Engineering Design Guide For Storage Tanks

Uploaded by

sonng.engEngineering Design Guide For Storage Tanks

Uploaded by

sonng.engCommon questions

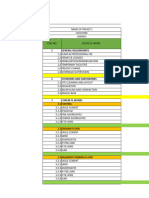

Powered by AIFloating roof seals play a crucial role in reducing product evaporation and vapor emissions in storage tanks. Primary seals serve as the first defense, usually involving stainless steel hangers and coil springs to ensure a snug fit and minimize gaps . The optimal seal design includes insulated components to prevent rim fires and maintain operational safety . Secondary seals further limit vapor losses and are required by most regulations above the primary seal. These often incorporate a segmental compression plate design, offering robustness and ease of maintenance. By ensuring a tight seal, both primary and secondary seal systems minimize evaporative loss, contributing to environmental compliance and cost-efficiency .

Primary and secondary seals in external floating roofs are essential for regulatory compliance and operational efficiency. Primary seals, mandated by most regulations, prevent product evaporation and reduce vapor emissions, thus keeping environmental impacts within legal limits . Secondary seals provide an additional layer of protection, further minimizing emissions and product loss, which is crucial for achieving stricter environmental standards and optimizing operational efficiency. Properly designed seals reduce maintenance costs and enhance safety by preventing leaks and reducing fire hazards, ensuring the integrity and longevity of storage tanks .

Integrating a rolling ladder in floating roof tank design is vital for ensuring safe and efficient operator access across varying roof levels. It requires that the tank diameter be at least 2.5 to 3.0 meters greater than the tank's height to provide adequate space for its operation . The design must ensure the ladder is self-adjusting to roof position changes, emphasizing flexibility and ease of use. Such integration is critical for operational safety and maintenance tasks, minimizing risk by providing stable access routes .

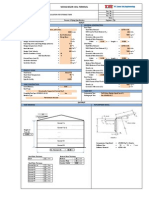

API 650 limits the maximum internal pressure to 2.5 psi when the tank is anchored to a counterbalancing weight, such as a concrete ringwall . The maximum design temperature is capped at 500°F; this ensures the material properties remain within safe and predictable performance standards . Additionally, the vacuum pressure is limited to 25 mm of water column, indicating the tank's restricted capability to handle vacuum conditions, which are critical for preventing collapse under certain operational scenarios .

API 650 specifies two methods for calculating shell thickness: the one-foot method for tank diameters less than 200 feet and the variable point method for tanks greater than 200 feet . For larger tanks, the variable point method considers the pressure exerted by the fluid and other operational factors that affect structural integrity. Factors influencing this calculation include the material properties, maximum operating pressure, and the presence of external forces such as wind and seismic activity. This ensures that the shell can withstand operational stresses while maintaining safety and compliance with code requirements .

API 620 allows for a maximum internal pressure of up to 15 psi, considerably higher than the 2.5 psi permitted by API 650, accommodating more pressurized applications . However, API 620 restricts the maximum design temperature to 250°F, compared to API 650's 500°F, indicating API 620 is tailored for operations requiring lower temperatures but higher pressures. This comparison underscores each code’s targeted applications, with API 620 being more suitable for cryogenic and low-temperature settings, whereas API 650 fits broader industrial applications .

Failure of the roof-to-shell joint in storage tanks is often initiated by buckling of the top angle, leading to tearing of the weld along the roof plate's periphery . This can be a consequence of inadequate design to handle pressure or weight distributions at the joint. If the joint is not frangible, implementing emergency venting devices in accordance with API 2000 is recommended to prevent catastrophic failure . These corrective actions aim to enhance tank safety by ensuring the joint can relieve excess pressure and accommodate load variations without structural compromise .

Seismic design considerations in API 650's Appendix E require checking the tank's stability against both wind moments and seismic moments. If a tank is found unstable under these conditions, alternatives such as increasing the shell thickness or annular plate thickness, or anchoring the tank as per code, may be necessary to enhance its stability . This highlights the importance of ensuring that the design addresses the environmental and geological seismic risks of the tank site, impacting both the immediate structural integrity and long-term durability of the tank .

The aluminum floating roof, according to Appendix H, is designed specifically for tanks with a fixed roof at the top of the tank shell, and it features plastic materials for the core and skin under certain conditions . This design includes an electrical interconnection for all conductive parts and must be capable of supporting at least two people. A key limitation is that aluminum floating roofs are generally suitable for smaller diameter tanks only, thus restricting their use compared to conventional steel floating roofs which can be applied to a wider range of tank sizes .

Atmospheric oil storage tanks are designed as per API 650, which covers materials, design, fabrication, erection, and testing requirements for vertical, cylindrical, aboveground, closed and open top, welded steel storage tanks with internal pressures approximating atmospheric pressure, except higher pressures when additional requirements are met . Water storage tanks, on the other hand, follow AWWA D100, which focuses on the construction and design standards specifically for water containment, emphasizing how these codes differ by the type of liquid being stored and the specific standards applicable to their respective materials and design constraints .