Professional Documents

Culture Documents

Dso138 Mini Troubleshooting Guide

Uploaded by

Ilyes KHOUILDIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dso138 Mini Troubleshooting Guide

Uploaded by

Ilyes KHOUILDICopyright:

Available Formats

DN138-13v01

DSO138mini Troubleshooting Guide

Applicable main board: 109-13800-00I

Applicable analog board: 109-13801-00H

1. Frequently Found Problems

1) LCD completely dark. No backlight

2) LCD lights up but no display (while screen)

3) Incorrect V+

4) Incorrect V-

5) Incorrect AV+

6) Incorrect AV-

7) Grids displayed and buttons working but no trace

8) When moving slide switches (SW1, SW2, or SW3) their screen indicators don’t change

accordingly

9) Incorrect vertical sensitivity

10) Can not reach good compensation for cap trimmer C4 or C6

2. Tools You Need

Ø Volt-Meter Prepare a commonly available digital multi-meter that has reasonable

accuracy. In case you only have old style mechanical volt-meter the voltage

reading could be lower than its real value due to low impedance of the meter.

Ø Ohm-Meter Ohm-meter is used to check resistance and continuity. Again you can use the

ohm-meter in a digital multi-meter.

Ø Oscilloscope We assume many users of this kit are beginners who do not have

oscilloscope so we are not going to discuss the troubleshooting methods with

oscilloscope. Users who have oscilloscope can use it to check and view signals

basing on their own understanding.

3. Troubleshooting Skills

Ø Unless otherwise stated voltage measurements should be made by placing the negative

pen to the reference point of circuit board (usually denoted as GND) and positive pen to

the point of interest. See the photo below.

Ø At resistance measurement please make sure to follow the rules below.

1) Power supply must be turned off if measurement is made to in-circuit

components.

2) To measure the resistance of in-circuit resistor you must disconnect at least one

end of the resistor to get correct reading. If you don’t the resistance formed by

the rest components in circuit will lower the reading.

Ø Use ohm-meter to find out opens and shorts. Similarly, you must cut power before doing

the checking.

Ø Always check power supplies first when you have problems. Make sure power supply

voltages are within acceptable ranges.

Ø When you measure resistors with large resistance avoid touching both pens with your

hands because the resistance of human body would lower the reading significantly.

JYE Tech -1- www.jyetech.com

DN138-13v01

4. Reference Voltages

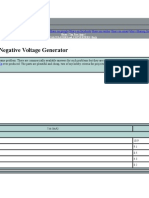

Fig. 1

5. Detailed Checking Steps for Commonly Found Problems

Symptom 1: LCD completely dark.. No backlight

Analysis: This indicates the LCD backlight LED does not get powered or is broken. LCD

backlight is powered by V+ via R4 (on the main board). So the problem cause

should be with V+, R4, LCD backlight itself, or the connections between them.

Solution: Check by the following procedures.

1) V+.

2) R4 (on main board) soldering and value.

3) Continuity from V+ to R4 and from R4 to LCD pins. For access to LCD

pins you might need to remove the adhesive tape that sticks LCD to

PCB.

4) LCD pin soldering.

Symptom 2: LCD lights up but no display (white screen)

Analysis: Since the LCD is controlled by the MCU (U1) the possible causes for this

problem could be:

1) The MCU is not running.

2) The MCU is running but can not communicate with the LCD due to poor

connections between them.

3) The LCD is bad.

Solution: Basing on analysis above we can

1) Verify MCU is running. At powering up the LED D1 on the main board

will blink three times. If you don’t see this it is likely that the MCU is

not running. Please check MCU power supply (+3.3V) and the crystal

and soldering.

2) If MCU is running check the connections between MCU and LCD by

referring to the schematic. Because the pins of MCU and LCD are small

and density is high it is difficult to do continuity check with ohm-meter

JYE Tech -2- www.jyetech.com

DN138-13v01

unless you have sharp pens. Visual check is advised.

Symptom 3: Incorrect V+

Analysis: By referring to the schematics you can see that V+ comes from either of two

sources. One is the USB power from J7 on the main board. The other is battery

from J6 on the analog board. If you power the device by USB V+ is from VBUS

via diode D2 (on the main board) and BOB1 if installed (on the analog board). If

you power the device by battery V+ is from the battery via BOB1. The problem

of V+ could be caused by open or higher than normal resistance in these

connections. On the other hand, V+ problem could also be caused by too large

load current because large current would drag down input voltage.

