Professional Documents

Culture Documents

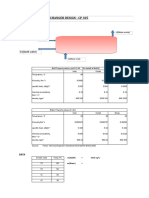

Overall Heat Transfer Coefficient: Physical Properties Units

Uploaded by

Ravindra SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Overall Heat Transfer Coefficient: Physical Properties Units

Uploaded by

Ravindra SinghCopyright:

Available Formats

Design an exchanger to sub-cool condensate from methanol condenser from 95*C to 40*C.

Flow rate

Physical properties Units

Heat capacity of Methanol = 2.84 KJ/kg * C

Heat Load = 4338.888889 kW

Heat capacity of water = 4.2 KJ/kg * C

Cooling water flow = 68.8712522 kg/s Methanol density = 750

Log-mean temperature = 30.78301888 *C Viscosity = 0.00034

Density of water = 995 kg/m^3 Heat capacity = 2.84

Correction factor Thermal cond. = 0.19

Value of R (for graph) = 3.666666667 Fouling coeff. (M)= 5000

Value of S (for graph) = 0.214285714 Fouling coeff. (H20)= 3000

From graph Ft = 0.85

Corrected temperature = 26.16556605 *C

Assumed U from Literature 500 W/m^2*C

Provisional area (in m2) 331.6487693

Tube dimensions

Inner Diameter = 16 mm

Outer diameter = 20 mm

Length of tube = 4.88 m

Tube sheet thickness = 5 cm

Net length = 4.83 m

Area of one tube = 0.306464 m2

Number of tubes = 1082.178557

Conductivity of tube alloy = 50 W/m*C

Overall heat transfer coefficient

Uo = 535.8872565 W/m2*C

0.001866

Check whether design is perfect for heat transfer?

Check whether design is perfect for heat transfer?

Pressure Drop Calculations

Viscosity of water = 0.0008 mNs/m2 Thermal cond. Water=

Tube side

Reynolds No. 12667.46

From fig. Jf 0.0043

Pressure Drop 5194.734 N/m2

tube side

5.194734 Kpa

Tube side pressure drop verification

Satisfactory pressure drop

ser from 95*C to 40*C. Flow rate of methanol 100,000 kg/h. Brackish water will be used as the coolant, with a temprature rise from 2

Given Data

3.666666667 Flow rate of methanol (Kg/hr) = 100000

Inlet temperature of condensate (*C) = 95

Temperatur reqired at outlet (*C)= 40

kg/m^3 Inlet temperature of brackish water (*C)= 25

Ns/m2 Outlet temperature of brackish water(*C)= 40

kJ/kg*C

W/m2*C

W/m2*C

W/m2*C Bundle Diameter (Db)

for triangular pitch

K1 = 0.249

n1 = 2.207

Db = 890.157 mm

Bundle Clearance = 68 mm

Shell diameter = 958.157 mm

Tube side coefficient

Mean water temperature = 32.5 *C Number of passes =

Tube cross sectional area = 200.96 mm2

Tube per pass = 541.0893

Tube flow area = 0.108737 m2

Water mass velocity = 633.3728 kg/(m2*s)

water linear velocity = 0.636556 m/s

Tube side coefficient,hi = 3361.432 W/m2*C

Shell side ht coefficient

Baffle spacing = 383.2628 mm Reynolds No.

Tube pitch = 25 mm Prandtl No.

Cross flow area = 0.073445 m2

Mass velocity = 378.211 Kg/s*m2

Equivalent diameter = 14.201 mm

Mean shell diameter = 67.5 *C

From fig. for 25 % baffle cut

Heat transfer factor = 0.0033

Heat transfer coeff. shellside = 1199.142 W/m2*C

erfect for heat transfer? Design is perfect

erfect for heat transfer? Design is perfect

Thermal cond. Water= 0.59 W/m*C Density of water = 995 Kg/m3

Shell side

Linear velocity = 0.504281 m/s

From fig. Jf 0.04

Pressure drop = 25947.49 N/m2

shell side

25.94749 Kpa

Shell Side pressure drop verification

Satisfactory Pressure Drop

ant, with a temprature rise from 25* C to 40*C.

