Professional Documents

Culture Documents

SJ19OY

Uploaded by

compos24Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SJ19OY

Uploaded by

compos24Copyright:

Available Formats

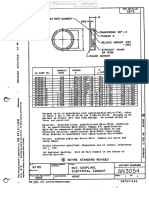

, - ~t5"", --r- 51..

o

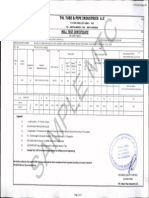

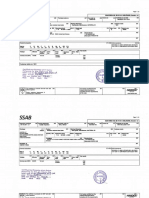

<8>- HACKNEY Hackney Ladish llnc.

© l::-~c~}~!:I 708 South Elmira Avenue - Russellville, AR 72802

Phone: (800) 527-4500 Fax: (479) 964-6231

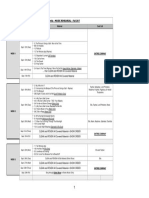

Mill Test Report

According To EN 10204 3.1

Raw Material SMLS/

Mfg. Heat code Item Description Specification/Grade for Material NACE

Heat No.

Welded

132 7553 SJ190Y A/SA 234- 2018A WPB (SMLS)

-#3 X 1 XS REOTEE Seamless NACE0175nso 15156

Heat Treatment NORMALIZEO 1670 Raw Material A105

Chemical Compoaltton '!I. Hardness BHN

p Tensile Test (ksl)

C I Si I Mn I s NI I Cr I Mo Cu l

I I V Nb I Al l Tl B I N I CE BASE I WELD Base Material - I Welding Seam -

Ladle I I

I I I I I l I l vs j

Product .190 I .190 I 1.150 I .007 I .003 I .160 I .090 I .040 _l .160 l .002 I .003 I .0250 _l .0020

I

I .0100

I

.43

147

I TS _I RA% I E'lb

50.4 I 72.3 . I

I VS I TS I RA% I E'lb

-·

I 46.8 I I I I

Impact Test

Spec ADDmONAL NOTES:

Temp

S1ze10 Deg. Ft LB Ft LB FtLB AvgR Avg Avg

LB Exp Exp Exp Sheer Shear Loe

mmx F/0 Exp Shear MTR ISSUE DATE: 10-09-2019

PRODUCTION HARDNESS TEST RESULTS HARDNESS BHN 146,147

We certify that the material herein described has been manufactured in accordance with the above standards and specifications and satisfies all the

4,

requirements of the editions specified. We certify all materials provided comply with EN 10204:2004 type 3.1. ISO 9001 certified. We certify these

fittings capable of passing hydrostatic test compatible with their rating. The above figures are correct as contained in the records of the Company. This

information has been electronically transmitted to our customer. Mark Ramey I MET Technician

MET Technician

Page 1 ol 1

You might also like

- 142 MM Hex 316L-1 - 231122 - 160553Document1 page142 MM Hex 316L-1 - 231122 - 160553Gavin BiggsNo ratings yet

- Growing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyFrom EverandGrowing Up in the Valley: Pioneer Childhood in the Lower Fraser ValleyNo ratings yet

- Welder CertificateDocument6 pagesWelder CertificateA. ΒρατσισταNo ratings yet

- MTC - Pipe Erw 10x10mm - s355j2h - THL, UaeDocument1 pageMTC - Pipe Erw 10x10mm - s355j2h - THL, UaetariqananNo ratings yet

- Active Metal BrazingDocument14 pagesActive Metal BrazingAdam GeorgeNo ratings yet

- Yc Inox Co., LTD.: Inspection CertificateDocument1 pageYc Inox Co., LTD.: Inspection CertificateMuneer KonajeNo ratings yet

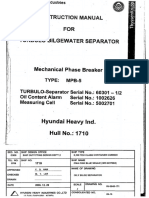

- Oily Bilge Separator - Instruction ManualDocument126 pagesOily Bilge Separator - Instruction ManualF CNo ratings yet

- MTC - Pipe ErwDocument1 pageMTC - Pipe ErwtariqananNo ratings yet

- D-35 Nitrogen Inert Gas SystemDocument12 pagesD-35 Nitrogen Inert Gas SystemEvgeny BabkovNo ratings yet

