Professional Documents

Culture Documents

What Happens To Bolt Tension in Large Joints

Uploaded by

David C HouserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Happens To Bolt Tension in Large Joints

Uploaded by

David C HouserCopyright:

Available Formats

Fritz Laboratory Reprint No.

286

WHAT HAPPENS

TO BOLT TENSION

IN LARGE JOINTS?

br

James J. Wallaerf

Gordon H. Sterling

John W. Fisher

Reprinted from FASTENERS, Volume 20, Number 3, 1965

Published by the INDUSTRIAL FASTENERS INSTITUTE

1517 Terminal Tower, Cleveland, Ohio 44113

What Happens to Bolt Tension

in Large Joints?

by JAMES J. WALLAERT,

Dravo Corp., Pittsburgh, Pa.; formerly, Research Asst.,

Fritz Engrg. Lab., Lehigh Univ., Bethlehem, Pa.

GORDON H. STERLING,

Research Asst., Fritz Engrg. Lab., Lehigh Univ.,

Bethlehem, Pa.

and JOHN W. FISHER,

Research Assistant Professor of Civil Engineering,

Fritz Engrg. Lab., Lehigh Univ., Bethlehem, Pa.

ABSTRACT INTRODUCTION

An experimental study was made of the changes Initial clamping force has no significant effect on

in bolt tension in high-strength A325 and A490 bolts the shear strength of rivets(1). Yielding of the rivet

connecting A440 (high-strength) and A514 (con- apparently reduces the clamping force and the shear

structional alloy) steel joints. Until major slip strength is unaffected. An investigation of the shear

occurred in the large bolted joints, high-strength strength of single bolts showed that the initial bolt

steel bolts lost little initial tension. The loss was tension had no appreciable effect on the shear

due to plate contraction caused by the Poisson effect. strength of A325 and A490 high-strength bolts@).

After major slip, the bolts came into bearing and However, little is known about the variation of

the variations in bolt tension became more pro- internal tension in bolts connecting large joints sub-

nounced. For bolts with a 4-in. grip, bolt tepsion jected to static tensile loads, particularly near the

I

decreased with an increase in joint load beyond the ultimate strength of the joint. The agreement be-

I slip load. As the joint load approached its ultimate tween predicted joint strengths and test results of

value, however, the bolts at the lap plate end began large joints was good when it was assumed that the

to show an increase in tension. This was brought load transfer was by bearing and shear(3).This also

about by the outward prying action of the lap suggested that bolt clamping was negligible at

plate. These results showed that the load trans- ultimate loads since frictional forces were negligible:

ferred by friction at the ultimate joint strength Several investigators have measured changes in

was negligible. bolt tension until slip occurs. Reference (4) reported

For bolts with an 8-in. grip, bolt tension increased tests of several small bolted butt splices connected

as the joint was loaded beyond the slip load. This by %-in. high-strength bolts and showed that the

increase, caused by bending of the bolts, indicated measured decrease in bolt tension varied directly

that some load was being transferred by frictional

resistance within the joint. However, because of the (1) Munse, W. H., and Cox, H. L., THE STATIC STRENGTH OF

RIVETS SUBJECTED TO COMBINED TENSION AND SHEAR,

lap plate prying phenomenon, there was a clear University of Illinois Enaineerina - E x. ~ e r i m e n Station

t Bulletin

No. 437, becember, 1956.

separation of the faying surfaces near the joint end. (2) Wallaert, J. J., and Fisher, J. W., SHEAR STRENGTH OF HIGH

Therefore, the bolt tension was not indicative of the STRENGTH BOLTS, Journal of t h e Structural Division, ASCE,

Vol. 91, ST3, 1965.

normal force acting on the faying surface. (3) Fisher, J. W., and Rumpf, J. L., ANALYSIS OF BOLTED BUTT

For all joints, the bolts a t the lap plate ends JOINTS, Journal of t h e Structural'Division, ASCE, Vol. 91,

ST5, 1965.

(under a higher combined shear and tension loading (4) Lenzen. K. H., THE EFFECT OF VARIOUS FASTENERS ON

than the bolts a t the main plate end) were usually THE FATIGUE STRENGTH OF A STRUCTURAL JOINT, Pro-

ceedings of t h e Association of American Railroads, Vol. 51,

the f i s t to fail. 1950.

This work was carried out as part of t h e Large Bolted Connections

Project sponsored financially by t h e Pennsylvania Department of

Highways, t h e Department of Commerce-Bureau of Public Roads,

t h e American Institute of Steel Construction, and t h e Research

Council on Riveted a n d Bolted Structural Joints.

