Professional Documents

Culture Documents

Module 4 - Ignition Systems - QSK60G

Uploaded by

Muhammad IshfaqCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module 4 - Ignition Systems - QSK60G

Uploaded by

Muhammad IshfaqCopyright:

Available Formats

HHP Natural Gas Engines - Controls

Module 4 – Ignition Systems

Cummins, Inc Training

2

Ignition Systems

Learning Objective

To build on the Ignition System knowledge provided by the Cummins, Inc.

Virtual College ‘Self-Study’ CD-ROM. At the end of this module participants

will be able to locate and identify HHP gas engine ignition control components

and understand their operation within a total system.

Agenda

• Virtual College CD-ROM, Any Questions?

• Engine Control System and Components. What’s this all about ?

• Engine Ignition System and Operating Principle.

• Engine CCD Inputs / Outputs.

• Spark Timing Control.

• Engine Knock Sensors.

• Engine Position Sensors.

• Engine Speed Sensor.

QSK60G – rev 2.0 Our energy working for you™.

3

Virtual Training CD-ROM

The following Ignition System Components have been extensively

covered in the Cummins, Inc. Virtual College Training CD-ROM ‘self-

study’ program for the High Horsepower Natural Gas Lean Burn Controls:

• Camshaft and Crankshaft Sensors (Speed, Position, etc.).

• CCD Ignition Module,

• CM558,

• ‘V’ Engine Knock Sensors.

ANY QUESTIONS???

QSK60G – rev 2.0 Our energy working for you™.

4

Questions

1. Which engine module controls ignition CM558 (SSM558).

timing?

2. On ‘V’ engines, which module supplies The CCD module.

voltage to the Ignition Coils?

3. Approximately, what voltage does the 300vDc.

CCD Module supply to the Coil-on-Plug

units?

4. The definition of engine knock is? The uncontrolled combustion of

the air/fuel mixture BEFORE or

AFTER the spark event.

5. Engine position is measured by? Crankshaft and Camshaft

mounted position sensors.

Do you need to review your Self-Study CD-ROM before the end of this

course? You WILL be tested on topics covered in the CD-ROM.

QSK60G – rev 2.0 Our energy working for you™.

5

‘V’ Engine Control Components

CM Fire Ignition

CM 558 Sync Module To Coil-on-Plugs

700 1, 2, 3, 4, 5….. etc.

Left Bank.

COP

MODBUS CENSE ‘V’ Engines

Link to

Genset

PLC COP

To Coil-on-Plugs

1, 2, 3, 4, 5….. etc.

One Knock

CM Fire Ignition Right Bank.

Sensor fitted

per cylinder 558 Sync Module

MODBUS link CAN 2.0 B Network J1939 Network

QSK60G – rev 2.0 (19,200 baud) (500 K baud) Our energy working

(250K baud)

for you™.

6

‘V’ Engine Ignition System

Fully Electronic Design to ensure precise timing and

spark control. Individual cylinder timing control.

Variable Energy System.

Varies Spark Energy based on In-Cylinder Pressure.

- At Low loads, Cylinder boost pressure lower, LESS spark

energy required.

- 12/18kV to start fuel burn.

- At High loads, Cylinder boost pressure higher, MORE spark energy

required.

- 26kV to start fuel burn.

Traditional Ignition Systems must address high load environment.

Therefore always fire the plug at maximum energy levels.

QSK60G – rev 2.0 Our energy working for you™.

7

‘V’ Engine Ignition Components

COP

Assembly CCD / PDM A CM558 B

1 per cylinder Module

1 per bank 1 per bank

Ignition Harness

1 per bank

Spark Plug NOTE: Additional engine modules fitted to provide full system are (x1)

1 per cylinder CM700 and (x1) CENSE. These modules does not perform any of the

ignition control functions.

THE ABOVE MODULES ARE SUPPLIED WITH INFORMATION BY A

NUMBER OF SENSORS / SENDERS MOUNTED ON THE ENGINE.

