Professional Documents

Culture Documents

SP-1097 DSS Welding Specs PDF

Uploaded by

Hari Prakash GrandheyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SP-1097 DSS Welding Specs PDF

Uploaded by

Hari Prakash GrandheyCopyright:

Available Formats

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

Petroleum Development Oman L.L.C.

Document title: Specification for Welding of Duplex and

Super Duplex Stainless Steel Pipelines

(Amendments/Supplements to API Std 1104)

Document ID SP- 1097

Document Type Specification

Security Unrestricted

Discipline Material & Corrosion

Owner UEC-Materials and Integrity Manager

Issue Date September 2018

Version 3.0

Keywords: This document is the property of Petroleum Development Oman, LLC. Neither

the whole nor any part of this document may be disclosed to others or reproduced, stored

in a retrieval system, or transmitted in any form by any means (electronic, mechanical,

reprographic recording or otherwise) without prior written consent of the owner.

July 2018 i SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

This page was intentionally left blank

July 2018 ii SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

i Document Authorisation

Authorised For Issue

Document Authorisation

Document Owner Document Custodian Document Author

(CFDH)

Behlani, Nasser NABHANI,TALAL Ghafri, Mohamed

UEC UEC1 UEC11

Date : 05-09-2018 Date : 05-09-2018 8:53 Date : 05-09-2018

12:00 AM AM 8:48 AM

July 2018 iii SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

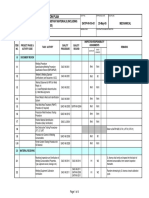

ii Revision History

The following is a brief summary of the 4 most recent revisions to this document. Details of

all revisions prior to these are held on file by the issuing department.

Version No. Date Author Scope / Remarks

Version 1.0 3/8/99 OTT/112 Extensive revision of original issue of SP

1189.

Version 2.0 25/05/05 UEC/11 Updated based on past experience

Version 3.0 24/06/18 UEC/11 Updated based on latest standards and

Lessons Learned.

iii Related Business Processes

Code Business Process (EPBM 4.0)

iv Related Corporate Management System (CMS) Documents

The related CMS Documents can be retrieved from the Corporate Management Portal

(CMS).

Keywords:

API 1104

Duplex Stainless Steel

Inspection

Off-plot

Pipelines

Procedure Qualification Record

Production Welding

Testing

Welding Procedure Specification

Welder Qualification

July 2018 iv SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

PETROLEUM DEVELOPMENT OMAN L.L.C. I

DOCUMENT TITLE: SPECIFICATION FOR WELDING OF DUPLEX AND I

I DOCUMENT AUTHORISATION III

II REVISION HISTORY IV

III RELATED BUSINESS PROCESSES IV

IV RELATED CORPORATE MANAGEMENT SYSTEM (CMS) DOCUMENTS IV

1. INTRODUCTION 1

1.1 Purpose 1

1.2 Changes to the Specification 1

2. SPECIFICATION FOR WELDING DUPLEX STAINLESS STEEL 2

2.1 Specification Requirements 2

2.2 Process Deliverables 2

2.3 Process Owner's Responsibility 2

2.4 Performance Levels / Indicators 2

2.5 Performance Monitoring 2

2.6 Effective period 3

2.7 Review and Improvement 3

3 GLOSSARY OF DEFINITIONS, TERMS AND ABBREVIATIONS 4

AMENDMENTS/SUPPLEMENTS TO API SPEC 1104 7

1 Scope 7

2 NORMATIVE REFERENCES 7

3 TERMS, DEFINITIONS, ACRONYMS AND ABBREVIATIONS 7

July 2018 v SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

4 SPECIFICATIONS 7

4.1 Equipment 7

4.2 Materials 8

5 QUALIFICATION OF WELDING PROCEDURES WITH FILLER METAL

ADDITIONS 10

5.1 Procedure Qualification 10

5.2 Record 10

5.3 Welding Procedure Specification 10

5.4 Essential Variables 13

5.5 Welding of Test Joints - Butt Welds 15

5.6 Testing Of Welded Joints - Butt Welds 16

5.7 Welding of Test Joints - Fillet Welds 20

5.8 Testing Of Welded Joints - Fillet Welds 20

5.8.1 Preparation 20

5.9 Welding of Test Repair Welds 21

5.10 Testing of Repair Welds 21

5.11 Records 21

6 QUALIFICATION OF WELDERS 22

6.1 General 22

6.2 Single Qualification 22

6.3 Multiple Qualification 23

6.4 Visual Examination 23

6.5 Destructive Testing 23

6.6 Non-destructive Testing (Radiography) - Butt Welds Only 24

6.7 Retesting 24

6.8 Records 24

7 DESIGN AND PREPARATION OF A JOINT FOR PRODUCTION WELDING 25

7.1 General 25

July 2018 vi SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

7.2 Alignment 26

7.3 Use of Line-Up Clamp for Butt Welds 26

7.4 Bevel 26

7.7 Cleaning Between Beads 27

7.8 Position Welding 27

7.10 Identification of Welds 27

7.11 Pre- and Post-Heat Treatment 27

7.13 Weld Interruption 28

7.14 Weld Finishing 28

7.15 Shielding and Backing Gas 28

8 Inspection and Testing of Production Welds 28

8.2 Methods of Inspection 28

8.3 Qualification of Inspection Personnel 28

8.4 Certification of Non-Destructive Testing Personnel 29

8.5 Extent of Inspection and Testing 29

8.6 Records 29

9 ACCEPTANCE STANDARDS FOR NON-DESTRUCTIVE TESTING 29

9.1 General 29

9.3 Radiographic Testing 30

9.4 Magnetic Particle Testing 31

9.5 Liquid Penetrant Testing 31

10 REPAIR AND REMOVAL OF WELD DEFECTS 31

10.2.6 Welded Double repairs 31

10.2.7 Repair Area length 31

10.2.7.1 Large Diameter Pipe 31

11 PROCEDURES FOR NON-DESTRUCTIVE TESTING (NDT) 32

11.1 Radiographic Test Methods 32

11.2 Magnetic Particle Test Method 33

July 2018 vii SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines

Version3.0

12 MECHANIZED WELDING WITH FILLER WIRE ADDITIONS 33

13 AUTOMATIC WELDING WITHOUT FILLER-METAL ADDITIONS 33

14 DOCUMENTATION 33

14.1 General 33

ANNEXURE TO API 1104 34

A ALTERNATIVE ACCEPTANCE STANDARDS FOR GIRTH WELDS 34

A.1 General 34

B IN-SERVICE WELDING 34

FIGURE A - LOCATION OF MACRO SECTION AND IMPACT TEST SPECIMENS

35

FIGURE B - ORIENTATION AND LOCATION OF CHARPY IMPACT SPECIMENS

36

FIGURE C - HARDNESS INDENT LOCATIONS 37

APPENDIX C REFERENCES 38

USER COMMENT FORM 40

July 2018 viii SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

1. Introduction

1.1 Purpose

This specification is a revision of SP-1097 version 2.0, Specification for Welding of Duplex

Stainless Steel Pipelines, issued in May 2005. The purpose of this specification is to define

the minimum technical requirements for the welding of duplex stainless steel pipelines and

flow lines.

The basis of this specification is API Std 1104 Twenty first edition, September 2013

including addendum 2 May 2016.

1.2 Changes to the Specification

This specification shall not be changed without approval from the Custodian, the Material &

Corrosion Functional Discipline Head UEC (CFDH), who owns this specification. If you

think the specification is not correct, write your comments on a copy of the User Comments

form. The form is included as the last page of this specification. Send the copy with your

comments and personal details to DCS.

September 2018 Page 1 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

2. Specification for Welding Duplex Stainless Steel

This Specification gives the minimum technical requirements for the welding of duplex

stainless steel pipelines and ancillary equipment where the applicable Code has been defined

by the Company as ASME B31.4 or ASME B31.8.

This Specification is applicable to all classes of pipelines as defined in SP-1211 and is based

on API Std 1104, 21edition, including addendum 2 May 2016. Appendix B gives

amendments and supplements to the base standard. Tables or figures supplementary to those

of API Std 1104 have been designated with capital letters.

This document is not applicable to:

Welding of on-plot pipe work and fabricated equipment, (covered by PDO specification

SP-1173)

Manufacture of longitudinally welded pipe,

Welding on to pipelines under operating conditions, (hot tap operations)

Welding of pipelines on use in sour service, as defined under NACE

MR0175/ISO15156

2.1 Specification Requirements

Welding, fabrication and inspection shall be in accordance with the requirements of API Std

1104, 21edition, including addendum 2 May 2016, as amended and supplemented by

Appendix B of this specification.