Kuldeep Singh Bhati 2011uch1759

Prateek A Sarin 2011uch1804

Aayush Agarwal

Vijendra Kumar Gupta

mber of passes = 2

15796.9847

5.08210526

You might also like

- Licensed Contractors by Business Name July22Document208 pagesLicensed Contractors by Business Name July22brijeshNo ratings yet

- Liquid Cooling Guidelines For Datacom Equipment CentersDocument102 pagesLiquid Cooling Guidelines For Datacom Equipment CentersChanh Tri NguyenNo ratings yet

- Round Tube and Plate Fin Air Cooled Condenser CalculationDocument8 pagesRound Tube and Plate Fin Air Cooled Condenser Calculationjamil100% (2)

- Alcorcon Engineering Review Center: Power & Industrial Plant EngineeringDocument15 pagesAlcorcon Engineering Review Center: Power & Industrial Plant EngineeringNeil SequioNo ratings yet

- Steam Coil SizingDocument2 pagesSteam Coil Sizingpavan100% (1)

- 2 Design CalculationDocument22 pages2 Design CalculationLynn HuiNo ratings yet

- Condenser CalculationsDocument9 pagesCondenser CalculationsAngelo Imbo100% (2)

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 pagesHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanNo ratings yet

- Solved Problems in Heat TransferDocument16 pagesSolved Problems in Heat TransferAngelica Joyce Benito100% (3)

- Design of Shell & Tube HXDocument45 pagesDesign of Shell & Tube HXAnonymous yLPPdPwNo ratings yet

- Shell and Tube Heat Exchanger1Document19 pagesShell and Tube Heat Exchanger1Lily NurdianaNo ratings yet

- MECHANICAL DESIGN: Superheater Design for Ammonia HeatingDocument13 pagesMECHANICAL DESIGN: Superheater Design for Ammonia HeatingSchaieraNo ratings yet

- MATERIAL Mechanical DesignDocument11 pagesMATERIAL Mechanical DesignanisNo ratings yet

- Rotary Dryer DesignDocument43 pagesRotary Dryer DesignsasitharNo ratings yet

- Alcorcon Engineering Review Center: Power & Industrial Plant EngineeringDocument12 pagesAlcorcon Engineering Review Center: Power & Industrial Plant EngineeringAriane Uytiepo GalasNo ratings yet

- Types of condensers and design calculationsDocument17 pagesTypes of condensers and design calculationsfarhaNo ratings yet

- PROCESS DESIGN CALCULATION Mas GitoDocument32 pagesPROCESS DESIGN CALCULATION Mas GitosehonoNo ratings yet

- Heat Exchanger Design CalculationsDocument8 pagesHeat Exchanger Design Calculationskikokiko KarimNo ratings yet

- Calculation of heat transfer coefficients in agitated vesselsDocument4 pagesCalculation of heat transfer coefficients in agitated vesselsdesignselva100% (1)

- Chapter 2 - Air Conditioning System - Part 2Document23 pagesChapter 2 - Air Conditioning System - Part 2khairul izzudinNo ratings yet

- Double Pipe Heat Exchanger Project #3 CalculationsDocument12 pagesDouble Pipe Heat Exchanger Project #3 CalculationsJames Buser100% (1)

- Design of Shell & Tube HXDocument62 pagesDesign of Shell & Tube HXUmirahRashidahNo ratings yet

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Organic Solvents and Water Shell and Tube Heat Exchanger DesignDocument31 pagesOrganic Solvents and Water Shell and Tube Heat Exchanger Designramesh pokhrelNo ratings yet

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Kebutuhan Panas Cement Mill (1) 1Document3 pagesKebutuhan Panas Cement Mill (1) 1ManekGorisNo ratings yet

- 5.3 Design of Waste Heat Boiler: (13) : DataDocument7 pages5.3 Design of Waste Heat Boiler: (13) : Datamoni beeNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument19 pagesShell and Tube Heat Exchanger DesignValium MorphineNo ratings yet

- Lesson 7 NumericalsDocument11 pagesLesson 7 Numericalssurya kiranNo ratings yet

