Professional Documents

Culture Documents

Max. Condensing Operating Condition in Summer

Uploaded by

ManekGorisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Max. Condensing Operating Condition in Summer

Uploaded by

ManekGorisCopyright:

Available Formats

Q4036N-JS4(e)

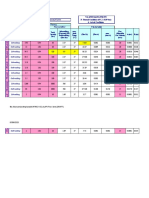

5. 汽封漏汽计算Steam sea leakage calculation

5.1 各段汽封漏汽流量Steam sea leakage flow at all sections

后 汽 封 Rear

前 汽 封Front steam seal

steam seal

段号Section No. 1 2 3 4 5 1 2

汽封齿数Steam seal teeth number 80 30 10 10 10 10 5

汽封直径Steam seal diameter cm 62.0 62.0 62.0 44.8 44.8 33.0 33.0

汽封间隙Steam seal gap cm 0.05 0.05 0.05 0.05 0.05 0.05 0.05

漏汽面积Steam leakage area cm2 9.739 9.739 9.739 7.037 7.037 5.184 5.184

rated condensing operating condition 3.162 1.764 0.415 -0.122 0.047 -0.128 0.065

max. power condition 3.464 1.932 0.458 -0.117 0.047 -0.128 0.065

漏汽量 condensing operating condition in summer 3.269 1.816 0.426 -0.120 0.047 -0.128 0.065

Steam

leakage max. condensing operating condition in summer 3.641 2.019 0.479 -0.114 0.047 -0.128 0.065

amount

t/h high pressure heater cut condition 2.990 1.862 0.432 -0.121 0.048 -0.128 0.065

75% condensing operating condition 2.399 1.364 0.319 -0.131 0.048 -0.128 0.065

50% condensing operating condition 1.670 0.971 0.226 -0.137 0.048 -0.128 0.065

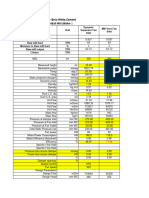

5.2 进入各换热器的流量(包括阀杆漏汽)Flow rate into the heat exchangers (including steam leakage from valve rod)

1号高 3号低 1号低

加No. 1 加No. 3 加No. 1 汽封加热器

至除氧器to 自密封装置self

漏汽去向steam leakage direction high low low steam seal

deaerator sealing device

pressur pressur pressur hedater

e heater e heater e heater

rated condensing operating condition 1.398 1.349 0.537 1.20 -0.362 0.212

max. power condition 1.532 1.474 0.575 1.20 -0.357 0.212

condensing operating condition in summer 1.453 1.39 0.546 1.20 -0.360 0.212

流量

flow max. condensing operating condition in summer 1.622 1.54 0.593 1.20 -0.354 0.212

rate t/h

high pressure heater cut condition 1.128 1.43 0.553 1.20 -0.362 0.213

75% condensing operating condition 1.035 1.045 0.45 1.20 -0.372 0.213

50% condensing operating condition 0.699 0.745 0.363 1.20 -0.378 0.213

第 1 页,共 1 页

You might also like

- Singa Gas Development Project: 4 of 12 Process Loadsheet For Flare Package (42-KZZ-791)Document9 pagesSinga Gas Development Project: 4 of 12 Process Loadsheet For Flare Package (42-KZZ-791)false mailNo ratings yet

- Calculating Pipe Sizing and Pressure DropDocument12 pagesCalculating Pipe Sizing and Pressure Dropchemkumar16No ratings yet

- Reboiler 1Document12 pagesReboiler 1kishna009No ratings yet

- HYDRAULIC CALCULATION SHEET FOR PLANT AIR BLOWERDocument1 pageHYDRAULIC CALCULATION SHEET FOR PLANT AIR BLOWERAgung Pandega PutraNo ratings yet

- Shop Manual GD610, GD620, GD660, GD670 PDFDocument664 pagesShop Manual GD610, GD620, GD660, GD670 PDFAing LaingNo ratings yet

- Distillation CalculationDocument9 pagesDistillation Calculationraviralagiri020% (1)

- Quality certificate analysisDocument6 pagesQuality certificate analysisClaudia TiradoNo ratings yet

- Thermodynamic Correction Curves For Model n600-16 7538538 Steam TurbineDocument27 pagesThermodynamic Correction Curves For Model n600-16 7538538 Steam Turbinearunrajmech09No ratings yet

- 2006-2008-Cbf1000-A-7 Cooling SystemDocument22 pages2006-2008-Cbf1000-A-7 Cooling SystemMurariu IonutNo ratings yet

- Balance de Materia 1Document12 pagesBalance de Materia 1diego veyzagaNo ratings yet

