Professional Documents

Culture Documents

Design of Concrete Structures Chapter 1: 1.2 Structural Forms

Uploaded by

jcvalenciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Concrete Structures Chapter 1: 1.2 Structural Forms

Uploaded by

jcvalenciaCopyright:

Available Formats

2 DESIGN OF CONCRETE STRUCTURES Chapter 1

To offset this limitation, it was found possible, in the second half of the nineteenth

century, to use steel with its high tensile strength to reinforce concrete, chiefly in those

places where its low tensile strength would limit the carrying capacity of the member.

The reinforcement, usually round steel rods with appropriate surface deformations

to provide interlocking, is placed in the forms in advance of the concrete. When

completely surrounded by the hardened concrete mass, it forms an integral part of the

member. The resulting combination of two materials, known as reinforced concrete,

combines many of the advantages of each: the relatively low cost, good weather and

fire resistance, good compressive strength, and excellent formability of concrete and

the high tensile strength and much greater ductility and toughness of steel. It is this

combination that allows the almost unlimited range of uses and possibilities of rein-

forced concrete in the construction of buildings, bridges, dams, tanks, reservoirs, and

a host of other structures.

It is possible to produce steels, at relatively low cost, whose yield strength is 3 to

4 times and more that of ordinary reinforcing steels. Likewise, it is possible to produce

concrete 4 to 5 times as strong in compression as the more ordinary concretes. These

high-strength materials offer many advantages, including smaller member cross sec-

tions, reduced dead load, and longer spans. However, there are limits to the strengths

of the constituent materials beyond which certain problems arise. To be sure, the

strength of such a member would increase roughly in proportion to those of the mate-

rials. However, the high strains that result from the high stresses that would otherwise

be permissible would lead to large deformations and consequently large deflections of

such members under ordinary loading conditions. Equally important, the large strains

in such high-strength reinforcing steel would induce large cracks in the surrounding

low tensile strength concrete, cracks that not only would be unsightly but also could

significantly reduce the durability of the structure. This limits the useful yield strength

of high-strength reinforcing steel to 100 ksi† according to many codes and specifica-

tions; 60 ksi steel is most commonly used.

Construction known as prestressed concrete, however, does use steels and con-

cretes of very high strength in combination. The steel, in the form of wires, strands,

or bars, is embedded in the concrete under high tension that is held in equilibrium by

compressive stresses in the concrete after hardening. Because of this precompression,

the concrete in a flexural member will crack on the tension side at a much larger load

than when not so precompressed. Prestressing greatly reduces both the deflections and

the tensile cracks at ordinary loads in such structures and thereby enables these high-

strength materials to be used effectively. Prestressed concrete has extended, to a very

significant extent, the range of spans of structural concrete and the types of structures

for which it is suited.

1.2 STRUCTURAL FORMS

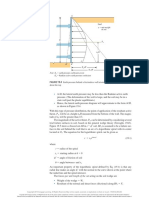

The figures that follow show some of the principal structural forms of reinforced con-

crete. Pertinent design methods for many of them are discussed later in this volume.

Floor support systems for buildings include the monolithic slab-and-beam floor

shown in Fig. 1.1, the one-way joist system of Fig. 1.2, and the flat plate floor, without

beams or girders, shown in Fig. 1.3. The flat slab floor of Fig. 1.4, frequently used for

more heavily loaded buildings such as warehouses, is similar to the flat plate floor,

but makes use of increased slab thickness in the vicinity of the columns, as well as

†Abbreviation for kips per square inch, or thousands of pounds per square inch.

You might also like

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Lec 3 CE 806 RCM Beams - Working Stress MethodDocument14 pagesLec 3 CE 806 RCM Beams - Working Stress MethodwasimkhaliqNo ratings yet

- Reinforcement C-WPS OfficeDocument7 pagesReinforcement C-WPS OfficeNoah Oluwatoyin AderiyikeNo ratings yet

- Arc 022 Building Technology 1: Department of ArchitectureDocument19 pagesArc 022 Building Technology 1: Department of ArchitectureLenard UsonNo ratings yet

- 09 - Chapter 1Document16 pages09 - Chapter 1pratik chauhanNo ratings yet

- Department of Civil Engineering: Presented byDocument13 pagesDepartment of Civil Engineering: Presented byavi boseNo ratings yet