- Model: Pump Injection SpecificationDocument2 pagesModel: Pump Injection SpecificationdieselmotorsbogotasasNo ratings yet

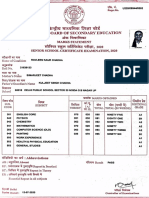

- Class 10th Result RkyDocument1 pageClass 10th Result Rkyry667955No ratings yet

- Weld Overlay GTAW NiCrMo-3Document21 pagesWeld Overlay GTAW NiCrMo-3shakeeb131992No ratings yet

- HARDOX400 - 10mm Plate - MTCDocument2 pagesHARDOX400 - 10mm Plate - MTCMohammad Adil100% (1)

- Chris Marine Surface Grinder Type CPLDocument22 pagesChris Marine Surface Grinder Type CPLSamer SalibaNo ratings yet

- CHAPTER 10 - Structural Steel Works, Sheet Roofing and Safety CanopyDocument6 pagesCHAPTER 10 - Structural Steel Works, Sheet Roofing and Safety CanopyMd.Rezaul IslamNo ratings yet

- 3.1 Catalog - RubbertechDocument3 pages3.1 Catalog - RubbertechSajad PkNo ratings yet

- DI4975Document1 pageDI4975Chandra Dwi SaputraNo ratings yet

- AILValves CatDocument32 pagesAILValves CatdigitalmgNo ratings yet

- Las Doc X 70 Hyundai MetDocument24 pagesLas Doc X 70 Hyundai MetdvsdNo ratings yet

- Welding Rod Selection PDFDocument1 pageWelding Rod Selection PDFBalasubramanian RasuNo ratings yet

- SS Data Sheet 2MMDocument1 pageSS Data Sheet 2MMm.aliNo ratings yet

- BBS 270P18-270P25Document8 pagesBBS 270P18-270P25Best GyanNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- Shield: M I I ADocument8 pagesShield: M I I AAjay RanganathanNo ratings yet

- MTC For E-7018Document2 pagesMTC For E-7018Babar Manzoor Ghauri100% (1)

- Round Bar 60mm, Square Bar 50 MM - MTCDocument1 pageRound Bar 60mm, Square Bar 50 MM - MTCMohammad Adil0% (1)

- H3155Document1 pageH3155Exile PeachNo ratings yet

- H3155 PDFDocument1 pageH3155 PDFExile PeachNo ratings yet

- DHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 12-24-2002 Order Number 43-YA-BC-373365Document2 pagesDHS, FEMA and Dept. of State: Failure of Hurricane Relief Efforts: 12-24-2002 Order Number 43-YA-BC-373365CREWNo ratings yet

- Fu&rr: Tt'1attDocument1 pageFu&rr: Tt'1attRavleenNo ratings yet

- DZR BrassDocument1 pageDZR BrasssmrdojeNo ratings yet

- Juki MO-804-OD4 MO-814-BD4 MO-816-DD4Document40 pagesJuki MO-804-OD4 MO-814-BD4 MO-816-DD4Ismael Vizalla OrckoNo ratings yet

- Scan0441 2Document3 pagesScan0441 2Indranil SarkarNo ratings yet

- Case Study WPS-PQR (AS-2)Document4 pagesCase Study WPS-PQR (AS-2)Mohamed ElrapatNo ratings yet

- Valve List - F-5001Document3 pagesValve List - F-5001Ajay PrajapatiNo ratings yet

- MAN B&W Diesel: Service LetterDocument3 pagesMAN B&W Diesel: Service LetterAleksandar Sasa SeferovicNo ratings yet

- Brazing Filler Metal Selector Chart: NicrobrazDocument2 pagesBrazing Filler Metal Selector Chart: NicrobrazathulpcucekNo ratings yet

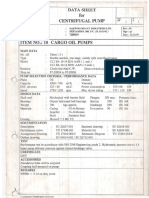

- Cargo Pump Curve - MT BourneDocument2 pagesCargo Pump Curve - MT Bournetimayaa1000100% (1)