Fig, 1-Strain Gage Instrumentation

on the Bolt Shank

?

with an increase of joint tensile load until major slip two 1-in. plates were bolted to each side of the main i

occurred. I t was apparent that the Poisson effect plate to form the butt splice.

was the principal cause of the change in bolt tension. Each of the five remaining joints had a nominal

The tension changes were determined from mea- thickness of 4 inches (two 1-in. plates for the main

sured changes in strain recorded by strain gages plate section with one 1-in. lap plate on each side).

attached to the bolt shank. One test of a single Load was applied to the joint continuously until

bolt specimen showed a decrease in the clamping major slip occurred. At increments of 50 to 100 kips

force of 7% up to slip, while a 9 bolt specimen the loading was momentarily stopped until all dials

showed a decrease of about 13%. and gages could be read. At these loads, the change

During recent studies of the coefficient of friction, in bolt strain indicated by the SR-4 strain gages was

the bolt tension was measured with the aid of strain recorded. Beyond the slip load of the joint the strain

gages attached to the bolt shank(5). The measured gage recordings were taken in the same manner. I

changes in bolt tension corresponded closely with Electric resistance strain gages were attached to

the computed values based on the Poisson effect. the bolt shanks in the manner shown in Fig. 1.Small

The purpose of the investigation described in this areas approximately % in. long and x6

in. deep

article was to measure the internal bolt tension as were milled just under the bolt head to provide a flat

load was applied to large connections to further surface on which to mount the gages. These milled

confirm that frictional load transfer was negligible areas did not extend into the shear planes. The

as the ultimate strength was approached. bolts were installed in the test joints with the gages

DESCRIPTION OF TEST SPECIMENS

oriented toward the joint edges as indicated in Table

A N D PROCEDURES 1,in order to minimize the effect of bolt bending.

Table 1 shows the types of butt splice joints Each bolt was calibrated in order to relate the

which were tested and the locations within the joints strain readings taken on the SR-4 gages to bolt

of the bolts where strain gages were attached. tension. A typical calibration curve is shown in

Joints El63 and El64 each had a nominal thick- Fig. 2a, which shows the elongation of the whole

ness of 8 inches. The main plate was formed by bolt as measured by a 1/10,000 in. dial gage.

four 1-in. thick plates. Lap plates consisting of Fig. 2b shows the strain readings recorded from the

SR-4 gages. Each gaged bolt was installed in the

test joints with an initial tension just slightly above

its proof load.

Additional details of the joint tests are given

in Reference (6).

TEST RESULTS A N D A N A L Y S I S

Variations of the internal bolt tension with joint

load in typical joints are shown in Figs. 3, 4, 5.

The change in bolt tension was determined from

. , Chiana. K. C.. and Vasarhelvi. D. D.. THE COEFFICIENT OF

(5)

FRICT~ONI N BOLTED J O I N T ~ ' M A D E ' W I T HVARIOUS STEELS

AND WlTH MULTIPLE CONTACT SURFACES, Thirteenth

Report o n Bolted Joints, University of Washington, 1964.

(6) Fisher, J. W., Rarnseier, P. O., and Beedie, L. S., STRENGTH

OF A440 STEEL JOINTS FASTENED WlTH A325 BOLTS,

Publications, IABSE, Vol. 23. 1963.

Bolts with SR-4 Strain Gagas

increase in bolt tension in joint El63 was probably

due to the catenary effect resulting from bending in

the long bolts. Apparently, the shorter bolts show

a decrease in tension because the catenary effect is

not present and the sudden impact a t slip causes a

relaxation of clamping force.

Behavior After Slip

Three separate and distinct behavior patterns

were noted in the variations in bolt tension after

major slip. Two are illustrated in Fig. 4. As load

was applied to the joint after major slip, several of

the bolts in the interior of the joints indicated an

increase in tension. Visual observations of the plate

edges indicated a relative movement of the indi-

vidual plates which would cause the bolt to assume

a curved shape. Thus, as load was increased on the

joint, tension was introduced into the bolts by their

catenary action. In addition, inelastic deformations

due to bearing and yielding of the A440 steel plate

caused a prying action which tended to move the

lap plate outward from the main plate. This action

was responsible for a further increase in the tensile

load of bolts near the lap plate end of the joint.

This outward movement of the lap plate with re-

spect to the main plate extended some distance from

the lap plate end. In joint El63 just prior to joint

failure, for example, it was possible to insert an

ordinary sheet of paper between the lap plate and

the main plate down to the third bolt row. The

separation at the first bolt row was about %-in.