- Properties of Reinforced Concrete: Chapter IntroductionDocument2 pagesProperties of Reinforced Concrete: Chapter Introductionatuhe DavisNo ratings yet

- Ce DesignDocument6 pagesCe DesignJhona PancitoNo ratings yet

- Journal Article - Comparison RCC - CompositeDocument6 pagesJournal Article - Comparison RCC - CompositeSri KayNo ratings yet

- DPSC Mod 1 IntroductionDocument12 pagesDPSC Mod 1 IntroductionKajalNo ratings yet

- Prestressed ConcreteDocument18 pagesPrestressed ConcreteLarete PaoloNo ratings yet

- Prestressed ConcreteDocument14 pagesPrestressed ConcreteMilenaNo ratings yet

- DocumentDocument1 pageDocumentSachin AbhiramNo ratings yet

- Prestressed Concrete: 2Nd Semester 2020-2021Document7 pagesPrestressed Concrete: 2Nd Semester 2020-2021Nino MontaNo ratings yet

- Study of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingDocument6 pagesStudy of Seismic and Wind Effect On Multi Storey R.C.C. Steel and Composite BuildingAkshay DobleNo ratings yet

- Te HWDocument2 pagesTe HWAngel RondillaNo ratings yet

- A Proposal For The Classi Cation of Structural Systems of Tall BuildingsDocument9 pagesA Proposal For The Classi Cation of Structural Systems of Tall BuildingsCivilEngClubNo ratings yet

- Libro de Reforzamiento HORMIGON ARMADO 2022-6Document25 pagesLibro de Reforzamiento HORMIGON ARMADO 2022-6David Magne MamaniNo ratings yet

- Composite ConstructionDocument4 pagesComposite ConstructionSAMSON, Dadajem C.No ratings yet

- R.C.C ReportDocument7 pagesR.C.C ReportNikita PandeyNo ratings yet

- Mechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteDocument8 pagesMechanical Properties of Steel Fiber Reinforced Self-Compacting ConcreteviolettaNo ratings yet

- Prestressed Concrete VS Reinforced ConcreteDocument15 pagesPrestressed Concrete VS Reinforced ConcreteJonathan ORotNo ratings yet

- Seismic Analysis of RCC and Composite StructuresDocument9 pagesSeismic Analysis of RCC and Composite Structuresvishnumani3011No ratings yet

- RC Notes by Engr. GREGDocument49 pagesRC Notes by Engr. GREGMichael SuanNo ratings yet

- RC Skeleton in Residential BuildingsDocument12 pagesRC Skeleton in Residential BuildingsMoHamed M. ScorpiNo ratings yet

- Acknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedDocument18 pagesAcknowledgement: M.R. Head of Civil Engineering Department, For Inspiring Take This Project. I Also ExpressedRicky RickxNo ratings yet

- RCD - PPT - Part 1Document32 pagesRCD - PPT - Part 1Christian Josh DomingoNo ratings yet

- Assign 1 & 2Document26 pagesAssign 1 & 2Rozhelle PedernalNo ratings yet

- 11assignment 3journal On Prestressed Concrete 2Document7 pages11assignment 3journal On Prestressed Concrete 2ARITRA CHAKRABORTYNo ratings yet

- Table 7d1.-U.S. Standard Reinforcing BarsDocument17 pagesTable 7d1.-U.S. Standard Reinforcing BarsHieu Huy NguyenNo ratings yet

- Pre-Stressed Concrete, LecDocument28 pagesPre-Stressed Concrete, LecWaqar AliNo ratings yet

- Prestressed Concrete 2Document18 pagesPrestressed Concrete 2Faizan rasoolNo ratings yet

- Remoreras - Module 3 ResearchDocument23 pagesRemoreras - Module 3 ResearchChristian RemorerasNo ratings yet

- Basis of Design & Analysis - 04Document102 pagesBasis of Design & Analysis - 04Ashraf Ali Hafeel AhamedNo ratings yet

- RCC2Document18 pagesRCC2Mangam RajkumarNo ratings yet

- TMT BarsDocument26 pagesTMT BarsPardeep KushwahaNo ratings yet

- RCC and SteelDocument12 pagesRCC and SteelSHAHID THAKURNo ratings yet

- R.C Hollow Beam Under Pure Torsion PDFDocument37 pagesR.C Hollow Beam Under Pure Torsion PDFsitehabNo ratings yet

