Professional Documents

Culture Documents

Esd5330 Speed Control Unit: Act Loop Gain (7amax) (15A Max) Act Loop Gain (7A Max) (15A Max) Added DTC 11 Msec 65 Msec

Uploaded by

KimOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Esd5330 Speed Control Unit: Act Loop Gain (7amax) (15A Max) Act Loop Gain (7A Max) (15A Max) Added DTC 11 Msec 65 Msec

Uploaded by

KimCopyright:

Available Formats

DISPLAY & CONROLS

G OVERNORS

ESD5330 ROW SWITCH FUNCTION NORMAL POSITION RESONANT DRIVE TRAINS (CONT’D) ADJUSTABLE CHOPPING FREQUENCY

A MERICA

Speed Control Unit

1 DTC 8X OFF If the system exhibits these characteristics, turn ON SW1, C2 to institute this fea- The actuator chopping frequency can be varied by adjusting P13. This allows for a

C ORP.

R ISO 9001

CERTIFIED 2 DTC 4X OFF

ture. Readjust the control system per the above procedure and the result should be

a significant reduction in throttle dither. Because the governor does not respond to

wider RPM adjustment range.

the resonance any longer does not mean the resonance is not still present in the CRANK TERMINATION

1 INSTALLATION

3 DTC 2X OFF drive train.

When no power is applied to the ESD5330, the crank relay contacts Terminals 5

4 DTC 1X OFF and 6 are normally closed. As the speed increases, the internal relay will change

IDLE AND RAMP SETTING

The ESD5330 speed control unit is rugged enough to be placed in a control cabinet 120, 225, 275 = ON

state and the green LED will light. The speed setting at which this occurs is deter-

5 Speed Loop For Actuator

or engine mounted enclosure with other dedicated control equipment. The circuit (adjust with engine Close the IDLE switch connecting Terminals N and P. This will cause the engine to mined by the multi turn speed setting potentiometer. CW adjustment will increase

Gain 4X Series 2001 = OFF slow to an idle speed. Adjust the IDLE setting for desired idle speed. the speed at which this transition takes place. Once the circuit has tripped, the

board is conformally coated to seal out moisture and resist vibration. If water, mist or SW2

stopped)

condensation can come in contact with the controller, it should be mounted vertical- crank termination circuit will remain tripped until DC power is removed from the unit.

Act Loop Gain (7AMax) For Actuator 120, 225, 275 = ON Open the IDLE switch between Terminals N and P. The engine will start acceler- This will reset the function.

ly. This will allow any accumulated fluids to drain away from the speed control unit. 6 ating toward rated speed. Adjustment of the ACCEL control will allow the engine

(15A MAX) Series 2001 = OFF

to accelerate with just enough fuel to bring the system to operating speed with ACCESSORY INPUT

For Actuator 120, 225, 275 = OFF lowest emissions. The desired acceleration and deceleration rates can be achieved

Act Loop Gain (7A Max) The AUXiliary input, Terminal M. directly accepts output signals from GAC Load

2 WIRING 7

(15A MAX) Series 2001 = ON

by manipulating the ACCEL and DECEL adjustments. Cycle the IDLE switch after

each ACCEL or DECEL adjustment change until the desired results are achieved. Sharing units, Auto Synchronizers and other governor system accessories. Consult

It is suggested to use an oil pressure switch to operate these contacts. Open N and the applicable GAC publications for details. It is recommended that this connection

See the back of this document for the wiring diagram. Added DTC 11 mSec For Actuator 120, 225, 275 = OFF

P and the engine speed will decelerate at a rate set by the DECEL control CW is from accessories be a shielded cable as it is a sensitive input terminal.

8

65 mSec Series 2001 = ON faster for both ACCEL and DECEL functions. If the GAC Auto Synchronizer is used alone, not in conjunction with a

TERMINAL DEFINITION NOTES Load Sharing Module, a resistor must be installed between Terminals M

All other Dip SW2 switches (1-4) should be set for optimum engine performance as per SPEED DROOP OPERATION and L. If a frequency trim potentiometer is also used, the resistor should

A&B Actuator (+/-) #14 AWG wire instructions provided. The factory speed setting for the controller is 1400 Hz or approx- NOTE

If droop operation is desired (speed setting reduces with increased engine load), be 910K ohms. If no frequency trim is used, the resistor should be 1.2M

imately at idle speed. The crank termination is set very low initially. close the switch contact across Terminals J and K. Rotate the DROOP adjustment ohms. This is required to match the voltage levels between the ESD5330

#14 AWG wire CW to increase the droop percentage “0” setting (Full CCW) = Zero droop. 100 = speed controller and the synchronizer.

WARNING An overspeed shut down device, independent of the governor sys- maximum droop.