Figure 6 is a sawed section of a portion of a joint

after failure. I t is visually evident that tension is

the measured changes in bolt strain and the calibra- being introduced into the long bolts because of the

tion curves. In some cases, the internal bolt tension catenary effect. (continued)

increased beyond the yield strength. In these in-

stances, the bolt load was determined from the Fig. 6-Bending of Long Bolts

load-strain relationship of the direct tension tests

of the particular bolt lot.

Behavior up to Major Slip

The test results plotted in Figs. 3, 4, and 5 show

that the bolt tension, as expected, had decreased

from 1 % to 8% a t major slip due to the Poisson

effect.

In most joints, major slip occurred suddenly and

all bolts throughout the joint came into complete

bearing. Joint slip caused a drop in load acting on

the joint due to the sudden deformation. This is

readily apparent in Figs. 3, 4, and 5. After slip the

long (8-in.) bolts showed an increase in load, as

shown in Fig. 4 for joint E163. Joints with 4-in.

grips showed a decrease in bolt tension after major

slip. This is clearly shown in Figs. 3 and 5. The

Figure 3 shows the behavior of the short bolts the load partition. The maximum variations between

(4-in. grip) tested in A440 steel joints. As the joint the predicted loads neglecting friction and tests

was loaded beyond slip, bolt tensions dropped con- were about 4 % ( 3 ) .

tinuously in all fasteners until the ultimate load was

CONCLUSIONS

approached. Near the ultimate load, considerable

lap plate prying action was present causing the bolts 1. Until inelastic deformations occur in the fasteners,

near the lap plate end to show an increase in tension the change in bolt tension was caused by the Poisson

(Bolt 1 in Fig. 3). The interior bolts in joints E721, effect. This caused a decrease in bolt tension of

E741, and K42d all showed a continual decrease in 1to 8% until major slip.

tension with joint load and no catenary action

2. In constructional alloy steel (A514) joints, the

was noted.

internal tension in A325 and A490 bolts decreased

The third type of behavior is illustrated in Fig. 5

continually with increasing joint load. At failure no

for joint J42b, A514 steel plates connected by A490

clamping force remained.

bolts. Joints J42b and J42c were proportioned so

that small inelastic deformations had occurred in 3. In A440 steel joints, the bolt tension usually

the plate material at the ultimate joint load. Con- decreased until the lap plates yielded and intro-

sequently, there was practically no lap plate prying duced prying or the catenary effect. This caused

and bolt tension decreased continually with joint additional tension to be induced into the bolt. This

load until failure occurred (Fig. 5). The sawed did not affect the joint behavior because the faying

section of joint J42b confirmed that little if any surfaces were not in contact near the end fasteners.

prying or catenary effects were present.

In any symmetrical butt splice, the fasteners at 4. The load carried by friction on the faying sur-

each end carry approximately equal loads in shear. faces of joints was negligible near ultimate load.

Consequently, one would expect that failure in a Hence, the bolts were transmitting most of the

joint would be precipitated by failure of one of the applied load by bearing and shear as the ultimate

end fasteners. Many tests have shown that the bolts strength of the joint was approached.

at the lap plate end of long joints are usually the 5. These tests also confirm that initial bolt tension

first to unbutton. Figures 3 and 4 show that the has a negligible influence on the shear strength of

prying action produces a large tensile component in the bolts.

the row of bolts a t the end of the lap plates. Since

these bolts are usually under a more severe combined ACKNOWLEDGEMENTS

shear and tensile condition than the bolts at the The work described in this paper is part of an

main plate end, the failure mode of long joints investigation of large bolted connections being con-

described above is logical. ducted a t Fritz Engineering Laboratory, Depart-

ment of Civil Engineering, Lehigh University. Pro-

Load Carried by Friction fessor W. J. Eney is head of the Department and

For the joints with short bolts, it was obvious Laboratory. Dr. L. S. Beedle is director of the

that near ultimate the load carried by friction was Laboratory. The project is sponsored financially by

negligible. As ultimate load was approached, the the Pennsylvania Department of Highways, the

bolts near the lap plate ends of A440 steel joints Department of Commerce-Bureau of Public Roads,

indicated an increase in tension. This was caused and the American Institute of Steel Construction.

by the prying of the lap plate away from the main Technical guidance is provided by the Research

plate. Council on Riveted and Bolted Structural Joints.