- Chapter One IntrodutionDocument30 pagesChapter One Introdution123No ratings yet

- Prestressed ConcreteDocument2 pagesPrestressed ConcreteJianne Cabugsa LitohonNo ratings yet

- Chapter 01 - Principles of Reinforced Concrete PDFDocument9 pagesChapter 01 - Principles of Reinforced Concrete PDFVatsala PareekNo ratings yet

- 2 PDFDocument41 pages2 PDF123No ratings yet

- Introduction About Steel FiberDocument25 pagesIntroduction About Steel FiberVirupakshappa C Koti100% (4)

- Reinforced Concrete Part 1Document33 pagesReinforced Concrete Part 1Danica Mae AmicayNo ratings yet

- RC-I Chapter 1 PDFDocument14 pagesRC-I Chapter 1 PDFWendimu TolessaNo ratings yet

- Design of Reinforced Concrete Structures IDocument5 pagesDesign of Reinforced Concrete Structures IWissam NadirNo ratings yet

- Compare Studu PDFDocument5 pagesCompare Studu PDFdarsu NaikNo ratings yet

- 1 s2.0 S2352012419301985 MainDocument13 pages1 s2.0 S2352012419301985 MainSaidronaNo ratings yet

- Paperworks RCDDocument15 pagesPaperworks RCDjohn rey toledoNo ratings yet

- C StructuralRehab BlackDocument3 pagesC StructuralRehab Blackimde2No ratings yet

- Retrofit Group StudyDocument30 pagesRetrofit Group StudyDivith B SannakkiNo ratings yet

- DR KP-JayaDocument7 pagesDR KP-JayaRiyaz SiddiqueNo ratings yet

- Prestressed Concrete: Name: Sajitha. H Roll. No: 19AR44 Subject: BMC IV College: SVS SOADocument12 pagesPrestressed Concrete: Name: Sajitha. H Roll. No: 19AR44 Subject: BMC IV College: SVS SOASajithaNo ratings yet

- Introduction To Reinforced Concrete Design Part 1Document6 pagesIntroduction To Reinforced Concrete Design Part 1jhess QuevadaNo ratings yet

- Chapter 1 IntroductionDocument10 pagesChapter 1 Introductionzeru3261172No ratings yet

- CE 552 Lecture 1Document31 pagesCE 552 Lecture 1Aljon Maglalang JimenezNo ratings yet

- Unit-I (Introduction & Methods of Prestressing)Document10 pagesUnit-I (Introduction & Methods of Prestressing)Sasi HoneyNo ratings yet

- Build 141 Bracing Supplement 7Document1 pageBuild 141 Bracing Supplement 7jcvalenciaNo ratings yet

- Phone 03 526 7436Document1 pagePhone 03 526 7436jcvalenciaNo ratings yet

- Build 141 Bracing Supplement 11Document1 pageBuild 141 Bracing Supplement 11jcvalenciaNo ratings yet

- Build 141 Bracing Supplement 12Document1 pageBuild 141 Bracing Supplement 12jcvalenciaNo ratings yet

- Build 141 Bracing Supplement 10Document1 pageBuild 141 Bracing Supplement 10jcvalenciaNo ratings yet

- 5 Lateral Resistance:) Luwk5Le5DiwDocument1 page5 Lateral Resistance:) Luwk5Le5DiwjcvalenciaNo ratings yet

- Visual/Appearance A H5/ H3.2 KD Posts: PLP - Prolam PostDocument1 pageVisual/Appearance A H5/ H3.2 KD Posts: PLP - Prolam PostjcvalenciaNo ratings yet

- PLVL - Prolam Visual Lintel PL8, PL12, PL17 H3.2KD: Visual/Appearance A Beams 88mmDocument1 pagePLVL - Prolam Visual Lintel PL8, PL12, PL17 H3.2KD: Visual/Appearance A Beams 88mmjcvalenciaNo ratings yet

- 4.4 Internal Ribs (Load Bearing) Width and Reinforcement: Figure 4 Typical Ribraft PlanDocument1 page4.4 Internal Ribs (Load Bearing) Width and Reinforcement: Figure 4 Typical Ribraft PlanjcvalenciaNo ratings yet

- Visual Posts: Stock Lengths: Grade: Structural Grade: Treatment: FinishesDocument1 pageVisual Posts: Stock Lengths: Grade: Structural Grade: Treatment: FinishesjcvalenciaNo ratings yet

