limestone Content

limestone content, respectivey. from Consolidated Undrained test

LL = 0.00001(LC)2 + 0.0529(LC) + 13.515 (4); The equations which can be derived from the

PL= -0.00001 (LC)2 + 0.0458(LC) + 11.599 (5); behaviour of soil based on the direct shear test are shown

PI = 0.0002(LC)2 + 0.0071(LC) + 1.9158 (6); in Equations (7), (8), and (9).

where;

LL = liquid limit; For Unconsolidated Undrained:

PL = plastic limit; c’ = -0.0034LC2 + 0.7899LC + 2.9756 (7);

PI = plastic limit;

and LC = limestone content in % For Consolidated Undrained:

c’ = -0.0019LC2 + 0.6222LC + 0.5184 (8);

D. Direct Shear Test For Consolidated Drained:

Cohesion is a shear strength parameter of a soil c’ = -0.0017LC2 + 0.4089LC + 1.781 (9);

wherein the adsorbed water and particle attraction work where;

with each other in order to create a mass which holds to c’ = cohesion in kPa, and;

the soil together [7]. The cohesion versus Limestone LC = limestone content of the sample in percent.

The direct shear test had a total of 90 trials.

There were three varying normal loads for the

test: 81.75 kPa, 109 kPa and 136.25 kPa. These

loads were the approximate loads for structural

buildings. Two trials were successfully done

for each type of specimen. All specimens were

Regional Conference in Civil Engineering (RCCE) 72

The Third International Conference on Civil Engineering Research (ICCER)

August 1st-2nd 2017, Surabaya – Indonesia

Figure4. Cohesion vs Limestone Content from

Consolidated Drained test

Figure5. Internal Angle of Friction vs Limestone Content

(%) from Unconsolidated Undrained Test

The behaviour of the graphs shown in figures 2, 3 & 4

indicate that as the limestone content increases the

cohesion also increases. The plasticity of the soil is a

factor which affects the cohesion. It was presented earlier

that the addition of limestone increases the plastic index

of the blends

According to [8], the excess water pressure increases

the shear strength of the soil, which also means that there

is an increase in its parameters such as the cohesion.

E. Angle of iInternal Friction

The angle of internal friction is the sliding resistance

between particles which is influenced by the following

conditions: effective stress, coefficient of friction

between the minerals, surface roughness, and the angle

of contact between grains [7]. Figures 5, 6 & 7 show the

Figure 6. Internal Angle of Friction vs Limestone Content

angle of internal friction versus limestone content for

(%) from Consolidated Undrained Test

UU, CU and CD , respectively.

shape of the soil. The shape of the conventional

The equations derived from the three tests are shown in embankment material is considered to be subangular to

Equatons (10), (11), and (12): angular while the limestone has a subrounded shape. The

conventional embankment material contributes to the

For Unconsolidated Undrained: increase of internal angle of friction because of the angle

of contact of its particle due to its angular shape.

= 0.0004LC2 - 0.1816LC + 45.907 (10)

For Consolidated Undrained:

= -0.0006LC2 – 0.1LC + 46.786 (11)

For Consolidated Drained: F. Stress-Strain Relationship

= -0.0002LC2 + 0.0327LC + 43.493 (12)

where,

= internal angle of friction of the limestone blend in

degrees, and

LC = limestone content of the sample (%).

Figures 5, 6 and 7 show that there is a decrease in the

internal angle of friction for every increase in limestone

content. The internal angle of friction is dependent on the

Figure 9. Vertical Displacement vs. Horizontal

displacement from 0% Consolidated Drained test

Figure7. Internal Angle of Friction vs Limestone Content

(%) from Consolidated Drained Test

Regional Conference in Civil Engineering (RCCE) 73

The Third International Conference on Civil Engineering Research (ICCER)