Solution:

1) Check input voltage. If input voltage is significantly lower than its normal

value disconnect the board and check the input voltage again. If the value

returns normal that indicates the board is over current. There could be shorts

somewhere between VBUS/V+ and GND. Sometimes a reversely installed

IC would create very large current.

2) If input voltage is normal check the connections from input to V+ for opens.

Symptom 4: Incorrect V-

Analysis: V- is generated by the negative voltage generator formed by U2 (ICL7660 on the

analog board), C12, and C13. Most of time problems of V- are caused by defects

in these components. But V- could also be dragged low by over large load current.

It is suggested to disconnect loading before troubleshooting the negative voltage

generator.

Solution:

1) Disconnect L2 and check if V- returns to normal. If it does that means V-

problem was caused by large load current. This large current is usually

created by shorts between AV- and ground. You need to uncover the short

spot.

2) If V- problem persists with L2 disconnected first replace C12 and C13 one

by one to see if you can get V- normal. If not replace U2.

Symptom 5: Incorrect AV+

Analysis: AV+ is from V+ through L1. If V+ is good but no AV+ that usually means L1 is

open. If both V+ and AV+ are significantly lower than normal that means there

are possibly shorts between AV+ and ground.

Solution:

1) If V+ is good and AV+ is low check the resistance of L1. The resistance of

L1 is 2 – 3 ohm maximum. If you find its value too large replace it.

2) If both V+ and AV+ are low check the resistance between AV+ and GND. If

you find its value is close to zero that means there are shorts. You need to

uncover the short spots.

3) Check the orientation of U1 on the analog board. If U1 is installed reversed

it will draw large current from AV+ that would make both AV+ and V+ low.

JYE Tech -3- www.jyetech.com

DN138-13v01

Symptom 6: Incorrect AV-

Analysis: AV- is from V- through L2. If V- is good but no AV- that usually means L2 is open.

If both V- and AV- are significantly lower than normal that means there are

possibly shorts between AV- and ground.

Solution:

1) If V- is good and AV- is low check the resistance of L2. The resistance of

L2 is 2 – 3 ohm maximum. If you find its value too large replace it.

2) If both V- and AV- are low check the resistance between AV- and GND.

If you find its value is close to zero that means there are shorts. You need

to uncover the short spots.

3) Check the orientation of U1 on the analog board. If U1 is installed

reversed it will draw large current from AV+ that would make both AV-

and V- low.

Symptom 7: Grids displayed and buttons working but no trace

Analysis: There are two possible causes for this problem. One is the ADC inside U1 on the

main board is broken. The other is the input voltage (i.e. output voltage of the

analog board) is off too much from its center value which is about 1V. At real

world the first cause is rare to see. In most case it is the second cause that makes

the problem.

Solution:

1) Make sure AV+ and AV- are correct.

2) Set the couple switch SW1 to GND position. Check the voltages V1 and

V2 on the analog board. V1 should be very close to 0V and V2 should be

close to 1.05V.

3) If V1 is off from 0V check the soldering of U1 and components R1 – R6

and C2 – C6.

4) If V1 is good but V2 is off from 1V for more than 0.5V check V4. V4

should be around -1.05V. If V4 is correct check U1B and resistors R9,

R10, and R11.

5) If V4 is not good check V3. V3 should be around 2.1V. If V3 is good

check U1A and resistors R13 and R15.

6) If V3 is not good check R14 and zener D1.

Symptom 8: When moving the slide switches(SW1, SW2, or SW3)their screen indicators

don’t change accordingly

Analysis: When moved the A poles of these switches do the functions they were designed to

do while the B poles serve as position detector. MCU determines switch position

by measuring voltages at B poles (via signals CPLSEL, VSENSEL1, and

VSENSEL2 respectively) and changes indicators accordingly. The levels of

signal CPLSEL, VSENSEL1, and VSENSEL2 can be AV+, Vz (2V), and 0V

depending on switch position. The indicator display problem indicates that the

MCU does not detect the signals correctly.

Solution:

JYE Tech -4- www.jyetech.com

DN138-13v01

1) Depending on which indicator is wrong place that switch at different

position and check the corresponding pads of connector J4 on the main

board. If the measured level is correct the problem is inside the main board.

Check the connection from the pad to MCU pins by following schematic

and see if there is open.

