Professional Documents

Culture Documents

Bleeder Vent

Uploaded by

ragulCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bleeder Vent

Uploaded by

ragulCopyright:

Available Formats

ENHANCEMENT OF CRUDE EXPORT FACILITIES

Document Title:

KUWAIT OIL BLEEDER VENT REQUIREMENT

COMPANY

CALCULATIONS for

(K.S.C.)

CRUDE OIL TANKS

Issue date: 26-12-2005 Document no: TK-01-ME-CAL-1010 Rev. 0 Page 2 of 3

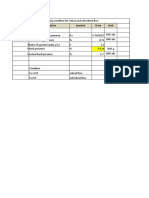

Bleeder Vent Requirements for Floating Roof Tanks

Design Code* : API Std. 2000, April 1998/ 5 th Edition, Section 4 Tank: 8 x 618,000 bbls crude oil

Design Data

Tank Nominal Diameter ND 92 m

Low Position of Roof in Service H 1.320 m

2

ND .

Tank Low Position Capacity C π . H C = 8775 m3

4

Weight of Roof W 705000 kg

Liquid Flow Rates (as per note 4 of KOC data Q in 16860 m3 / hr

sheet DAS-1617-ME-1900-01) Q out 16860 m3 / hr

Flash Point Index f 1 (f =1 if flash point of liquid < 37.8oC)

(f =0 otherwise)

Inbreathing Requirement

Required venting capacityfor liquid movement out of tank Q i1 0.94. Q out

Q i1 = 15848.4 Nm3 / hr

Minimum er quired venting capacityfor thermal inbreathing Q i2 1122 Nm3 / hr

Total inbreathing requirement Qi Q i1 Q i2 Q i = 16970.4 Nm3 of air / hr

Outbreathing Requirement

Required venting capacityfor liquid movement into tank Q o1 if f , 2.02. Q in , 1.01. Q in

Q o1 = 34057.2 Nm3 / hr

Minimum er quired venting capacityfor thermal outbreathing Q o2 1122 Nm3 / hr

Total outbreathing requirement Qo Q o1 Q o2 Q o = 35179.2 Nm3 of air / hr

ENHANCEMENT OF CRUDE EXPORT FACILITIES

Document Title:

KUWAIT OIL BLEEDER VENT REQUIREMENT

COMPANY

CALCULATIONS for

(K.S.C.)

CRUDE OIL TANKS

Issue date: 26-12-2005 Document no: TK-01-ME-CAL-1010 Rev. 0 Page 3 of 3

Bleeder Vent Selection

Flow coefficient assumed cf 0.5

Inner diameter of vent pipe ID 330 mm

Outer diameter of center pipe od 89 mm

Design pressure and vacuum Pp 40 Pv 40 mm water

Number of bleeder vent valves n 10

Flow per vent at set vacuum

2 2

π . ID π . od .

q 1v 0.0145518. c f . Pv q 1v = 3649.5 Nm3 of air / hr

4 4

Flow per vent at set pressure

2 2

π . ID π . od .

q 1p 0.0145518. c f . Pp q 1p = 3649.5 Nm3 of air / hr

4 4

Q 1v n . q 1v Q 1p n . q 1p

Available venting capacity of 10 vents Q 1v = 36495 or Q 1p = 36495 Nm3 of air / hr

RESULT: The venting capacity is sufficient for the required inbreathing and outbreathing

(*) Note: API STD 2000 is designed for fixed roof tanks that are prone to vacuum and

pressure loads during emptying and filling process. A floating roof tank, when its roof is

resting on its legs at its lowest position, acts as a fixed roof tank as it is prone to vacuum

and pressure loads during the initial filling or final emptying stages. That is the reason why

bleeder vents are required on a floating roof tank, and that is why API STD 2000 is

used for the purpose of calculation of bleeder vents.

