Professional Documents

Culture Documents

Kebutuhan Panas Cement Mill (1) 1

Uploaded by

ManekGoris0 ratings0% found this document useful (0 votes)

18 views3 pagesKebutuhan kalor

Original Title

Kebutuhan Panas Cement Mill (1)1

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKebutuhan kalor

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views3 pagesKebutuhan Panas Cement Mill (1) 1

Uploaded by

ManekGorisKebutuhan kalor

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

Menghitung Panas Yang dibutuhkan untuk menguapkan air pada material

Heat input :

1. Grinding heat

Qg = ( 3.6 x Eff x N ) / G , kJ/kg

2. Clinker heat

Qk = ( ( 0.00046 x tk ) + 0.733 ) x ( tk - to )

Heat output :

1. Cement heat

Qc = ( ( 0.00046 x tc ) + 0.733 ) x ( tc - to )

2. Radiation / Convection

Qr/c = ( ( (D/2) + L ) x D x phi x k ) / ( G x 1000 )

3. Venting air

Qa = ( Cpa x Va x ( ta - to )) / ( G x 1000 )

4. Water evaporation

Qw = ( r x w ) / 1000

Diketahui bahwa : Input Data

N = mill motor power 2500 kw

Eff = mill drive efficiency 0.87

G = mill output/cement product 65.00 ton/h

Cpk = Specific heat value for clinker 0.7514 kj/kg.C

tk = clinker temperatur 40 C

to = ambient air temperatur 30 C

Cpc = specific heat value for cement 0.7675 kj/kg.C

tc = cement temperatur 75 C

D = nominal mill diameter 3.86 m

L = mill length 12.50 m

k = heat transfer factor 12000 kj/m2.h

Va = venting air volume 27757 Nm3/h

Cpa = specific heat value for air 1.3 kj/Nm3.C

ta = air temperatur after mill 80 C

W = water rate ( include moisture content in feed material ) 14.7949901912 kg/ton feed

r = heat of evaporation ( include heating up of water ) 2257 kj/kg

Result :

Item Heat Input Item Heat Output

Grind. heat 120 Cement heat 34.538

Clinker heat 7.514 Radiation /

Convection 32.289

Venting air 27.757

Water Evap. 33.392

Total input 127.976 Total output 127.976 Kj/Kg

39123.65781415 kJ/jam

Total Air dalam Raw Material :

Gypsum 126.75 kg

Limestone 633.8 kg

FA 211.3 kg

Trass 211.25 kg

Total 1183 kg

shg panas utk menguapkan raw material feed = 2670031.00 kJ/jam

Kekurangan panas yang harus ditambahkan = 2630907.342 kJ/jam

2493609.21861 BTU/jam

628802.640226 Kcal/Jam

Kebutuhan bahan bakar untuk mengurangi moisture material feed

Kalori Solar 9240 Kcal/liter

Kalori yang harus ditambahkan 628802.64 Kcal/Jam

Kebutuhan solar untuk mengurangi moisture 68.0522 Liter/Jam

11.7068286 m2

You might also like

- Thermal System Analysis Document TitleDocument4 pagesThermal System Analysis Document TitleAisyah NandanitaNo ratings yet

- اليوم الثالثDocument31 pagesاليوم الثالثعاشق الصمتNo ratings yet

- Heat PinchDocument6 pagesHeat PinchYeeXuan TenNo ratings yet

- Boiling and CondensingDocument2 pagesBoiling and CondensingZia Ul NoorNo ratings yet

- Pumping 6Document2 pagesPumping 6Foulen FouleniNo ratings yet

- Energy Efficiency Planning, Funding and Improvements For New Hampshire's Drinking Water and Wastewater SystemsDocument24 pagesEnergy Efficiency Planning, Funding and Improvements For New Hampshire's Drinking Water and Wastewater Systemsmmihai_popa2006No ratings yet

- MV Protocol - CementDocument55 pagesMV Protocol - CementSanjeev PmNo ratings yet