2) If the level at J4 pads is wrong check the soldering of related switches and

pin-header J5 on the analog board and J4 on the main board.

Symptom 9: Incorrect vertical sensitivity

Analysis: Vertical sensitivity is determined by the overall gain of the analogue channel. All

the following components play a part in determining the overall gain:

Ø The first attenuation stage. This stage includes the following

components.

10mV range -- R1, C2

0.1V range -- R2, R3, C3, and C4

1V range -- R4, R5, C5, C6, and C7

Ø The first amplifier. This includes U1D.

Ø The second attenuation stage. This stage includes R6, R7, and R8

Ø The second amplifier. This includes R9, R10, R11, and U1B.

Solution:

1) If you find gain error is the same for all ranges the issue is likely with

components in the first and second amplifiers and the second attenuation

stage. Check the related parts.

2) If gain error happens only to some ranges check the parts relating to those

ranges.

3) Pay close attention to resistor values since they are easy to misread.

Symptom 10: Can not reach good compensation for cap trimmer C4 or C6

Analysis: In theory the ideal value of C4 would make the following equation true.

C4 / C3 = R2 / R3

Similarly the ideal value of C6 would make the following equation true.

(C6//C7) / C3 = R4 / R5

At calibrating C4 (C6) if you see waveform with rounded angle that means C4

(C6//C7) is too large or C3 (C5) is too small. On the opposite if you see

waveform with overshoots that means C4 (C6//C7) is too small or C3 (C5) is too

large.

Solution:

1) If waveform appears round angled and you can not make it right-angled by

turning C4 try increasing C3 by adding a small capacitor (0.5pF or so) in

parallel with C3 or replacing C3 with a slightly larger capacitor.

2) If waveform appears round angled and you can not make it right-angled by

turning C6 try reducing C6//C7 by replacing C7 with a smaller capacitor (10

– 20pF less).

3) If waveform appears overshoot and you can not make it right-angled by

turning C4 try reducing C3 by replacing it with a slightly smaller one.

4) If waveform appears overshoot and you can not make it right-angled by

JYE Tech -5- www.jyetech.com

DN138-13v01

turning C6 try increasing C6//C7 by replacing C7 with a larger capacitor (10

– 20pF greater).

Revision History

Version Date Summary

v01 2018.06.08 Draft

JYE Tech -6- www.jyetech.com

You might also like

- Basic Concepts 1Document14 pagesBasic Concepts 1Somefd SomedfdNo ratings yet

- 2009-11!27!194320 Plasma TV Trouble Shooting DW3-No-pix-troubleshootDocument10 pages2009-11!27!194320 Plasma TV Trouble Shooting DW3-No-pix-troubleshootVernon NashNo ratings yet

- Multimeter TesterDocument32 pagesMultimeter TesterMarjenneil0% (1)

- How To Use A Multimeter Simplified - A Complete DIY Step by Step Guide On How To Use A Multimeter To Measure Voltage, Current, Resistance, Continuity and in Troubleshooting Circuits PDFDocument30 pagesHow To Use A Multimeter Simplified - A Complete DIY Step by Step Guide On How To Use A Multimeter To Measure Voltage, Current, Resistance, Continuity and in Troubleshooting Circuits PDFilovepieriaNo ratings yet

- My Roboventure - Subhransu PDFDocument34 pagesMy Roboventure - Subhransu PDFSai Swaroop MandalNo ratings yet

- How To Use A Multimeter Simplified - A Complete DIY Step by Step Guide On How To Use MultimeterDocument43 pagesHow To Use A Multimeter Simplified - A Complete DIY Step by Step Guide On How To Use MultimeterWilliam BautistaNo ratings yet

- 1 1 2 A Investigating Basic Circuits DLB CompleteDocument9 pages1 1 2 A Investigating Basic Circuits DLB Completeapi-2769485670% (1)

- DIGITAL MULTI-METER - The Definitive Guide On To Effectively Use Your Digital Multi-Meter PDFDocument50 pagesDIGITAL MULTI-METER - The Definitive Guide On To Effectively Use Your Digital Multi-Meter PDFHerman HeseNo ratings yet

- Analog Discovery Circuits Lab GuideDocument8 pagesAnalog Discovery Circuits Lab GuideOmotoyosi Taiwo100% (1)

- How To Use A MultimeterDocument19 pagesHow To Use A Multimetersrk_uk100% (1)

- Measuring Electricity Using Multi MeterDocument6 pagesMeasuring Electricity Using Multi MeterAddiNo ratings yet

