Professional Documents

Culture Documents

CR01-Work Center Create

Uploaded by

Dhanush Kumar0 ratings0% found this document useful (0 votes)

102 views14 pagesCR01-Work Center Create

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCR01-Work Center Create

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

102 views14 pagesCR01-Work Center Create

Uploaded by

Dhanush KumarCR01-Work Center Create

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 14

Work Center / Resource Create

What is Work center / Resource?

A work center is an organizational or physical unit that performs

manufacturing activities. A work center can be a machine or group

of machines and equipment.

Work centers may be grouped into a work center hierarchy where

every work center (except the top one) in the hierarchy is

subordinate to another work center.

Each work center contains its working hours information, which is

used to determine the available capacity is entered. The available

capacity for a work center is calculated using the number of

available hours. work center contains Scheduling and costing

information.

Resource is same as work center but it is used in PP-PI. There is

no difference between work center and Resource other than calling

it in a different name. Work center will be used in Routing and

Rate routing where as Resources will be used in Master Recipe.

Objective of this Document

This document will explain how to create work center.

List of prerequisites:-

Cost center details

What is the Menu path to log on to this Transaction code?

To create Work center:-

LogisticsProduction Master Data Work Centers Work Center

CR01 - Create

To create Resource:-

LogisticsProduction-process Production planning Master Data

Resources Resource CRC1 - Create

Note:- Creation of work center is explained here, except the menu

path and transaction, by following below steps, resource can also

be created.

1. Press Twice CR01 – Create.

2. Maintain the following data:

Field Name Values

Plant Enter the plant.

Example: 1200

Work center Enter work center

name.

Work center Enter category.

cat. Example: 0007

(Production line).

Plant Enter reference

(Copy from) work center plant.

Ref. Work Enter the reference

center work center.

(Copy from)

Note: If a reference work center is used to create the new work

center a pop-up box is displayed to select the data to be copied.

Click in the appropriate check boxes, then click on the Copy

button.

3. Click on the Enter button.

4. Maintain the following data:

Field Name Values

Work center Enter work center

description.

Example: Total

palletizing unit 7

Person Enter the person

responsible responsible.

Example: 001 (PE

Planner)

Usage Enter usage code

007 if the work

center is used in

repetitive

processes.

Enter usage code

008 if the work

center group is

used in discrete

processes.

Standard Enter standard

value key value key.

Example: SAP1

(Normal production)

Note: Long text may be entered for the work center by clicking on

the Create text button, entering information, then click on the

Back button .

5. Click on the Enter button.

6. Select must be entered in dropdown

.

7. Click Default values .

8. Maintain the following data:

Field Name Values

Control key Enter control key.

Example: PP01

(Repetitive

manufacturing)

Setup Enter control key.

Example: H (Hours)

Machine Enter control key.

Example: H (Hours)

Labour Enter control key.

Example: H (Hours)

9. Click on the Capacities .

10. Maintain the following data:

Field Name Values

Setup Enter formula.

formula Example: SAP005

(Production setup

requirements).

Processing Enter capacity

formula category.

Example: SAP006

(Production machine

requirements).

Note:- When creating Resource, Formula has to be entered in the

other formula field.

11. Click on the Enter button.

12. Click Capacity header button

13. Maintain the following data:

Field Name Values

Capacity Enter a

category description.

Example:

Operational unit

capacity, cat 009

Capacity Enter capacity

planner grp planner group.

Example: C01

Factory Enter the factory

calendar ID calendar. Optional.

Active Enter version

version number.

Example: 01 (Normal

available capacity)

Base unit of Enter unit of

meas. measure.

Example: H (Hours)

Finish Enter finish time.

Example: 24:00:00

Capacity Enter the capacity

utilization utilization.

Example: 100

No. of Enter the number of

indiv. cap. individual

capacities.

Example: 1

Relevant to Click in the check

finite box to set.

scheduling Example: Set

Long term Click in the check

planning box to set.

Example: Set

Note: The number of individual capacities is the number of machines

or equipment.

14. Click on the Enter button.

Do the following steps to define periods when the capacity

availability is not 100%. For example, during plant shutdown

capacity availability would be 0%.

