Professional Documents

Culture Documents

LW300KN: Outline Dimensions

Uploaded by

Myrcol RedesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LW300KN: Outline Dimensions

Uploaded by

Myrcol RedesCopyright:

Available Formats

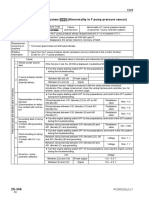

LW300KN

Outline Dimensions

54°

45°

1010

4870

Dedicated to serve high-end

3830

3320

LW300KN

2930

LW

300

KN

heavy-duty applications

24

1198

82

360

2900

7245

Main Specifications

Description Specification Unit

Rated operating load 3000 kg

Bucket capacity 1.5~2.5 m³

Machine weight 10900±200 kg

Dump clearance at maximum lift 2770~3260 mm

Reach at maximum lift 1010~1210 mm

Wheel base 2900 mm

Tread 1850 mm

Height of hinge at maximum lift height 3830 mm

Working height(fully lifted) 4870 mm

Max.breakout force 130 kN

Max.horse power 95 kN

Hydraulic cycle time-raise 5.4 s

Total hydraulic cycle time 9.3 s

Min. turning radius over tyres 5170 mm

Articulation angle 38±1 °

Gradeability 28 °

Tyre size 17.5-25-12PR

Overall machine dimension L×W×H 7245×2482×3320 mm

Model WP6G125E22

Emission standards Emission 2

Rated Power/Speed 92/2200 kW/rpm

Fuel Tank 170 L

Hydraulic Tank 175 L

Travel speed

Ⅰ-gear(F/R)

Ⅱ-gear(F/R)

12/16

38/-

km/h

km/h

Heavy load

重载·节能

Structure and specification are subject to change without notice.In case there is any difference between

the description of the machine and the substantial machine,the substantial machine should govern.

Description Specification

Rated bucket capacity 1.8m³

Rated loading capacity 3000kg

20170330

Rated power 92kW

XCMG FOR YOUR SUCCESS Gross weight 10900kg

Dumping height 2930mm

Maximum breakout force 130kN

LW300KN Inheritance of classic and high maturity and stability

Heavy-duty, high reliability, and energy-conservation

Product Overview

As an outstanding representative of the industry's super-heavy-duty models, LW300KN

boasts remarkable advantages in terms of “High energy-conservation, efficiency, reliability,

and comfort” compared with industry’s like products and is extensively applicable for earth-

moving projects, aggregate yards, municipal constructions, and other bulk material trans-

ports.

XCMG’s exclusive technologic advantages

XCMG’s exclusive technologic advantages

This product is applied with XCMG’s exclusive four leading patents and proprietary tech-

nologies.

XCMG's exclusive energy-conservation technology - The perfect combination between

XCMG’s patented energy-conservation drive system and low speed energy-conservation

engine builds the one and only 3t energy-conservation product in the industry, with the

economy superior by >10% to the industry’s like products.

XCMG’s patented lubrication technology - The transmission is applied with the XCMG’s

patented optimal lubrication system design technology to thoroughly improve the indus-

try’s difficulties of insufficient and non-uniform transmission lubrications and make the

transmission life remarkably leading the industry.

XCMG's patented high strength frame -

With the application of the XCMG’s exclu-

sive high strength single plate beam

skeleton structure, the “load-carrying

material ratio” is remarkably leading the

industry products.

XCMG's unique structure design - The

extended wheelbase and the classic 3rd

generation loader structure realize higher

working capacity, smaller turning radius,

and lower wear of rear wheels.

LW300KN Inheritance of classic and high maturity and stability

Heavy-duty, high reliability, and energy-conservation

High firmness and reliability

XCMG’s patented heavy-duty drive system assembly Comprehensive optimized working device

The ZL50 planetary transmission is equipped and the imported parts are applied for critical carrying The thickened boom plates, the rectangular tube arm support

locations. The transmission lubrication system is optimally designed by test system and methods of beams, and the enlarged cross section and thickened beam

XCMG’s patented technologies so that the lubricating oil volume is distributed on-demand to thoroughly plates remarkably improve the adaptability to severe working

improve the industry’s difficulties of insufficient and non-uniform transmission lubrications and make the conditions.

transmission life remarkably leading the industry.