1st-2stress

AugustThe nd

2017,strain

Surabaya – Indonesiaof the soil is

relationship

anisotropic meaning that it has different behaviours for

different directions (Budhu, 2000). In the direct shear

test the stress-strain diagram was taken from the graph of

the shear force versus the shear displacement. Figure 8

best represent the stress strain diagram of the different

H. Shear Strength Properties and Plasticity Index

Das (2011) stated that the plasticity of the soil affects

its internal angle of friction. It can be seen in figure 10

that as the plasticity index increases there is a

corresponding decrease in the internal angle of friction of

the soil. The difference in behaviour of the drained and

undrained condition of the soil can also be observed. In

the graph, the drained condition has a gentler slope,

meaning the decrease in internal angle of friction of the

soil is more gradual than that of the undrained condition

Figure8. Stress-strain diagram of Unconsolidated

Undrained 40 % Limestone Content

blends

The graph in Figure 8 was derived from the

unconsolidated undrained test of 40% limestone content

and it was found out through the observation of the

diagram that the soil is considered to be elastoplatic. At

first, the soil behaves nonlinearly elastic then was

subjected to plastic deformation. This behaviour was

applicable for all the blends and also for the

Consolidated Undrained and Consolidated Drained tests. Figure 10. Variation Internal Angle of Friction with

Due to the elastoplastic behaviour, the parameters Plasticity Index (PI) for the different direct shear test

derived from the direct shear test falls under the critical displacement from 0% Consolidated Drained test

state which is defined as the stress state reached in a soil

when continuous shearing occurs at constant volume and

shear stress [9]. Emprical relationships between angle of internal friction

The normal stress applied affects the stress-strain and plasticity index were also derived as shown in

behaviour of the soil which was tested. As the normal Equations, (13), (14), and (15).

stress increases, the shear stress also increases. This is

due to the friction produced by the normal force during For Consolidated Drained,

the shearing process. y = 47.95x-0. 15 (13)

For Consolidated Undrained,

G. Dilatancy y = 57.683x-0.4 (14)

The vertical displacement of the specimen during For Unconsolidated Undrained,

shear can be related to its density. Figure 9 represents y = 63.49x-0.462 (15)

the same behaviour for all consolidated tests (CD and

CU) for all the blends. The dilatancy occurred because For the cohesions of the blends, it is best

there was a preconsolidation stress applied to the described by a second degree relationship with the

sample and when the shear stress was applied a Plasticity Index of the soil (figure 11). Meaning, that

certain angle of dilation occurred which yielded the there would be a certain Plasticity Index wherein the

graph For the Unconsolidated Undrained tests, cohesion of the soil would peak and produce the

compression was observed since the soil sample was maximum cohesion which is approximately 4.1.

subjected to vertical stress and horizontal stress

simultaneously.

Regional Conference in Civil Engineering (RCCE) 74

The Third International Conference on Civil Engineering Research (ICCER)

August 1st-2nd 2017, Surabaya – Indonesia

V. SUMMARY AND CONCLUSIONS

The direct shear tests conducted show the

relationship of its strength parameters (cohesion and

angle of internal friction) with the amount of limestone

in the mix. There is a noticeable increase in the cohesion

with the increase of limestone. Opposite trend was

observed for the angle of internal friction. Equations for

various combinations were introduced to give an

estimate for geotechnical parameters like specific

gravity, index densities and Atterberg limits. Equations

to compute for cohesion and angle of internal friction for

different limestone contents were also introduced.

Figure 11. Relationship between the Cohesion and

Plasticity Index of the Blends

V. REFERENCES

[1] B. Felekoglu, “Utilisation of high volumes of limestone

quarry wastes in concrete industry (self-compacting concrete

Equations (16), (17), and (18) were derived from the case),” Resour. Conserv. Recycl., vol. 51, pp. 770–791, 2007.

correlation of the samples between the cohesion and the [2] D. S. Ramer, “Performance of Roadway Embankments on

plastic index shown in figure 11. Lime Waste,” Geotech. High Water Content Mater. ASTM

where; STP 1374, pp. 351–361, 2000.

[3] R. Dunlop, “Reviews of Roads with lime/cement pavement

c’ = Cohesion and; layers,” AusUan Road Res., vol. 10, no. 3, pp. 12–26, 1998.

PI = Plastic Index, [4] K. Chao, Soil Water Retention curves for Remolded

Expansive Soils. . Engineering Analytics, Inc., 2008.

For Consolidated Drained, [5] B. Das, Fundamentals of Geotechnical Engineering.