15. Click Interval avail. cap. button .

Create Work Center Capacity: Intervals of Available Capacity

16. Click New line Shift+F1 Button .

Add Interval of Available Capacity

17. Maintain the following data:

Field Name Values

Valid from Enter start date.

Example: 010802

Valid to Enter end date.

Example: 310802

Capacity Enter percentage.

utilization Example: 0 (if a

shutdown or other

period of

inactivity)

18. Click Copy Enter Button .

19. Click Back F3 .

20. Click Choose button .

21. Click Back F3 twice.

22. Click Scheduling .

23. Maintain the following data:

Field Name Values

Capacity Enter Capacity

category category..

Example: 008

(Processing unit)

Setup Enter Setup

formula formula.

Example: SAP005

(Production setup

requirements)

Processing Enter Processing

formula formula.

Example: SAP006

(Production machine

requirements)

Note:- When creating Resource, Formula has to be entered in the

other formula field.

24. Click Costing .

Note: Here you enter the costing information provided by a CO

controller.

25. Maintain the following data:

Field Name Values

Cost center Enter value for the

cost center.

Example: 1201024

Activity Enter value in

type Column Activity

type.

Example: 1PDH01

(Production hours)

Activity Enter value in

unit Column Activity

unit.

Example: HR

Formula Enter value in

Column Formula.

Example: SAP001

(Production setup

time

Activity Enter value in

type Column Activity

type.

Example: 1PDH01

(Production hours)

Activity Enter value in

unit Column Activity

unit.

Example: HR

Formula Enter value in

Column Formula.

Example: SAP002

(Production machine

time

Note: correct formula should be entered for each Activity.

26. Click Save .

27. The message bar displays “Work center xxxx in plant xxxx was

created”

You might also like

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- Work Center in SAP PP: Create, Change, DisplayDocument10 pagesWork Center in SAP PP: Create, Change, DisplaysowjanyaNo ratings yet

- SAP Foreign Currency Revaluation: FAS 52 and GAAP RequirementsFrom EverandSAP Foreign Currency Revaluation: FAS 52 and GAAP RequirementsNo ratings yet

- SAP PP Work CentreDocument15 pagesSAP PP Work CentrebethojiNo ratings yet

- Concentrate Production ProcessDocument8 pagesConcentrate Production ProcessDavidNo ratings yet

- SAP MII and PCo Drive Real-Time Manufacturing VisibilityDocument5 pagesSAP MII and PCo Drive Real-Time Manufacturing VisibilitydvdmxNo ratings yet

- SAP NetWeaver Process Integration A Complete Guide - 2020 EditionFrom EverandSAP NetWeaver Process Integration A Complete Guide - 2020 EditionNo ratings yet

- DSAP MFG C202 Change Master RecipeDocument23 pagesDSAP MFG C202 Change Master RecipeDeepak SinghNo ratings yet

- PP Interview QuestionsDocument33 pagesPP Interview QuestionschameladeviNo ratings yet

- Hydra Mes Within Sap Environment Eng 276148Document4 pagesHydra Mes Within Sap Environment Eng 276148Pro5perNo ratings yet

- CAPP - Computer Aided Process Planning: Standard Value Calculation Via CAPP-anDocument23 pagesCAPP - Computer Aided Process Planning: Standard Value Calculation Via CAPP-anRaju100% (1)

- CAPP - Computer Aided Process Planning Overview: (Author: N. Mohan Raj, Chennai)Document31 pagesCAPP - Computer Aided Process Planning Overview: (Author: N. Mohan Raj, Chennai)RjNo ratings yet

- Workorder - Infosys Badi (Coois Modefication)Document9 pagesWorkorder - Infosys Badi (Coois Modefication)mohameds1988No ratings yet

- QM03 16 CalibrationDocument29 pagesQM03 16 CalibrationK Veera Kishore KumarNo ratings yet

- Alternative Materials in BOM & Production OrderDocument16 pagesAlternative Materials in BOM & Production Ordersrinivasa varmaNo ratings yet

- MRP ExerciseDocument3 pagesMRP ExerciseAbdelrahman El-OrbanyNo ratings yet

- 47 QM-020 Result Recording - Lot BasedDocument12 pages47 QM-020 Result Recording - Lot BasedElanNo ratings yet