A 20 amp fuse must be installed in the

C&D Battery Power

(-/+) positive battery lead to protect against

any overload or short circuit ⚠ tem, should be provided to prevent loss of engine control, which may

cause personal injury or equipment damage. STARTING FUEL ADJUSTMENT

Turn the STARTING FUEL RAMPING to minimum CCW position (0). Crank the

ACCESSORY SUPPLY

The +10 Volt regulated supply, Terminal L, can be utilized to provide power to GAC

governor system accessories. Up to 40 mA of current can be drawn from this sup-

Battery positive (+) input is Terminal D engine and quickly rotate the starting fuel adjustment to CW until the engine starts ply. The ground reference for this supply is Terminal G.

without excess smoke. Repeat several times to find the best setting. Some engines

Wires must be twisted and/or shielded for 4 STARTING THE ENGINE require large amounts of fuel to start but most modern engines respond to limiting

fuel during cranking. Once the engine starts repeatedly in a satisfactory manner,

FINAL SPEED SETTING

their entire length

adjust the Fuel Ramping adjustment CW so the engine accelerates to rated speed After the Droop, Frequency Trim, and/or accessory inputs have been connected,

If the cranking termination occurs too quickly, preventing the engine from starting, turn quickly, without excess smoke. readjust the operating SPEED and IDLE.

Magnetic Pickup Gap between speed sensor and gear teeth the crank termination adjustment CW. The actuator should snap to full fuel until the en-

E&F The acceleration adjustment may be set to the fastest positions if start fuel ramping

(- is ground) should not be smaller than 0.02 in. (45mm) gine starts and runs at a low idle setting. Adjust the SPEED setting CW for the desired is not desired.

operating speed.

Speed sensor voltage should be at least

0.51VAC RMS during crank INTERNAL SPEED RAMPING FUNCTION 8 TROUBLESHOOTING

If the IDLE speed adjustment is set too low, the engine may never ex-

CAUTION Each time the ESD5330 is started the speed ramping function operates by taking

G Ground Signal ceed the crank termination point, possibly causing starter damage. control of the engine at near idle position and automatically raises the engine speed System Inoperative

until the speed set point is reached. The acceleration time is controlled by the accel- If the engine governing system does not function, the fault may be determined by performing the

Should the engine be unstable, turn the GAIN and STABILITY adjustments CCW until eration control. If the idle switch is then closed, the speed will decelerate at the rate

Shielded cable required for lengths over 15 ft voltage tests described in Steps 1 through 3. Positive (+) and negative (-) refer to meter polarity.

H Frequency Trim the engine is stable. If the system remains unstable or not operating properly, refer to set by the deceleration adjustment control.

(5 m) & connected to Terminal G the SECTION 8 SYSTEM TROUBLESHOOTING. Should normal values be indicated during troubleshooting steps, then the fault may be with the

actuator or the wiring to the actuator. Tests are performed with battery power on and the engine

J&K Droop Active when closed off, except where noted. See actuator publication for testing procedure on the actuator.

TERMINAL DEFINITION NOTES

5 GOVERNOR SPEED SETTINGTHE EDG During these ramping periods, the speed control has a small amount of droop add-

ed to attain stability at low engine speeds. The droop is eliminated once rated speed

STEP WIRES NORMAL READING

PROBABLE CAUSE OF

ABNORMAL READING

L&R Gain 1 & Gain 2 Gain 1 when open / Gain 2 when closed

The governed speed set point is increased by clockwise rotation of the SPEED adjust- is reached unless droop is added by closing the switch at J and K terminals. 1 D(+) & C(-) Battery Supply 1. DC battery power not connected.

Load Sharing / Synchronizing, Ground at ment pot. Remote speed adjustment can be obtained with an optional 5K Frequency Voltage Check for blown fuse

M Aux Input Trim Control. (See Section 10 WIRING DIAGRAM) The internal ramp generator can also be used for wide range variable speed ap-

Terminal G 2. Low battery voltage

plications. Connecting a 0-10 VDC variable voltage to terminal “N” with respect to 3. Wiring error

N&P Idle Active when closed terminal “G” will provide a means to achieve variable speed governing. To calibrate

6 ADJUSTING FOR STABILITY the speed range, either limit the voltage to a level which provides the desired range

with an external potentiometer or add resistance in series with terminal N as shown

2 E&F 1.0 VAC RMS min. while

cranking

1. Gap between speed sensor and

gear teeth too great. Check Gap

RECOMMENDATIONS

nce the engine is running at operating speed and at no load, the following governor

O in the diagram. 2. Improper or defective wiring to

1. Shielded cable should be used for all external connections to the ESD performance adjustment can be made to increase engine stability. the speed sensor. Resistance

control. DUAL GAIN FEATURE between 3 and Ground should be

PARAMETER ADJUSTMENT PROCEDURE The ESD5330 can operate with two distinct gain settings. The two gain adjust- 160 to 1200 ohms. See specific

2. One end of each shield, including the speed sensor shield, should be mag pickup data for resistance.

grounded to a single point on the ESD case. 1. Rotate the GAIN adjustments CW until instability develops. ments, Gain 1 and Gain 2 are independent adjustments. With the connection from

R and L “Open,” the Gain 1 adjustment is in operation. With a connection from 3. Defective speed sensor.