The bucket is thoroughly made of high strength steel plates to

The drive shaft flanges are of DIN and SAE standard specifications and the distribution diameter of the improve the wear resistance and impact resistance by more

fastening bolts is enlarged to realize super-strong torsion resistance and adapt to severe working condi- than 30% and prolong the service life.

tions.

All load-carrying portions of the drive axle are solid and firm enough to ensure excellent overload resistance

and meet the needs of diversified high strength and high load operations.

High energy-conservation and efficiency

As the sole low speed engine energy-conservation product among the industry's 3t

loaders, it’s leading the industry’s energy-conservation trend.

With the scientific matching and system optimization to play the machine performance to the maximum

degree, the operating economy of the XCMG LW300KN is superior by >10% to the industry like products.

The high capacity torque converter of patented technologies and the in-depth optimized box axle system

ZL50 transmission with Proved XCMG exclusive drive axle realize the best matching and remarkably improve the fuel utilization efficiency.

patented technologies

The low-speed energy-conservation engine equipped achieves outstanding fuel-saving performance while

improving the power performance.

Box frame structure of super-strong carrying capacity

With the application of the double-pump confluence and steering priority equivalent unloading technologies,

The heavy-duty extended wheelbase (2,900mm) structure design is applied. The front frame adopts the the hydraulic system increases the machine traction under composite working condition, remarkably reduces

XCMG’s characteristic thick plate structure and the rear frame adopts the reliable single plate beam the energy consumption, and improves the working efficiency.

structure to reinforce the skeleton and adapt to the severe working conditions.

Primary turbine Secondary Pump

turbine impeller

With scientific strength analysis, the

design of the material and structure is

optimized and the “load-carrying materi-

al ratio” is remarkably leading the

industry products to achieve higher

The high capacity torque converter with optimized turbine set grille structure The double-pump confluence system minimizes the

reliability. improves the double-pump confluence system to maximize the transmission energy consumption.

efficiency and minimize the energy consumption. In addition, the reduced

thermal balance temperature of the hydraulic oil effectively improves the

reliability of the related parts.

LW300KN Inheritance of classic and high maturity and stability

Heavy-duty, high reliability, and energy-conservation

Variety attached tools meeting

High safety and comfort requirements of different working conditions

The full-view cab sufficiently takes in consideration the

human-machine functions to realize high operation safety and comfort.

Clamp: For grab and transport of

The full-coverage delicate interior trim parts, the large view, and the optional multifunctional player and luxury various woods and tubing.

loudspeakers build the best operating environment.

Snow plough: For snow removing

The domestically advanced combination instrument is applied, featuring beautiful modeling and convenient in roads and urban streets.

operations and maintenances. All control switches, instruments, and warning and indicator lamps are integrated

and all buttons are easily accessible to realize all working motions with ease.

The panorama rear windscreen, high-mounted rear lamps, and reversing sensor equipped ensure good visual

field and reversing safety.

The standard pilot control and A/C system make the operations more comfortable.

Specification of variant attachments

Log clamp IV Toad's mouth Grasping

Item Log clamp I 对、错互换式 grass Pallet fork Snowplow Unit

(offset tooth) clamp machine

Dump clearance at maximum lift(front dump) 2980 2819 2784 2910 3025 3000 mm

Reach at maximum lift(front dump) 1410 1222 1134 1630 2028 1610 mm

Dump clearance/reach at maximum lift(side dump) mm

overall hight at maximum lift 3500 mm

Max. dumping angle(work tool)

Convenient maintenances

35 45 45 30 20 25 °

Max.opening 1616 1644 1576 1410 2800 mm

Undertaking the concept of “ground maintenances”, all maintenance Max. clamping diameter 830 590 580 50 1045 mm

locations are scientifically arranged to ease the checking and maintenances. Max.working width(snowplow) 3018 mm

The large spacing between upper and lower hinged plates realizes high structural strength and sufficient mainte- Slewing angle (horizontal) ±30 °

nance space.