You might also like

- Inbreathing OutbreathingDocument17 pagesInbreathing OutbreathingInggit100% (2)

- Atmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Document1 pageAtmospheric Storage Tanks Venting Req API 2000 (6th ED 2009)Mohammed AttiaNo ratings yet

- API 2000 Venting1Document5 pagesAPI 2000 Venting1aw_ae100% (1)

- Data Sheet SphericalDocument12 pagesData Sheet SphericalYosses Sang Nahkoda100% (2)

- PVV Cal Sheet LabixDocument45 pagesPVV Cal Sheet LabixPranpath Narupantawart50% (2)

- Tank CalcDocument21 pagesTank CalcInggitNo ratings yet

- Sulfuric Acid Tank - APIDocument4 pagesSulfuric Acid Tank - APISakthi VelNo ratings yet

- API 2000 Spread SheetDocument43 pagesAPI 2000 Spread Sheetjagan100% (3)

- Cooling Water Sprinkler SystemDocument38 pagesCooling Water Sprinkler SystemGladson Js100% (1)

- TEG Dehydartion PackageDocument69 pagesTEG Dehydartion Packageragul100% (1)

- TEG Dehydartion PackageDocument69 pagesTEG Dehydartion Packageragul100% (1)

- R V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingDocument10 pagesR V C V: API STD 2000-2014, Calculation For Max. Flow Rates For Normal InbreathingAnonymous a4Jwz14W0% (1)

- Center Vent & Peripheral Vent CalDocument1 pageCenter Vent & Peripheral Vent CalrichardchiamNo ratings yet

- Storage Tank Normal Venting Capacity Calculations PDFDocument1 pageStorage Tank Normal Venting Capacity Calculations PDFNathan MoralesNo ratings yet

- Venting-CalculationsDocument3 pagesVenting-CalculationsKartik PatelNo ratings yet

- Storage Tank Normal Venting Capacity CalculationsDocument1 pageStorage Tank Normal Venting Capacity CalculationstutuionutNo ratings yet

- Ammonia Gas Spherical Storage TankDocument7 pagesAmmonia Gas Spherical Storage TankBenedick Jayson MartiNo ratings yet

- 3191-CS-01 Rev A-009-011Document3 pages3191-CS-01 Rev A-009-011Syed Zain AliNo ratings yet

- Thermal PSV Sizing MercerDocument1 pageThermal PSV Sizing MercerapgoslingNo ratings yet

- Data Sheet Fuel Gas Filter Rev 0Document22 pagesData Sheet Fuel Gas Filter Rev 0Bowo Edhi WibowoNo ratings yet

- Design of Atmospheric Tanks - API650Document25 pagesDesign of Atmospheric Tanks - API650Faizal CANo ratings yet

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- Crude Tower Simulation-HYSYS v8.6 PDFDocument62 pagesCrude Tower Simulation-HYSYS v8.6 PDFrawadNo ratings yet

- Inlet Diffuser CalculationDocument1 pageInlet Diffuser CalculationMohammed Faizal NvNo ratings yet

- Vent Capacity (API Standard 2000)Document1 pageVent Capacity (API Standard 2000)Vince Bagsit PolicarpioNo ratings yet

- Tank Normal Venting (API)Document1 pageTank Normal Venting (API)ام يمنى ايمنNo ratings yet

- Calculate The Wall Thickness of Methanol Storage TankDocument4 pagesCalculate The Wall Thickness of Methanol Storage TankhaidirNo ratings yet

- Mechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Document38 pagesMechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Hamid MansouriNo ratings yet

- Degassing Boot SizingDocument31 pagesDegassing Boot SizingRexx Mexx50% (2)

- Vent SizingDocument5 pagesVent SizingPrashant Malve0% (1)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoNo ratings yet

- Venting: As Per Section 4.3 of API 2000, InbreathingDocument2 pagesVenting: As Per Section 4.3 of API 2000, InbreathingJoshue AdeleNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Cons Tank enDocument27 pagesCons Tank enSujesh Beherain Vasudeva100% (1)