2. Then, gradually move the adjustment CCW until stability returns. R to L “Closed”, Gain 2 is in operation. Switching between the two gain settings

should have an imperceptible difference in speed change. The dual gain function is 3 L(+) & G(-) 10 VDC, Internal Supply 1. Short on Terminal P. ( This will

P cause a defective unit)

especially useful for engines, which exhibit different characteristics under different

3 PRE-START SETUP

(GAIN) 3. Finally, Move the adjustment one division further CCW to insure

stable performance. situations. An engine may run very stable at high speeds and less stable at lower 2. Defective speed control unit

speeds. Setting a single gain control for the lower speeds then yields less than an

4. If instability persists, adjust the next parameter. optimum setting at the higher speeds. A simple switch can be toggled for low or 4 A(+) & C(-) 2.0 V less than bettery 1. Starting FUEL LIMIT set too low.

Preset the adjustments. Check to see that the GAIN, STABILITY, and External Fre- voltage while cranking 2. IDLE set too low.

quency Trim (if used) are set to their mid positions. Also check to see that the high speed operation. Additionally in gaseous fuel engine applications where the

1. Follow the same adjustment procedure as the P parameter using quality or type of gas is changed, the two gain settings can be used to idealize the 3. SPEED adjustment set too low.

STARTING FUEL adjustment is set to “100” initially. I the Stability potentiometer. governor for each type of fuel.

(STABILITY) 4. Wiring error to the actuator.

2. If instability persists, adjust the next parameter. For cold engine instability, a temperature-sensing switch can reset the governor’s 5. Defective speed control.

Dip Switches SW2-5, SW2-6, and SW2-7 must be set in their proper

CAUTION position before starting the engine. See the following table for normal gain once the engine has reached a normal operating temperature. 6. Defective actuator.

D 1. Follow the instability procedure in Section (8) SYSTEM TROUBLE

switch position. (DEADTIME) SHOOTING.

These are some examples where the ESD5330 can be used to provide more opti-

NOTE A strip chart recorder can be used to further optimize the adjustments. If further mum control of dynamic engine characteristics while providing the best of govern- Instability

DIP SWITCHES performance improvements are required, refer to Section (8) SYSTEM TROUBLE- ing control.

SHOOTING.

ROW SWITCH FUNCTION NORMAL POSITION OVERSPEED MONITOR PROBABLE CAUSE OF

INSTABILITY SYMPTOM

SW1

C1 Lead Lag Circuit OFF 7 ADDITIONAL FEATURES The overspeed monitor circuit trip point is set by the multi-turn potentiometer. This

is normally set by raising the engine speed to the specific trip point speed and Fast Instability An irregularity of 1.

ABNORMAL READING

Set SW1 C1 to OFF (Lead/Lag) and/or set

C2 Standard Drive Train OFF turning the adjustment CCW until the O.S. circuit turns ON (Red LED). This will also speed above 3Hz. SW2 switches 1,2, and 3 to ON (DTC). If

RESONANT DRIVE TRAINS turn off the actuator output circuit and change the state of the internal relay con- (Perceived as a instability continues then:

NOTE When switch C2 is ON, Resonant Drive Train is enabled. tacts at terminals 1, 2, 3. To reset the O.S. circuit, push the “Reset” switch through

Many applications require a flexible coupling between the engine and its load. This can take the jitter) 2. Set SW1 C2 (Soft Coupling Filter) to ON. If

form of a soft rubber segmented coupling or a drive shaft which behaves as a natural spring. The

the hole provided or recycle the DC power to the unit. The “Test” switch will reduce instability continues then:

reasons such couplings are used is for alignment purposes, torsional considerations, or because

the O.S. setting about 20%. If the engine is running at rated speed and the test

button is pushed the O.S. monitor circuit should trip. 3. Turn off battery changers or other electrical

of the excess length of the drive shaft has a natural spring effect. In any case, the drive train can equipment to see if the symptom disappears.

act as a resonant device causing variable loads at a cylindrical rate to be impressed on the engine

and its flywheel. Such variations sometimes occur at a frequency that the governor responds to

The relay contacts at terminals 1, 2, 3 should be used to turn OFF the engine, ei- Slow Periodic An irregularity of 1. Set SW1 C1 (Lead/Lag) to ON. If instability

very well.

ther fuel or air. Do not rely on time control to turn “OFF” the actuator as a means of speed below 3Hz. continues then:

shutting off the engine. A fault could have occurred in the actuator, linkage, cables, (Sometimes severe)

etc. which the ESD5330 has control over. 2. Set SW2 switches (DTC) to the ON/OFF

This can cause excessive throttle movement at the same frequency as the resonance. The positions in the sequential order described in

ESD5330 Speed Control Unit 11.13 PIB 4164 A ESD5300 speed control unit has a special circuit that minimizes the offset on the resonances the next table.

on the governor.