In joints with long bolts, there was some load Messrs. R. J. Christopher, P. 0. Ramseier, and

transfer by friction in the joint interior because R. Kormanik assisted with the tests. Mr. W. Digel

considerable internal tension remained. However, reviewed the manuscript. Thanks are also given to

because of lap plate prying, the behavior of the Miss Rosalie Fischer for typing the manuscript; to

joint near its end was not affected by frictional Mr. R. Sopko and his staff for preparation of the

forces. Tests have indicated that the load carried Figures and photography; and to Mr. K. R. Harpel

by friction near the main plate end of the joint and and the staff of technicians a t Fritz Laboratory for

in the joint interior had only a small influence on their help in the actual test work.

You might also like

- The Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingFrom EverandThe Mechanical Properties of Wood: Including a Discussion of the Factors Affecting the Mechanical Properties, and Methods of Timber TestingNo ratings yet

- Strength of Materials: An Introduction to the Analysis of Stress and StrainFrom EverandStrength of Materials: An Introduction to the Analysis of Stress and StrainRating: 5 out of 5 stars5/5 (1)

- 10 1 1 875 5824 PDFDocument33 pages10 1 1 875 5824 PDFحمودي معزNo ratings yet

- The Anchorage Bend in The Begg TechniqueDocument7 pagesThe Anchorage Bend in The Begg TechniqueSyed Mohammad Osama AhsanNo ratings yet

- Zhu Yang Capacity Steel CHS Xjoints Strengthened With External Stiffening Rings 2017 9Document9 pagesZhu Yang Capacity Steel CHS Xjoints Strengthened With External Stiffening Rings 2017 9thomas rojasNo ratings yet

- The Distribution of Load and Stress in The Threads of Fasteners - A ReviewDocument20 pagesThe Distribution of Load and Stress in The Threads of Fasteners - A ReviewFernando FuentesNo ratings yet

- Zhu Han Experimental Study The Axial Compressive Strength CHS Tjoints Reinforced With Stiffening Rings 2016 7Document7 pagesZhu Han Experimental Study The Axial Compressive Strength CHS Tjoints Reinforced With Stiffening Rings 2016 7thomas rojasNo ratings yet

- Design and Behavior of Gusset Plate Connections: ArticleDocument12 pagesDesign and Behavior of Gusset Plate Connections: ArticleLiewKianHongNo ratings yet

- Effect of End Blocks On Anchorage Zone Stresses in Prestressed Concrete GirdersDocument15 pagesEffect of End Blocks On Anchorage Zone Stresses in Prestressed Concrete Girdersrohit kumarNo ratings yet

- Caracteristicas de Fuerzas de Resortes AbiertosDocument4 pagesCaracteristicas de Fuerzas de Resortes Abiertosandres marencoNo ratings yet

- (Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFDocument64 pages(Allan, R.N., & J.W. Fisher.,1967) - Behavior of Bolted Joints With Oversize or Slotted Holes PDFchristos032100% (2)

- Design and Behavior of Gusset Plate Connections PDFDocument12 pagesDesign and Behavior of Gusset Plate Connections PDFAnkit GuptaNo ratings yet

- Design and Behavior of Gusset Plate Connections PDFDocument12 pagesDesign and Behavior of Gusset Plate Connections PDFAnkit GuptaNo ratings yet

- Reinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake LoadingDocument20 pagesReinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake LoadingSidharth MahajanNo ratings yet

- 1-s2.0-S0263823116300167-Jonathan D Glassman Plate Buckling 2016Document39 pages1-s2.0-S0263823116300167-Jonathan D Glassman Plate Buckling 2016NaubaNo ratings yet

- Chatterjee S 1978 PHD Thesis PDFDocument351 pagesChatterjee S 1978 PHD Thesis PDFRahul OjhaNo ratings yet

- Strength of A440 Steel Joints Connected With A325 Bolts PublicatDocument52 pagesStrength of A440 Steel Joints Connected With A325 Bolts Publicathal9000_mark1No ratings yet

- An Investigation Into The Mechanism of Orbital Blowout FracturesDocument6 pagesAn Investigation Into The Mechanism of Orbital Blowout FracturesHải Ngọc Đinh VũNo ratings yet

- Gusset Plate AnalysisDocument12 pagesGusset Plate AnalysisAnonymous f068hbNo ratings yet

- Effects of Deviators and Tendon Configuration On Behavior of Externally Prestressed BeamsDocument9 pagesEffects of Deviators and Tendon Configuration On Behavior of Externally Prestressed BeamspicottNo ratings yet

- Stresses in Deep Beams.Document122 pagesStresses in Deep Beams.akash kumarNo ratings yet

- Stress Characteristics and Fatigue Crack Behaviour of The Longitudinal Rib-to-Cross Beam Joints in An Orthotropic Steel DeckDocument10 pagesStress Characteristics and Fatigue Crack Behaviour of The Longitudinal Rib-to-Cross Beam Joints in An Orthotropic Steel Deckjuan carlos molano toroNo ratings yet

