Professional Documents

Culture Documents

Collar Bolts: in Shell and Tube Heat Exchangers

Uploaded by

Mahdi HocineOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Collar Bolts: in Shell and Tube Heat Exchangers

Uploaded by

Mahdi HocineCopyright:

Available Formats

B o lt i n g S p e c i f i c a t i o n s

Collar bolts

in shell and tube heat exchangers

Collar bolts are used in By Baher Elsheikh, SABIC, Saudi Arabia

removable bundle heat

exchangers to hold the In the new, tenth edition of TEMA, which was published

bundle in place and in 2019, recommendations have been added under part

remove the channel RCB-11.8 for the use of collar bolts in removable bundles

with a B-type bonnet. These are summarized below and,

without interrupting

as per the recommended configuration, shown in Fig. 1.

or breaking the seal When specified by the purchaser, collar studs can be used

between the tubesheet on units with removable tube bundles. Collar studs are rec-

and the shell. This ommended for B-type bonnets. The OD of the stationary

tubesheet should match the mating flange OD and should

article examines recent

be through-bolted. Every fourth stud in the bolt circle

specifications on the (with a minimum of four) should be a collar type I for type

use of collar bolts II as shown in Fig. 1.

and concludes with a Collar bolts are only used to maintain the gasket integrity

and position when the channel is removed and torqued

consideration of the

prior to adding pressure.

pros and cons in their As an alternative to collar studs, every fourth bolt hole in

application. the tubesheet can be drilled and tapped to the size of the » Fig. 2. TEMA, figure N-1-2, type B stationary head.

stud bolt. The studs in the threaded holes should be dou-

TYPE I COLLAR STUD (SOLID TYPE) ble nutted on the shell side or provided with machined

1.5 D

+ 1/8” (3mm) 3/4” (19mm) 1/2” (12mm) TYP. flats to allow for the tube side nut without rotating the

MACHINE TO THREAD stud.

ROOT DIAMETER

In API 660, Para 7.5.2.4, a full diameter stationary

tubesheet should be provided for removable tube bundle

R 1/16” (1.5mm) TYP.

exchangers with bonnets (see TEMA, Fig. N-1.2, type B

MACHINE TO THREAD 1/2” (12mm) MIN.

ROOT DIAMETER stationary head, quoted in Fig. 2). The tubesheet should

FINISH SQUARE (OR FLATS) be provided with collar studs or tapped tubesheet holes

for a minimum of 25% of the bolts (with a minimum

TYPE II COLLAR STUD (NUT TYPE)

75% DIA FLAT of four). It should be possible to hrostatically test the

3/4” (19mm) (OR SQUARE) tubesheet design of the shell side when the bonnet has

MACHINE HEAVY HEX NUT

TO MINOR DIAMETER been removed and all the bolts have been installed.

If collar bolts or drilled and tapped holes are used, then at

least four should be permitted and their location should

DRILL AND TAP FOR STUD

be identified on the drawings and by stamped markings

1/4” (6mm) SET SCREW on the OD of the tubesheet.

In PIP VEFV1100M Vessel/S&T Heat Exchanger Stand-

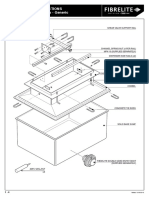

ASSEMBLY AND DRILLING DETAILS(TYPES I AND II) ard Details, a standard configuration for the collar bolts

dimensions is provided as shown in Fig. 3.

+ 1/8” (3mm)

COLLAR DIA

Surface condensers are designed to the requirements of

COLLAR LENGTH + 1/8” (3mm)

the Heat Exchange Institute (HEI) per the typical con-

figuration shown in Fig. 4, in which both the tubesheet

is fixed and the gasket between the tubesheet and shell

flanges cannot be attended to without the removal of one

of the tubesheets.

The following warning is quoted from the manual of

CHANNEL GIRTH FLANGE SHELL GIRTH FLANGE one of the most famous and reputable surface condenser

manufacturers in the world:

TUBESHEET “It is important not to break the seal between tubesheet

and shell flange. The tubes are expanded into each

tubesheet holding them firmly in place, and the shell

Fig. 1. seal must not be replaced without retubing the entire

»

Heat Exchanger World May 2020 39

B o lt i n g S p e c i f i c a t i o n s

condenser. To prevent breaking the joint, it is important

that all the nuts are removed from the waterbox flange TUBESHEET

side and not from the shell flange side. Do not loosen or TUBE

remove the stake studs and double nuts on the shell side.”

A leak on the shell side would have a great impact at the GASKET

plant as it would break the vacuum. The use of collar SHELL SIDE GASKET TUBE SIDE

bolts in such a configuration is a must.