QSK60G – rev 2.0 Our energy working for you™.

8

‘V’ Engine - SEM COP Assembly (from May ‘03)

Easily identified by its

integral harness and 3-

pin Deutsch Connector.

HT Insulator Extension removable

A - (–) Vdc.

A B - (+) Vdc - 330v to

Primary Winding.

C B C - Not Used.

IMPORTANT! If this coil has been stored horizontally, it is possible to get an internal flash-over between

the LV and HV circuits. However, the coil is self-healing due to its liquid polymer insulation. Therefore,

allow the coil to stand in its correct position for a minimum of 15 minutes before re-energising the coil.

QSK60G – rev 2.0 Our energy working for you™.

9

Engine Ignition System - Operating Principle

Knock Sensors

Inlet Pressure

CM558

Inlet Temperature

Ignition Module

L.V. Signal

CCD

Primary

Coil

EPS/Cam

Sensors

H.T. Signal Secondary

24+1 Coil

NOTE: Engine Speed is one of the main factors in determining Engine

Timing. Additionally, Intake Manifold Pressure (IMP) input gives the ability

to change the timing to compensate for varying Engine Loads and Intake

Manifold Temperature (IMT) input gives the ability to offset the timing to

compensate for ignitability due to changing intake temperatures.

QSK60G – rev 2.0 Our energy working for you™.

10

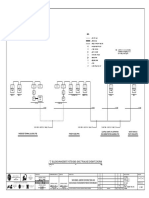

‘V’ Engine - CCD Inputs / Outputs

COP # 1

>A>

>B>

The CCD output pins for firing sequence are fixed as shown. The

harness connections therefore can affect the cylinder firing

order! Engine firing order is programmed into CM558 modules.

>A>

COP # 2 J1939 (+)

>B>

• <P<

J1939 (–)

CM558 A Plug Pin 03

<R< CM558 A Plug Pin 13

J1939 Shield

>A> <U< CM558 A Plug Pin 04

Spark Timing A

>A> >R> <K< CM558 B Plug Pin 28

COP # 3 >B>

• >D>

<T<

Spark Reference A

1708 Com (+)

CM558 B Plug Pin 27

<H< Manual Selector Switch

>P> 1708 Com (–)

<J< Manual Selector Switch

Capacitive Coil Keyswitch

>A> >B> <F<

COP # 4 Driver (CCD)

>B>

• >E> <D<

>N> <E<

(B Bank) ECM Ground

<B<

>F> Battery (–)

>A> <N<

COP # 5 >B>

• >C>

<A<

Battery (+)

• >G> <C<

Battery (+)

Battery (–)

<L<

ECM Ground

>A> <S<

COP # 6 >B>

•

Check wiring diagram for specific Bank

wiring configuration as well as specific

>A>

COP # 7 >B>

• • engine type (QSV91 B Bank shown).

>A>

>B>

>A>

>B>

WARNING: Incorrect fitting can

COP # 8 COP # 9 cause exhaust explosion.

QSK60G – rev 2.0 Our energy working for you™.

11

QSK 60G Ignition Component Layout

CCD Module CM 558 Module

Coil on Plug (COP) x16 CENSE Module

CCD Module

CM 558 Module

NOTE: CM 700 Module mounted in DC Box

QSK60G – rev 2.0 Our energy working for you™.

12

QSK 45/60G Ignition Components Location

QSK 60G

Coil-on-Plugs

CM558 Module

QSK 45G

Camshaft

Sensors

CCD Ignition

Module

QSK60G – rev 2.0 Our energy working for you™.

13

CCD Ignition Module (CCD)

ICM Coil • The transformer converts 24vdc to

Secondary approximately 300vdc.

Winding

Capacitor • The primary windings of the coils are

Transformer

Switch powered on and off by the capacitive

discharge process in the Ignition

300V

Control Module (ICM).

• When the spark timing signal is sent

(5v switched earth within CM558

Primary Magnetic Module), the switch is closed causing

CM558 Winding Core

the current to flow in the primary

winding of the coil, creating a

24V magnetic field.