For slow instability use the SLOW INSTABILITY SEQUENCE and for fast instability use the

FAST INSTABILITY SEQUENCE. Start by setting the switches to reflect Sequence 1. If in-

9 SPECIFICATIONS 10 WIRING DIAGRAM

stability persists, adjust the switches to reflect Sequence 2. Continue through each sequence

until instability stops.

PERFORMANCE

SW2 SWITCH SETTINGS FOR INSTABILITY 10.281

Isochronous Operation ± 0.25% (261,1)

SLOW INSTABILITY FAST INSTABILITY 1.250 9.000

SW2-1 SW2-2 SW2-3 SW2-4 Speed Range / Governor 1.0 - 7.5 KHz Continuous (31,8) (228,6)

SEQUENCE SEQUENCE Ø0.281 6.000

(152,4)

1 ON ON ON ON 16 Speed Drift with Temperature ± 1% Maximum (7,1)

2 ON ON ON OFF 15 Idle Speed Adjust Range 25 - 85% of rated speed

Droop Range 0 - 5% for a 1.5 A actuator current change

3 ON ON OFF ON 14

Speed Trim Range ± 200 Hz

4 ON ON OFF OFF 13

Remote Variable Speed Range Accel. Adjustment 266 Hz/sec - 1300 Hz/sec

5 ON OFF ON ON 12 Decel. Adjustment 250 Hz/sec - 1000 Hz/sec STARTING FUEL

GA

OVERNORS

TEST

1 2 3 4 5 6

MERICA

FUEL RAMP

6 ON OFF ON OFF 11 Starting Fuel Adjustment C ORP.

RESET

0.0 - 1.5 A 120, 175, 225, 275 Actuators / SW2-7 “OFF” CRANK

7 ON OFF OFF ON 10 0.3 - 5.0 A (24 Volt Only) 2000 Actuator / SW2-7 “ON”

SPEED CONTROL UNIT OVERSPEED TERMINATION

OVERSPEED

MODEL: ESD5330 IDLE

8 ON OFF OFF OFF 9 Overspeed Set Point 2330 Hz - 8500 Hz S/N : SPEED RAMP

DECEL ACCEL

9 OFF ON ON ON 8 Crank Termination Set Point 200 Hz - 2050 Hz MADE IN AGAWAM, MA U.S.A. SW2 SWITCHES CRANK

1 - 4 DEAD TIME COMP ON TERMINATION

10 OFF ON ON OFF 7 Terminal Sensitivity 5 - 8 ACTUATOR CONFIG

SW2

H 105 Hz, ±15 Hz/Volt @ 5 K Impedance CAUTION 1 2 3

1 2

4 5 6 7 8

6.125

11 OFF ON OFF ON 6 M 130 Hz, ±15 Hz/Volt @ 1 M Impedance ENGINE SPEED CONTROL

SW1 SWITCHES

E3 E2 (155,6)

SW1

K 685 Hz, ±40 Hz/Volt @ 326 K Impedance COMPONENT. WHEN INSTALLING

OR SERVICING, REFER TO C1 ON LEAD-LAG ON

OFF LEAD-LAG OFF

12 OFF ON OFF OFF 5 N 1000 Hz, ±50 Hz/Volt @ 8 K Impedance PRODUCT PUBLICATION

C2

ON RESONANT DRIVE TRAIN DROOP 6.625

OFF STANDARD DRIVE TRAIN (168,3)

STABILITY

13 OFF OFF ON ON 4 INPUT / OUTPUT CF ADJ.

FREQ GAIN 1

GAIN 1

Supply 24 VDC Battery Systems DROOP

14 OFF OFF ON OFF 3

(Transient and Reverse Voltage Protected)

24V

BATTERY

TRIM GAIN 2

GROUND

_ IDLE

10V

15 OFF OFF OFF ON 2 Maximum Continuous Supply 32 Volts

ACTUATOR + PICK-UP

AUX

GAIN 2

16 OFF OFF OFF OFF 1 Polarity Negative Ground (Case Isolated) A B C D E F G H J K L M N P R

SPEED

Slow Periodic An irregularity of 3. If slow stability is unaffected by the explained Power Consumption 100 mA (no actuator current)

(continued) speed below 3Hz. procedure above, add a small amount of

Speed Signal Range 1.0 - 50 VAC

(Sometimes severe) droop.