- Using Moment and Axial Interaction Equations To Account For Moment and Shear Lag Effects in Tension MembersDocument9 pagesUsing Moment and Axial Interaction Equations To Account For Moment and Shear Lag Effects in Tension MembersSergioAlcantaraNo ratings yet

- Buckling of Thin Metal Shells 167Document1 pageBuckling of Thin Metal Shells 167pawkomNo ratings yet

- On Force and Tooth Movement PDFDocument14 pagesOn Force and Tooth Movement PDFSelvaNo ratings yet

- ARTIGO Critical Pressure Conditions in Silos-ROTTERDocument7 pagesARTIGO Critical Pressure Conditions in Silos-ROTTERlucasNo ratings yet

- Fatigue Crack Propagation in Steel: Low Cycle Fatigue Behavior of JoinedDocument44 pagesFatigue Crack Propagation in Steel: Low Cycle Fatigue Behavior of JoinedGerard Piedra GarcíaNo ratings yet

- Asymmetric Headgear 2Document5 pagesAsymmetric Headgear 2Ali HmoudNo ratings yet

- Holst 2000Document18 pagesHolst 2000Thiago Lins CostaNo ratings yet

- Fracture Gradient PaperDocument7 pagesFracture Gradient Paperlulut falaNo ratings yet

- Shear Strength of Stud Connectors in Lightweight and Normal-Weight ConcreteDocument13 pagesShear Strength of Stud Connectors in Lightweight and Normal-Weight Concretefs jiNo ratings yet

- Test Unit Preparation: Fig. 5 - Posítions Oí Electrícal Resístance Straín Gages For 8-And 12-Bar UnítsDocument1 pageTest Unit Preparation: Fig. 5 - Posítions Oí Electrícal Resístance Straín Gages For 8-And 12-Bar UnítsRonal J Clavijo RNo ratings yet

- Fatigue Strength of Steel Members With Welded DetailsDocument12 pagesFatigue Strength of Steel Members With Welded DetailsDhilip KumarNo ratings yet

- Punching Shear Strength of Reinforced Concrete Column Footings Under Eccentric Compression: Experiment and AnalysisDocument2 pagesPunching Shear Strength of Reinforced Concrete Column Footings Under Eccentric Compression: Experiment and AnalysisHà Nguyễn Thành TháiNo ratings yet

- 85 s26Document8 pages85 s26Eltigani HamadNo ratings yet

- What Is The Term Used in The Construction Industry To Mitigate TheDocument3 pagesWhat Is The Term Used in The Construction Industry To Mitigate TheEliza Mae AquinoNo ratings yet

- Flexural Cracks in Reinforced Concrete Beams : by Michael Chit Arthur F. KirsteintDocument14 pagesFlexural Cracks in Reinforced Concrete Beams : by Michael Chit Arthur F. KirsteintRahil QureshiNo ratings yet

- Design of Tension Circular Flange Joints in Tubular StructuresDocument9 pagesDesign of Tension Circular Flange Joints in Tubular StructuresAnonymous tmRaHhNo ratings yet

- J49-2010-ASCE JGEE Nonlinear Efficiency Pile GroupDocument14 pagesJ49-2010-ASCE JGEE Nonlinear Efficiency Pile Groupsadiaajmal09No ratings yet

- Shear Strength of High-Strength BoltsDocument61 pagesShear Strength of High-Strength Boltsloox600No ratings yet

- Artículo Falla en Juntas Viga ColumnaDocument10 pagesArtículo Falla en Juntas Viga ColumnaZachary WootenNo ratings yet

- Fracture Mechanics of Through-Crack Cylindrical Pressure VesselsDocument35 pagesFracture Mechanics of Through-Crack Cylindrical Pressure Vesselsbfred_4No ratings yet

- Siegel Et Al 2014 Neutral Plane Method For Drag Force of Deep Foundations and The AASHTO LRFD Bridge Design SpecificatiDocument10 pagesSiegel Et Al 2014 Neutral Plane Method For Drag Force of Deep Foundations and The AASHTO LRFD Bridge Design SpecificatirotkviceNo ratings yet

- Load Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementDocument29 pagesLoad Distribution Along Fully Grouted Bolts With Emphasis On Cable Bolt ReinforcementCyrillus Arthur SaputraNo ratings yet

- Strength of Joints That Combine Bolts and WeldsDocument10 pagesStrength of Joints That Combine Bolts and WeldsDhimas Surya NegaraNo ratings yet