- LAMPIRAN B: PERHITUNGAN NERACA MASSADocument18 pagesLAMPIRAN B: PERHITUNGAN NERACA MASSASatria Muliya PutraNo ratings yet

- Thermal power plant economiser guideDocument7 pagesThermal power plant economiser guideSteve M D'souzaNo ratings yet

- Calculate Boiler Efficiency Using Direct MethodDocument53 pagesCalculate Boiler Efficiency Using Direct Methoddineshkbunker08No ratings yet

- Building Heat Loss Building Heat Gain: 1000Xbtu/H 1000Xbtu/H 1000Xbtu/HDocument69 pagesBuilding Heat Loss Building Heat Gain: 1000Xbtu/H 1000Xbtu/H 1000Xbtu/HFarid FarjadNo ratings yet

- Sustainable Energy Future: Efficiency and RenewablesDocument15 pagesSustainable Energy Future: Efficiency and Renewableszs28844No ratings yet

- Introduction To Boundary LayerDocument14 pagesIntroduction To Boundary LayerAyman KeirNo ratings yet

- CFD SimulationDocument39 pagesCFD SimulationSambhav JainNo ratings yet

- Kiddawalime Energy Audit Report Ver1Document77 pagesKiddawalime Energy Audit Report Ver1Birimumaso DavidNo ratings yet

- Vvvvgood Eneary PDFDocument128 pagesVvvvgood Eneary PDFsureshchitra100% (1)

- Indirect MethodDocument6 pagesIndirect MethodFarurrodin Syah AlfahrobiNo ratings yet

- Exp 3 Pump and Motor EfficiencyDocument10 pagesExp 3 Pump and Motor EfficiencyDinesh KumbharwarNo ratings yet

- Chapter 2 Boiler SystemDocument45 pagesChapter 2 Boiler SystemSurendra Louis Dupuis NaikerNo ratings yet

- Boiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamDocument17 pagesBoiler Efficiency: Heat Input Is Pulverised Coal Heat Output Is Superheated SteamHumayun Rashid KhanNo ratings yet

- Steam Tracing Design Considerations and InstallationDocument6 pagesSteam Tracing Design Considerations and InstallationaimangamalNo ratings yet

- 9what Is A Boiler?Document59 pages9what Is A Boiler?Ali MuradNo ratings yet

- BoilerDocument65 pagesBoilermangal SinghNo ratings yet

- ME-216E Lab Manual for Energy ConversionDocument40 pagesME-216E Lab Manual for Energy ConversionmechgokulNo ratings yet

- M 377 ContentDocument33 pagesM 377 Contenttamilradha821No ratings yet

- Lampiran 2 Perhitungan Neraca PanasDocument19 pagesLampiran 2 Perhitungan Neraca PanasWali YudinNo ratings yet

- US Energy Efficiency Full ReportDocument165 pagesUS Energy Efficiency Full Reportjosepmcdalena6542No ratings yet

- WEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaDocument10 pagesWEAST HEAT RECOVERY Heating Purpose For Woldia University CaftiriaMisge ChekoleNo ratings yet

- 1d Condution (2013) Finite Volume MethodDocument55 pages1d Condution (2013) Finite Volume MethodHuyTqNo ratings yet

- Fuel Savings and Efficiency CalculatorDocument6 pagesFuel Savings and Efficiency Calculatorrajayu20002724No ratings yet

- Cascade Non Refrigeration 1.3 WebDocument16 pagesCascade Non Refrigeration 1.3 WebHua Hidari Yang100% (1)

- 20th Exam P1 B PDFDocument11 pages20th Exam P1 B PDFAlbert SekarNo ratings yet

- Cooling Tower Evaporation, Heat and Mass Balance CalculationDocument1 pageCooling Tower Evaporation, Heat and Mass Balance CalculationSachin TechguideNo ratings yet