Despite the illustrated advantages of using collar bolts,

there is debate in the industry about disadvantages in

their use as well – namely that they might be might

C

bring about more trouble from their inclusion instead

of enhancing the maintainability of the heat exchanger.

In the following section, their main pros and cons are WRENCH FLATS

summarized. THREADED COLLAR

COUNTERBORE (FOR

Pros and cons LOCKING STUD ONLY)

Pros for the use of collar bolts

OVERALL LENGTH

The main objective and advantage in using collar bolts

SPECIFIED BOLT LENGTH

is to enhance maintainability, considering the fact that

THREAD TO

each time the channel is removed, the bundle should be SUITE LOCKING

STUD

removed for replacing the gasket between the tubesheet

and the shell to avoid leakage after pressurizing the

exchanger. The replacement of the bundle gasket is time WRENCH FLATS THREAD FULL LENGTH THREADED COLLAR

consuming and increases Mean Time To Repair/Restore

(MTTR).

Cons for the use of the collar bolts

(a) An alternative viewpoint on the use of collar bolts Fig. 3.Colllar bolt/locking stud for heat exchangers.

»

is that it is not mandatory to remove the bundle if

the channel is removed. This opinion is based on the

experience of using kamprofile gaskets with graphite

facing and the application of initial correct stress and

following the use of the recommended torque to reach Impingement Exhaust Relief Valve

Protection (*) Connection(s) Connection

the desired gasket stress.

(b) In cases where the use of tapped holes results in bolts Condenser Air Off-

Dome

that stick, the amount of time needed to attend to Area Shell Take(s)

Tube

machining and the replacement of bolts would be time Support Tubes Water

consuming and might be beyond the feasible limits of Plates Outlet(s)

the maintenance crew for this task. Pass

(c) Inadequate marking or stamping of the collar bolts Partition

might mislead the maintenance crew, and collar bolts

might be removed by mistake.

(d) There might be relative higher cost accruing to the

larger tubesheet size and the aching required for the

bolt holes in the tubesheet.

References:

(1) API Std 660 - Shell-and-Tube Heat Exchangers

(2) TEMA Tenth Edition, 2019 (Standards Of The Tubular

Exchanger Manufacturers Association).

Water

(3) PIP VEFV1100M Vessel/S&T Heat Exchanger Stand- Inlet(s)

ard Details.

(4) Explore The World Of Piping – EWP

http://www.wermac.org/equipment/collarbolt.html) « Bathtub

Shell Hotwell

Waterbox Support

Expansion or Vertical

Flange Saddles

Joint Cylindrical

ABOUT THE AUTHOR Type

Hand Waterbox Shell

Baher Elsheikh is a Mechanical Engineer at SABIC. He has Flange Condensate

Holes (*) Cover

seventeen years of experience in the engineering, reliability, Outlet(s)

construction, commissioning and inspection management Tubesheet

of pressure equipment, piping systems, fired heaters, and

power boilers.

Fig. 4. Surface condenser.

»

40 Heat Exchanger World May 2020

You might also like

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 pagesCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineNo ratings yet

- Collar BoltsDocument2 pagesCollar BoltsMahdi HocineNo ratings yet

- API 660 Vs TEMADocument2 pagesAPI 660 Vs TEMAloqNo ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C MembersAmey ShettiNo ratings yet

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarNo ratings yet

- Shell and Tube Heat Exchangers (API 660 vsTEMA)Document3 pagesShell and Tube Heat Exchangers (API 660 vsTEMA)Aravind MadhuNo ratings yet

- Reinforcing Detailing of R.C.C MembersDocument47 pagesReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingMuhammad Saqib Abrar94% (16)

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 pagesالخطأ والصواب في تسليح العناصر الانشائيهSwift WardNo ratings yet

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Document22 pages3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Gaurav BedseNo ratings yet

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 pagesReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaNo ratings yet

- Reinforcement DetailingDocument47 pagesReinforcement DetailingSun Rise100% (1)

- Reinforcement DetailingDocument47 pagesReinforcement DetailingLimar SetstraNo ratings yet

- DownloadDocument47 pagesDownloadGajanVashishth100% (1)

- SP40-Steel Portal FrameDocument82 pagesSP40-Steel Portal FrameTarun saiNo ratings yet

- Procedures for Rotational Capacity Testing for High Strength BoltsDocument15 pagesProcedures for Rotational Capacity Testing for High Strength Boltsefmartin1321No ratings yet

- RC DetailingDocument82 pagesRC DetailingkishoreNo ratings yet

- Andsaw For The Lathe: by Dennis HorlerDocument6 pagesAndsaw For The Lathe: by Dennis HorlerJohn BrittonNo ratings yet