Supply

• As the magnetic field is created, it

WARNING: The ignition system can induces a higher voltage in the

secondary windings, jumping the

deliver up to 40,000 VDC to the spark

spark plug gap when enough energy

plugs. Extreme care needs to be taken is available to overcome spark plug

when working with this high-voltage and combustion chamber

system or bodily injury can occur. resistances.

QSK60G – rev 2.0 Our energy working for you™.

14

Spark Timing Control

• The base ignition timing is based on the current engine

speed, intake manifold temperature and pressure.

• Ignition timing is controlled by the ICM and cannot be

adjusted.

• The signals from engine-mounted knock sensors are sent to

the CM558 to detect knock/detonation during the

combustion cycle.

• If heavy knock (4.5v) is detected a shutdown request is

initiated.

QSK60G – rev 2.0 Our energy working for you™.

15

Knock Sensors

A-Bank Free-End Knock Sensor

The QSK45 / 60G engines have one Knock

Sensor per cylinder. Knock Sensors are

located in the space between the cylinders

covers and on the ends of the first and last

cylinder heads. Knock Sensors require

calibration via INSITE on replacement.

B-Bank

Knock Sensor: QSK 45 / 60G:

NOMINAL OUTPUT: 1vdc.

> 2.2 volt - Ignition retarded 3º

(twice maximum = 6º).

> 4.5 volt Critical Engine Shutdown.

Must be torqued to correct value.

Knock Sensor

QSK60G – rev 2.0 Our energy working for you™.

16

Engine Position Sensor

Left-Bank Camshaft Gear - Rear face, used for timing reference

by Engine Position Sensor. There are 24 segments +1, these

relate engine position, which is read by both bank CM558

modules. The pin (+1) instructs the control system to re-start the

ignition cycle. Firing order is determined by the CM558 modules.

Engine Position Sensor - Screws into sensor adapter.

Engine Left-Bank

Engine Position

Engine Position Sensor Adapter - Located at Engine Data Plate

Location Sensor

rear of left-bank cam gear housing.

QSK60G – rev 2.0 Our energy working for you™.

17

Engine Speed Sensor

Engine Speed Sensor - Senses engine speed for engine protection and control purposes.

QSK60G – rev 2.0 Our energy working for you™.

Module 4 – Ignition Systems

END

Cummins, Inc Training

You might also like

- 5d - Ignition System2Document9 pages5d - Ignition System2agvassNo ratings yet

- QSK 60G & 60G High Efficiency Series Gas Engines Module 6 – ENGINE CONTROL SYSTEMDocument40 pagesQSK 60G & 60G High Efficiency Series Gas Engines Module 6 – ENGINE CONTROL SYSTEMagvassNo ratings yet

- Module 7 Fuel SystemDocument28 pagesModule 7 Fuel SystemAguilar AlexNo ratings yet

- Cummins Fire Power Digital Panel Operation GuideDocument80 pagesCummins Fire Power Digital Panel Operation GuideSpectrumRaijin100% (2)

- Instruction Sheet: Installation Instructions For InpowerDocument5 pagesInstruction Sheet: Installation Instructions For InpowerJaffer Hussain100% (1)

- Railway Engine Training-CUMMINS EngineDocument50 pagesRailway Engine Training-CUMMINS EnginemajjisatNo ratings yet

- PCC 3201Document9 pagesPCC 3201386No ratings yet

- Generator Drive Control System ECM FeaturesDocument34 pagesGenerator Drive Control System ECM FeaturesAung Kyaw Zaw100% (2)

- Cummins 4B3.9-G11 FR94625 enDocument5 pagesCummins 4B3.9-G11 FR94625 enTeodoro Cornelius AltuveNo ratings yet

- Tad1242ge PDFDocument7 pagesTad1242ge PDFVanessa Cristina dos Santos GarciaNo ratings yet