- Double Effect EvapDocument32 pagesDouble Effect EvapJubell MogoteNo ratings yet

- Design: of Shell & Tube Heat ExchangerDocument27 pagesDesign: of Shell & Tube Heat ExchangerBalamurugan SakthivelNo ratings yet

- Chap 8. CondenserDocument9 pagesChap 8. CondenserAli Ahsan100% (1)

- Design Heat Exchanger Shell and Tube TheDocument8 pagesDesign Heat Exchanger Shell and Tube ThezatamaqeelNo ratings yet

- Calculating heat transfer and temperature change in a crude oil storage tankDocument3 pagesCalculating heat transfer and temperature change in a crude oil storage tankbadelitamariusNo ratings yet

- Condener m2Document6 pagesCondener m2yamen-691904No ratings yet

- Brackish WaterDocument35 pagesBrackish WaterChemsys SunnyNo ratings yet

- Shell & Tube Heat Exchanger: Qaim Ali 2005-Chem-87Document32 pagesShell & Tube Heat Exchanger: Qaim Ali 2005-Chem-87Kotaiah NaikNo ratings yet

- Desing of CoolerDocument25 pagesDesing of CoolermeetNo ratings yet

- Valid of Turbulent Flow: The Chemical Engineers' Resource PageDocument8 pagesValid of Turbulent Flow: The Chemical Engineers' Resource PagebunnyNo ratings yet

- Plate HEDocument3 pagesPlate HEyamen-691904No ratings yet

- Desing of HEDocument25 pagesDesing of HEmeetNo ratings yet

- Kettle Reboiler Design and Heat Transfer AnalysisDocument4 pagesKettle Reboiler Design and Heat Transfer AnalysisSmit patelNo ratings yet

- Monteron Jaji C4 2Document15 pagesMonteron Jaji C4 2John Lloyd TulopNo ratings yet

- IntroductionDocument17 pagesIntroductionMitul PrajapatiNo ratings yet

- Cooling EquipmentDocument15 pagesCooling EquipmentRomelyn Suyom PingkianNo ratings yet

- Lampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainDocument21 pagesLampiran 1: Perhitungan Nilai RD Dan Pressure Drop DesainAdiyat AdiNo ratings yet

- Jacketed Vessel Heat Transfer Coeff and Delta PDocument4 pagesJacketed Vessel Heat Transfer Coeff and Delta Pyamen-691904No ratings yet

- Design of HE-1: Hot Stream (234 C)Document4 pagesDesign of HE-1: Hot Stream (234 C)BITTU MEENANo ratings yet

- Tube Rating: Properties of Fluid Inside TubeDocument4 pagesTube Rating: Properties of Fluid Inside Tubesiti_zubaidah_37No ratings yet

- Water Heater DesignDocument4 pagesWater Heater DesignKaushik SahaNo ratings yet

- Attachment 3: Calculation of Inner Space VentilationDocument4 pagesAttachment 3: Calculation of Inner Space VentilationDuy VuNo ratings yet

- DimensionsDocument11 pagesDimensionsAsavela NotshwelekaNo ratings yet

- VND Openxmlformats-Officedocument Presentationml Presentation&rendition 1Document8 pagesVND Openxmlformats-Officedocument Presentationml Presentation&rendition 1Harsh SrivastavaNo ratings yet

- Heat Exchanger design parametersDocument5 pagesHeat Exchanger design parametersUmme Laila JatoiNo ratings yet

- Gambar Skema HE: Example 12.1Document5 pagesGambar Skema HE: Example 12.1FarisNo ratings yet

- Evaporator SectionDocument24 pagesEvaporator SectionpassionNo ratings yet

- Tutorial Heat & Mass 431 No4Document2 pagesTutorial Heat & Mass 431 No4Moll22No ratings yet

- Evaporator DesignDocument1 pageEvaporator DesignNaqqash SajidNo ratings yet

- 2023Oct24-Tripod-Water Coil CalculationDocument9 pages2023Oct24-Tripod-Water Coil CalculationTân NguyễnNo ratings yet