Swing angle (snowplow) °

The new skeleton structure engine hood with large upturning side gates boasts large opening angle and make the

Rack back angle at ground 23 °

services and maintenances easier for the engine and radiator.

Length(work tool) 1460 1460 1420 1780 1950 1730 1365 mm

The central fuse case centrally indicates the working status of electric system and eases the maintenances.

Width(work tool) 1875 1820 1650 2026 2198 2015 3018 mm

The preloaded hydraulic oil tank realizes less air exchange and high cleanliness of hydraulic system.

Height(work tool) 1520 1500 1750 1330 1740 890 1120 mm

Tine length(pallet fork) 1050 mm

Overall machine dimensions-length 7327 7319 7281 7537 7811 7245 7212 mm

Overall machine dimensions-width 2350 2350 2350 2350 2350 2350 3018 mm

Overall machine dimensions-height 3320 3320 3320 3320 3320 3320 3320 mm

You might also like

- XCMG Wheel Loader LW300KNDocument4 pagesXCMG Wheel Loader LW300KNMeliw WuNo ratings yet

- LW500FN: Wheel LoaderDocument6 pagesLW500FN: Wheel LoaderAbdelmadjid AmiraNo ratings yet

- Mitsubishi 6D16 A54727 Parts Catalogue (MG330) PDFDocument897 pagesMitsubishi 6D16 A54727 Parts Catalogue (MG330) PDFTharindu ManamperyNo ratings yet

- Brocure LG876 (7 Ton)Document1 pageBrocure LG876 (7 Ton)fauzan ahmadNo ratings yet

- Sem 660DDocument2 pagesSem 660DDebby Wahyuni100% (1)

- Hino 700 Wheel TyreDocument24 pagesHino 700 Wheel TyreAgung Dwi PrasetiyoNo ratings yet

- Engine 125 2Document392 pagesEngine 125 2Augusto OliveiraNo ratings yet

- ZD220-3 Operation - Maintenance 使用说明书(英文)Document58 pagesZD220-3 Operation - Maintenance 使用说明书(英文)muhammad lukmanNo ratings yet

- Main Parameters of XCMG Wheel Loader LW300KNDocument2 pagesMain Parameters of XCMG Wheel Loader LW300KNDhee DoodzNo ratings yet

- Alpha Series - Front End Cylinder With Single EyeDocument2 pagesAlpha Series - Front End Cylinder With Single EyeAji Aryandie100% (1)

- Comparison ZX48U-5A Vs Kobelco SK50P-6 (Bahasa) PDFDocument21 pagesComparison ZX48U-5A Vs Kobelco SK50P-6 (Bahasa) PDFTheo TodingNo ratings yet

- Omm PC800,850-8R - Pen00419-00Document399 pagesOmm PC800,850-8R - Pen00419-00Andri Assoi100% (1)

- Brosur Sany SY750-HDocument2 pagesBrosur Sany SY750-Hmbah petrukNo ratings yet

- Dx300lca in PDFDocument11 pagesDx300lca in PDFMuhaiminNo ratings yet

- Bulldozer d65pDocument10 pagesBulldozer d65pRisky UpNo ratings yet

- FAST HD Products Spectrum 2019Document5 pagesFAST HD Products Spectrum 2019雨王No ratings yet

- Total Waktu Waktu Proses Pelaksana: Diperiksa: Diketahui: Sub. Comp. MOD: PC200 - 7 S/N: Com: Main Pump SN: Sub PumpDocument11 pagesTotal Waktu Waktu Proses Pelaksana: Diperiksa: Diketahui: Sub. Comp. MOD: PC200 - 7 S/N: Com: Main Pump SN: Sub Pumphanafi yusuf100% (1)

- DC13 SPECSDocument1 pageDC13 SPECSAmir Bambang YudhoyonoNo ratings yet

- Recommended Part WP6G125E22Document1 pageRecommended Part WP6G125E22Sutan RichardNo ratings yet

- Transmission GuideThe title "TITLE Transmission GuideDocument106 pagesTransmission GuideThe title "TITLE Transmission Guideirwan yuniardi100% (1)

- Komatsu PC300-7 Hydraulic Excavator SpecsDocument10 pagesKomatsu PC300-7 Hydraulic Excavator SpecsWilliam ChangNo ratings yet