- Engine Fault Code Diagnostic GuideDocument6 pagesEngine Fault Code Diagnostic Guidehs421100% (2)

- QSK60 Starting SystemDocument4 pagesQSK60 Starting SystemagvassNo ratings yet

- Maintenance of A.C GeneratorsDocument26 pagesMaintenance of A.C GeneratorsMohamed HamdallahNo ratings yet

- 04-SnycLoadShare2015 DSEDocument35 pages04-SnycLoadShare2015 DSEJonathan BareñoNo ratings yet

- Product Management Bulletin: Cummins Power Generation AnnouncesDocument3 pagesProduct Management Bulletin: Cummins Power Generation Announcessorangel_123No ratings yet

- Training AvrDocument64 pagesTraining AvrCamilo Andres Cardozo FajardoNo ratings yet

- General: Technical Data TAD721GEDocument8 pagesGeneral: Technical Data TAD721GEbaljeetjatNo ratings yet

- Power Start PS0500 - Series Controls: C 8 D5 / C 11 D5 Series GensetsDocument35 pagesPower Start PS0500 - Series Controls: C 8 D5 / C 11 D5 Series GensetsJoshika R67% (3)

- Henzmen DC6Document10 pagesHenzmen DC6Noman MasoodNo ratings yet

- 4 X3.6TAA G1 (35 40kVA) PDFDocument4 pages4 X3.6TAA G1 (35 40kVA) PDFCHETAN PRAJAPATI RDONo ratings yet

- MTU 4000 With MIP v1.8Document23 pagesMTU 4000 With MIP v1.8Aurelio Serrano100% (2)

- PCC 3201 Paralleling ControllerDocument11 pagesPCC 3201 Paralleling ControllerChanat MeonsiNo ratings yet

- Barber ColmanDocument61 pagesBarber ColmanrepelindNo ratings yet

- PCC 3100 Service ManualDocument5 pagesPCC 3100 Service Manualmauribrav100% (2)

- Basic Engine SpecsDocument4 pagesBasic Engine SpecsOdlanier José Mendoza100% (1)

- Installation Guide for FT-10 PowerCommand Control 2100 Genset Network Communications Module Kit 541–0770Document5 pagesInstallation Guide for FT-10 PowerCommand Control 2100 Genset Network Communications Module Kit 541–0770Khaled KamelNo ratings yet

- 26455Document46 pages26455klo422No ratings yet

- 06-Mics Kerys - Navigation: Titre de La DiapositiveDocument145 pages06-Mics Kerys - Navigation: Titre de La DiapositiveMohammad HazbehzadNo ratings yet

- QSK 45GDocument25 pagesQSK 45Gvassindou67% (3)

- G-Drive Electronic Product & Feature Guide: January 2008Document36 pagesG-Drive Electronic Product & Feature Guide: January 2008Александр Щеблыкин50% (4)

- Engine Oil Pressure Sensors Troubleshooting GuideDocument14 pagesEngine Oil Pressure Sensors Troubleshooting GuideAbdul Khaliq100% (1)

- B U L K H E A D: Green Data LinksDocument2 pagesB U L K H E A D: Green Data LinksedI_restrepo_1No ratings yet

- Actuator and Governor Control Operation SpecsDocument7 pagesActuator and Governor Control Operation SpecsstmeuNo ratings yet

- Co MapDocument67 pagesCo MapShawon Mohammad Shahryiar100% (2)

- ISX and QSX15 Troubleshooting Repair ManualDocument4 pagesISX and QSX15 Troubleshooting Repair ManualLaiq100% (2)

- Basic Maintenance Engine QST, NTA, K38Document84 pagesBasic Maintenance Engine QST, NTA, K38helmi100% (1)

- Cummins Guidanz Mobile User TrainingDocument56 pagesCummins Guidanz Mobile User TrainingP.p. Arul IlancheeranNo ratings yet

- ID FLX Lite 1.9 Reference GuideDocument149 pagesID FLX Lite 1.9 Reference Guideluisgomezpasion1No ratings yet