- Multi MeterDocument6 pagesMulti MeterKinjalkumar M. GarasiyaNo ratings yet

- 1 1 2 Ak Investigating Basic Circuits DLBDocument9 pages1 1 2 Ak Investigating Basic Circuits DLBapi-290804719100% (1)

- Applied Physics: Lab ManualDocument13 pagesApplied Physics: Lab ManualMuhammad Ahsan ShahèénNo ratings yet

- EDC Lab 2Document16 pagesEDC Lab 2Muhammad AwaisNo ratings yet

- Understanding Essential Lab EquipmentDocument16 pagesUnderstanding Essential Lab EquipmentMuhammad AwaisNo ratings yet

- Lab 1 - Diode Characteristics and ApplicationsDocument8 pagesLab 1 - Diode Characteristics and ApplicationsMD NAZMUN HASAN NAFEESNo ratings yet

- 1.1.2.A Investigating Basic Circuits - DMSDocument8 pages1.1.2.A Investigating Basic Circuits - DMSBilly bobsNo ratings yet

- Power Diode WorksheetDocument20 pagesPower Diode WorksheetLộc Phạm vănNo ratings yet

- Free Report on Solving Power Supply Problems in CRT TVs and MonitorsDocument15 pagesFree Report on Solving Power Supply Problems in CRT TVs and Monitorsbioteky100% (1)

- Troubleshooting April 22 2015Document9 pagesTroubleshooting April 22 2015Geoffrey AlleyneNo ratings yet

- How to use a multimeter to measure voltage, current, resistance and test diodes and transistorsDocument5 pagesHow to use a multimeter to measure voltage, current, resistance and test diodes and transistorswaar lockNo ratings yet

- Lab Exploring LEDsDocument8 pagesLab Exploring LEDsNasermahmoud AhmedNo ratings yet

- How to Use a Multimeter to Measure Voltage, Current, Resistance & ContinuityDocument4 pagesHow to Use a Multimeter to Measure Voltage, Current, Resistance & Continuitymario_1303No ratings yet

- Analog Discovery Setup and ExplorationRev3Document7 pagesAnalog Discovery Setup and ExplorationRev3DanielAeiounAeioumNo ratings yet

- 1.1.2.A Investigating Basic Circuits - DMSDocument9 pages1.1.2.A Investigating Basic Circuits - DMSBilly bobsNo ratings yet

- CRT Television Troubleshooting Guide - Humphrey KimathiDocument77 pagesCRT Television Troubleshooting Guide - Humphrey KimathiJoserecon Bonilla100% (2)

- EEE2045F Diode PracticalDocument6 pagesEEE2045F Diode PracticaljaconlateNo ratings yet

- Checking Steps For Ir Module 1 138Document5 pagesChecking Steps For Ir Module 1 138kumbrovNo ratings yet

- Nintendo Checks PDFDocument25 pagesNintendo Checks PDFBagotaiTamásNo ratings yet

- CM3 Water Level Sensor DiagnostiDocument2 pagesCM3 Water Level Sensor DiagnostiArgenis Eduardo García PelayoNo ratings yet

- DL850 DiagnosticsDocument20 pagesDL850 DiagnosticssonotiumNo ratings yet

- ECG AmplifierDocument8 pagesECG AmplifierBosco LamNo ratings yet

- Exp 08 Analog DiscoveryOrM2kDocument24 pagesExp 08 Analog DiscoveryOrM2kMuhammed UmarNo ratings yet

- Lab 2 ReportDocument9 pagesLab 2 Reportapi-302057574No ratings yet

- How to Measure Voltage, Current and Continuity with a MultimeterDocument28 pagesHow to Measure Voltage, Current and Continuity with a MultimeterMax StewartNo ratings yet

- Lab Practices HandoutDocument7 pagesLab Practices HandoutDonovan DibsNo ratings yet

- ECE 170 Lab #1 Basic MeasurementsDocument13 pagesECE 170 Lab #1 Basic MeasurementsOlimpiu StoicutaNo ratings yet

- IQan Trouble Shooting-RockDocument20 pagesIQan Trouble Shooting-RockВячеслав РубцовNo ratings yet

- AVR ATtiny USB TutorialDocument30 pagesAVR ATtiny USB TutorialNIKOLAOS NANNOSNo ratings yet