- Energy Savings of Pump Applications - General IndustryDocument13 pagesEnergy Savings of Pump Applications - General IndustryDave DuasoNo ratings yet

- 1.5 Energy Action Planning - Revised (Table Format) P9Document9 pages1.5 Energy Action Planning - Revised (Table Format) P9LOGANATHAN.RNo ratings yet

- Evaluation of Energy Efficiency of ADocument53 pagesEvaluation of Energy Efficiency of AHüseyin TavaslıoğluNo ratings yet

- Energy Efficiency Opportunity in FansDocument23 pagesEnergy Efficiency Opportunity in Fansdhanusiya balamuruganNo ratings yet

- Calculating PHR and Boiler LossesDocument13 pagesCalculating PHR and Boiler LossesSiddhant SatpathyNo ratings yet

- Boiler Excess Air Tune-UpDocument15 pagesBoiler Excess Air Tune-UpAlif Nur FirdausNo ratings yet

- Boiler Efficiency Combustion EfficiencyDocument8 pagesBoiler Efficiency Combustion EfficiencyBelalNorNo ratings yet

- Cement Eng 1 PDFDocument48 pagesCement Eng 1 PDFBülent BulutNo ratings yet

- RAC Benchmarking - Report PDFDocument94 pagesRAC Benchmarking - Report PDFmanchuricoNo ratings yet

- Energyauditofboiler 161207011009Document38 pagesEnergyauditofboiler 161207011009Randy PrandykaNo ratings yet

- Cooling Tower: Refrigeration and Air Conditioning LabDocument40 pagesCooling Tower: Refrigeration and Air Conditioning LabEngr Saad Bin SarfrazNo ratings yet

- Ch4 PsychrometricsDocument102 pagesCh4 PsychrometricsJayant SisodiaNo ratings yet

- Energy Efficiency Solutions: Tackling The Energy Challenges ThroughDocument16 pagesEnergy Efficiency Solutions: Tackling The Energy Challenges ThroughHadrien FaryalaNo ratings yet

- Boiler Pumps Fans Sizing CalculationsDocument4 pagesBoiler Pumps Fans Sizing CalculationsFarrahxviiiNo ratings yet

- Chapter 3 Gas Power CyclesDocument42 pagesChapter 3 Gas Power CyclesAmirul HazzmiNo ratings yet

- Energy Consumption ReferenceDocument63 pagesEnergy Consumption ReferenceKumar SwamiNo ratings yet

- Boiler Efficiency StudyDocument3 pagesBoiler Efficiency Studyvinayg85No ratings yet

- A2A Training Modules 1 To 3Document54 pagesA2A Training Modules 1 To 3Jose DenizNo ratings yet

- ECAM5Document28 pagesECAM5Niket KawaleNo ratings yet

- Boiler Efficiency by Indirect Method Coal Fired BoilerDocument4 pagesBoiler Efficiency by Indirect Method Coal Fired BoilerM Ziaul ArifNo ratings yet

- CFD Study of Air Flow over Two Side-By-Side Circular CylindersDocument11 pagesCFD Study of Air Flow over Two Side-By-Side Circular CylindersNirman MarioNo ratings yet

- Course PracticeDocument20 pagesCourse PracticeAbhinav RavellaNo ratings yet

- C.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFDocument10 pagesC.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFErGiteshAroraNo ratings yet

- Combined Heat and Power Calculator Guidance Document V5Document33 pagesCombined Heat and Power Calculator Guidance Document V5jasenkoNo ratings yet

- Solar Cooling: Kushal Panchal & Suraj Parihar 130813111006 & 120810111005 4 Sem EC Venus InternationalcollegeoftechnologyDocument26 pagesSolar Cooling: Kushal Panchal & Suraj Parihar 130813111006 & 120810111005 4 Sem EC Venus InternationalcollegeoftechnologyRavi Pratap SinghNo ratings yet

- REBOILER (RB-101) : Operating ConditionsDocument27 pagesREBOILER (RB-101) : Operating ConditionsBenedick Jayson MartiNo ratings yet