- EmsDocument46 pagesEmsravi kumarNo ratings yet

- PMG PDFDocument6 pagesPMG PDFrajan_2002eeeNo ratings yet

- PCC3.3 Diagram: Download NowDocument5 pagesPCC3.3 Diagram: Download NowHillol DuttaguptaNo ratings yet

- QSK19 Engine Fuel System Familiarization2Document73 pagesQSK19 Engine Fuel System Familiarization2Tiagohowpy Ramos100% (1)

- Hyundai Forklift Trucks Specs and Optional Attachments GuideDocument7 pagesHyundai Forklift Trucks Specs and Optional Attachments GuideAlexendra100% (1)

- V28 Rebuild GuidelinesDocument26 pagesV28 Rebuild Guidelinesacere18100% (1)

- Understanding Generator Set RatingsDocument48 pagesUnderstanding Generator Set RatingsdaneNo ratings yet

- Conversion of 3 Phase 12 Lead Alternator To Single Phase AlternatorDocument2 pagesConversion of 3 Phase 12 Lead Alternator To Single Phase AlternatorАлександр ЩеблыкинNo ratings yet

- SK28876Document2 pagesSK28876Michael GonzálesNo ratings yet

- C1373Document3 pagesC1373Harry Wart WartNo ratings yet

- QSX15 SpecDocument4 pagesQSX15 Specpdealers100% (1)

- Module 8 - MaintDocument19 pagesModule 8 - MaintWilliam RuizNo ratings yet

- QST30 PDFDocument175 pagesQST30 PDFJavier Camacho Terrones86% (7)

- 1506a-E88tag3 Electropak Pn3088Document2 pages1506a-E88tag3 Electropak Pn3088Md Sh100% (1)

- Heinzmann DC6 Governor for Perkins EnginesDocument10 pagesHeinzmann DC6 Governor for Perkins EnginesRath Asypaden100% (1)

- A041 J096Document0 pagesA041 J096Michal HroudaNo ratings yet

- QSB QSL CM2250 - Control SystemDocument41 pagesQSB QSL CM2250 - Control SystemMussardNo ratings yet

- Performance: Rebuilds For Your KTA50 G3Document4 pagesPerformance: Rebuilds For Your KTA50 G3Sopian PianNo ratings yet

- Description of Option H6 (Serial Communication - Cummins GCS)Document15 pagesDescription of Option H6 (Serial Communication - Cummins GCS)farhan rajib100% (1)

- N45sm1a 51 To 59KWDocument3 pagesN45sm1a 51 To 59KWsaiyedasadNo ratings yet

- Ignition ModuleDocument4 pagesIgnition ModuleMari Carmen RodriguezNo ratings yet

- HHP Natural Gas Engines - Controls: Module 3 - Fuel SystemsDocument35 pagesHHP Natural Gas Engines - Controls: Module 3 - Fuel SystemsMohamed Ramadan MorsiNo ratings yet

- Cylinder Head Valve Assembly ErrorDocument5 pagesCylinder Head Valve Assembly ErrorMuhammad IshfaqNo ratings yet

- qst30 System SpecificationsDocument24 pagesqst30 System SpecificationsMuhammad IshfaqNo ratings yet

- 003-004 Overhead Set: General InformationDocument12 pages003-004 Overhead Set: General InformationMuhammad IshfaqNo ratings yet

- Vibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsDocument23 pagesVibration Excessive: This Troubleshooting Procedure Should Be Followed For The Following SymptomsMuhammad Ishfaq100% (1)

- 005-012 Fuel Injection Pumps, In-Line: InstallDocument14 pages005-012 Fuel Injection Pumps, In-Line: InstallMuhammad Ishfaq100% (3)

- 243 New-EnDocument4 pages243 New-Enjaskaran singhNo ratings yet

- Marine and Industrial qsk60Document10 pagesMarine and Industrial qsk60Muhammad IshfaqNo ratings yet