- Diagnosing Problems Without Expensive ToolsDocument5 pagesDiagnosing Problems Without Expensive ToolsRodrigo EvaristoNo ratings yet

- CRT Television Troubleshooting Guide - Humphrey Kimathi NVDocument77 pagesCRT Television Troubleshooting Guide - Humphrey Kimathi NVRajesh100% (4)

- 555 Negative Voltage Generator: Share On Google Share On Facebook Share On Twitter Share On Email More Sharing ServicesDocument5 pages555 Negative Voltage Generator: Share On Google Share On Facebook Share On Twitter Share On Email More Sharing ServicesAakanksha BajpaiNo ratings yet

- Troubleshooting & Repair Guide - Part 2Document9 pagesTroubleshooting & Repair Guide - Part 2Eugene FlexNo ratings yet

- Activity 1.1.2 Investigating Basic Circuits (DMS) : Part A: Creating A Circuit and Measuring A Circuit's PropertiesDocument9 pagesActivity 1.1.2 Investigating Basic Circuits (DMS) : Part A: Creating A Circuit and Measuring A Circuit's PropertiesNick SNo ratings yet

- Electrical Basics Worksheet: Body Electrical Definitions and Rules DefinitionsDocument18 pagesElectrical Basics Worksheet: Body Electrical Definitions and Rules DefinitionsLong HàNo ratings yet

- Dell E152Fpb LCD Monitor RepairDocument3 pagesDell E152Fpb LCD Monitor RepairMicheal speedNo ratings yet

- Measuring Voltage and Resistance with a MultimeterDocument5 pagesMeasuring Voltage and Resistance with a MultimeterNishanth.M nishuNo ratings yet

- Measuring The IV Curve of Semiconductors With An ArduinoDocument1 pageMeasuring The IV Curve of Semiconductors With An ArduinoNatalia PetrovaNo ratings yet

- Voltage Drop Test 122718Document3 pagesVoltage Drop Test 122718Abdul JabbarNo ratings yet

- Basic Electronics (Lab Manual)Document66 pagesBasic Electronics (Lab Manual)Abdullah Sohail100% (2)

- Application Note AN02 - ELM327 Circuit Construction: Testing The ELM327 ICDocument3 pagesApplication Note AN02 - ELM327 Circuit Construction: Testing The ELM327 ICpogo pogoNo ratings yet

- How To Make AC 220 Volt Automatic Stabilizer UsingDocument7 pagesHow To Make AC 220 Volt Automatic Stabilizer UsingGian LayanNo ratings yet

- Manual de Reparación de Líneas Can p1000 NissanDocument8 pagesManual de Reparación de Líneas Can p1000 NissanautissanNo ratings yet

- An Introduction To AC Signals and Their Measurement: 1 ObjectivesDocument8 pagesAn Introduction To AC Signals and Their Measurement: 1 ObjectivesguapohonNo ratings yet

- Experment 5 Led (Light Emmiting Diode)Document2 pagesExperment 5 Led (Light Emmiting Diode)Tekalegn DemsisNo ratings yet

- Course: Electronic Circuit Design Lab No: 13 Title: Complimentary Pair Amplifier (Push-Pull Amplifier) CID: - DateDocument11 pagesCourse: Electronic Circuit Design Lab No: 13 Title: Complimentary Pair Amplifier (Push-Pull Amplifier) CID: - DateAamir ChohanNo ratings yet

- DuoKit 2 User GuideDocument20 pagesDuoKit 2 User GuideGREG KIRBY50% (2)

- Condensadores Cerámicos SMD DatasheetDocument15 pagesCondensadores Cerámicos SMD DatasheetJose BenavidesNo ratings yet

- LM324-N-MIL Low-Power, Quad-Operational Amplifier: 1 Features 3 DescriptionDocument30 pagesLM324-N-MIL Low-Power, Quad-Operational Amplifier: 1 Features 3 DescriptionIlyes KHOUILDINo ratings yet

- Lm3242 6-Mhz, 750-Ma Miniature Adjustable Step-Down DC-DC Converter With Auto Bypass For RF Power AmplifiersDocument32 pagesLm3242 6-Mhz, 750-Ma Miniature Adjustable Step-Down DC-DC Converter With Auto Bypass For RF Power AmplifiersIlyes KHOUILDINo ratings yet

- LM324-MIL Quadruple Operational Amplifier: 1 Features 3 DescriptionDocument25 pagesLM324-MIL Quadruple Operational Amplifier: 1 Features 3 DescriptionIlyes KHOUILDINo ratings yet