Maximum Actuator Current Internally Limited to 9 A Continuous

4. Additional Dead Time Control can be added

by connecting a capacitor across the two Maximum Current, Relay Contact

6A

posts below the ACCEL/DECEL adjustments. (Terminals 1 - 6) Rating

The postitive side (+) of the cap is to be GAIN 2 GAIN 1

Chopping Frequency Range 60 - 380 Hz

connected to E3. 20 MFD and above should

be used. ENVIRONMENTAL O GAIN SELECT

N

Ambient Temperature -40° to 85°C (-40 to 185°F) SW2 O

F

F 1 2 3 4 5 6 7 8

Non-Periodic Erratic Engine 1. Increasing the GAIN should reduce the in- Relative Humidity up to 95%

CLOSE TO IDLE

Behavior stability but not totaly correct it. If increasing All Surface Finishes Fungus Proof and Corrosion Resistant O 1 2

the gain reduces the irregularity, the problem N 20A

is probably with the engine. Higher gain COMPLIANCE / STANDARDS SW1 O

F

AUXILIARY INPUT

- LOAD SHARING AND /OR

allows the governor to respond faster and F SYNCHRONIZER

correct for the disturbance. Look for engine Agency CE and RoHS Requirements C1 C2 ACTUATOR 10V ACCESSORY

misfirings, erratic fuel system, load changes SUPPLY (40 mA MAX)

on the engine generator set, or voltage Communications RS-232-C, IEEE J1939 S1

regulator irregularities. CAUTION _ R VALUE SETS

PHYSICAL

SW2 SWITCHES 5 - 8 MUST BE SET + CLOSE FOR DROOP MAX SPEED

If unsuccessful in solving instability, contact GAC for assistance. Dimension See Section 1 “Installation” TO MATCH THE ACTUATOR BEING BATTERY 0 - 10V DC

info@governors-america.com 413-786-5600

Weight 6oz USED IN THE APPLICATION OPTIONAL

VOLTAGE

FREQUENCY WIDE RANGE

Mounting Any position, Vertical Preferred MAGNETIC TRIM - 5K SPEED CONTROL

SPEED

Insufficient Magnetic Speed Signal PICK-UP

RELIABILITY

The speed control unit will govern well with 1.0 VAC RMS speed sensor signal. A speed sensor

signal of 3 volts RMS or greater at governed speed is recommended. A strong magnetic speed Vibration 1G, 20-100 Hz

sensor signal will eliminate the possibility of missed or extra pulses. The amplitude of the speed Shock 10 G (11ms)

sensor signal can be raised by reducing the gap between the speed sensor tip and the engine ring

gear. The gap should not be any smaller than 0.020 in (0.45 mm). When the engine is stopped, Testing 100% Functional Testing

back the speed sensor out by 3/4 turn after touching the ring gear tooth to achieve a satisfactory

air gap.

Electromagnetic Compatibility (EMC)

EMI SUSCEPTIBILITY - The governor system can be adversely affected by large interfering sig-

nals that are conducted through the cabling or through direct radiation into the control circuits.

All GAC speed control sensors contain filters and shielding designed to protect the units sensitive

circuits from moderate external interfering sources.

Although it is difficult to predict levels of interference, applications that include magnets, solid sate

ignition systems, radio transmitters, voltage regulators or battery chargers should be considered

suspect as possible interfering sources.

If it is suspected that external fields, either those that are radiated or conducted, are or will affect

the governor systems operation, it is recommended to use shielded cable for all external connec-

tions. Be sure that only one end of the shields, including the speed sensor shield, is connected to

a single point on the case of the speed control unit. Mount the speed control to a grounded metal

back plate or place it in a sealed metal box.

Radiation is when the interfering signal is radiated directly through space to the governing system.

To isolate the governor system electronics from this type of interference source, a metal shield or

a solid metal container is usually effective.

Conduction is when the interfering signal is conducted through the interconnecting wiring to the

governor system electronics. Shielded cables and installing filters are common remedies.

In severe high-energy interference locations such as when the governor system is directly in the

field of a powerful transmitting source, the shielding may require to be a special EMI class shield-

ing. For these conditions, contact GAC application engineering for specific recommendations.

ESD5330 Speed Control Unit 11.13 PIB 4164 A

You might also like

- Reference Only Uncontrolled Document For H Istorical Reference OnlyDocument2 pagesReference Only Uncontrolled Document For H Istorical Reference OnlyMarcio AlexNo ratings yet

- Gen Stepper CTRLDocument1 pageGen Stepper CTRLsparky1No ratings yet

- ESC63C Series Speed Control Unit: Troubleshooting SpecificationsDocument1 pageESC63C Series Speed Control Unit: Troubleshooting Specificationsfaraidun100% (1)

- Warning: ESD5100 Series Speed Control UnitDocument6 pagesWarning: ESD5100 Series Speed Control Unitinstrumentacion.hsrNo ratings yet

- Manual Regulador de Velocidade Gac Esd 5111 PDFDocument2 pagesManual Regulador de Velocidade Gac Esd 5111 PDFGugui68100% (1)

- EG1065X Governor McPhersonDocument7 pagesEG1065X Governor McPhersonOrlando GalvanNo ratings yet

- Visctronic 12 Volt 732/842/882 Fan Drives: StartDocument2 pagesVisctronic 12 Volt 732/842/882 Fan Drives: StartElmer Tintaya MamaniNo ratings yet