- Ft20kl-Scania P360CB (Sis) (Ra020ar3-1905010)Document3 pagesFt20kl-Scania P360CB (Sis) (Ra020ar3-1905010)tiko fajarNo ratings yet

- Product Features Specifications Metric U.SDocument2 pagesProduct Features Specifications Metric U.SFranklin LewisNo ratings yet

- XE215C ExcavatorDocument2 pagesXE215C Excavatorasme acehNo ratings yet

- DL550 - Specification Sheet - 20160502Document27 pagesDL550 - Specification Sheet - 20160502AbdelrahmanNo ratings yet

- SDLG Lg936l BrochureDocument3 pagesSDLG Lg936l Brochureade pratamaNo ratings yet

- Sheet Service - SKT80SDocument3 pagesSheet Service - SKT80SAnanda risaNo ratings yet

- Mitsubishi EnginesDocument4 pagesMitsubishi EnginesIK100% (1)

- Hyva 70535211 Fe A149-3-03830-K1645-Hd-HcDocument2 pagesHyva 70535211 Fe A149-3-03830-K1645-Hd-HcFrans MetinNo ratings yet

- SDLG E660fDocument2 pagesSDLG E660fErvin MesaNo ratings yet

- Truck Crane: Zoomlion Heavy Industry Science & Technology Co.,LtdDocument4 pagesTruck Crane: Zoomlion Heavy Industry Science & Technology Co.,Ltdtatagang0% (1)

- HarisDocument28 pagesHarisZen PNo ratings yet

- Backhoe Loader B877Document4 pagesBackhoe Loader B877MS Buk3100% (1)

- Pengantar Komponen Utama TrukDocument16 pagesPengantar Komponen Utama TrukAlmarkNo ratings yet

- Technical Specification CWB6BLLDN2-6X4Document1 pageTechnical Specification CWB6BLLDN2-6X4Muhaimin100% (1)

- Reliable performance of Hidromek Motor Grader MG330Document20 pagesReliable performance of Hidromek Motor Grader MG330ediNo ratings yet

- Clg855h (Gcic t2) Service Manual 202007002-EnDocument642 pagesClg855h (Gcic t2) Service Manual 202007002-EnRicky Safira zahiraNo ratings yet

- Parts List Contact DetailsDocument144 pagesParts List Contact DetailsKhowchae KunapatNo ratings yet

- Service Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224Document4 pagesService Code in Electrical System (Abnormality in F Pump Pressure Sensor) E224ariy yuli styawan100% (1)

- EX1200-6 Prinsip Operasional - Bahasa - Rev1 2017Document301 pagesEX1200-6 Prinsip Operasional - Bahasa - Rev1 2017ppd brcg100% (1)

- Omm FD-17Document192 pagesOmm FD-17Muhammad Afian Perdana100% (1)

- Owner'S Manual D-Series: ALLU Screener CrusherDocument24 pagesOwner'S Manual D-Series: ALLU Screener CrusherFabian Ariza ArizaNo ratings yet

- D3K2Document4 pagesD3K2Agung ArdhanaNo ratings yet

- LGMG CMT96 Steering Axle Parts CatalogDocument18 pagesLGMG CMT96 Steering Axle Parts CatalogShaneNo ratings yet

- Clase A Categoría I - NuevoDocument85 pagesClase A Categoría I - NuevoChrystian Meller Vasquez MaytaNo ratings yet

- Belt Inspect Adjust Replace PDFDocument4 pagesBelt Inspect Adjust Replace PDFnay hlaing SoeNo ratings yet

- HM400-3R Leaflet Cen00510-01 - 86997 PDFDocument9 pagesHM400-3R Leaflet Cen00510-01 - 86997 PDFKevin Andrian0% (1)

- Ze60e 10 Ze75e 10Document2 pagesZe60e 10 Ze75e 10Hengky HengkyNo ratings yet

- SANY TRUCK CRANE STC 250 SPECS AND LIFTING RANGEDocument8 pagesSANY TRUCK CRANE STC 250 SPECS AND LIFTING RANGEfajarNo ratings yet