Thomson Learning, 2006.

c’ = -4.2713PI2 + 36.299PI - 50.162 (16); [6] G. Chilingar, Asphaltenes and asphalts, 2nd ed. Netherland:

Elsevier Science, BV, 2000.

For Consolidated Undrained, [7] G. Sowers, Introductory Soil Mechanics and Foundations.

c’ = -7.0947PI2 + 61.396PI - 88.637 (17); The Macmillan Company, 1961.

[8] J. Duncan, Soil Strength and Slope Stability. New Jersey:

John Wiley & Sons, Inc.

For Unconsolidated Undrained, [9] M. Budhu, Soil Mechanics & Foundations. New York: John

c’ = -8.2956PI2 + 69.328PI - 95.206 (18). Wiley & Sons, Inc., 2000.

You might also like

- Service Manual Selenia Dimensions V1.8 Rev 3Document418 pagesService Manual Selenia Dimensions V1.8 Rev 3IMEEDCO SRL100% (1)

- Riva, Anna - Secrets of Magical Seals A Modern Grimoire of Amulets, Charms, Symbols and TalismansDocument35 pagesRiva, Anna - Secrets of Magical Seals A Modern Grimoire of Amulets, Charms, Symbols and Talismansbondogoof83% (12)

- Brosur Excava-200 PDFDocument6 pagesBrosur Excava-200 PDFfajardiniantNo ratings yet

- Brosur Excava-200 PDFDocument6 pagesBrosur Excava-200 PDFfajardiniantNo ratings yet

- Answers YEAR 9 EXAM TERM 2Document13 pagesAnswers YEAR 9 EXAM TERM 2Mustafa Al Qady50% (2)

- Coriolis Mass Flow MeterDocument2 pagesCoriolis Mass Flow MeterSreejesh SundaresanNo ratings yet

- Characterization Study On The Influence of Limestone and Shell Lime As A Fine Aggregate Substitute A Traditional Approach On Lime Plaster RestorationDocument8 pagesCharacterization Study On The Influence of Limestone and Shell Lime As A Fine Aggregate Substitute A Traditional Approach On Lime Plaster Restorationelmer cervantesNo ratings yet

- Materials Today: Proceedings: S.C. Boobalan, M. Sivakami DeviDocument4 pagesMaterials Today: Proceedings: S.C. Boobalan, M. Sivakami DeviClaudiaNo ratings yet

- Stabilization of Expansive Soil by Lime and Fly Ash : (Received: Jan. 28,2002) AbstractDocument5 pagesStabilization of Expansive Soil by Lime and Fly Ash : (Received: Jan. 28,2002) AbstractРадо МицевNo ratings yet

- Black Cotton SoilDocument4 pagesBlack Cotton Soilibson045001256100% (2)

- The Engineering Properties of Coral Limestone Used As Sub Base in Dar-Bagamoyo Road ProjectDocument15 pagesThe Engineering Properties of Coral Limestone Used As Sub Base in Dar-Bagamoyo Road ProjectGerald MaregesiNo ratings yet

- A Study of Using A Variety of Wasted Materials As Additives in Soil StabilizationDocument6 pagesA Study of Using A Variety of Wasted Materials As Additives in Soil StabilizationRoshanNo ratings yet

- Utilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentDocument25 pagesUtilization of Lime For Stabilizing Soft Clay Soil of High Organic ContentLarisa ChindrișNo ratings yet

- Stabilization of Black Cotton Soil Using Sodium Chloride and Fly AshDocument14 pagesStabilization of Black Cotton Soil Using Sodium Chloride and Fly AshSandy ManNo ratings yet

- Effect of Replacement of Lateritic Soils With Granite Fines On The Compressive and Tensile Strengths of Laterized ConcreteDocument6 pagesEffect of Replacement of Lateritic Soils With Granite Fines On The Compressive and Tensile Strengths of Laterized ConcreteEdem CHABINo ratings yet

- Geotechnical Characteristics of Coal Mine Spoil - FityusDocument10 pagesGeotechnical Characteristics of Coal Mine Spoil - FityusCharlie YoungNo ratings yet