- keepflo_refrigerant_distributors_catalogDocument20 pageskeepflo_refrigerant_distributors_catalog霍广东No ratings yet

- Everest Blower Troble Shooting ManualDocument10 pagesEverest Blower Troble Shooting Manualdumb2471817100% (1)

- Jihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191Document2 pagesJihar Stage 3 Project: HPC Contract No: HPC/08-06 Petrofac Job No: JI-191HarryBouterNo ratings yet

- Steam Trap Calculation Sheet - 01Document7 pagesSteam Trap Calculation Sheet - 01Erwin Firmansyah Saputro0% (1)

- 362Document2 pages362Ajay AsodariyaNo ratings yet

- Tubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The WorkstringDocument2 pagesTubing String Testing (TST) Valve: Provides Tubing Testing Capability With Automatic Fill of The Workstringadi nugroho100% (1)

- Sga - TK Steam Balance: and ForDocument9 pagesSga - TK Steam Balance: and ForThiet PhamNo ratings yet

- Introduction To DGSDocument58 pagesIntroduction To DGSAan Sarkasi AmdNo ratings yet

- Lionn Auto SoftwaresDocument2 pagesLionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- trial details april 2024Document45 pagestrial details april 2024RS MANIKANDANNo ratings yet

- Stability Calculation BarcazaDocument26 pagesStability Calculation BarcazaRenzo Gonzales EsquenNo ratings yet

- Hitech Therm 60Document16 pagesHitech Therm 60Sales Support100% (1)

- Steam Trap Calculation Sheet - 02Document9 pagesSteam Trap Calculation Sheet - 02Erwin Firmansyah Saputro0% (1)

- Liquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340Document10 pagesLiquid Ring Vacuum Pumps: LPH 75320, LPH 75330, LPH 75340pablodugalNo ratings yet

- See Sheet API-2000: Normal Venting Liquid Movement Thermal EffectDocument33 pagesSee Sheet API-2000: Normal Venting Liquid Movement Thermal EffecthhvgNo ratings yet

- Hengshui Yinli Rubber Products Company ProfileDocument27 pagesHengshui Yinli Rubber Products Company ProfileAbdennourNo ratings yet

- Compressor SealingDocument20 pagesCompressor SealingdachrydaxNo ratings yet

- Heatreatment Evaluation ReportDocument14 pagesHeatreatment Evaluation ReportFelizarta Ell JessieNo ratings yet

- Shop Trial ME - 0001Document2 pagesShop Trial ME - 0001dsssaszNo ratings yet

- Ace CatalogueDocument8 pagesAce Catalogueosmanyildirim85No ratings yet

- 0715 LZ56WZ1 V01Document8 pages0715 LZ56WZ1 V01hobolghaniNo ratings yet

- Rogers - Unknown - RO4400 Series BondplyDocument4 pagesRogers - Unknown - RO4400 Series BondplyHadi SaeidiManeshNo ratings yet

- Boiler TrainingDocument117 pagesBoiler TrainingAlvinNo ratings yet

- Esp Calculation Sheet - m1Document7 pagesEsp Calculation Sheet - m1Buraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Project: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataDocument1 pageProject: Plot 68 Amghara SITE: Kuwait Ac Unit: Pacu 01 General DataSajidNo ratings yet

- Esp Calculation Table (Ranjith)Document6 pagesEsp Calculation Table (Ranjith)RanjithNo ratings yet

- LPH 65320 LPH 65327Document9 pagesLPH 65320 LPH 65327Eko WageurNo ratings yet

- Stability CalculationDocument6 pagesStability CalculationRenzo Gonzales EsquenNo ratings yet

- Gauging LinerDocument2 pagesGauging LinerArun SNo ratings yet

- NE1130BZ: Compressor Technical SpecificationDocument9 pagesNE1130BZ: Compressor Technical SpecificationIsidro MendozaNo ratings yet

- System ChecksumsDocument2 pagesSystem ChecksumsPraveen Raj RNo ratings yet

- Compressor Dry Gas SealsDocument53 pagesCompressor Dry Gas SealsMuhammad Imtiaz100% (1)

- Riyadh Ductwork Project Pressure Loss CalculationsDocument1 pageRiyadh Ductwork Project Pressure Loss CalculationsHyder AliNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetZineddine ALICHENo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetkhaledNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetBuraq Aircondition Cont & Gen Maint LLC BuraqNo ratings yet

- Riyadh Ductwork Project Pressure Loss CalculationsDocument1 pageRiyadh Ductwork Project Pressure Loss CalculationsFahad NaveedNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetLeandro FelipeNo ratings yet