- Man 8.163Document198 pagesMan 8.163halilagic75% (8)

- Sdmo Mics Nexys Control Panel ManualDocument22 pagesSdmo Mics Nexys Control Panel ManualKetfi Abdelghani55% (11)

- L 9466Document11 pagesL 9466marcosNo ratings yet

- Caterpillar Cat Th417c Telehandler Operator and Maintenance ManualDocument24 pagesCaterpillar Cat Th417c Telehandler Operator and Maintenance ManualIlyes KHOUILDI100% (1)

- Plastic Power Transistors Mje2955T PNP Mje3055T NPN TO-220 Plastic PackageDocument3 pagesPlastic Power Transistors Mje2955T PNP Mje3055T NPN TO-220 Plastic PackageIlyes KHOUILDINo ratings yet

- HT 1621Document20 pagesHT 1621sakthivel159No ratings yet

- Sdmo Mics Nexys Control Panel ManualDocument22 pagesSdmo Mics Nexys Control Panel ManualKetfi Abdelghani55% (11)

- Alternator Tach Signals: Understanding the IssuesDocument1 pageAlternator Tach Signals: Understanding the IssuesEdin HadzicNo ratings yet

- GPS Tracker ST-902: User ManualDocument10 pagesGPS Tracker ST-902: User ManualIlyes KHOUILDINo ratings yet

- Data Sheet Acquired From Harris Semiconductor SCHS093C Revised October 2003Document20 pagesData Sheet Acquired From Harris Semiconductor SCHS093C Revised October 2003Ilyes KHOUILDINo ratings yet

- LMC7660 Switched Capacitor Voltage Converter: Features DescriptionDocument21 pagesLMC7660 Switched Capacitor Voltage Converter: Features DescriptioneNo ratings yet

- STK4162IIDocument9 pagesSTK4162IIFredy Reinaldo Rivera MartínezNo ratings yet

- RFD15P05, RFD15P05SM, RFP15P05: 15A, 50V, 0.150 Ohm, P-Channel Power Mosfets FeaturesDocument8 pagesRFD15P05, RFD15P05SM, RFP15P05: 15A, 50V, 0.150 Ohm, P-Channel Power Mosfets FeaturesIlyes KHOUILDINo ratings yet

- LMC7660 Switched Capacitor Voltage Converter: Features DescriptionDocument21 pagesLMC7660 Switched Capacitor Voltage Converter: Features DescriptioneNo ratings yet

- Gioi Thieu Stm8sDocument103 pagesGioi Thieu Stm8sVũ AnhNo ratings yet

- Incubator Analyzer Using Bluetooth AndroidDocument7 pagesIncubator Analyzer Using Bluetooth AndroidIlyes KHOUILDINo ratings yet

- Gioi Thieu Stm8sDocument103 pagesGioi Thieu Stm8sVũ AnhNo ratings yet

- LM2907 PDFDocument18 pagesLM2907 PDFUrfan AshrafNo ratings yet

- Mobile: Standard Rates Lyca Plus RatesDocument1 pageMobile: Standard Rates Lyca Plus RatesIlyes KHOUILDINo ratings yet

- TLP621 Photocouplers GuideDocument9 pagesTLP621 Photocouplers GuideKawann CostaNo ratings yet

- GSM Relay PDFDocument10 pagesGSM Relay PDFMario Alejandro Cortes AmorochoNo ratings yet

- RFD15P05, RFD15P05SM, RFP15P05: 15A, 50V, 0.150 Ohm, P-Channel Power Mosfets FeaturesDocument8 pagesRFD15P05, RFD15P05SM, RFP15P05: 15A, 50V, 0.150 Ohm, P-Channel Power Mosfets FeaturesIlyes KHOUILDINo ratings yet

- Accent ManualDocument136 pagesAccent ManualTushar RathodNo ratings yet

- Alternator Tach Signals: Understanding the IssuesDocument1 pageAlternator Tach Signals: Understanding the IssuesEdin HadzicNo ratings yet

- STK4162IIDocument9 pagesSTK4162IIFredy Reinaldo Rivera MartínezNo ratings yet

- BM1040QDocument1 pageBM1040QIlyes KHOUILDINo ratings yet

- Tektronix TDS210 Programmer ManualDocument256 pagesTektronix TDS210 Programmer Manualxlam99No ratings yet