- Structural Properties of Rice Husk Ash CDocument6 pagesStructural Properties of Rice Husk Ash Cwasiu segunNo ratings yet

- Durability Properties of Concrete With Natural Sand and Manufactured SandDocument5 pagesDurability Properties of Concrete With Natural Sand and Manufactured SandArun KumarNo ratings yet

- 2 Straw Stabilized Local Clay BricksDocument11 pages2 Straw Stabilized Local Clay BricksYousif MawloodNo ratings yet

- Engineering characteristics of sand-clay mixtures for clay coresDocument8 pagesEngineering characteristics of sand-clay mixtures for clay coresKarwan AhmedNo ratings yet

- Partial Replacement of River Sand With Volcanic Pyroclastics As Fine Aggregates in Concrete ProductionDocument5 pagesPartial Replacement of River Sand With Volcanic Pyroclastics As Fine Aggregates in Concrete ProductionJeriel PacerNo ratings yet

- Replacement of River Sand With Proportions of Sea SandDocument8 pagesReplacement of River Sand With Proportions of Sea SandDharma banothuNo ratings yet

- Experimental Study On Stablization of Black Cotton Soil by Fly Ash, Coconut Coir Fiber & Crushed GlassDocument4 pagesExperimental Study On Stablization of Black Cotton Soil by Fly Ash, Coconut Coir Fiber & Crushed GlassYoris R ChannelNo ratings yet

- Materials Today: Proceedings: A. El Machi, S. Mabroum, Y. Taha, A. Tagnit-Hamou, M. Benzaazoua, R. HakkouDocument7 pagesMaterials Today: Proceedings: A. El Machi, S. Mabroum, Y. Taha, A. Tagnit-Hamou, M. Benzaazoua, R. Hakkoulahcen essNo ratings yet

- Evaluation of Clinker Stabilized Fly AshDocument18 pagesEvaluation of Clinker Stabilized Fly AshManoj Kumar MishraNo ratings yet

- Utilization of Marble and Granite Slurry in Clay BricksDocument3 pagesUtilization of Marble and Granite Slurry in Clay BricksPrashant pandeNo ratings yet

- The Effects of Coconut Shell Ash Admixed With Lime in Variation To Curing Time For Road ConstructionDocument9 pagesThe Effects of Coconut Shell Ash Admixed With Lime in Variation To Curing Time For Road ConstructionYi Sun ShinNo ratings yet

- Mallick-Mishra2017 Article EvaluationOfClinkerStabilizedFDocument16 pagesMallick-Mishra2017 Article EvaluationOfClinkerStabilizedFCHRISTIAN ARIZA GOMEZNo ratings yet

- Elert 2017 PDFDocument9 pagesElert 2017 PDFJosé Miguel AzañonNo ratings yet

- Effect of by Product Steel Slag On The en - 2017 - Journal of King Saud Universi PDFDocument6 pagesEffect of by Product Steel Slag On The en - 2017 - Journal of King Saud Universi PDFMihir BhalgatNo ratings yet

- Kafd Escyp 2020 01Document4 pagesKafd Escyp 2020 01Klisman A. Flores DurandNo ratings yet

- Estimated and Real Durability of Unfired Clay Bricks Determining Factors and Representativeness of The Laboratory TestsDocument6 pagesEstimated and Real Durability of Unfired Clay Bricks Determining Factors and Representativeness of The Laboratory Testskhaoula mouihNo ratings yet

- Proposal1 5Document10 pagesProposal1 5GideonNo ratings yet

- A Review and Study On Stabilization of Expansive Soil Using Brick DustDocument8 pagesA Review and Study On Stabilization of Expansive Soil Using Brick DustalibuxjatoiNo ratings yet

- Experimental Study On Manufacturing of Bricks Using Waste Magnesite Soil PDFDocument5 pagesExperimental Study On Manufacturing of Bricks Using Waste Magnesite Soil PDFManikandan BmNo ratings yet

- Behavior of Concrete With Quarry Dust As Partial Replacement of Fine AggregateDocument8 pagesBehavior of Concrete With Quarry Dust As Partial Replacement of Fine AggregateSuman VarmaNo ratings yet