- Donper Ne6170bzDocument9 pagesDonper Ne6170bzriyowNo ratings yet

- Flowcon SM 15-40Mm: Dynamic Self Balancing Control ValveDocument6 pagesFlowcon SM 15-40Mm: Dynamic Self Balancing Control Valvefmelman 04No ratings yet

- Valv Bola 1-2 2000 WogDocument1 pageValv Bola 1-2 2000 WogAndres Salvador MenaNo ratings yet

- Raw Mill - Birla White CementDocument9 pagesRaw Mill - Birla White Cementanurag soniNo ratings yet

- Duct Element Duct Section Width (MM) Height (MM) Air Flow RATE (CFM) AIR Flow Rate (L/S) AIR Flow Rate (m3/s) Duct Length (M) No - of Fittings Friction Loss For St. Duct (Pa/m)Document7 pagesDuct Element Duct Section Width (MM) Height (MM) Air Flow RATE (CFM) AIR Flow Rate (L/S) AIR Flow Rate (m3/s) Duct Length (M) No - of Fittings Friction Loss For St. Duct (Pa/m)ibnrafeeqNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation Sheetroslan1966No ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation Sheethussr2No ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation Sheetsarcoram64No ratings yet

- HT Xlpe PDFDocument3 pagesHT Xlpe PDFrengaramanujanNo ratings yet

- Consolidacion Civil FinalDocument30 pagesConsolidacion Civil FinalPacheco Diaz JorvisNo ratings yet

- Plan Bricking 2010 New Rev.2Document14 pagesPlan Bricking 2010 New Rev.2ManekGoris100% (1)

- Micro Schedule 2010.rev3Document5 pagesMicro Schedule 2010.rev3ManekGoris100% (1)

- Tracking spare parts overhaul 2016Document68 pagesTracking spare parts overhaul 2016ManekGorisNo ratings yet

- MD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733Document21 pagesMD - MMD: Monobloc Centrifugal Electric Pump in Compliance With en 733ManekGorisNo ratings yet

- Bulan Downtime Durasi TanggalDocument1 pageBulan Downtime Durasi TanggalManekGorisNo ratings yet

- Kebutuhan Flow MeterDocument2 pagesKebutuhan Flow MeterManekGorisNo ratings yet

- Specifications and Data for Various PumpsDocument11 pagesSpecifications and Data for Various PumpsManekGorisNo ratings yet

- Tabell Spek PompaDocument11 pagesTabell Spek PompaManekGorisNo ratings yet

- Data 1 Unit 1Document59 pagesData 1 Unit 1ManekGorisNo ratings yet

- Spesifikasi Pompa Pond & WWTPDocument4 pagesSpesifikasi Pompa Pond & WWTPManekGorisNo ratings yet

- Form WoDocument2 pagesForm WoManekGorisNo ratings yet

- 150 AyDocument12 pages150 AyManekGorisNo ratings yet

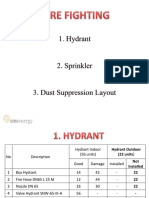

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Pump TestDocument52 pagesPump TestManekGorisNo ratings yet

- 25jul2019 - Presentasi Hydrant Fire Fighting - FinalDocument8 pages25jul2019 - Presentasi Hydrant Fire Fighting - FinalManekGorisNo ratings yet

- Diameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SDocument1 pageDiameter Pipa OD: 4 " ID 100 MM 0.1 M Velocity (V) 2000 Mm/s Q 15.71 Mm3/SManekGorisNo ratings yet

- Lining Bin Fine CoalDocument14 pagesLining Bin Fine CoalManekGorisNo ratings yet

- PumpDocument18 pagesPumpManekGorisNo ratings yet

- Grate Plate Cooler101215Document4 pagesGrate Plate Cooler101215ManekGorisNo ratings yet

- 7065SG 12 (S) MDocument1 page7065SG 12 (S) MManekGorisNo ratings yet

- Harga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorDocument10 pagesHarga Barang & Material Perencanaan Instalasi Hydrant Indoor & OutdoorManekGorisNo ratings yet

- Air BlasterDocument9 pagesAir BlasterManekGorisNo ratings yet

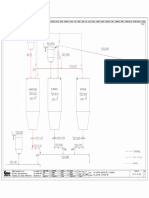

- Cement MIll Flow SheetDocument2 pagesCement MIll Flow SheetManekGorisNo ratings yet

- Venting Dosing Calsiner PDFDocument1 pageVenting Dosing Calsiner PDFManekGorisNo ratings yet

- Pumps & Pumping Systems: Training Session On Energy EquipmentDocument40 pagesPumps & Pumping Systems: Training Session On Energy EquipmentKaushik SenguptaNo ratings yet