- Cold Room CalculatorDocument3 pagesCold Room CalculatorSamer ChahroukNo ratings yet

- Plan Bricking 2010 New Rev.2Document14 pagesPlan Bricking 2010 New Rev.2ManekGoris100% (1)

- Micro Schedule 2010.rev3Document5 pagesMicro Schedule 2010.rev3ManekGoris100% (1)

- Tracking spare parts overhaul 2016Document68 pagesTracking spare parts overhaul 2016ManekGorisNo ratings yet

- MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733Document21 pagesMD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733ManekGorisNo ratings yet

- Bulan Downtime Durasi TanggalDocument1 pageBulan Downtime Durasi TanggalManekGorisNo ratings yet

- Kebutuhan Flow MeterDocument2 pagesKebutuhan Flow MeterManekGorisNo ratings yet

- Specifications and Data for Various PumpsDocument11 pagesSpecifications and Data for Various PumpsManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Data 1 Unit 1Document59 pagesData 1 Unit 1ManekGorisNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Form WoDocument2 pagesForm WoManekGorisNo ratings yet

- 150 AyDocument12 pages150 AyManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Pump TestDocument52 pagesPump TestManekGorisNo ratings yet

- 25jul2019 - Presentasi Hydrant Fire Fighting - FinalDocument8 pages25jul2019 - Presentasi Hydrant Fire Fighting - FinalManekGorisNo ratings yet

- Diameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SDocument1 pageDiameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SManekGorisNo ratings yet

- Venting Dosing Calsiner PDFDocument1 pageVenting Dosing Calsiner PDFManekGorisNo ratings yet

- PumpDocument18 pagesPumpManekGorisNo ratings yet

- Grate Plate Cooler101215Document4 pagesGrate Plate Cooler101215ManekGorisNo ratings yet

- Max. Condensing Operating Condition in SummerDocument1 pageMax. Condensing Operating Condition in SummerManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Lining Bin Fine CoalDocument14 pagesLining Bin Fine CoalManekGorisNo ratings yet

- Venting Dosing Calsiner PDFDocument1 pageVenting Dosing Calsiner PDFManekGorisNo ratings yet

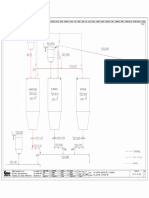

- Cement MIll Flow SheetDocument2 pagesCement MIll Flow SheetManekGorisNo ratings yet

- Pumps & Pumping Systems: Training Session On Energy EquipmentDocument40 pagesPumps & Pumping Systems: Training Session On Energy EquipmentKaushik SenguptaNo ratings yet

- Air BlasterDocument9 pagesAir BlasterManekGorisNo ratings yet

- 7065SG 12 (S) MDocument1 page7065SG 12 (S) MManekGorisNo ratings yet

- WA0001 Acuan OperatorDocument3 pagesWA0001 Acuan OperatorManekGorisNo ratings yet

- Lining Bin Fine CoalDocument14 pagesLining Bin Fine CoalManekGorisNo ratings yet

- Francis and Kaplan Reaction TurbinesDocument5 pagesFrancis and Kaplan Reaction TurbinesfahadNo ratings yet

- Correcting Astigmatism with Toric IOLsDocument28 pagesCorrecting Astigmatism with Toric IOLsArif MohammadNo ratings yet

- Cooling Tower Make Up Water CalculationDocument4 pagesCooling Tower Make Up Water CalculationarshadNo ratings yet

- Active Energy Efficiency Using Speed ControlDocument25 pagesActive Energy Efficiency Using Speed ControlAhmad DeyabNo ratings yet

- Mec-003 EngDocument58 pagesMec-003 EngnitikanehiNo ratings yet

- Design and Application of FeederDocument35 pagesDesign and Application of Feederbgn10101977No ratings yet