- Geotechnical and Environmental Evaluation of Lime-CementDocument12 pagesGeotechnical and Environmental Evaluation of Lime-CementferraNo ratings yet

- Achieving Sustainability in Vibro Stone Column Techniques: C. J. SerridgeDocument12 pagesAchieving Sustainability in Vibro Stone Column Techniques: C. J. SerridgeSarangi M PNo ratings yet

- 10 1016@j Matpr 2020 01 384Document8 pages10 1016@j Matpr 2020 01 384Geeta JiraliNo ratings yet

- Tropical Peat Soil Stabilization Using Coal AshDocument5 pagesTropical Peat Soil Stabilization Using Coal AshDanang Setiya RaharjaNo ratings yet

- Sjce 56 133-138 FTDocument6 pagesSjce 56 133-138 FTMac Eteli HappinessNo ratings yet

- Jon JonasDocument4 pagesJon JonasMatt PuertoNo ratings yet

- STRENGTHENING BLACK COTTON SOILDocument7 pagesSTRENGTHENING BLACK COTTON SOILVishnucharan BandariNo ratings yet

- IJETR022413Document4 pagesIJETR022413erpublicationNo ratings yet

- Geotechnical Aspects of Overburden Materials For Stowing in Underground Coal Mines IJERTCONV4IS03014Document2 pagesGeotechnical Aspects of Overburden Materials For Stowing in Underground Coal Mines IJERTCONV4IS03014ME-MNG-12 MD YOUSUFNo ratings yet

- Effect of Lime Treatment On California Bearing Ratio (CBR) of Expansive SoilDocument7 pagesEffect of Lime Treatment On California Bearing Ratio (CBR) of Expansive SoilAnonymous izrFWiQNo ratings yet

- Reuse and Stabilization of Sulphide MineDocument9 pagesReuse and Stabilization of Sulphide MinecivildepartmentmycemNo ratings yet

- Effects of Soldier-Ant Mound On The Strength of Lateritic Clay SoilsDocument12 pagesEffects of Soldier-Ant Mound On The Strength of Lateritic Clay SoilsADEYEMI ADEBOJENo ratings yet

- Carbonate Aggregates as Concrete AlternativeDocument12 pagesCarbonate Aggregates as Concrete AlternativeElber Cuya PillacaNo ratings yet

- Irjet Soil Stabilization by Using Jute FDocument4 pagesIrjet Soil Stabilization by Using Jute FRithYNo ratings yet

- An Empirical Model For Predicting Hydraulic ConducDocument9 pagesAn Empirical Model For Predicting Hydraulic ConducFernando Andrés Ortega JiménezNo ratings yet

- UIPEPaperDocument18 pagesUIPEPaperomonaedwin2No ratings yet

- Stress-Strain Behaviour of Fine Grained Soils With Varying Sand ContentDocument9 pagesStress-Strain Behaviour of Fine Grained Soils With Varying Sand ContentAbdelmoez ElgarfNo ratings yet

- Geotechnical properties of weathered limestone for road constructionDocument7 pagesGeotechnical properties of weathered limestone for road constructionmayvel cortesNo ratings yet

- Kumar, M. Arun Kulanthaivel, P. Selvapraveen, S. Vinodhkumar, S. Naveenraj, VDocument8 pagesKumar, M. Arun Kulanthaivel, P. Selvapraveen, S. Vinodhkumar, S. Naveenraj, VBRUNO KARASIAKNo ratings yet

- Experimental Study On Sand Replacement by Termite Mound Soil GOWRIDocument33 pagesExperimental Study On Sand Replacement by Termite Mound Soil GOWRIVijayakumarNo ratings yet

- Bricks PDFDocument4 pagesBricks PDFM Sohaib AshfaqNo ratings yet

- Feasible Use of Recycled Concrete Aggregates and Crushed Clay Brick As Unbound Road Sub-Base PDFDocument8 pagesFeasible Use of Recycled Concrete Aggregates and Crushed Clay Brick As Unbound Road Sub-Base PDFpaulorossyfmNo ratings yet

- 1 s2.0 S2405844020303078 MainDocument8 pages1 s2.0 S2405844020303078 MainramaNo ratings yet