- Gusset PlatesDocument11 pagesGusset PlatesJoseph Cristhian Lipa FloresNo ratings yet

- Design and Behavior of Gusset Plate ConnectionsDocument11 pagesDesign and Behavior of Gusset Plate ConnectionsEmil ParangueNo ratings yet

- Reinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake Loading PDFDocument20 pagesReinforced Concrete Edge Beam-Column-Slab Connections Subjected To Earthquake Loading PDFPrabu RengarajanNo ratings yet

- On The Perturbation and Break Up of A Highspeed, Elongating Metal JetDocument9 pagesOn The Perturbation and Break Up of A Highspeed, Elongating Metal JetSantosh IngoleNo ratings yet

- Stiffness of Screw-Reinforced LVL in Compression Perpendicular To The GrainDocument13 pagesStiffness of Screw-Reinforced LVL in Compression Perpendicular To The GrainUlrich HübnerNo ratings yet

- Elastic Stresses in Single Mitred BendsDocument22 pagesElastic Stresses in Single Mitred BendsWang Kin HuiNo ratings yet

- Vibration Analysis of Two Wheeler Connecting Rod: Yeshwant Rao, B S Praveen KumarDocument3 pagesVibration Analysis of Two Wheeler Connecting Rod: Yeshwant Rao, B S Praveen KumarIonut PuscasuNo ratings yet

- Composite Beams With Formed Steel Deck: John A. Grant, JR., John W. Fisher, and Roger G. SlutterDocument20 pagesComposite Beams With Formed Steel Deck: John A. Grant, JR., John W. Fisher, and Roger G. SlutterConan EdogawaNo ratings yet

- Vibration in Screw Jack Mechanisms: Experimental Results: Journal of Sound and Vibration April 2005Document18 pagesVibration in Screw Jack Mechanisms: Experimental Results: Journal of Sound and Vibration April 2005Uğur KoyunNo ratings yet

- Effect of Prestressing Force On Natural Frequencies of Concrete Beams Gan Et Al LuDocument22 pagesEffect of Prestressing Force On Natural Frequencies of Concrete Beams Gan Et Al LuHossein MozahebNo ratings yet

- Eccentric Beam-Column JointDocument7 pagesEccentric Beam-Column JointsokamantyNo ratings yet

- Allan-Fischer Behavior of Bolted Joints With Oversize or Slotted Holes AugustDocument65 pagesAllan-Fischer Behavior of Bolted Joints With Oversize or Slotted Holes AugustaykutNo ratings yet

- Composite Beams: P. AnsourianDocument27 pagesComposite Beams: P. AnsourianLeonardoMadeira11No ratings yet

- Internal Friction and Ultrasonic Attenuation in Solids: Proceedings of the Third European Conference University of Manchester, England, 18-20 July 1980From EverandInternal Friction and Ultrasonic Attenuation in Solids: Proceedings of the Third European Conference University of Manchester, England, 18-20 July 1980No ratings yet

- ETHist SO04Document3 pagesETHist SO04David C HouserNo ratings yet

- Computation: A Modification of The Fast Inverse Square Root AlgorithmDocument14 pagesComputation: A Modification of The Fast Inverse Square Root AlgorithmDavid C HouserNo ratings yet

- Maintenance and Instruction Manual 1. Transport: Galperti TechDocument7 pagesMaintenance and Instruction Manual 1. Transport: Galperti TechDavid C HouserNo ratings yet

- CAD Support: Release 2019 R3 ANSYS Workbench Platform Reader/Plug-InsDocument5 pagesCAD Support: Release 2019 R3 ANSYS Workbench Platform Reader/Plug-InsDavid C HouserNo ratings yet

- Archer - Fatigue of A Welded Steel Attachment Under Combined Direct Stress and Shear StressDocument6 pagesArcher - Fatigue of A Welded Steel Attachment Under Combined Direct Stress and Shear StressDavid C HouserNo ratings yet

- Sensors: Low-Cost Impact Detection and Location For Automated Inspections of 3D Metallic Based StructuresDocument17 pagesSensors: Low-Cost Impact Detection and Location For Automated Inspections of 3D Metallic Based StructuresDavid C HouserNo ratings yet

- NBS Monograph 88 PDFDocument52 pagesNBS Monograph 88 PDFDavid C HouserNo ratings yet

- Service Life Prediction of Residential Interior Finishes For LifeDocument16 pagesService Life Prediction of Residential Interior Finishes For LifeDavid C HouserNo ratings yet

- Performing Customized Post Processing Using Design Assessment in MechanicalDocument51 pagesPerforming Customized Post Processing Using Design Assessment in MechanicalDavid C HouserNo ratings yet