- RD001-01_V15Document14 pagesRD001-01_V15alaynnastaabx786No ratings yet

- Collar Bolts in Shell and Tube Heat ExchangersDocument3 pagesCollar Bolts in Shell and Tube Heat ExchangersBaher ElsheikhNo ratings yet

- Shearing Blind Rams SBRDocument8 pagesShearing Blind Rams SBRDavid OrtegaNo ratings yet

- CAT LM Series GET Brochure All MakesDocument20 pagesCAT LM Series GET Brochure All MakesRyan Abubakar Obili PakayaNo ratings yet

- Asme B18.7 2007Document13 pagesAsme B18.7 2007Jesse ChenNo ratings yet

- 313 1Document15 pages313 1PEARL ANGELIE UMBANo ratings yet

- Power Rasp, Build Your OwnDocument6 pagesPower Rasp, Build Your OwnJim100% (1)

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesGuillermoNo ratings yet

- Ubrass InstructionsDocument4 pagesUbrass InstructionsBenito SilvaNo ratings yet

- Parts Operation and Maintenace Manual: MODEL ZQ127/25Y Drill Pipe Power TongDocument26 pagesParts Operation and Maintenace Manual: MODEL ZQ127/25Y Drill Pipe Power TongAlejandra TabarezNo ratings yet

- PYROTENAX FIRE SURVIVAL CABLE TERMINATION GUIDEDocument12 pagesPYROTENAX FIRE SURVIVAL CABLE TERMINATION GUIDEShameel PtNo ratings yet

- 300880-1 Instruction Sheet: U.S. Patent No. 3,735,078Document4 pages300880-1 Instruction Sheet: U.S. Patent No. 3,735,078Fer PabNo ratings yet

- Boa Coil: Heavy-Duty, Reusable FasteningDocument2 pagesBoa Coil: Heavy-Duty, Reusable Fasteningblessed cccNo ratings yet

- Installation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Document4 pagesInstallation Instructions Tatsuno Dispenser Sump - Generic: 40Fc Sealant x4Camilo CorreaNo ratings yet

- Tema EnqDocument24 pagesTema Enqabhishek198327No ratings yet

- Hole-Cutting Mechanical TeesDocument19 pagesHole-Cutting Mechanical TeesEdwin Collado FigueroaNo ratings yet

- NBR-15417-2007 - Vasos de Pressão - Inspecao de Segurança em ServiçoDocument3 pagesNBR-15417-2007 - Vasos de Pressão - Inspecao de Segurança em ServiçoRodrigo PagnossinNo ratings yet

- Procedures For Rotational Capacity Testing For High Strength BoltsDocument12 pagesProcedures For Rotational Capacity Testing For High Strength BoltsAGnes Stephani MuntheNo ratings yet

- Assembly Instructions For Taper JointsDocument12 pagesAssembly Instructions For Taper JointsmohdNo ratings yet

- Catálogo de Conexiones ClampDocument2 pagesCatálogo de Conexiones ClampCarlos Nina OchoaNo ratings yet

- ProTech - 2PPvz - 23rd April 1999Document9 pagesProTech - 2PPvz - 23rd April 1999mm1919No ratings yet

- Verado 200-275 Workshop-2Document90 pagesVerado 200-275 Workshop-2Servicios Luna LSNo ratings yet

- Flexible Hose Ins.+Test.Document3 pagesFlexible Hose Ins.+Test.Filip NikolevskiNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Cylindrical Compression Helix Springs For Suspension SystemsFrom EverandCylindrical Compression Helix Springs For Suspension SystemsNo ratings yet

- Modelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleFrom EverandModelling a Tiger I s.Pz.Abt.507, East Prussia, November 1944: In I/35 scaleNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Practical Guide to the Operational Use of the Beretta 92F/M9 PistolFrom EverandPractical Guide to the Operational Use of the Beretta 92F/M9 PistolNo ratings yet

- PWHT Asme Sec Viii Div 1 Table Ucs56Document1 pagePWHT Asme Sec Viii Div 1 Table Ucs56Mahdi HocineNo ratings yet

- 4 Types of API Exam QuestionsDocument1 page4 Types of API Exam QuestionsMahdi HocineNo ratings yet

- Benefits of The Multiple Echo Technique For Ultrasonic Thickness TestingDocument10 pagesBenefits of The Multiple Echo Technique For Ultrasonic Thickness TestingMahdi HocineNo ratings yet

- Comparision of ISO 9712 & ASNTDocument6 pagesComparision of ISO 9712 & ASNTMurali Krishnan Selvaraja100% (1)

- Diesel Mechanics by Frank SandersDocument164 pagesDiesel Mechanics by Frank SandersMahdi HocineNo ratings yet