- Stabilization of weak subgrade soil using fly ash and rice husk ashDocument5 pagesStabilization of weak subgrade soil using fly ash and rice husk ashumi shakilaNo ratings yet

- CBR For Black Cottan Soil With Coconut Shells' PDFDocument4 pagesCBR For Black Cottan Soil With Coconut Shells' PDFAnbu GanesanNo ratings yet

- Bearing Capacity of Reinforced Pond Ash: Joyanta Maity, Bikash Chandra ChattopadhyayDocument4 pagesBearing Capacity of Reinforced Pond Ash: Joyanta Maity, Bikash Chandra ChattopadhyayerpublicationNo ratings yet

- Estimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine AggregateDocument5 pagesEstimating The Strength of Concrete Cube Using Copper Slag in The Replacement of Fine Aggregateshivanand hippargaNo ratings yet

- Materials Today: Proceedings: S. Andavan, Vamsi Krishna PagadalaDocument5 pagesMaterials Today: Proceedings: S. Andavan, Vamsi Krishna PagadalaAman SonkerNo ratings yet

- An Experimental Investigation On Properties of Concrete by Using Silica Fume and Glass Fibre As AdmixtureDocument4 pagesAn Experimental Investigation On Properties of Concrete by Using Silica Fume and Glass Fibre As AdmixturePattifer ReadeNo ratings yet

- Research of Slope Stability Analysis of Super High Dumping Site Based On Cellular AutomatonDocument6 pagesResearch of Slope Stability Analysis of Super High Dumping Site Based On Cellular AutomatonMuh FadhilNo ratings yet

- Research of Slope Stability Analysis of Super High Dumping Site Based On Cellular AutomatonDocument6 pagesResearch of Slope Stability Analysis of Super High Dumping Site Based On Cellular AutomatonMuh FadhilNo ratings yet

- CONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFDocument6 pagesCONFERENCE Direct Shear Strength Properties of Limestone-Blended PDFbagus yosan setiawanNo ratings yet

- Numerical Reasoning Test1 QuestionsDocument23 pagesNumerical Reasoning Test1 QuestionsSampe SitumorangNo ratings yet

- JCCC SLRDocument8 pagesJCCC SLRbagus yosan setiawanNo ratings yet

- ShapeDocument1 pageShapebagus yosan setiawanNo ratings yet

- Enhanced Oil Recovery - Latil.MDocument245 pagesEnhanced Oil Recovery - Latil.MOkewole Olayemi SamuelNo ratings yet

- Pengukuran Permeabilitas Relatif Dengan Reservoir FluidDocument5 pagesPengukuran Permeabilitas Relatif Dengan Reservoir Fluidbagus yosan setiawanNo ratings yet

- Paper ASP PetrofacDocument12 pagesPaper ASP Petrofacbagus yosan setiawanNo ratings yet

- New Frontiers in Directional Drilling: Latest Methods and TechnologiesDocument10 pagesNew Frontiers in Directional Drilling: Latest Methods and Technologiesbagus yosan setiawanNo ratings yet

- Gas ChannelingDocument9 pagesGas ChannelingNabajit BaruahNo ratings yet

- NOV Mono Rod Pump Systems PDFDocument12 pagesNOV Mono Rod Pump Systems PDFSIMON S. FLORES G.No ratings yet

- PB GeologyDocument116 pagesPB Geologybagus yosan setiawanNo ratings yet

- Dr. Amir Shafeeq: Associate ProfessorDocument9 pagesDr. Amir Shafeeq: Associate ProfessorMudasar RasheedNo ratings yet

- The Construction of Self-Made Freaks: Interviews with the Vampire WomanDocument68 pagesThe Construction of Self-Made Freaks: Interviews with the Vampire WomanAdriano LeoneNo ratings yet

- Answer Key - CK-12 Chapter 09 Algebra 1 Honors Concepts (Revised)Document9 pagesAnswer Key - CK-12 Chapter 09 Algebra 1 Honors Concepts (Revised)Anni LaritaNo ratings yet

- The Metaphorical StructureDocument12 pagesThe Metaphorical StructuredeeNo ratings yet