- The Suites Sonata Premier East Gallery PlaceDocument1 pageThe Suites Sonata Premier East Gallery PlacejcvalenciaNo ratings yet

- 5 PDFDocument1 page5 PDFjcvalenciaNo ratings yet

- Structural: Timber Guide 2017Document1 pageStructural: Timber Guide 2017jcvalenciaNo ratings yet

- Seismic Design of Tall Buildings"Document1 pageSeismic Design of Tall Buildings"jcvalenciaNo ratings yet

- Source: 2017 LATBSDCDocument1 pageSource: 2017 LATBSDCjcvalenciaNo ratings yet

- 3 PDFDocument1 page3 PDFjcvalenciaNo ratings yet

- Started The Application of Energy-Dissipating Devices Such As BrbsDocument1 pageStarted The Application of Energy-Dissipating Devices Such As BrbsjcvalenciaNo ratings yet

- Glossary: (Refer Also To AS/NZS 3845 Part 1 2015 and Part 2 2017)Document1 pageGlossary: (Refer Also To AS/NZS 3845 Part 1 2015 and Part 2 2017)jcvalenciaNo ratings yet

- Nonlinear Structural Analysis: Shabir TalpurDocument1 pageNonlinear Structural Analysis: Shabir TalpurjcvalenciaNo ratings yet

- Steel Post Thrie-Beam Guardrail (Modified Blockout) (Sgr09B)Document1 pageSteel Post Thrie-Beam Guardrail (Modified Blockout) (Sgr09B)jcvalenciaNo ratings yet

- Strong-Post W-Beam Guardrail (Sgr04B) : Semi-Rigid Roadside & Median BarriersDocument1 pageStrong-Post W-Beam Guardrail (Sgr04B) : Semi-Rigid Roadside & Median BarriersjcvalenciaNo ratings yet

- Strongpost W-Beam Double-Sided Guardrail (Sgm04B) : Open Source - No Specific Supplier TL3. NCHRP-350 TL-3Document1 pageStrongpost W-Beam Double-Sided Guardrail (Sgm04B) : Open Source - No Specific Supplier TL3. NCHRP-350 TL-3jcvalenciaNo ratings yet

- Principles - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 844 PDFDocument1 pagePrinciples - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 844 PDFjcvalenciaNo ratings yet

- 5 PDFDocument1 page5 PDFjcvalenciaNo ratings yet

- Principles - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 845 PDFDocument1 pagePrinciples - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 845 PDFjcvalencia0% (1)

- Principles - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 843 PDFDocument1 pagePrinciples - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 843 PDFjcvalenciaNo ratings yet

- Principles - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 842 PDFDocument1 pagePrinciples - Of.Foundation - Engineering. - 9th - Ed - Braja.M.Das 842 PDFjcvalenciaNo ratings yet

- ABANTI COLOUR TEX LTD. (NEW BUILDINGS) Structural Full 16092019Document107 pagesABANTI COLOUR TEX LTD. (NEW BUILDINGS) Structural Full 16092019ABDUL JABBERNo ratings yet

- SJI 1st Edition Composite Steel Joists FinalDocument235 pagesSJI 1st Edition Composite Steel Joists FinalRaul Mauricio RodriguezNo ratings yet

- NZS 3101-2006 Example 001Document8 pagesNZS 3101-2006 Example 001RMM100% (1)

- Software Verification: EXAMPLE Eurocode 2-04 PT-SL-001Document7 pagesSoftware Verification: EXAMPLE Eurocode 2-04 PT-SL-001võ hoàng thái100% (1)

- Fiber Reinforced Concrete Lif Takviyeli BetonDocument70 pagesFiber Reinforced Concrete Lif Takviyeli BetonaygunbayramNo ratings yet

- Cement: Nilanjan MitraDocument25 pagesCement: Nilanjan MitrassriramiitNo ratings yet

- Jib Crane Example ProblemDocument7 pagesJib Crane Example Problemearthboy2u100% (1)

- 6.6.5 TRUSSES: 6.6.5.1 Steel Truss ConstructionDocument3 pages6.6.5 TRUSSES: 6.6.5.1 Steel Truss ConstructionMalith De SilvaNo ratings yet

- Method of Statement For Foundation of P5, P11 69kvDocument8 pagesMethod of Statement For Foundation of P5, P11 69kvTwin Bulls100% (2)