- ADD 103 Series PTI2045ADocument4 pagesADD 103 Series PTI2045ALeonardo LimbergerNo ratings yet

- Product Information: Reference OnlyDocument4 pagesProduct Information: Reference OnlyOmarColon100% (1)

- Two Element Speed Switch: DescriptionDocument2 pagesTwo Element Speed Switch: DescriptionmohammedalathwaryNo ratings yet

- Locomotive: Service ManualDocument5 pagesLocomotive: Service ManualGabrielaNo ratings yet

- ESD5100 SeriesDocument5 pagesESD5100 SeriesCarlos AguiarNo ratings yet

- Governor Controller (GAC ESD5111) - DatasheetDocument5 pagesGovernor Controller (GAC ESD5111) - Datasheetazhan77No ratings yet

- DELTA-P Oil Differential Pressure Switch: ApplicationDocument1 pageDELTA-P Oil Differential Pressure Switch: ApplicationWALTER RUEDANo ratings yet

- GOB EG1065x Manual en PDFDocument8 pagesGOB EG1065x Manual en PDFRonaldCarrasquelNo ratings yet

- SCR Drive Troubleshooting PDFDocument14 pagesSCR Drive Troubleshooting PDFsorangel_123No ratings yet

- Product Information: Reference OnlyDocument2 pagesProduct Information: Reference OnlyOmarColonNo ratings yet

- B & M Transmission Lock-Up Converter ControlDocument4 pagesB & M Transmission Lock-Up Converter ControlTerje BergNo ratings yet

- RAJA+ Fully Automatic Star Delta Controller 3TE7431: Installation, Operation & Maintenance InstructionsDocument6 pagesRAJA+ Fully Automatic Star Delta Controller 3TE7431: Installation, Operation & Maintenance InstructionsM.Faredhu HussainNo ratings yet

- 0 Proportional Speed Regulator With IntegratorDocument2 pages0 Proportional Speed Regulator With IntegratortuNo ratings yet

- STAR CONTROL Flyer 03 2016 enDocument2 pagesSTAR CONTROL Flyer 03 2016 enJeins'c JocętNo ratings yet

- Reg. Velocidade GAC ESD 5550 5570Document8 pagesReg. Velocidade GAC ESD 5550 5570thyagoenerg100% (1)

- Warning: ESD5200 Series Speed Control UnitDocument6 pagesWarning: ESD5200 Series Speed Control UnitAnas BasarahNo ratings yet

- ApRe Wiring Diagram and Settings V13.EnDocument3 pagesApRe Wiring Diagram and Settings V13.EnHenri KleineNo ratings yet

- Dci 111Document8 pagesDci 111jose luisNo ratings yet

- CC995ADocument67 pagesCC995AMauricio HdezNo ratings yet

- Electronic Governor CatalogDocument26 pagesElectronic Governor CatalogAung Mh100% (1)

- Super Sport Plus InstrDocument2 pagesSuper Sport Plus InstranuradhaNo ratings yet

- For Preparation Description: Click HereDocument1 pageFor Preparation Description: Click HereOneysi Reyes UlloaNo ratings yet

- Electronic Protection & Control of Motors, Generators and PumpsDocument1 pageElectronic Protection & Control of Motors, Generators and PumpsYesfferys GonzalezNo ratings yet

- YSD-FSK639D Governor-Usermanual enDocument19 pagesYSD-FSK639D Governor-Usermanual enMohamed A.AlbadriNo ratings yet

- DYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFDocument8 pagesDYN1-10693-001-0-12 or DYN1-10693-001-0-24 PDFSyed Mohammad NaveedNo ratings yet

- 06a - Fuel System AddendumDocument5 pages06a - Fuel System Addendumjbert55No ratings yet

- ISKRA PFC Max PDFDocument2 pagesISKRA PFC Max PDFemmanskiNo ratings yet

- EN FANOXPC DATA MPC MotorProtection GL GC17 R03 PDFDocument2 pagesEN FANOXPC DATA MPC MotorProtection GL GC17 R03 PDFarolnNo ratings yet

- 1008 - TC88 - Quick Start GuideDocument2 pages1008 - TC88 - Quick Start Guidehrrt GarageNo ratings yet

- TCS3P125 PDFDocument10 pagesTCS3P125 PDFJuan José Tovar PérezNo ratings yet

- Esd5500E Series Speed Control Tlnit: WarningDocument5 pagesEsd5500E Series Speed Control Tlnit: WarningKarla HolandaNo ratings yet

- Cigre SC B5-WorkshopDocument40 pagesCigre SC B5-WorkshopCarlos Roberto Hernandez FerrerNo ratings yet

- Aux BLR FD FanDocument6 pagesAux BLR FD Fankleber17100No ratings yet

- Section 1. INTRODUCTION: Product DescriptionDocument34 pagesSection 1. INTRODUCTION: Product DescriptionAkhterNo ratings yet