- qsk23 Data SheetDocument2 pagesqsk23 Data SheetMuhammad IshfaqNo ratings yet

- Loctite 577™: Technical Data SheetDocument4 pagesLoctite 577™: Technical Data SheetCristian SerbovNo ratings yet

- QSK60 Over Head Valve Setting PerformaDocument2 pagesQSK60 Over Head Valve Setting PerformaMuhammad Ishfaq100% (1)

- CatDocument4 pagesCatMuhammad IshfaqNo ratings yet

- Cat 3516Document4 pagesCat 3516Muhammad IshfaqNo ratings yet

- Basin Creek Power Plant Provides Clean EnergyDocument2 pagesBasin Creek Power Plant Provides Clean EnergyMuhammad IshfaqNo ratings yet

- Power House 1Document2 pagesPower House 1Muhammad IshfaqNo ratings yet

- Top 40 Reasons For Motor Oil Consumption PDFDocument6 pagesTop 40 Reasons For Motor Oil Consumption PDFMuhammad IshfaqNo ratings yet

- Fiji Power ServiceDocument2 pagesFiji Power ServiceMuhammad IshfaqNo ratings yet

- QSK60 Maintenance ScheduleDocument11 pagesQSK60 Maintenance ScheduleMuhammad Ishfaq100% (4)

- Cummins 161110083846 PDFDocument18 pagesCummins 161110083846 PDFMuhammad IshfaqNo ratings yet

- QSK60G Temp Control GuidelinesDocument4 pagesQSK60G Temp Control GuidelinesMuhammad IshfaqNo ratings yet

- Fuel Consumption CalculationDocument4 pagesFuel Consumption CalculationTariqMaqsoodNo ratings yet

- 1000-0099B enDocument3 pages1000-0099B enMuhammad Ishfaq100% (2)

- Hybrid Varieties and Saving Seed - Archives - Aggie HorticultureDocument3 pagesHybrid Varieties and Saving Seed - Archives - Aggie HorticultureMuhammad IshfaqNo ratings yet

- Aftercooler Parts For Qsk60 Gas EngineDocument3 pagesAftercooler Parts For Qsk60 Gas EngineMuhammad IshfaqNo ratings yet

- Exhaust Temp K394Document1 pageExhaust Temp K394Muhammad IshfaqNo ratings yet

- QSV Oil Analysis Guidelines, Rev. 02Document7 pagesQSV Oil Analysis Guidelines, Rev. 02Muhammad IshfaqNo ratings yet

- Cucumber Hybrid Seed Production (Hilights)Document8 pagesCucumber Hybrid Seed Production (Hilights)Muhammad IshfaqNo ratings yet

- Tomato Paste PulpDocument26 pagesTomato Paste PulpYousef TahnonNo ratings yet

- Record Templates for Organic FarmersDocument22 pagesRecord Templates for Organic FarmersMuhammad IshfaqNo ratings yet

- BRKARC 2001 Cisco ASR1000 Series Routers System Solution Architectures 2013 Orlando 2 Hours PDFDocument115 pagesBRKARC 2001 Cisco ASR1000 Series Routers System Solution Architectures 2013 Orlando 2 Hours PDFSaptarshi BhattacharjeeNo ratings yet

- Unit - 4Document53 pagesUnit - 4Meghna BhatnagarNo ratings yet

- IC 555 TimerDocument11 pagesIC 555 TimersaifaljanahiNo ratings yet

- HP 1980A Operations ManualDocument522 pagesHP 1980A Operations ManualKyle NahasNo ratings yet

- IEEE Xplore - Enterprise Information Security Architecture A Review of Frameworks, Methodology, and Case StudiesDocument2 pagesIEEE Xplore - Enterprise Information Security Architecture A Review of Frameworks, Methodology, and Case StudiesHugo PagolaNo ratings yet

- Facilities ManagementDocument23 pagesFacilities ManagementAhmed SamyNo ratings yet