- Borst, C. v. (Ed.) (1970), The Mind-Brain Identity Theory, MacmillanDocument252 pagesBorst, C. v. (Ed.) (1970), The Mind-Brain Identity Theory, MacmillanAlejandro AguiLara100% (2)

- Autogenous, Semi-Auto-Genous and Ball Mills For Wet and Dry GrindingDocument16 pagesAutogenous, Semi-Auto-Genous and Ball Mills For Wet and Dry Grindingmushava nyoka100% (1)

- User Manual Notch ApparatusDocument4 pagesUser Manual Notch Apparatusrohit kumarNo ratings yet

- CHAYANIKA MTech 2013-15Document62 pagesCHAYANIKA MTech 2013-15Maher TolbaNo ratings yet

- STK0825F 1Document8 pagesSTK0825F 1Námaste AbaddonNo ratings yet

- UJIAN CLO 1 - SISTEM PERSAMAAN LINEAR - Attempt ReviewDocument7 pagesUJIAN CLO 1 - SISTEM PERSAMAAN LINEAR - Attempt ReviewAkbar PalekoriNo ratings yet

- Thermal TestDocument11 pagesThermal TestBhavani GujjariNo ratings yet

- June 2019 QP (Mechanics)Document16 pagesJune 2019 QP (Mechanics)Nisheli Amani PereraNo ratings yet

- Israeli Code For Seismic Resistance AssessmentDocument54 pagesIsraeli Code For Seismic Resistance AssessmentTimur UzunogluNo ratings yet

- AHRI Standard 270 2015Document13 pagesAHRI Standard 270 2015Faheem MushtaqNo ratings yet

- Lecture 6 The Engineer S Transit and Theodolite PDFDocument10 pagesLecture 6 The Engineer S Transit and Theodolite PDFleah mae arnaez100% (1)

- Non-Contact ForceDocument9 pagesNon-Contact ForceAnil BatraNo ratings yet

- Smart Hospital Fault Detection and Alert SystemDocument21 pagesSmart Hospital Fault Detection and Alert SystemPravat SatpathyNo ratings yet

- Hydraulic and Pneumatic Tools GuideDocument4 pagesHydraulic and Pneumatic Tools GuideShishir VardeNo ratings yet

- Radiation Safety DecDocument50 pagesRadiation Safety DecAhmed shaban100% (1)

- SyllabusDocument2 pagesSyllabusdevang_siNo ratings yet

- Process Modeling SimulationDocument11 pagesProcess Modeling SimulationNOMAN ASHRAFNo ratings yet

- MEMS Assignment On Crystal Structure of Silicon: R.Vijayaraghavan - 11MMT0002Document6 pagesMEMS Assignment On Crystal Structure of Silicon: R.Vijayaraghavan - 11MMT0002Vijayraghavan RameshNo ratings yet

- Usbr1020 PDFDocument3 pagesUsbr1020 PDFAbdul Ghafoor100% (1)

- Hyundai Heavy Industries - Engine Power Plant PDFDocument8 pagesHyundai Heavy Industries - Engine Power Plant PDFardian.sapartomoNo ratings yet

- Low-Profile Patch Antennas For Biomedical and Wireless ApplicationsDocument15 pagesLow-Profile Patch Antennas For Biomedical and Wireless ApplicationsDhamo DharanNo ratings yet

- Expancel - Elastomeric Cool Roof Coatings - 20062016 - AG - PNT01 - EN - MDocument8 pagesExpancel - Elastomeric Cool Roof Coatings - 20062016 - AG - PNT01 - EN - MThanh VuNo ratings yet

- Pulsatile Oldroyd-B Blood Flow Dynamics in A Stenosed ArteryDocument9 pagesPulsatile Oldroyd-B Blood Flow Dynamics in A Stenosed ArteryJuana Valentina CamachoNo ratings yet

- Experiment 8: Determination of The Ratio of The Specific Heats of AIRDocument9 pagesExperiment 8: Determination of The Ratio of The Specific Heats of AIRwallace kitoNo ratings yet