- Test Ce Tificate: C EMI AL OM OS On PercentDocument2 pagesTest Ce Tificate: C EMI AL OM OS On PercentPravin HonmuteNo ratings yet

- Inconel 625 - Stick (SMAW) and TIG - MIG Welding ProcedureDocument6 pagesInconel 625 - Stick (SMAW) and TIG - MIG Welding ProcedureAngga ErlanggaNo ratings yet

- A94ADocument5 pagesA94AASHISH GORDENo ratings yet

- Cleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - EngneeringDocument5 pagesCleanfuelsproject (-,.-Y) :5611 5Jljlffl &: Pe'Ofac - EngneeringVasilica BarbarasaNo ratings yet

- HOT Induction Bend MPS - CommentedDocument11 pagesHOT Induction Bend MPS - CommentedHASAN SHAHRIAR100% (1)

- WPS PQR PDFDocument23 pagesWPS PQR PDFAhmad Daniel100% (1)

- Vol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Document78 pagesVol 10 INSTALLATION & OPERATING MANUAL (IOM) 50 MMBTU - BOOK No 10Akhosh KrishnaNo ratings yet

- Tba810s SGSDocument6 pagesTba810s SGSjosue sotoNo ratings yet

- Ticket RedbusDocument1 pageTicket RedbusbavithrarajanNo ratings yet

- Adobe Scan 15 Jul 2023Document1 pageAdobe Scan 15 Jul 2023lyshadhingra16No ratings yet

- Reactor Building: TVO Olkiluoto 3 NPP SiemensDocument8 pagesReactor Building: TVO Olkiluoto 3 NPP SiemensVraja DasiNo ratings yet

- T T - Tubacex Ubos Inox Dables S A: Mill Test C T IcateDocument3 pagesT T - Tubacex Ubos Inox Dables S A: Mill Test C T IcatePRANAY OMTECHNo ratings yet

- Air Dryer Max-06Document17 pagesAir Dryer Max-06Phan Cao An TruongNo ratings yet

- Selection Guide Thermowells TH 1 PDFDocument2 pagesSelection Guide Thermowells TH 1 PDFFatoni Gea AirlanggaNo ratings yet

- AN3054 - REV-8 Nut, Coupling, Electrical ConduitDocument1 pageAN3054 - REV-8 Nut, Coupling, Electrical ConduitMark JuhrigNo ratings yet

- KT 80Document10 pagesKT 80SebastianNo ratings yet

- 21BL312 W-2021-033 - 6000x2500x30 - S355J2+N (PP26647002) 54928-1 - 2Document2 pages21BL312 W-2021-033 - 6000x2500x30 - S355J2+N (PP26647002) 54928-1 - 2johnnyNo ratings yet

- Adobe Scan 17 Sep 2023Document1 pageAdobe Scan 17 Sep 2023kaurn4446No ratings yet

- 55 3 PDFDocument1 page55 3 PDFVita Revi AlesyaNo ratings yet

- Lentilles de Prescription: Fashion Frames - Contact Lenses Prescription Lenses Montures - Verres de ContactDocument1 pageLentilles de Prescription: Fashion Frames - Contact Lenses Prescription Lenses Montures - Verres de ContactAbu Sayed Md. RashedNo ratings yet

- MF-R Series - PTC Resettable Fuses: Features Additional InformationDocument10 pagesMF-R Series - PTC Resettable Fuses: Features Additional InformationEko PurwantoNo ratings yet

- Electrical Safety ReadingDocument12 pagesElectrical Safety Readingcompos24No ratings yet

- Inspection Certificate: .SiahDocument1 pageInspection Certificate: .Siahcompos24No ratings yet

- Revised PosterDocument1 pageRevised Postercompos24No ratings yet

- Midwest Mediakit Q417Document14 pagesMidwest Mediakit Q417compos24No ratings yet

- Song: Let's Misbehave (Cole Porter) : Best Supporting Actor and Actress Runner UpDocument7 pagesSong: Let's Misbehave (Cole Porter) : Best Supporting Actor and Actress Runner Upcompos24No ratings yet

- Cinderella - Music RehearsalDocument1 pageCinderella - Music Rehearsalcompos24No ratings yet