The scope of API Std 1104 is confined to carbon and low alloy steels and the extensive

amendments and supplements of the text in Appendix B have been necessary to incorporate

the special requirements for welding duplex stainless steels. Other general amendments and

supplements are included in Appendix B where considered necessary to ensure pipeline

integrity in accordance with PDO and Shell Group requirements

The Clause numbering in Appendix B follows that of API Std 1104. Where clauses of API

1104 are not amended or supplemented they shall apply in their entirety.

2.2 Process Deliverables

Process deliverables comprise field welded duplex stainless steel pipelines, flow lines and

related welded fabrications designed to ASME B31.4 or ASME B31.8 and intended for off-

plot oil and gas service.

2.3 Process Owner's Responsibility

The owner of this specification, UEC as CFDH Materials and Corrosion, is responsible for

authorising all proposed deviations or amendments to the specification and for the

instigation of periodic reviews and updates in accordance with Clauses 1.2 and 2.7.

2.4 Performance Levels / Indicators

See relevant API Std 1104 weld inspection and testing acceptance criteria and the

amendments/supplements given in Appendix B of this specification.

2.5 Performance Monitoring

Requirements for monitoring welding process variables, welder performance and weld

quality are detailed in relevant sections of API Std 1104 as amended by Appendix B of this

specification.

September 2018 Page 2 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

2.6 Effective period

The requirements of this specification shall remain in force indefinitely unless superseded by

an authorised revision.

2.7 Review and Improvement

This specification will be reviewed and updated once every three years. The review

authority will be UEC (CFDH) Materials and Corrosion.

September 2018 Page 3 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

3 Glossary of Definitions, Terms and Abbreviations

Certain terms and abbreviations used in this document are defined below. The listed

definitions shall be considered to supplement those given in API Std 1104.

General Definitions

Contractor The party which carries out all or part of the design,

engineering, procurement, construction, commissioning or

management of a project, or operation or maintenance of a

facility. The Company may undertake all or part of the duties of

the Contractor.

Manufacturer/ The party which manufactures or supplies equipment and

Supplier services to perform the duties specified by the Contractor.

Company Petroleum Development Oman LLC. The Company will

generally specify the technical requirements. The Company may

also include an agent or consultant authorised to act for, and on

behalf of, the Company.

User The Company, Consultant or Contractor who uses this

document.

Corporate Functional The person within the Company responsible for the discipline to

Discipline Head which the standard belongs

shall Indicates a requirement. Any deviation to a requirement shall be

approved by the CFDH.

should Indicates a recommendation. A deviation to a recommendation

shall be approved by the Company welding-TA 2.

may Indicates a possible course of action.

Specific Definitions

Batch or Lot As defined in AWS A5.01, Clause 5 (Classification) and Clause

(see App. B, 6 (Testing)

4.2.2.1)

Duplex A chromium-nickel-molybdenum stainless steel containing a

stainless steel balance of austenite and ferrite stabilising alloying elements

such that the microstructure at room temperature consists of

approximately equal proportions of austenite and ferrite.

Nominal Nominal thickness t shall have the following meanings:

thickness

- butt joint; parent metal thickness, which for joints between

a dissimilar thickness is that of the thinner material.

- fillet weld; parent metal thickness, which for joints between

dissimilar thicknesses is that of the thicker material.

- set-on branch connection; thickness of branch pipe

- set-through branch connection; thickness of main pipe.

September 2018 Page 4 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Verified Copy A photocopy of an original document which has been re-

endorsed and signed by the organisation producing the

photocopy to verify that none of the information has been

adulterated.

Welding Co- The Contractor nominated authority on the quality aspects of

ordinator welding. The Welding Co-ordinator shall be a Welding

Engineer meeting the recommendations for European Welding

Engineer (refer ISO 14731). However, other

national/international qualifications may be considered at the

discretion of the Company. The Welding Co-ordinator shall be

approved by the Company TA-2 (Welding).