- Eltorai, Ibrahim M A Spotlight On The History of Ancient EgyptianDocument215 pagesEltorai, Ibrahim M A Spotlight On The History of Ancient EgyptianJonas PsontomfanceNo ratings yet

- HTTP WWW Red Bag Com Engineering Guides 251 BN Eg Ue204 Guide For The Preparation of Equipment Classification Lists For Pressure Vessel HTMLDocument13 pagesHTTP WWW Red Bag Com Engineering Guides 251 BN Eg Ue204 Guide For The Preparation of Equipment Classification Lists For Pressure Vessel HTMLmashudi_fikriNo ratings yet

- Plant Pathology Curriculum Revised for BSc, MSc and PhD DegreesDocument90 pagesPlant Pathology Curriculum Revised for BSc, MSc and PhD Degreesjahangir khanNo ratings yet

- Pervious ConcreteDocument4 pagesPervious ConcretesuwashNo ratings yet

- Linear RegressionDocument15 pagesLinear RegressionAnil Bera67% (3)

- Chemistry April 14 Reading Essentials - Properties of MatterDocument6 pagesChemistry April 14 Reading Essentials - Properties of MatterAljhon A. MarajuniNo ratings yet

- GSS Open RecruitmentDocument3 pagesGSS Open RecruitmentFazrie AkbarNo ratings yet

- 309 22-2S CS 136 Proj9 (Searches)Document2 pages309 22-2S CS 136 Proj9 (Searches)Qamar FarooqNo ratings yet

- MSCCH 504Document309 pagesMSCCH 504Harshal YadavNo ratings yet

- BG800 PPT IntroductionDocument25 pagesBG800 PPT IntroductionsegedNo ratings yet

- BQ3 - UnknownDocument3 pagesBQ3 - UnknownAnkitNo ratings yet

- YIELD STABILITYDocument7 pagesYIELD STABILITYgagaNo ratings yet

- Office Address: National Government Center EDSA, Diliman, Quezon City, Philippines Telephone Nos.: (02) 929-6071 To 78 Website: WWW - Nia.gov - PH Telefax No. (632) 928-9343 TIN No. 000-916-415Document2 pagesOffice Address: National Government Center EDSA, Diliman, Quezon City, Philippines Telephone Nos.: (02) 929-6071 To 78 Website: WWW - Nia.gov - PH Telefax No. (632) 928-9343 TIN No. 000-916-415IMEG MindanaoNo ratings yet

- A Review On Water Management Issues: Potential and Challenges in IndonesiaDocument15 pagesA Review On Water Management Issues: Potential and Challenges in IndonesiajameszulfanNo ratings yet

- Square PharmaceuticalsDocument2 pagesSquare PharmaceuticalsAl NomanNo ratings yet

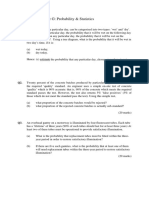

- Probability and Statistics ExamDocument4 pagesProbability and Statistics ExamLeul SolomonNo ratings yet

- Explains The Indicators For FitnessDocument7 pagesExplains The Indicators For FitnessCHITO PENJIE ODUYANo ratings yet

- Fed Question BankDocument5 pagesFed Question BankAnonymous eWMnRr70qNo ratings yet

- Short Circuit & Overload - Causes, Prevention & Ohm's LawDocument16 pagesShort Circuit & Overload - Causes, Prevention & Ohm's LawChristian DeanNo ratings yet

- WLP G10 Q1 W1 LithosphereFatalla PDFDocument4 pagesWLP G10 Q1 W1 LithosphereFatalla PDFJoanne TalingeNo ratings yet

- Pipeline and Piping RepairDocument18 pagesPipeline and Piping RepairkhoerulNo ratings yet

- Isoparaffins On Rtx-DHA-100 (ASTM D6729-14) : Conc. Peaks T (Min) (WT.%) Conc. Peaks T (Min) (WT.%)Document1 pageIsoparaffins On Rtx-DHA-100 (ASTM D6729-14) : Conc. Peaks T (Min) (WT.%) Conc. Peaks T (Min) (WT.%)ridermateNo ratings yet