- SINUMERIK 808D Diagnostics Manual 201212 EngDocument324 pagesSINUMERIK 808D Diagnostics Manual 201212 EngpsilvamarNo ratings yet

- Experiment No: 01 Name of The Experiment: Experimental Study of A Single Phase Half Wave Uncontrolled RectifierDocument30 pagesExperiment No: 01 Name of The Experiment: Experimental Study of A Single Phase Half Wave Uncontrolled RectifierJahedul IslamNo ratings yet

- ST2101Document34 pagesST2101sandeep_hotNo ratings yet

- EC3271 Circuit and Analysis Lab ManualDocument57 pagesEC3271 Circuit and Analysis Lab ManualSivagami Mani43% (7)

- Lab 4 (Filter) BEEL 1125Document6 pagesLab 4 (Filter) BEEL 1125Denayshan SelvarajooNo ratings yet

- Deccan College of Engineering & Technology: Power Electronics Laboratory ManualDocument73 pagesDeccan College of Engineering & Technology: Power Electronics Laboratory ManualharshNo ratings yet

- 1MA294 3e Sigfox Device TestDocument39 pages1MA294 3e Sigfox Device Testmano012No ratings yet

- J. Phys.: Conf. Ser. 1287 012022 Experiments Kundt’s tubeDocument9 pagesJ. Phys.: Conf. Ser. 1287 012022 Experiments Kundt’s tubeCitra Lestari LudjiNo ratings yet

- DPU-414 Serial Thermal Printer Service Manual: Seiko Instruments IncDocument37 pagesDPU-414 Serial Thermal Printer Service Manual: Seiko Instruments IncAbiNo ratings yet

- RSO - Before Fault RectificationDocument3 pagesRSO - Before Fault RectificationSayan AichNo ratings yet

- Communication Engineering Lab ManualDocument53 pagesCommunication Engineering Lab Manualtharunkumarreddy100% (1)

- Operation Manual For USB Autoscope IVDocument18 pagesOperation Manual For USB Autoscope IVMarcio OliveiraNo ratings yet

- Chapter 4 - AM DemodulatorDocument17 pagesChapter 4 - AM Demodulator21-08523No ratings yet

- 00Document60 pages00Ahmed AzadNo ratings yet

- TV Service ModesDocument93 pagesTV Service ModesjohnleiNo ratings yet

- P2220 Ponta de ProvaDocument4 pagesP2220 Ponta de Provahigor costaNo ratings yet

- Circuit Analysis With MultisimDocument198 pagesCircuit Analysis With Multisimtltorrent100% (1)

- Welcome To FreX16Document23 pagesWelcome To FreX16Veljko Nikolic100% (1)

- Manual Yamaha YST-SW800 (Service)Document26 pagesManual Yamaha YST-SW800 (Service)Alex NikitinNo ratings yet

- Cathode Ray Oscilloscope (CRO) ExplainedDocument14 pagesCathode Ray Oscilloscope (CRO) Explainedamanyire BrianNo ratings yet

- CDP-CX57 Service ManualDocument58 pagesCDP-CX57 Service ManualdocetallicoNo ratings yet

- NXP I2Cbus Elements SASEDocument79 pagesNXP I2Cbus Elements SASEPablo Cotan100% (2)

- Service Notes: Issued by RJADocument15 pagesService Notes: Issued by RJAcarlosNo ratings yet

- 269-314900 - Rev A - FTIR - IG50 - LASER AND POWER SUPPLY - IGDocument30 pages269-314900 - Rev A - FTIR - IG50 - LASER AND POWER SUPPLY - IGIndhu VaratharajanNo ratings yet

- Quantum Technology Instruction Manual For Model HVP-51-DIFF-5Document94 pagesQuantum Technology Instruction Manual For Model HVP-51-DIFF-5kleephNo ratings yet

- Beko Chassis 12.6Document5 pagesBeko Chassis 12.6Mihai AlexandruNo ratings yet

- Mizar3 Alcor3 - Service ManualDocument80 pagesMizar3 Alcor3 - Service Manualsergiupogacian6303No ratings yet

- SIEMENS Adjustment Instructions Table of ContentsDocument37 pagesSIEMENS Adjustment Instructions Table of ContentsCosty100% (2)

- Voltage Programmer's Guide 1.0.6Document100 pagesVoltage Programmer's Guide 1.0.6Graham SlaterNo ratings yet