- WA0001 Acuan OperatorDocument3 pagesWA0001 Acuan OperatorManekGorisNo ratings yet

- Venting Dosing Calsiner PDFDocument1 pageVenting Dosing Calsiner PDFManekGorisNo ratings yet

- Kebutuhan Panas Cement Mill (1) 1Document3 pagesKebutuhan Panas Cement Mill (1) 1ManekGorisNo ratings yet

- Lining Bin Fine CoalDocument14 pagesLining Bin Fine CoalManekGorisNo ratings yet

- Ips-E-Pr-771 SthexDocument43 pagesIps-E-Pr-771 Sthexdr_s_m_afzali8662No ratings yet

- Physics of WeldingDocument8 pagesPhysics of WeldingAbu SaadNo ratings yet

- Pump Fundamental Training Latest 2021Document153 pagesPump Fundamental Training Latest 2021nishanuddin zainalNo ratings yet

- Service Card IPMDocument3 pagesService Card IPMIng. Gilberto Macias ReyesNo ratings yet

- Britannia Field ReportDocument6 pagesBritannia Field Reportdaul93No ratings yet

- NIRMAL PRODUCTS FOR PROCESS AND NATURAL GAS INDUSTRIESDocument8 pagesNIRMAL PRODUCTS FOR PROCESS AND NATURAL GAS INDUSTRIESConcept -CEPLNo ratings yet

- Process: Accutech Laser PVT LTD Master List of MachinesDocument11 pagesProcess: Accutech Laser PVT LTD Master List of MachinesMagesh WaranNo ratings yet

- EconomizerDocument18 pagesEconomizershashwat shuklaNo ratings yet

- Chapter3 Thermo1Document36 pagesChapter3 Thermo1tisha revillaNo ratings yet

- Gtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWDocument19 pagesGtaw and Gmaw Equipment and Supplies: 7.2 Arc Welding Power Sources For GTAWNachiket MujumdarNo ratings yet

- Vendor DataDocument6 pagesVendor DatasubudhiprasannaNo ratings yet

- 8100 Series Brochure PDFDocument12 pages8100 Series Brochure PDFHeny MarthaNo ratings yet

- Heating and Air-Conditioning Principles: Learning ObjectivesDocument11 pagesHeating and Air-Conditioning Principles: Learning ObjectivesMubarek TeshomeNo ratings yet

- Steam-Distillation ExperimentDocument3 pagesSteam-Distillation Experimentrachit rayNo ratings yet

- CE2202 Fluid Mechanics NOTESDocument0 pagesCE2202 Fluid Mechanics NOTESGp ChengNo ratings yet

- Cce Test - 1677610418Document13 pagesCce Test - 1677610418yosifNo ratings yet

- Wor ShopDocument4 pagesWor ShopDavid Santiago Ayala RodriguezNo ratings yet

- 26 (Surface Tension, Viscosity)Document3 pages26 (Surface Tension, Viscosity)Kaveesh KulkarniNo ratings yet

- EWWD-VZ D-EIMWC003D01-17 Installation and Operation Manuals ArabicDocument80 pagesEWWD-VZ D-EIMWC003D01-17 Installation and Operation Manuals ArabicSalman MNo ratings yet

- Mindray-Wato-Ex-65 - Service ManualDocument322 pagesMindray-Wato-Ex-65 - Service Manualichraq nouarNo ratings yet

- Dual Fuel SystemDocument2 pagesDual Fuel Systemchdeepak96No ratings yet

- Cross Reference GuideDocument3 pagesCross Reference GuideWahyu YanuarNo ratings yet

- Level Measurement ExperimentDocument14 pagesLevel Measurement ExperimentTajTaj86% (7)

- MTC 02 W Throttle Check Valve (320BAR)Document4 pagesMTC 02 W Throttle Check Valve (320BAR)박준용No ratings yet

- Volatility - Properties of MatterDocument3 pagesVolatility - Properties of MatterKhaled ElsayedNo ratings yet

- Tech Tip #19: How Do You Keep Steam Coils From Freezing?Document7 pagesTech Tip #19: How Do You Keep Steam Coils From Freezing?adil_farooq_6No ratings yet

- Atmospheric PollutionDocument19 pagesAtmospheric PollutionFaraz100% (1)

- Aircraft Hydraulic and Pneumatic Systems GuideDocument2 pagesAircraft Hydraulic and Pneumatic Systems GuidePravin HandeNo ratings yet

- Week 1 Properties of FluidDocument15 pagesWeek 1 Properties of FluidJoquem PamesaNo ratings yet

- 120lab Report 3Document4 pages120lab Report 3Valerie Mae Librero Areño100% (2)