- Battery StorageDocument46 pagesBattery StorageKishore MuluguNo ratings yet

- Engineering Design (II) - Sheet 3Document2 pagesEngineering Design (II) - Sheet 3Mohamed SaidNo ratings yet

- UPS5000-S-1200 KVA Quick GuideDocument20 pagesUPS5000-S-1200 KVA Quick Guidenobita3No ratings yet

- Harga Acp (Alumunium Composit Panel) Merk Ukuran USD Satuan HargaDocument2 pagesHarga Acp (Alumunium Composit Panel) Merk Ukuran USD Satuan HargaSigit Andi PNo ratings yet

- Building Management System (BMS) Basic Trunkline Schematic Diagram 2Document3 pagesBuilding Management System (BMS) Basic Trunkline Schematic Diagram 2Anonymous NcB95G6XwNo ratings yet

- Asus X553MA Repair Guide Rev2.0Document7 pagesAsus X553MA Repair Guide Rev2.0UMA AKANDU UCHENo ratings yet

- Presentation On Latest Trends in Power System by Chandan Kumar ChandaDocument43 pagesPresentation On Latest Trends in Power System by Chandan Kumar Chandaanon_15824371971% (7)

- "Flexible Bench": S.P.M Polytechnic Kumathe, Solapur 2018-2019Document3 pages"Flexible Bench": S.P.M Polytechnic Kumathe, Solapur 2018-2019Abhijeet DhavaleNo ratings yet

- Huawei CloudEngine S5731-H Series Switches BrochureDocument13 pagesHuawei CloudEngine S5731-H Series Switches BrochureMurillo SilvaNo ratings yet

- Turkish State Railways (TCDD) : Infrastructure Development & Regulations in Railway SectorDocument32 pagesTurkish State Railways (TCDD) : Infrastructure Development & Regulations in Railway Sector임동우No ratings yet

- Interior DesignDocument13 pagesInterior DesignHajar SuwantoroNo ratings yet

- Java Programming Chapter 3 GUI With JavafxDocument15 pagesJava Programming Chapter 3 GUI With JavafxShimelis KassaNo ratings yet

- Lateral Arm Upright Biopsy Accessory: Hologic Affirm™Document2 pagesLateral Arm Upright Biopsy Accessory: Hologic Affirm™Keli Fabiana RodriguesNo ratings yet

- Practice Quiz - Deploying Applications - Coursera PDFDocument1 pagePractice Quiz - Deploying Applications - Coursera PDFjuhireddyNo ratings yet

- C400 Firmware Update Instructions Rev0309Document6 pagesC400 Firmware Update Instructions Rev0309raberNo ratings yet

- Rizwan Habib / Roll - 131: Online Travel Agency (OTA)Document13 pagesRizwan Habib / Roll - 131: Online Travel Agency (OTA)rizwan_habibNo ratings yet

- Josephine Dorado - Resume With Fulbright HighlightsDocument3 pagesJosephine Dorado - Resume With Fulbright HighlightsJosephine DoradoNo ratings yet

- Front End Ruby On Rails Developer Resume October 2014Document2 pagesFront End Ruby On Rails Developer Resume October 2014Justin HolzmannNo ratings yet

- Distance Measuring by Ultrasonic SensorDocument6 pagesDistance Measuring by Ultrasonic Sensorcristian123No ratings yet

- Recruiter Position at Noida-Based NLB ServicesDocument2 pagesRecruiter Position at Noida-Based NLB ServicesRajesh SinghNo ratings yet

- Configure a L2TPDocument3 pagesConfigure a L2TPVentas Nature PrimeNo ratings yet

- IOP Marine Fuel Injector Tester VPUD 1100Document7 pagesIOP Marine Fuel Injector Tester VPUD 1100Samer SalibaNo ratings yet

- ZXA10 C610 Product Description - V1.1.0 - 20190411Document64 pagesZXA10 C610 Product Description - V1.1.0 - 20190411Edson Lira100% (2)

- Naveen Kumar GDocument2 pagesNaveen Kumar GRajeshkumar PothupalepuNo ratings yet