- Spherical Tank PDFDocument1 pageSpherical Tank PDFevrim77No ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- Ssags PSV SizingDocument5 pagesSsags PSV SizingEkundayo JohnNo ratings yet

- Evaporation Loss Measurement For Storage TanksDocument6 pagesEvaporation Loss Measurement For Storage Tankssuman_94103No ratings yet

- ITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpDocument20 pagesITP F TK-4101 & TK-4201 A/B: Persian Gulf Star Gas Condensate Refinery-Kal Station Booster PumpHamid MansouriNo ratings yet

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Volume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFDocument12 pagesVolume and Wetted Area of Partially Filled Vertical Vessels - Neutrium PDFdaimon_p100% (1)

- Svrcek S 3 Phase Separator ArticleDocument12 pagesSvrcek S 3 Phase Separator ArticleRobert MontoyaNo ratings yet

- EDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFDocument33 pagesEDO-PPP-ME-GNR-INT-XXX-013-107-108-Rev-A-AMMONIA STORAGE TANK DESIGN PDFErol DAĞ100% (1)

- Inbreathing Outbreathing of TanksDocument30 pagesInbreathing Outbreathing of Tanksomesh2008No ratings yet

- Double DeckDocument4 pagesDouble DeckJose CarlosNo ratings yet

- CPI SeparatorDocument3 pagesCPI SeparatorRajdeepsinhNo ratings yet

- Frangible Roof To Shell JointDocument1 pageFrangible Roof To Shell JointSAGARNo ratings yet

- Bulk Air Eliminator R1Document1 pageBulk Air Eliminator R1hydrothermsNo ratings yet

- Tank Vessel Overflow Line SizingDocument4 pagesTank Vessel Overflow Line SizingSteve Wan100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Basket Strainer PDC 350NBDocument1 pageBasket Strainer PDC 350NBKailas Nimbalkar0% (1)

- Edo-cal-me-gnr-Int-xxx-014-216-244-Rev.a-heating Coil and Suction Heater Calculatin Report For Crude Oil Storage TankDocument13 pagesEdo-cal-me-gnr-Int-xxx-014-216-244-Rev.a-heating Coil and Suction Heater Calculatin Report For Crude Oil Storage TankErol DAĞNo ratings yet

- Engineering Design Guide For Storage TanksDocument107 pagesEngineering Design Guide For Storage Tankssonng.engNo ratings yet

- 001.17056.000028-AK007-01 Cartridge FilterDocument5 pages001.17056.000028-AK007-01 Cartridge FilterQuy RomNo ratings yet

- SESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Document65 pagesSESCO.L90.D.501-03 - Basic Calculation of Machinery - Rev00Quyet PhungNo ratings yet

- Air Conditioning - Airteach - Provision Plant, A.C PlantDocument88 pagesAir Conditioning - Airteach - Provision Plant, A.C PlantGabriel AgafiteiNo ratings yet

- Diesel CycleDocument7 pagesDiesel Cyclesidabutar.2205531082No ratings yet

- A83 - Ring Wall TankDocument9 pagesA83 - Ring Wall TankRose Mary ChackoNo ratings yet

- Calculation and Spesification of Engine Room Air Ventilation SystemDocument12 pagesCalculation and Spesification of Engine Room Air Ventilation SystemMuzami ThahirNo ratings yet

- Ejercicio 246 PSV438 RESUELTODocument2 pagesEjercicio 246 PSV438 RESUELTOHumberto Ivan Gonzales TapiaNo ratings yet

- Sr. No Description Symbol Data Unit: CF 1 P V 2 2Document11 pagesSr. No Description Symbol Data Unit: CF 1 P V 2 2Dharmik PatelNo ratings yet

- C050203 - 0710 - 1110 - E - RGL - Specter Summit - FULL - 0Document34 pagesC050203 - 0710 - 1110 - E - RGL - Specter Summit - FULL - 0Dennis ArhinNo ratings yet