- Study On Spectrum of Acoustic Emission Signals of Bridge CraneDocument8 pagesStudy On Spectrum of Acoustic Emission Signals of Bridge CraneDavid C HouserNo ratings yet

- Extracting Relative Displacements in ANSYS Mechanical: Alex Grishin 3/1/2018Document37 pagesExtracting Relative Displacements in ANSYS Mechanical: Alex Grishin 3/1/2018David C HouserNo ratings yet

- Filemon - Useful Ranges of Centerpoint Curves For Design of Crank-And-Rocker LinkagesDocument7 pagesFilemon - Useful Ranges of Centerpoint Curves For Design of Crank-And-Rocker LinkagesDavid C HouserNo ratings yet

- Inglis - Stresses in A Plate Due To The Presence of Cracks and Sharp CornersDocument23 pagesInglis - Stresses in A Plate Due To The Presence of Cracks and Sharp CornersDavid C HouserNo ratings yet

- Forsyth, Stubbington - The Slip-Band Extrusion Effect Observed in Some Aluminum Alloys Subjected To Cyclic StressDocument5 pagesForsyth, Stubbington - The Slip-Band Extrusion Effect Observed in Some Aluminum Alloys Subjected To Cyclic StressDavid C HouserNo ratings yet

- Kanazawa, Miller, Brown - Cyclic Deformation of 1% Cr-Mo-V Steel Under Out-Of-Phase LoadsDocument12 pagesKanazawa, Miller, Brown - Cyclic Deformation of 1% Cr-Mo-V Steel Under Out-Of-Phase LoadsDavid C HouserNo ratings yet

- Murakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDocument14 pagesMurakami - Analysis of Stress Intensity Factors of Modes I, II and III For Inclined Surface Cracks of Arbitrary ShapeDavid C HouserNo ratings yet

- Wang, Miller - The Effects of Mean and Alternating Shear Stresses On Short Fatigue Crack Growth RatesDocument14 pagesWang, Miller - The Effects of Mean and Alternating Shear Stresses On Short Fatigue Crack Growth RatesDavid C HouserNo ratings yet

- Crossland - Effect of Large Hydrostatic Pressures On The Torsional Fatigue Strength of An Alloy Steel PDFDocument20 pagesCrossland - Effect of Large Hydrostatic Pressures On The Torsional Fatigue Strength of An Alloy Steel PDFDavid C HouserNo ratings yet

- Brown, Miller - Biaxial Cyclic Deformation Behaviour of SteelsDocument14 pagesBrown, Miller - Biaxial Cyclic Deformation Behaviour of SteelsDavid C Houser100% (1)

- Galambos - Load and Resistance Factor DesignDocument9 pagesGalambos - Load and Resistance Factor DesignDavid C HouserNo ratings yet

- Ritchie - Near-Threshold Fatigue-Crack Propagation in SteelsDocument26 pagesRitchie - Near-Threshold Fatigue-Crack Propagation in SteelsDavid C HouserNo ratings yet

- Brown, Miller - Initiation and Growth of Cracks inDocument16 pagesBrown, Miller - Initiation and Growth of Cracks inDavid C HouserNo ratings yet

- Forsyth - Some Metallographic Observations On The Fatigue of MetalsDocument9 pagesForsyth - Some Metallographic Observations On The Fatigue of MetalsDavid C HouserNo ratings yet

- Forsyth - A Two Stage Process of Fatigue Crack GrowthDocument20 pagesForsyth - A Two Stage Process of Fatigue Crack GrowthDavid C HouserNo ratings yet

- Mason - Alternating Stress ExperimentsDocument77 pagesMason - Alternating Stress ExperimentsDavid C HouserNo ratings yet

- Hood - On Some Peculiar Changes in The Internal Structure of Iron, Independent Of, and Subsequent To, The Several Processes of Its ManufDocument8 pagesHood - On Some Peculiar Changes in The Internal Structure of Iron, Independent Of, and Subsequent To, The Several Processes of Its ManufDavid C HouserNo ratings yet

- Inglis - Stresses in A Plate Due To The Presence of Cracks and Sharp CornersDocument23 pagesInglis - Stresses in A Plate Due To The Presence of Cracks and Sharp CornersDavid C HouserNo ratings yet

- Rotvel - An Effective Strain Concept For Crack Propagation and Fatigue Life With Specific Applications To Biaxial Stress FatigueDocument19 pagesRotvel - An Effective Strain Concept For Crack Propagation and Fatigue Life With Specific Applications To Biaxial Stress FatigueDavid C HouserNo ratings yet