- NTK/KW/15/7829Document4 pagesNTK/KW/15/7829Anurag TalwekarNo ratings yet

- Design of Shell & TubeDocument33 pagesDesign of Shell & TubeKathir VelNo ratings yet

- Ael-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilDocument3 pagesAel-2597-Mec-Cl-0305-R1 - Sizing Calculation of Heating CoilpavanNo ratings yet

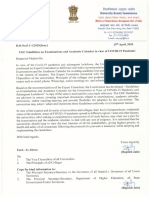

- Registration Form, NCCL MARCH, 2019Document1 pageRegistration Form, NCCL MARCH, 2019Ravindra SinghNo ratings yet

- Statement of Solidarity RGNUL - HPNLUDocument1 pageStatement of Solidarity RGNUL - HPNLURavindra SinghNo ratings yet

- Dlsa Internship (Delhi)Document3 pagesDlsa Internship (Delhi)Ravindra SinghNo ratings yet

- Dworkin Law As InterpretationDocument43 pagesDworkin Law As InterpretationGonçaloBargadoNo ratings yet

- SolidarityDocument2 pagesSolidarityRavindra SinghNo ratings yet

- Indian Partnership Act 1923 PDFDocument12 pagesIndian Partnership Act 1923 PDFRavindra SinghNo ratings yet

- Justice - John Galsworthy's Summary PDFDocument12 pagesJustice - John Galsworthy's Summary PDFDr Anuvesh Gill100% (2)

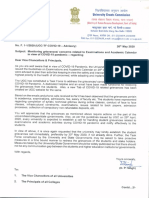

- Letter Regarding UGC Guidelines On Examinations and Academic CalendarDocument1 pageLetter Regarding UGC Guidelines On Examinations and Academic CalendarAnkur GoelNo ratings yet

- D C Wadhwa V State of Bihar-1Document4 pagesD C Wadhwa V State of Bihar-1Ravindra SinghNo ratings yet

- The Case For The DefenceDocument4 pagesThe Case For The DefenceArshiya SharmaNo ratings yet

- Dlsa Internship (Delhi)Document3 pagesDlsa Internship (Delhi)Ravindra SinghNo ratings yet

- Statement of Solidarity RGNUL - HPNLUDocument1 pageStatement of Solidarity RGNUL - HPNLURavindra SinghNo ratings yet

- National Seminar 15feb-2020Document6 pagesNational Seminar 15feb-2020Ravindra SinghNo ratings yet

- Maina Singh Vs So Rajasthan - 20191015000042-1Document3 pagesMaina Singh Vs So Rajasthan - 20191015000042-1Ravindra SinghNo ratings yet

- Jitu BannaananDocument3 pagesJitu BannaananRavindra SinghNo ratings yet

- Monitoring Grievances Related To ExamsDocument2 pagesMonitoring Grievances Related To ExamsRavindra SinghNo ratings yet

- ComrdywithjaydeepDocument1 pageComrdywithjaydeepRavindra SinghNo ratings yet

- More Than A Love Story....Document6 pagesMore Than A Love Story....Ravindra SinghNo ratings yet

- Natures Last CallDocument4 pagesNatures Last CallRavindra SinghNo ratings yet

- Cumulative Inflow For Last DecadeDocument2 pagesCumulative Inflow For Last DecadeRavindra SinghNo ratings yet

- Book12 PDFDocument110 pagesBook12 PDFRavindra SinghNo ratings yet

- The Salient Features of NELP Are As UnderDocument5 pagesThe Salient Features of NELP Are As UnderRavindra SinghNo ratings yet

- TopicsDocument2 pagesTopicsRavindra SinghNo ratings yet

- Tata Engineers Limited: General Accessories by Vessel VendorDocument3 pagesTata Engineers Limited: General Accessories by Vessel VendorRavindra SinghNo ratings yet

- Tata Engineers Limited: General Accessories by Vessel VendorDocument3 pagesTata Engineers Limited: General Accessories by Vessel VendorRavindra SinghNo ratings yet

- Letter Regarding UGC Guidelines On Examinations and Academic CalendarDocument1 pageLetter Regarding UGC Guidelines On Examinations and Academic CalendarAnkur GoelNo ratings yet