- Refrigeration Gas PlantDocument1 pageRefrigeration Gas PlantragulNo ratings yet

- Being A Chemical Engineering Student, What Technical QuestionsDocument4 pagesBeing A Chemical Engineering Student, What Technical QuestionsragulNo ratings yet

- 32 Samss 013 PDFDocument17 pages32 Samss 013 PDFragulNo ratings yet

- Oil Tank Caculations 10222019 PDFDocument1 pageOil Tank Caculations 10222019 PDFragulNo ratings yet

- Cooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantDocument3 pagesCooling Tower Package Engineering in Halliburton - Multi Chem Batch PlantragulNo ratings yet

- Manual Tecnico - Cooling Tower Pumbing and PipingDocument40 pagesManual Tecnico - Cooling Tower Pumbing and Pipingcarmen hernandezNo ratings yet

- Risk and Reliability Assessment in ChemicalDocument22 pagesRisk and Reliability Assessment in ChemicalragulNo ratings yet

- Rules of ThumbDocument105 pagesRules of ThumbEllen DawitriNo ratings yet

- Tamilnadu Amend PDFDocument12 pagesTamilnadu Amend PDFragulNo ratings yet

- All NFPA TablesDocument24 pagesAll NFPA TablesKhyle Laurenz DuroNo ratings yet

- Lube Oil System Sizing Calculations - API614 Chapter 3Document1 pageLube Oil System Sizing Calculations - API614 Chapter 3ragul100% (1)

- KFD Test Paper Sample Questions 1Document25 pagesKFD Test Paper Sample Questions 1ragulNo ratings yet

- Oil Tank Caculations 10222019 PDFDocument1 pageOil Tank Caculations 10222019 PDFragulNo ratings yet

- Full Text 02Document94 pagesFull Text 02vishnu vijayanNo ratings yet

- Environmental Product Declaration EPD 24 06Document8 pagesEnvironmental Product Declaration EPD 24 06ragulNo ratings yet

- Steam and Energy Systems PDFDocument264 pagesSteam and Energy Systems PDFragulNo ratings yet

- Cooling Tower Fundamentals PDFDocument117 pagesCooling Tower Fundamentals PDFsoumenhazraNo ratings yet

- Colebrook Equation (Solved) (Darcy)Document2 pagesColebrook Equation (Solved) (Darcy)ragulNo ratings yet

- Heat Exchanger Design Lecture - 07Document24 pagesHeat Exchanger Design Lecture - 07Mohmmad ShaikhNo ratings yet

- PDHDocument72 pagesPDHragulNo ratings yet

- Guideline12 2000 PDFDocument19 pagesGuideline12 2000 PDFJohn BarrowNo ratings yet

- Cooling Tower Fundamentals PDFDocument117 pagesCooling Tower Fundamentals PDFsoumenhazraNo ratings yet

- KFD Test Paper Sample Questions 1Document25 pagesKFD Test Paper Sample Questions 1ragulNo ratings yet

- Difference Between Orifice & Restriction Orifice - LinkedInDocument6 pagesDifference Between Orifice & Restriction Orifice - LinkedInragulNo ratings yet

- Applied Computational Fluid Dynamics PDFDocument354 pagesApplied Computational Fluid Dynamics PDFragul100% (2)

- Self Introduction SpeechDocument2 pagesSelf Introduction SpeechParesh ShrivastavaNo ratings yet

- Guides For Storage Tanks Nozzles Orientation - LinkedInDocument5 pagesGuides For Storage Tanks Nozzles Orientation - LinkedInragulNo ratings yet

- Eaton PDFDocument565 pagesEaton PDFAlejandro RojasNo ratings yet

- Stabilized Approach: Tool KitDocument5 pagesStabilized Approach: Tool KitQushay Al IdrusNo ratings yet