- ESKATE Rectangular Square Flange 24193 1Document1 pageESKATE Rectangular Square Flange 24193 1John DoeNo ratings yet

- Impact Wrenches 1121EDocument12 pagesImpact Wrenches 1121Ekevintwink17 TwinkNo ratings yet

- Technical Catalog HRA10VSO100DFR/31R: FeaturesDocument13 pagesTechnical Catalog HRA10VSO100DFR/31R: FeaturesMichail ArmitageNo ratings yet

- UJ440Document356 pagesUJ440Gleidson DjalmaNo ratings yet

- Vertical Sealess VS: Technical IndexDocument2 pagesVertical Sealess VS: Technical Indexyavor karaivanovNo ratings yet

- MTM Irfan Amin PDFDocument68 pagesMTM Irfan Amin PDFIrfan AminNo ratings yet

- Tal-Ge-Png-Iso-1hs001101 - 02 (As Built)Document1 pageTal-Ge-Png-Iso-1hs001101 - 02 (As Built)Jan pierre Arismendis paibaNo ratings yet

- WHY Cifa: Series Truck Pumps & Placing BoomsDocument12 pagesWHY Cifa: Series Truck Pumps & Placing BoomsXiangzhendongNo ratings yet

- Piping Fabrication Spec 39Document8 pagesPiping Fabrication Spec 39godennyNo ratings yet

- 3858 Parts CatalogueDocument48 pages3858 Parts CatalogueSergey Slomchinskiy100% (6)

- Iso 7040Document1 pageIso 7040serzo75No ratings yet

- 1.daftar Harga Suku CadangDocument2 pages1.daftar Harga Suku CadangCahyadi AndhikaNo ratings yet

- Updated - SOT II Assignment 12 - JITHU KRISHNA JDocument3 pagesUpdated - SOT II Assignment 12 - JITHU KRISHNA JmarinerNo ratings yet

- S01 Inflating Box - D PDFDocument54 pagesS01 Inflating Box - D PDFFer NuñezNo ratings yet

- Previous Page: Presses Soup ShapesDocument22 pagesPrevious Page: Presses Soup ShapesKunwar Apoorva SinghNo ratings yet

- Seaflex Waterload ™ Range: Austin & Mclean 300T Load Test On Maersk AdvancerDocument2 pagesSeaflex Waterload ™ Range: Austin & Mclean 300T Load Test On Maersk AdvancerPWkannon100% (1)

- Standard SteelDocument13 pagesStandard SteelYvan Nuñez EscobedoNo ratings yet

- 1-0988-US-Linear Bearings-NLGI000-2-Voltage+24Document2 pages1-0988-US-Linear Bearings-NLGI000-2-Voltage+24li geneNo ratings yet

- Caterpillar Transmission Filter Pehj0251-00Document2 pagesCaterpillar Transmission Filter Pehj0251-00Parinpa KetarNo ratings yet

- Asus X556UJ-RGDocument6 pagesAsus X556UJ-RGTeofilTrif100% (1)

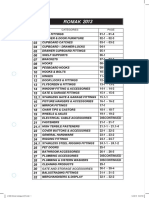

- R o Romak Catalogue 2013Document141 pagesR o Romak Catalogue 2013BillNo ratings yet

- 5555 Back Pressure Valve, Double Seated (Balanced) : SeriesDocument3 pages5555 Back Pressure Valve, Double Seated (Balanced) : SeriesJohnf PreciadoNo ratings yet

- Cold Formed SteelDocument40 pagesCold Formed SteelAwhan ArchitecNo ratings yet

- Accelerator LeverDocument2 pagesAccelerator LeverДмитрий ТуржанскийNo ratings yet

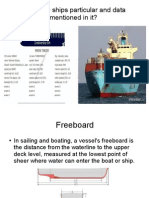

- FreeboardDocument12 pagesFreeboardRodneyNo ratings yet

- Iso 7380 2 2022Document10 pagesIso 7380 2 2022Rubén RodriguezNo ratings yet

- TJS Spot Gun 3321N 3328N UsermanualDocument60 pagesTJS Spot Gun 3321N 3328N UsermanualJm KamachoNo ratings yet

- Cat 14M Hamide - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDocument6 pagesCat 14M Hamide - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPMehdi Chakroune100% (1)

- Smart Filter™ Wellbore PurifierDocument5 pagesSmart Filter™ Wellbore PurifierAjith MohandasNo ratings yet

- Test Instructions For Overrunning Alternator Pulleys (OAP/OAD)Document2 pagesTest Instructions For Overrunning Alternator Pulleys (OAP/OAD)venothNo ratings yet