- TCM FG (FD) 30 (C, T, W) Forklift Truck Gas - Diesel Powered Parts CatalogueDocument594 pagesTCM FG (FD) 30 (C, T, W) Forklift Truck Gas - Diesel Powered Parts Catalogueكلاركات أوناشNo ratings yet

- Om 933L PDFDocument155 pagesOm 933L PDFirfanNo ratings yet

- Engine Specifications GuideDocument8 pagesEngine Specifications GuideJoko SukarionoNo ratings yet

- Bomag bw219 INGLES PDFDocument2 pagesBomag bw219 INGLES PDFDaniel Gregorio LacastroNo ratings yet

- Deutz 1013 Agricultural Specs PDFDocument6 pagesDeutz 1013 Agricultural Specs PDFALWINo ratings yet

- LGMG CMT96 Transmission Parts CatalogDocument84 pagesLGMG CMT96 Transmission Parts CatalogShaneNo ratings yet

- LW300KN: Outline DimensionsDocument4 pagesLW300KN: Outline Dimensionsمحمود المستكاويNo ratings yet

- Outline Dimensions: XCMG Construction Machinery Co., LTDDocument4 pagesOutline Dimensions: XCMG Construction Machinery Co., LTD余No ratings yet

- Lw300kn November 2022Document2 pagesLw300kn November 2022Aditya Maulana BainalNo ratings yet

- Outline Dimensions: XCMG Construction Machinery Co., LTDDocument4 pagesOutline Dimensions: XCMG Construction Machinery Co., LTD余No ratings yet

- XCMG ZL50GN G-Series Wheel Loader - Outline DimensionDocument6 pagesXCMG ZL50GN G-Series Wheel Loader - Outline Dimensionhenok wube0% (1)

- BL60 Parts Catalogue GuideDocument746 pagesBL60 Parts Catalogue GuideAlvin Smith93% (15)

- LW300KN: Outline DimensionsDocument4 pagesLW300KN: Outline DimensionsMyrcol RedesNo ratings yet

- Service Parts List: Transmission 15.7MHR36425-1 4265203Document80 pagesService Parts List: Transmission 15.7MHR36425-1 4265203Myrcol Redes100% (3)

- High-power DH24 bulldozer from ShantuiDocument2 pagesHigh-power DH24 bulldozer from ShantuiMyrcol RedesNo ratings yet

- EX200-5 TRAVEL DEVICE Hitachi HOP OnlineDocument3 pagesEX200-5 TRAVEL DEVICE Hitachi HOP OnlineMyrcol RedesNo ratings yet

- XCMG Intelligence XLS603 Asphalt Distributor(单页样本)Document2 pagesXCMG Intelligence XLS603 Asphalt Distributor(单页样本)Myrcol Redes100% (1)

- High-power DH24 bulldozer from ShantuiDocument2 pagesHigh-power DH24 bulldozer from ShantuiMyrcol RedesNo ratings yet

- BL60 Parts Catalogue GuideDocument746 pagesBL60 Parts Catalogue GuideAlvin Smith93% (15)

- XT870 backhoe loader excavation specificationsDocument2 pagesXT870 backhoe loader excavation specificationsMyrcol RedesNo ratings yet

- High-power DH24 bulldozer from ShantuiDocument2 pagesHigh-power DH24 bulldozer from ShantuiMyrcol RedesNo ratings yet

- XCMG XE215BR 155HP Excavator for Construction and MiningDocument2 pagesXCMG XE215BR 155HP Excavator for Construction and MiningMyrcol Redes100% (1)

- 1a-Lista Precio Bombas Inv - Omap 17-01-2023Document2 pages1a-Lista Precio Bombas Inv - Omap 17-01-2023aliciaNo ratings yet

- US Gears Overdrive ManualDocument23 pagesUS Gears Overdrive ManualNuman2100% (2)

- BT Lifter With Scale: LHM200SC Sales Guide enDocument28 pagesBT Lifter With Scale: LHM200SC Sales Guide enporter1980No ratings yet