- How to Handle Rework in Production Planning Using Trigger Points and Rework Order TypesDocument4 pagesHow to Handle Rework in Production Planning Using Trigger Points and Rework Order TypesMinal TripathiNo ratings yet

- Inspection Points: Key Settings and Usage: Rss FeedlikeDocument13 pagesInspection Points: Key Settings and Usage: Rss FeedlikeGangarani Galla100% (1)

- PP Master Data Version 002Document34 pagesPP Master Data Version 002pranitNo ratings yet

- TSN Murthy - Sap PPDocument7 pagesTSN Murthy - Sap PPvaddyseshuNo ratings yet

- Using Two Planning Strategies For The Same MaterialDocument10 pagesUsing Two Planning Strategies For The Same MaterialVigneshNo ratings yet

- SPI-PTSI PP01 PP Overview P V1.00Document27 pagesSPI-PTSI PP01 PP Overview P V1.00Motyib EkhlaaqNo ratings yet

- 45 Important SAP PP Interview Questions Answers Set 1 - CareersLiteDocument34 pages45 Important SAP PP Interview Questions Answers Set 1 - CareersLiterushikeshdeokar155No ratings yet

- The Ultimate C - C - TS422 - 1909 - SAP Certified Application Associate - SAP S4HANA Production Planning and ManufacturingDocument2 pagesThe Ultimate C - C - TS422 - 1909 - SAP Certified Application Associate - SAP S4HANA Production Planning and ManufacturingKirstingNo ratings yet

- SAP Capacity Planning - Pool CapacityDocument42 pagesSAP Capacity Planning - Pool CapacityArya RagNo ratings yet

- User Manual Bi - Bex-AnalyserDocument31 pagesUser Manual Bi - Bex-AnalyserYogesh PatilNo ratings yet

- Batch Management: Create A Characteristic Using T-Code CT04Document8 pagesBatch Management: Create A Characteristic Using T-Code CT04Nagesh PatilNo ratings yet

- LSMW IntroductionDocument37 pagesLSMW IntroductionAlina AlexNo ratings yet

- Apo Sapapo - Curto Simu Id Display Pds JPNDocument12 pagesApo Sapapo - Curto Simu Id Display Pds JPNnguyencaohuyNo ratings yet

- Master Recipes - Calculate Material Quantities Using Batch DataDocument6 pagesMaster Recipes - Calculate Material Quantities Using Batch DataetiennehanfNo ratings yet

- Purpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)Document20 pagesPurpose: 2. Inclusions in This Document:: Master Inspection Characteristics (MIC)nikku115No ratings yet

- IDES MK Length Based PlanningDocument21 pagesIDES MK Length Based PlanningaprianNo ratings yet

- SAP HR OM, PD and TrainingDocument774 pagesSAP HR OM, PD and TrainingIsaac Frankenstien NchitoNo ratings yet

- Ananth Technlogies Limited: SAP ImplementationDocument17 pagesAnanth Technlogies Limited: SAP ImplementationVenkat VaranasiNo ratings yet

- SAP Batch ManagementDocument3 pagesSAP Batch ManagementDrcyto100% (1)

- Set Up Customer Exits For External Batch Number Assignment: Further NotesDocument1 pageSet Up Customer Exits For External Batch Number Assignment: Further Noteskoushik goswamyNo ratings yet

- Selection of Production VersionDocument7 pagesSelection of Production VersionBalanathan VirupasanNo ratings yet

- Reporting Point Backflush in REM ProcessDocument8 pagesReporting Point Backflush in REM ProcessKoustubha KhareNo ratings yet

- Transfer Long Text Values of XStepsDocument17 pagesTransfer Long Text Values of XStepsJalal Masoumi KozekananNo ratings yet

- Custom BAPI CreationDocument12 pagesCustom BAPI Creationbharath_sajjaNo ratings yet

- Optimize MRP Material Requirement PlanningDocument4 pagesOptimize MRP Material Requirement PlanningganeshNo ratings yet

- Variant Configuration Basics - 40 CharactersDocument3 pagesVariant Configuration Basics - 40 Charactersnithinb_kumar65No ratings yet

- Shop Floor OperatopmDocument22 pagesShop Floor OperatopmAmir AliNo ratings yet

- MRP AreaDocument6 pagesMRP AreaAllwynRajkumarNo ratings yet

- Sap PP Material Master Production Version mm02 PDFDocument9 pagesSap PP Material Master Production Version mm02 PDFAjay SinghNo ratings yet