- Down FileDocument34 pagesDown FileppedringNo ratings yet

- Mpi TestDocument7 pagesMpi TestOgwu Charles KanayoNo ratings yet

- Weld Duplex Ss SteelDocument12 pagesWeld Duplex Ss SteelSan JaNo ratings yet

- Atlas Technical Handbook of ST Steel 05 2008 PDFDocument45 pagesAtlas Technical Handbook of ST Steel 05 2008 PDFPoncho RmzNo ratings yet

- Down FileDocument34 pagesDown FileppedringNo ratings yet

- RQD After 20 Years Deere 1989Document101 pagesRQD After 20 Years Deere 1989Johan Van Staveren100% (1)

- Colpitts OscillatorDocument3 pagesColpitts OscillatorBharat SwabhimanNo ratings yet

- 988G Perf ReportDocument10 pages988G Perf Reportlark_100% (1)

- NEC3 ECC Project Manager Form Templates V1-02Document61 pagesNEC3 ECC Project Manager Form Templates V1-02cityren75% (8)

- Debugging Solaris Using OBPDocument59 pagesDebugging Solaris Using OBPzeekndtroyNo ratings yet

- MR j2 CT m6 Setup - WDocument56 pagesMR j2 CT m6 Setup - WMauro S CabralNo ratings yet

- Acceptance Criteria For Weld DefectsDocument2 pagesAcceptance Criteria For Weld DefectsBaljee Singh100% (2)

- Be - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019Document2 pagesBe - Mechanical Engineering - Semester 4 - 2023 - February - Applied Thermodynamics at Pattern 2019loharjay772No ratings yet

- A1 Principles of Teaching - Ans.KeyDocument11 pagesA1 Principles of Teaching - Ans.KeyJam Uly Gasty100% (2)

- Q881507-9 Installation and Operating Manual PDFDocument1,059 pagesQ881507-9 Installation and Operating Manual PDFngocanhvyNo ratings yet

- HSBCDocument21 pagesHSBCHarsha SanapNo ratings yet

- 5500 Qtrap Hardware GuideDocument18 pages5500 Qtrap Hardware Guidebadabing123No ratings yet

- 3600 Reader SpreadsDocument12 pages3600 Reader SpreadsfurqanNo ratings yet

- TELE-audiovision International - The World‘s Largest Digital TV Trade Magazine TELE-audiovision International - 全球发行量最大的数字电视杂志Document15 pagesTELE-audiovision International - The World‘s Largest Digital TV Trade Magazine TELE-audiovision International - 全球发行量最大的数字电视杂志Alexander WieseNo ratings yet

- Lifting operations procedureDocument81 pagesLifting operations procedureAria Imam Ambara100% (3)

- Modern Foundation Construction with Ground ScrewsDocument130 pagesModern Foundation Construction with Ground ScrewssaivigneshfacebookNo ratings yet

- Residential Enclosure Options for Surface and Flush MountingDocument26 pagesResidential Enclosure Options for Surface and Flush MountingramadhanNo ratings yet

- Pramod ADocument4 pagesPramod ANandhini GowdaNo ratings yet

- User Manual of DS-8100-S DVR (V2.0.1)Document97 pagesUser Manual of DS-8100-S DVR (V2.0.1)Carlos Rojas ZapataNo ratings yet

- Lean PokaYokeDocument2 pagesLean PokaYokemilou88No ratings yet

- Rrepetitive Controller BasicDocument23 pagesRrepetitive Controller BasicSuranjana DasNo ratings yet

- Propeller Design CalculationDocument8 pagesPropeller Design CalculationDave Carter100% (7)

- 355 S DetectorDocument4 pages355 S DetectorFaizal ThelordImmortal100% (1)

- Dry BlockDocument2 pagesDry BlockSheik SulthanNo ratings yet

- Base Plate - MammutDocument8 pagesBase Plate - MammutAwais Hameed100% (1)

- Contoh Perhitungan EvaporatorDocument55 pagesContoh Perhitungan EvaporatorHeny AnggorowatiNo ratings yet

- Application of Artificial Neural Network (Ann) in Machining Analysis of Al-Sic Metal Matrix Composites by PCD 1600 InsertsDocument7 pagesApplication of Artificial Neural Network (Ann) in Machining Analysis of Al-Sic Metal Matrix Composites by PCD 1600 InsertsSpeeder JohnNo ratings yet

- Securiton Smoke Detector Performance DeclarationDocument2 pagesSecuriton Smoke Detector Performance DeclarationAnonymous YWmB9HDgNo ratings yet

- Teatrocompleto07eche DjvuDocument1,082 pagesTeatrocompleto07eche DjvudenialmanNo ratings yet

- 71.NCM-W NCM F Network Communicaiton ModulesDocument2 pages71.NCM-W NCM F Network Communicaiton ModulesGary JavierNo ratings yet