- Vehicle Technical Information Guide For Cruise Control: Model Years: 1996-2009Document48 pagesVehicle Technical Information Guide For Cruise Control: Model Years: 1996-2009Night ShadeNo ratings yet

- 1948-1979 Ford Pickup TruckDocument284 pages1948-1979 Ford Pickup TruckMax Arboleya100% (1)

- 9Document6 pages9dskumar49No ratings yet

- Beml Final 2019 PDFDocument51 pagesBeml Final 2019 PDFsayandh spNo ratings yet

- Hamm 3520 - H176 - enGBDocument2 pagesHamm 3520 - H176 - enGBTiago AlvesNo ratings yet

- Chapter 3 Pavement DesignDocument22 pagesChapter 3 Pavement DesignAbdulmelik AdemNo ratings yet

- Mazda M5OD Transmission - WikipediaDocument3 pagesMazda M5OD Transmission - WikipediaC KayNo ratings yet

- ToyotaDocument28 pagesToyotaAmmad JilaniNo ratings yet

- Application: Product DetailsDocument1 pageApplication: Product DetailsImran MehboobNo ratings yet

- Farmtrac 45 Super SmartDocument1 pageFarmtrac 45 Super SmartSajal RathoreNo ratings yet

- RX20 EN 2019 Manual WebDocument442 pagesRX20 EN 2019 Manual WebVladimir Panuch100% (3)

- Kubota Tracked Dumper: Truck Easy Loading OperationDocument4 pagesKubota Tracked Dumper: Truck Easy Loading OperationKeron TrotzNo ratings yet

- Warehouse Safety GuideDocument6 pagesWarehouse Safety GuideFaiz FalehNo ratings yet

- AV - VEHDYN - 2012 Lecture Slides and CalcsDocument91 pagesAV - VEHDYN - 2012 Lecture Slides and CalcsSeyton123No ratings yet

- IED & VBIED Smart Card 4 - 02jan04Document2 pagesIED & VBIED Smart Card 4 - 02jan04Tom ThomasNo ratings yet

- Yanmar-SV26-spare Parts ManualDocument12 pagesYanmar-SV26-spare Parts Manualtrademaster1912No ratings yet

- Cost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, EmptyDocument29 pagesCost of Handling and TR Ansporting Material: 1 - Loading 2 - Hauling, Loaded 3 - Unloading 4 - Returning, Emptyascom asNo ratings yet

- Lateral Path Tracking Control of Autonomous Land Vehicle Based On ADRC and Differential FlatnessDocument3 pagesLateral Path Tracking Control of Autonomous Land Vehicle Based On ADRC and Differential FlatnessRay Alejandro Lattarulo AriasNo ratings yet

- Merritt Morning Market 3567 - May 28Document2 pagesMerritt Morning Market 3567 - May 28Kim Leclair100% (1)

- Saudi Aramco Safe Fueling ProcedureDocument16 pagesSaudi Aramco Safe Fueling Procedurerana qamarNo ratings yet

- Electronic SuspensionDocument2 pagesElectronic SuspensionRakesh ShettyNo ratings yet

- Etm 214 - Etv 214 - Etm 216 - Etv 216Document4 pagesEtm 214 - Etv 214 - Etm 216 - Etv 216Ari Yulianto NugrohoNo ratings yet

- Orderpickers: R30XM R30XMA R30XMS R30XMFDocument4 pagesOrderpickers: R30XM R30XMA R30XMS R30XMFAlbertoNo ratings yet

- Komatsu Saa6d107e 1 Series Engine Complete Workshop Service Repair Manual PDFDocument105 pagesKomatsu Saa6d107e 1 Series Engine Complete Workshop Service Repair Manual PDFArwinsyah Arwinsyah78% (9)

- "Goldhofer" Hydraulic Platform Trailer 10 Axles With Prime Mover 1 UnitDocument1 page"Goldhofer" Hydraulic Platform Trailer 10 Axles With Prime Mover 1 UnitPriyoNo ratings yet

- The Fruit Reception StationDocument11 pagesThe Fruit Reception StationArifal100% (1)

- ZF Steering Columns - ZF LenksystemeDocument2 pagesZF Steering Columns - ZF LenksystemewurtukukNo ratings yet