- ESG2002 Controller PDFDocument15 pagesESG2002 Controller PDFAung Mh100% (1)

- 2301A Speed Control: ApplicationsDocument4 pages2301A Speed Control: ApplicationsFabio Andres Plata TorresNo ratings yet

- Esd5500E Series Speed Control Unit: Product Technical Information PTI 1002EDocument7 pagesEsd5500E Series Speed Control Unit: Product Technical Information PTI 1002EalstomNo ratings yet

- Model 1207A: Microprocessor Motor Speed ControllersDocument2 pagesModel 1207A: Microprocessor Motor Speed ControllersgersonplovasNo ratings yet

- KRP928 ManualDocument4 pagesKRP928 ManualWahyu pramonoNo ratings yet

- Section 307 01 AutomaticDocument11 pagesSection 307 01 AutomaticWillie AustineNo ratings yet

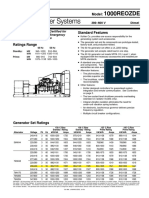

- 1000REOZDEDocument4 pages1000REOZDELanh TranNo ratings yet

- Apecs DPG-2223-00X: Digital ControllersDocument4 pagesApecs DPG-2223-00X: Digital ControllersRafael FernandoNo ratings yet

- Electronic Digital Governor: Performance EnvironmentalDocument8 pagesElectronic Digital Governor: Performance EnvironmentalMaxDalmiNo ratings yet

- ht-hsg100 Ds en 04-2014 v1-1Document4 pagesht-hsg100 Ds en 04-2014 v1-1Basaveswar KorlaNo ratings yet

- Idle ShutdownDocument5 pagesIdle ShutdownMarco MelchorNo ratings yet

- DPG 2201 00X PDFDocument4 pagesDPG 2201 00X PDFFernando FerminNo ratings yet

- UntitledDocument25 pagesUntitledCarlos ToralNo ratings yet

- Dss 1 SwiftshiftinstructionsDocument2 pagesDss 1 SwiftshiftinstructionsJorge BaptistaNo ratings yet

- SYC6714 Synchronizer: Ngine Overning YstemDocument4 pagesSYC6714 Synchronizer: Ngine Overning Ystemthanhhai31No ratings yet

- DRV 104Document26 pagesDRV 104Sitt Nyein SoeNo ratings yet

- Littelfuse ProtectionRelays ECS Datasheet-1130259Document4 pagesLittelfuse ProtectionRelays ECS Datasheet-1130259Modi JayNo ratings yet

- Symptom: P0235-Boost Pressure Sensor PlausibilityDocument12 pagesSymptom: P0235-Boost Pressure Sensor PlausibilityJose Pozo RoblesNo ratings yet

- Chocolate Cake RecipeDocument3 pagesChocolate Cake RecipeKimNo ratings yet

- ForkliftDocument2 pagesForkliftKimNo ratings yet

- Moist Chocolate Cake2Document3 pagesMoist Chocolate Cake2KimNo ratings yet

- Triple Chocolate CakeDocument3 pagesTriple Chocolate CakeKimNo ratings yet

- Moist Chocolate CakeDocument3 pagesMoist Chocolate CakeKimNo ratings yet

- The Best Chocolate Cake RecipeDocument2 pagesThe Best Chocolate Cake RecipeKimNo ratings yet

- Watermelon SeedsDocument2 pagesWatermelon SeedsKimNo ratings yet

- Canadian Shepherd DogDocument2 pagesCanadian Shepherd DogKimNo ratings yet

- American ShepherdDocument2 pagesAmerican ShepherdKimNo ratings yet

- Norwegian BuhundDocument3 pagesNorwegian BuhundKimNo ratings yet

- Finnish LapphundDocument3 pagesFinnish LapphundKimNo ratings yet

- TreeDocument2 pagesTreeKimNo ratings yet

- German ShepherdDocument3 pagesGerman ShepherdKimNo ratings yet

- Orange SeedDocument4 pagesOrange SeedKimNo ratings yet

- KiwisDocument3 pagesKiwisKimNo ratings yet

- MangoDocument2 pagesMangoKimNo ratings yet

- Grape SeedDocument4 pagesGrape SeedKimNo ratings yet

- DurianDocument3 pagesDurianKimNo ratings yet

- Duck EggDocument3 pagesDuck EggKimNo ratings yet

- What Are Salmon Fish Eggs or Fish Roe?Document2 pagesWhat Are Salmon Fish Eggs or Fish Roe?KimNo ratings yet

- Sweet Orange Evergreen Leaves Flowers Berry: MandarinDocument2 pagesSweet Orange Evergreen Leaves Flowers Berry: MandarinKimNo ratings yet