- DDMDocument47 pagesDDMTezinNo ratings yet

- 107 1 NTU SDS 14 1 Damping Modification For Spectrum Lap Loi ChungDocument43 pages107 1 NTU SDS 14 1 Damping Modification For Spectrum Lap Loi Chung陳俊鴻No ratings yet

- Cast-In Place ConcreteDocument217 pagesCast-In Place ConcreteFarid ObandoNo ratings yet

- Complete Staging Design For 3.0m SpanDocument22 pagesComplete Staging Design For 3.0m SpanHegdeVenugopal100% (4)

- Compressive Strength of OPC: Types of Cement 3 Days 7 Days 28 DaysDocument13 pagesCompressive Strength of OPC: Types of Cement 3 Days 7 Days 28 DaysAsghar Hussain Shah S/o Zubair Shah MS Engg. Management (Swat Campus)No ratings yet

- 3 Lateral Load DistributionDocument81 pages3 Lateral Load DistributionHit PopatNo ratings yet

- 3 2 9 A SizingspreadfootingDocument2 pages3 2 9 A Sizingspreadfootingapi-3839152030% (1)

- Three-Dimensional Response of Neighboring Buildings Sitting On Pile Foundations To Seismic PoundingDocument25 pagesThree-Dimensional Response of Neighboring Buildings Sitting On Pile Foundations To Seismic PoundingDebabrata PodderNo ratings yet

- Concrete Components Reference PDFDocument750 pagesConcrete Components Reference PDFPanha MenhNo ratings yet

- Boundary WallDocument1 pageBoundary WallgohilnarendraNo ratings yet

- Preliminary Structural DesignDocument8 pagesPreliminary Structural Designaikaless100% (1)

- Bs CRACKWIDTH CALCULATIONDocument4 pagesBs CRACKWIDTH CALCULATIONDeepthi Kotian100% (1)

- Plastic HingesDocument10 pagesPlastic HingesBala SubramanianNo ratings yet

- UNITENICCBT08 Mix Designof Styrofoam ConcreteDocument13 pagesUNITENICCBT08 Mix Designof Styrofoam ConcreteDoge IronyNo ratings yet

- ASTM C11-15a Standard Terminology Relating To Gypsum and Related Building Materials and SystemsDocument6 pagesASTM C11-15a Standard Terminology Relating To Gypsum and Related Building Materials and SystemsJesus Prado100% (1)

- Design of Bending MembersDocument21 pagesDesign of Bending MembersChico AlvesNo ratings yet

- Unit Weight of Tile With MortarDocument4 pagesUnit Weight of Tile With MortarzcvzxNo ratings yet

- Prestressed Precast Concrete Beam Bridge DesignDocument346 pagesPrestressed Precast Concrete Beam Bridge Designaleitaosilva100% (2)

- รายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4Document21 pagesรายการคำนวณวิศวกรรมโครงส้ราง แบบที่ 4jackcoolsNo ratings yet

- 115-Eurocode Design - Cantilever DeflectionDocument1 page115-Eurocode Design - Cantilever Deflectionrodriguez.gaytanNo ratings yet

- Protastructure 2018 Whats New PDFDocument57 pagesProtastructure 2018 Whats New PDFDokan groupNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!From EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Rating: 4 out of 5 stars4/5 (3)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- A Welder’s Handbook to Robotic ProgrammingFrom EverandA Welder’s Handbook to Robotic ProgrammingRating: 5 out of 5 stars5/5 (3)

- Structural Cross Sections: Analysis and DesignFrom EverandStructural Cross Sections: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (19)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.From EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Rating: 4 out of 5 stars4/5 (5)

- Practical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)From EverandPractical Robotics in C++: Build and Program Real Autonomous Robots Using Raspberry Pi (English Edition)No ratings yet

- Artificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsFrom EverandArtificial Intelligence: Learning about Chatbots, Robotics, and Other Business ApplicationsRating: 5 out of 5 stars5/5 (3)

- Earthquake-Resistant Structures: Design, Build, and RetrofitFrom EverandEarthquake-Resistant Structures: Design, Build, and RetrofitRating: 4.5 out of 5 stars4.5/5 (8)

- SAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildFrom EverandSAM: One Robot, a Dozen Engineers, and the Race to Revolutionize the Way We BuildRating: 5 out of 5 stars5/5 (5)