- Cinderella - Mic Plot - Act 1Document5 pagesCinderella - Mic Plot - Act 1compos24No ratings yet

- Cinderella - Mic Plot - Act 2Document5 pagesCinderella - Mic Plot - Act 2compos24No ratings yet

- ITT AutomotiveDocument3 pagesITT AutomotiveVisweswara Reddy100% (1)

- P1001 Argus Overcurrent Document SetDocument4 pagesP1001 Argus Overcurrent Document SetInayat HathiariNo ratings yet

- Wetland Organizational StructureDocument35 pagesWetland Organizational StructureMuhammad Bilal ChauhdaryNo ratings yet

- Maintenance: Modus OperandiDocument17 pagesMaintenance: Modus OperandiPrabhu VijayakumaranNo ratings yet

- 3610 Customer ServiceDocument16 pages3610 Customer ServiceSrinivas Rao100% (1)

- Euromodul Containers System Constructions enDocument6 pagesEuromodul Containers System Constructions enCaraiane CatalinNo ratings yet

- Design and Development of A Low Power Laboratory ResistojetDocument10 pagesDesign and Development of A Low Power Laboratory ResistojetAlien GmpNo ratings yet

- Change LogDocument20 pagesChange LogakdereNo ratings yet

- Project Use Case Description FINALDocument16 pagesProject Use Case Description FINALdaniyal100% (2)

- KXZ2 Leaflet Final ForASIA 0Document10 pagesKXZ2 Leaflet Final ForASIA 0Mohamad Zakwan SezeliNo ratings yet

- Kings: Question BankDocument3 pagesKings: Question BankImmanuel VinothNo ratings yet

- AcslprogrammingcomponentinstructionsDocument2 pagesAcslprogrammingcomponentinstructionsapi-328824013No ratings yet

- Hmrsm04 003 LF SM enDocument19 pagesHmrsm04 003 LF SM enCristian BarraNo ratings yet

- BARBERI Oil Drainage Valve DIN 42551, En50216-4 Type C2Document1 pageBARBERI Oil Drainage Valve DIN 42551, En50216-4 Type C2MarloNo ratings yet

- 20413e05 Welding of Carbon Steel Offshore PipelineDocument70 pages20413e05 Welding of Carbon Steel Offshore PipelineMA GPNo ratings yet

- ActiveX Applications On CMU - 090312Document45 pagesActiveX Applications On CMU - 090312iasysNo ratings yet

- Parenting Internet StyleDocument15 pagesParenting Internet StyleRizka Sitti MuliyaNo ratings yet

- VOSS Automotive Valve CatalogueDocument41 pagesVOSS Automotive Valve CatalogueManuel Pedro InácioNo ratings yet

- 01-Theory of Architecture (Notes 01)Document35 pages01-Theory of Architecture (Notes 01)pat100% (1)

- Heavy Oil and Gas LiftDocument5 pagesHeavy Oil and Gas Liftadsnah0% (1)

- OSN Spare PartDocument56 pagesOSN Spare PartAhmed M GomaaNo ratings yet

- Complete Maths Handwritten Notes by RehanDocument163 pagesComplete Maths Handwritten Notes by RehansarojNo ratings yet

- Form Manual700Document37 pagesForm Manual700mehdi810100% (1)

- ABAP Code Sample To Upload Data Using BDC RecordingDocument9 pagesABAP Code Sample To Upload Data Using BDC RecordingMythili DuraisamiNo ratings yet

- Agus BWDocument3 pagesAgus BWSuhedi SapinNo ratings yet

- Css Cheat Sheet: ShorthandDocument1 pageCss Cheat Sheet: ShorthandPetrit Kabashi100% (1)

- IndexDocument15 pagesIndexjorge_reeveNo ratings yet

- Brake Report-1Document7 pagesBrake Report-1talhaNo ratings yet

- Variable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95Document40 pagesVariable Displacement Pump A4VSO: RE 92 050/09.97 1/40 Replaces: 03.97 and 11.95nguyễn văn dũngNo ratings yet

- Harvard Referencing Information WorksheetDocument5 pagesHarvard Referencing Information WorksheetRachel KingNo ratings yet