- GB - SGI LPG - CNG Software Manual - Version 5.1.0Document46 pagesGB - SGI LPG - CNG Software Manual - Version 5.1.0Ricardo PintoNo ratings yet

- Thermal Engg Lab ManualDocument190 pagesThermal Engg Lab Manualmmk.mech59No ratings yet

- Alternative 1Document8 pagesAlternative 1JeanNo ratings yet

- D 5682 - 95 Rdu2oditotuDocument4 pagesD 5682 - 95 Rdu2oditotuwpwmhatNo ratings yet

- Resume - Gawali Nikita Yuvraj - Format2Document2 pagesResume - Gawali Nikita Yuvraj - Format2Nikita GawaliNo ratings yet

- 2019 - Roadmap OverviewDocument5 pages2019 - Roadmap OverviewClean Air BDNo ratings yet

- AccessoriesDocument2 pagesAccessoriesPankaj JadhavNo ratings yet

- Inorganic Chemistry by Shriver & AtkinsDocument43 pagesInorganic Chemistry by Shriver & AtkinsManish AdvaniNo ratings yet

- 0385004362Document200 pages0385004362usriko9999No ratings yet

- Common ConstantsDocument3 pagesCommon Constantskristan7No ratings yet

- PHYSICAL SCIENCE ReviewerDocument65 pagesPHYSICAL SCIENCE ReviewerjaywarvenNo ratings yet

- Single Phase Smart MeterDocument1 pageSingle Phase Smart MeterBehailu FelekeNo ratings yet

- Ee2305 Set 1Document3 pagesEe2305 Set 1kaliappan45490No ratings yet

- VKBSDocument40 pagesVKBSharish_sekarNo ratings yet

- Ventilation On DemandDocument3 pagesVentilation On DemandAngelo Ramirez RojasNo ratings yet

- Gas Lift - Unloading (Leslie Thompson)Document59 pagesGas Lift - Unloading (Leslie Thompson)Reza RamadhanNo ratings yet

- T1 V1 F10 I1 F11 C1 F9 I2 W1 I3 W2: Position of Parts in Engine CompartmentDocument5 pagesT1 V1 F10 I1 F11 C1 F9 I2 W1 I3 W2: Position of Parts in Engine CompartmentAlha Ega AnadaNo ratings yet

- Saej 1004 V 002Document6 pagesSaej 1004 V 002Marcos Verissimo Juca de PaulaNo ratings yet

- Power Quality Improvement Using Unified Power Quality ConditionerDocument10 pagesPower Quality Improvement Using Unified Power Quality ConditionerCHEIF EDITORNo ratings yet

- YM80SA Abrasive Belt Polishing Machine-Operation ManualDocument7 pagesYM80SA Abrasive Belt Polishing Machine-Operation ManualAgha Ali KhanNo ratings yet

- Design Basis Memorandum - Regulatory Document IndexDocument123 pagesDesign Basis Memorandum - Regulatory Document Indexaugur8866124No ratings yet

- Personal Monitoring ServicesDocument71 pagesPersonal Monitoring Services212mp009No ratings yet

- Grade 9 Science Physics 2 DLPDocument9 pagesGrade 9 Science Physics 2 DLPManongdo AllanNo ratings yet

- Rack & Pinoin Rotary AvtutarDocument24 pagesRack & Pinoin Rotary AvtutarTanmoy DuttaNo ratings yet

- 03.5 - FPFF - Fire Preventing and FightingDocument78 pages03.5 - FPFF - Fire Preventing and FightingkunaalNo ratings yet

- Omni Manual DigitalDocument22 pagesOmni Manual DigitalSerge RosovNo ratings yet

- Panasonic sd698s - RPHDocument40 pagesPanasonic sd698s - RPHAnonymous 2iQ1B59100% (1)

- Qsk19 Mcrs Performance Curves Fr4609 755 1800 08may2013-PcDocument3 pagesQsk19 Mcrs Performance Curves Fr4609 755 1800 08may2013-Pckman548No ratings yet