- The ProjectionDocument37 pagesThe ProjectionRavindra SinghNo ratings yet

- 08 Chapter-1 PDFDocument24 pages08 Chapter-1 PDFRavindra SinghNo ratings yet

- Management Assignment SelectionDocument12 pagesManagement Assignment SelectionRavindra SinghNo ratings yet

- CHAPTER 6 Heat TransferDocument15 pagesCHAPTER 6 Heat TransferaimanrslnNo ratings yet

- Basics of Refrigeration 2018-2019Document33 pagesBasics of Refrigeration 2018-2019cliffordNo ratings yet

- Mixed Convection in The Semi-Circular Lid-Driven Cavity With Heated Curved Wall Subjugated To Constant Heat Flux For Non-Newtonian Power-Law FluidsDocument9 pagesMixed Convection in The Semi-Circular Lid-Driven Cavity With Heated Curved Wall Subjugated To Constant Heat Flux For Non-Newtonian Power-Law FluidsKrunal GangawaneNo ratings yet

- Heat and Mass Transfer Chapter 11Document12 pagesHeat and Mass Transfer Chapter 11yogesh shindeNo ratings yet

- Training Manual On Application of Building InsulationDocument47 pagesTraining Manual On Application of Building InsulationAthish KumarNo ratings yet

- Thermal Conductivity of Insulating Powder ExperimentDocument4 pagesThermal Conductivity of Insulating Powder ExperimentmuralidharanNo ratings yet

- Annexure I & II (Weekend)Document2 pagesAnnexure I & II (Weekend)zubbbuNo ratings yet

- Temp Humidity Control - FinalDocument97 pagesTemp Humidity Control - FinalAli HabibNo ratings yet

- Assignment 2 2022 UseDocument2 pagesAssignment 2 2022 UseDICKSON SIMUTAMINo ratings yet

- Chapter 2Document41 pagesChapter 2muhammad shahadat awanNo ratings yet

- Exchanger Hydrogen: AluminumDocument176 pagesExchanger Hydrogen: AluminumDanut StanciuNo ratings yet

- Design, Calculation and Cost Estimation of HVAC System For School BuildingDocument12 pagesDesign, Calculation and Cost Estimation of HVAC System For School BuildingMd KaleemNo ratings yet

- He SelectionDocument7 pagesHe SelectionKaizerNo ratings yet

- Cooling Load CalculationDocument5 pagesCooling Load CalculationmicrefeeNo ratings yet

- 8.13 Chiller Optimization: B. G. LiptákDocument24 pages8.13 Chiller Optimization: B. G. LiptákRahmi ArslanNo ratings yet

- Company Profile MetalindoDocument38 pagesCompany Profile MetalindoAngga PratamaNo ratings yet

- Bessel Application PDFDocument4 pagesBessel Application PDFBrunoSantos100% (1)

- 3 3.102PDocument2 pages3 3.102PYogeshThakurNo ratings yet

- Heat Transfer - Group 4Document29 pagesHeat Transfer - Group 4Lorna AhlaamiNo ratings yet

- Cold Room Refrigeration EquipmentsDocument4 pagesCold Room Refrigeration EquipmentsLorena PertierraNo ratings yet

- Chapter 1 Lecture 1Document40 pagesChapter 1 Lecture 1Chee HoeNo ratings yet

- NF For Heat TransferDocument7 pagesNF For Heat TransferMohd Rashid SiddiquiNo ratings yet

- Washington State Energy CodeDocument119 pagesWashington State Energy Codeet2bruNo ratings yet

- HVAC & Water Boilers-Heaters - AlamoDocument16 pagesHVAC & Water Boilers-Heaters - AlamoctaslacaNo ratings yet

- Modelling and Simulation of Absorption Solar Air Conditioning SystemDocument20 pagesModelling and Simulation of Absorption Solar Air Conditioning SystemShadi KarkabaNo ratings yet

- 02 - York University1-s2.0-S1359431122012029-mainDocument12 pages02 - York University1-s2.0-S1359431122012029-mainmohammad emamiNo ratings yet