- REM e T eDocument22 pagesREM e T ervk386No ratings yet

- Different Types of Scraps in SapDocument3 pagesDifferent Types of Scraps in Sapwipro@651975No ratings yet

- Availbility CheckDocument21 pagesAvailbility CheckVikas SoniNo ratings yet

- PP-Interview Questions: Login Register Getting Started Newsletters StoreDocument3 pagesPP-Interview Questions: Login Register Getting Started Newsletters StoreVijayabhaskar PapanaNo ratings yet

- UD Reverse SAPnoteDocument6 pagesUD Reverse SAPnoteperumalNo ratings yet

- Metals Make to Order ScenarioDocument9 pagesMetals Make to Order ScenarioaprianNo ratings yet

- Quality Certificate - Goods ReceiptDocument5 pagesQuality Certificate - Goods Receiptbcg_503No ratings yet

- SAP DIMP 4.71 Learning Map For Solution ConsultantsDocument2 pagesSAP DIMP 4.71 Learning Map For Solution ConsultantsBobby GarrettNo ratings yet

- Create Production Order On Co01Document28 pagesCreate Production Order On Co01Sandeep PatidarNo ratings yet

- Inspection PointsDocument7 pagesInspection PointsAmol PethkarNo ratings yet

- 03 05 2020 Delhi PDFDocument35 pages03 05 2020 Delhi PDFDhanush KumarNo ratings yet

- Cross-plant production planning with special procurement types 70 and 80Document17 pagesCross-plant production planning with special procurement types 70 and 80Arjun KNo ratings yet

- CR03-Work CenterDisplayDocument4 pagesCR03-Work CenterDisplayDhanush KumarNo ratings yet

- Concise summary of 10-year electricity usage recordsDocument638 pagesConcise summary of 10-year electricity usage recordsDhanush KumarNo ratings yet

- Change Work Center Details in SAPDocument4 pagesChange Work Center Details in SAPDhanush KumarNo ratings yet

- BvfomDocument9 pagesBvfomDhanush KumarNo ratings yet

- Is Worst Yet To Come For Maha? Experts Weigh In: Capital ReopeningDocument18 pagesIs Worst Yet To Come For Maha? Experts Weigh In: Capital ReopeningDhanush KumarNo ratings yet

- Change Work Center Details in SAPDocument4 pagesChange Work Center Details in SAPDhanush KumarNo ratings yet

- IBP - Integrated Business Planning ModulesDocument9 pagesIBP - Integrated Business Planning ModulesDhanush Kumar100% (1)

- Understanding Production Order Variance - Part 1 PerformanceDocument1 pageUnderstanding Production Order Variance - Part 1 PerformanceDhanush KumarNo ratings yet

- Format - Rent AgreementDocument2 pagesFormat - Rent AgreementDhanush KumarNo ratings yet

- Integrating PPDSDocument2 pagesIntegrating PPDSDhanush KumarNo ratings yet

- How To Get Change History of Master RecipeDocument1 pageHow To Get Change History of Master RecipeDhanush KumarNo ratings yet

- No Goods Receipt: Hector Freeman View The Full DiscussionDocument2 pagesNo Goods Receipt: Hector Freeman View The Full DiscussionDhanush KumarNo ratings yet

- SAP Data Migration MethodologyDocument1 pageSAP Data Migration MethodologyDhanush KumarNo ratings yet

- Third Party Sale: Satya Prakash View The Full DiscussionDocument2 pagesThird Party Sale: Satya Prakash View The Full DiscussionDhanush KumarNo ratings yet

- How To Find User Exit For Any TDocument1 pageHow To Find User Exit For Any TDhanush KumarNo ratings yet

- ATP OverDocument2 pagesATP OverDhanush KumarNo ratings yet

- IDoc ORDERS05 setup with middlewareDocument2 pagesIDoc ORDERS05 setup with middlewareDhanush Kumar0% (1)

- Capacity Planning and CM25Document2 pagesCapacity Planning and CM25Dhanush KumarNo ratings yet