- Bananas WorldDocument2 pagesBananas WorldKimNo ratings yet

- PapayasDocument2 pagesPapayasKimNo ratings yet

- WatermelonDocument3 pagesWatermelonKimNo ratings yet

- StrawberryDocument3 pagesStrawberryKimNo ratings yet

- Dog CareDocument2 pagesDog Careghoshtapan4321No ratings yet

- Dog Behaviour PDFDocument68 pagesDog Behaviour PDFcarloNo ratings yet

- PHC - Health Benefits of PetsDocument2 pagesPHC - Health Benefits of PetsKimNo ratings yet

- Reasons To Get A DogDocument1 pageReasons To Get A DogKimNo ratings yet

- My New Dog: A Kids Guide To Having A Happy Dog and Lifelong CompanionDocument18 pagesMy New Dog: A Kids Guide To Having A Happy Dog and Lifelong CompanionKimNo ratings yet

- Full Download Human Biology 11th Edition Starr Solutions ManualDocument35 pagesFull Download Human Biology 11th Edition Starr Solutions Manualsheathe.zebrinny.53vubg100% (41)

- Amplificadores Automotivos PyramidDocument13 pagesAmplificadores Automotivos Pyramidedusf1000No ratings yet

- Financial Analysis of Ashok LeylandDocument120 pagesFinancial Analysis of Ashok LeylandSiva Kumaravel0% (1)

- Faculty Vitae 1. Name: C.TamilselviDocument2 pagesFaculty Vitae 1. Name: C.Tamilselvisadeeskumar.dNo ratings yet

- HBS - Zara Fast Fashion Case Write UpDocument4 pagesHBS - Zara Fast Fashion Case Write Upaaronhwalton100% (1)

- Engineering Mathematics Questions and AnswersDocument9 pagesEngineering Mathematics Questions and AnswersZaky Muzaffar100% (1)

- Theben Timer SUL 181DDocument2 pagesTheben Timer SUL 181DFerdiNo ratings yet

- Perfect Picture SummaryDocument3 pagesPerfect Picture SummaryReiaNo ratings yet

- Taxonomy: Family StaphylococcaceaeDocument40 pagesTaxonomy: Family StaphylococcaceaeMarissa Terrado SorianoNo ratings yet

- Munchies BrochureDocument28 pagesMunchies BrochureIbrahim Diaz LazoNo ratings yet

- DD 3600 3500 3000 Parts CatalogDocument46 pagesDD 3600 3500 3000 Parts CatalogAndres Fdo Mora D100% (2)

- Practice Quiz Reflection Project Initiation and Key ComponentsDocument3 pagesPractice Quiz Reflection Project Initiation and Key ComponentsFalastin Tanani67% (3)

- Review Problems On Gas TurbineDocument9 pagesReview Problems On Gas TurbinejehadyamNo ratings yet

- KPI's Troubleshooting GuideDocument27 pagesKPI's Troubleshooting GuideMohamed SayedNo ratings yet

- Spike Magazine Cup PackDocument5 pagesSpike Magazine Cup PackBungle MarleyNo ratings yet

- 2019q123.ev3-Descon Engro Level Gauges-QDocument7 pages2019q123.ev3-Descon Engro Level Gauges-Qengr_umer_01No ratings yet

- FL Switch 2000Document124 pagesFL Switch 2000marcosNo ratings yet

- Game On Series BibleDocument28 pagesGame On Series Bibleapi-513832615No ratings yet

- Trend Trading StocksDocument64 pagesTrend Trading Stockssasi717100% (1)

- Components of Vectors Prepared By: Victor Rea OribeDocument17 pagesComponents of Vectors Prepared By: Victor Rea OribeGerone Tolentino AtienzaNo ratings yet

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDocument52 pagesCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- Autodesk Design Review: About DWF and DWFXDocument7 pagesAutodesk Design Review: About DWF and DWFXNesreNo ratings yet

- Imcp - RocketbookDocument11 pagesImcp - Rocketbookapi-690398026No ratings yet

- Proposed 4way D54 Proposed 2way D56: Issue Date DescriptionDocument3 pagesProposed 4way D54 Proposed 2way D56: Issue Date DescriptionADIL BASHIRNo ratings yet

- Augmentation of Labour: Nabhan A, Boulvain MDocument8 pagesAugmentation of Labour: Nabhan A, Boulvain MMade SuryaNo ratings yet

- Cases To Examine - EuthanasiaDocument1 pageCases To Examine - EuthanasiadamianmackytNo ratings yet

- Police Cranston School Committee Member Stole PTO FundsDocument1 pagePolice Cranston School Committee Member Stole PTO FundsashaydelineNo ratings yet

- IPT .Quarter 2 (Grade 7-Mathematics, English &TLE)Document2 pagesIPT .Quarter 2 (Grade 7-Mathematics, English &TLE)ARRIANE JOY TOLEDONo ratings yet

- CV Old NicDocument4 pagesCV Old NicTensonNo ratings yet

- Maryam Ejaz Sec-A Marketing Assignment (CHP #15)Document3 pagesMaryam Ejaz Sec-A Marketing Assignment (CHP #15)MaryamNo ratings yet