- Exchange Rate in MIGO Should Be Determined On GR Document DateDocument2 pagesExchange Rate in MIGO Should Be Determined On GR Document DateDhanush Kumar0% (2)

- Getting An Error in ML81NDocument2 pagesGetting An Error in ML81NDhanush KumarNo ratings yet

- Batch Status Change History in SAP EWMDocument1 pageBatch Status Change History in SAP EWMDhanush KumarNo ratings yet

- Batch Status Change History in SAP EWMDocument1 pageBatch Status Change History in SAP EWMDhanush KumarNo ratings yet

- Boms Alternative, Phantom Components and Production Orders: To MeDocument2 pagesBoms Alternative, Phantom Components and Production Orders: To MeDhanush KumarNo ratings yet

- ATP OverDocument2 pagesATP OverDhanush KumarNo ratings yet

- Message V1 244: Bing Lu View The Full DiscussionDocument1 pageMessage V1 244: Bing Lu View The Full DiscussionDhanush KumarNo ratings yet

- Planning Board Adjust and Reschedule Block LimitsDocument1 pagePlanning Board Adjust and Reschedule Block LimitsDhanush KumarNo ratings yet

- SCN ThreadDocument3 pagesSCN ThreadDhanush KumarNo ratings yet

- Telecommunications: Office of The Communications Authority (OFCA)Document2 pagesTelecommunications: Office of The Communications Authority (OFCA)ChiWoTangNo ratings yet

- Citect SCADA 2018 R2 - Configuration - Study GuideDocument19 pagesCitect SCADA 2018 R2 - Configuration - Study GuideAlex Sales0% (1)

- Menomonee Falls Express News 091413Document32 pagesMenomonee Falls Express News 091413Hometown Publications - Express NewsNo ratings yet

- The Role of Business in Social and Economic Development Chapter 1Document18 pagesThe Role of Business in Social and Economic Development Chapter 1Emil EscasinasNo ratings yet

- SQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsDocument6 pagesSQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsAchamyeleh TamiruNo ratings yet

- Study of The Pre-Processing Impact in A Facial Recognition SystemDocument11 pagesStudy of The Pre-Processing Impact in A Facial Recognition Systemalmudena aguileraNo ratings yet

- Document - University Admission SystemDocument100 pagesDocument - University Admission SystemNaresh SharmaNo ratings yet

- OCS Study Analyzes Instrument Performance for NC Oceanography ProgramDocument127 pagesOCS Study Analyzes Instrument Performance for NC Oceanography ProgramAniruddhNo ratings yet

- 11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsDocument1 page11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsLuz Alinsunurin DulogNo ratings yet

- Demethanizer OperationDocument6 pagesDemethanizer OperationHoustonAbducteeNo ratings yet

- Geotextile Its Application To Civil Engineering ODocument7 pagesGeotextile Its Application To Civil Engineering OezequilNo ratings yet

- Microprocessor 8086 Memory and ArchitectureDocument13 pagesMicroprocessor 8086 Memory and ArchitecturehrrameshhrNo ratings yet

- 4 Way Test of The Things We Think, Say or DoDocument5 pages4 Way Test of The Things We Think, Say or DoObakoma JosiahNo ratings yet

- Ficha Técnica Lithonia-JcblDocument9 pagesFicha Técnica Lithonia-JcblEmiliano HernándezNo ratings yet

- COVID-19 Impact on Philippine ExportsDocument5 pagesCOVID-19 Impact on Philippine ExportsHazel BorboNo ratings yet

- Standards in Nursing Education ProgrammeDocument13 pagesStandards in Nursing Education ProgrammeSupriya chhetryNo ratings yet

- Order From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedDocument9 pagesOrder From U.S. Disctrict Judge Jesus G. Bernal To Chino Valley UnifiedBeau YarbroughNo ratings yet

- Gek 106852aDocument10 pagesGek 106852awednetoxNo ratings yet

- Accounting Basics: Recording TransactionsDocument8 pagesAccounting Basics: Recording TransactionsRegina Bengado100% (1)

- Editable Classroom Officers TemplateDocument6 pagesEditable Classroom Officers TemplateRachelle AbalosNo ratings yet

- 2003 June Calc Paper 6 (H)Document20 pages2003 June Calc Paper 6 (H)abbasfazilNo ratings yet

- Annual Report 2067 68 Final PDFDocument399 pagesAnnual Report 2067 68 Final PDFBijay Poudel100% (1)

- DAA UNIT-3 (Updated)Document33 pagesDAA UNIT-3 (Updated)pilli maheshchandraNo ratings yet

- Plastic PackagingDocument47 pagesPlastic PackagingRajaSekarsajja100% (1)

- Ir 2101Document14 pagesIr 2101Willard DmpseyNo ratings yet

- IsotopesDocument35 pagesIsotopesAddisu Amare Zena 18BML0104No ratings yet

- Pantangco DigestDocument2 pagesPantangco DigestChristine ZaldivarNo ratings yet

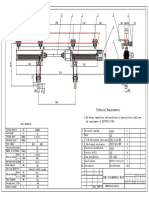

- 2X16-24 Monorail Hoist-04 - 2Document1 page2X16-24 Monorail Hoist-04 - 2RafifNo ratings yet

- Bus Crash LawsuitDocument7 pagesBus Crash LawsuitNewsTeam20No ratings yet

- People V VillanuevaDocument2 pagesPeople V VillanuevaLavernaNo ratings yet

- ChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessFrom EverandChatGPT Millionaire 2024 - Bot-Driven Side Hustles, Prompt Engineering Shortcut Secrets, and Automated Income Streams that Print Money While You Sleep. The Ultimate Beginner’s Guide for AI BusinessNo ratings yet

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyFrom EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyRating: 3.5 out of 5 stars3.5/5 (111)

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)

- Digital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyFrom EverandDigital Gold: Bitcoin and the Inside Story of the Misfits and Millionaires Trying to Reinvent MoneyRating: 4 out of 5 stars4/5 (51)

- CompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideFrom EverandCompTIA Security+ Get Certified Get Ahead: SY0-701 Study GuideRating: 5 out of 5 stars5/5 (2)

- Scary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldFrom EverandScary Smart: The Future of Artificial Intelligence and How You Can Save Our WorldRating: 4.5 out of 5 stars4.5/5 (54)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyFrom EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNo ratings yet

- The Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumFrom EverandThe Infinite Machine: How an Army of Crypto-Hackers Is Building the Next Internet with EthereumRating: 3 out of 5 stars3/5 (12)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- The Corporate Startup: How established companies can develop successful innovation ecosystemsFrom EverandThe Corporate Startup: How established companies can develop successful innovation ecosystemsRating: 4 out of 5 stars4/5 (6)

- The Future of Geography: How the Competition in Space Will Change Our WorldFrom EverandThe Future of Geography: How the Competition in Space Will Change Our WorldRating: 4.5 out of 5 stars4.5/5 (4)

- Chip War: The Quest to Dominate the World's Most Critical TechnologyFrom EverandChip War: The Quest to Dominate the World's Most Critical TechnologyRating: 4.5 out of 5 stars4.5/5 (227)

- The Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldFrom EverandThe Master Algorithm: How the Quest for the Ultimate Learning Machine Will Remake Our WorldRating: 4.5 out of 5 stars4.5/5 (107)

- Reality+: Virtual Worlds and the Problems of PhilosophyFrom EverandReality+: Virtual Worlds and the Problems of PhilosophyRating: 4 out of 5 stars4/5 (24)

- Pick Three: You Can Have It All (Just Not Every Day)From EverandPick Three: You Can Have It All (Just Not Every Day)Rating: 4.5 out of 5 stars4.5/5 (4)

- AI Superpowers: China, Silicon Valley, and the New World OrderFrom EverandAI Superpowers: China, Silicon Valley, and the New World OrderRating: 4.5 out of 5 stars4.5/5 (398)

- Artificial Intelligence: A Guide for Thinking HumansFrom EverandArtificial Intelligence: A Guide for Thinking HumansRating: 4.5 out of 5 stars4.5/5 (30)

- The E-Myth Revisited: Why Most Small Businesses Don't Work andFrom EverandThe E-Myth Revisited: Why Most Small Businesses Don't Work andRating: 4.5 out of 5 stars4.5/5 (708)

- Mastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)From EverandMastering Large Language Models: Advanced techniques, applications, cutting-edge methods, and top LLMs (English Edition)No ratings yet