Abbreviations

a Throat Thickness of Fillet Weld

AWS American Welding Society

CSWIP Certification Scheme for Welding Inspection Personnel

D Nominal Outside Diameter

FCAW Flux Cored Arc Welding

GMAW Gas Metal Arc Welding

GTAW Gas Tungsten Arc Welding

HAZ Heat Affected Zone

HV Vickers Hardness

NDE Non-destructive Examination

PAMS Portable arc monitoring system

PCN Personnel Certification in NDE

PQR Procedure Qualification Record

PRE Pitting Resistance Equivalent

PT Penetrant Testing

PWHT Post Weld Heat Treatment

RT Radiographic Testing

SAW Submerged Arc Welding

SMAW Shielded Metal Arc Welding

t Nominal Thickness

TA Technical Authority,

September 2018 Page 5 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

UNS Unified Numbering System

WPS Welding Procedure Specification

September 2018 Page 6 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Amendments/Supplements to API Spec 1104

1 Scope

Delete the 1st paragraph and replace with the following;

This specification covers the arc welding of butt, branch and fillet welds in duplex and super

duplex stainless steel pipelines used in field constructions.

Welding may be carried out by a SMAW, GTAW, GMAW, SAW, PAW or gas shielded

FCAW process, or a combination of these processes. A manual, automatic welding

technique, or combination of these techniques, may be used. The first and second passes of

single sided butt welds SHALL be made using GTAW process. Filler metal shall be used

for all passes. Roll welding shall be accepted when an automatic welding process is used.

GMAW, GTAW, and gas shielded FCAW shall be restricted to construction areas protected

against wind and draught.

The following shall not be used:

1. Socket welds

2. Semi-automatic processes.

3. Oxy-fuel gas welding processes

4. Gas welding, self- shielded gas FCAW welding and flash butt welding processes

5. Permanent backing bars

2 Normative References

See also Appendix C of this specification.

3 Terms, definitions, Acronyms and Abbreviations

See also above Appendix A of this specification.

4 Specifications

4.1 Equipment

Add the following:

Welding parameter measuring equipments shall be calibrated.

GTAW power units shall incorporate a high frequency starting unit, slope-out control and

gas delay facility as a minimum. Direct contact shall be prevented between duplex stainless

steel and carbon steel equipment.

Grinding wheels dedicated to duplex and super duplex stainless steel work shall be used.

Wire brushes shall be of stainless steel. All such dedicated equipment and consumables

shall be identified by colour coding or other suitable means.

September 2018 Page 7 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

4.2 Materials

4.2.1 Pipe and Piping Components

Replace existing section as follows:

Pipe shall be in accordance with one of the following:

DEP 31.40.20.34

Fittings shall be in accordance with one of the following:

DEP

Shell MESC codes

The Contractor shall obtain verified copies of the materials certificates for all free-issue

items to be welded. Contractor supplied items shall have original or verified copies of

materials certificates and certification. Items without materials certificates shall not be used

unless they are re-certified by re-testing by company authorised representative.

4.2.2 Filler metals and Fluxes

4.2.2.1 Types

Add as follows:

Only Company-approved Manufacturers shall be used. Other manufacturers may be

accepted if a 3 years track record is presented and agreed with Material Corrosion Integrity

(M CI) TA 1

The welding consumable certificate shall be in accordance with ISO 10474 type 3.1.

Alternatively each batch of welding consumables may be tested in accordance with

applicable consumable classification specification.

The chromium content shall be at least match with the parent material and nickel content

shall be over match with the parent material analysis.

All filler metals shall have classification society, e.g. Lloyd's, DNV type approval

4.2.2.2 Storage and handling of filler metals and fluxes

Add the following:

Contractor shall develop consumable handing procedure in line with consumable

manufacturer recommendations and approved by Company welding TA 2.

4.2.3 Shielding gases

4.2.3.1 Types

Add the following:

The shielding and purge gas shall be certified as complying with ISO 14175, or equivalent.

The purity or component concentrations of the gas shall be as specified on the WPS and

shall be the same for procedure qualification and production welding

September 2018 Page 8 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

The dew point of shielding and purge gas shall be -30 degree C or below

4.2.3.2 Storage and handling

Add the following:

Gases in containers that are unidentifiable shall not be used.

September 2018 Page 9 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

5 Qualification of Welding Procedures with Filler Metal

Additions

5.1 Procedure Qualification

Add the following:

The WPS and PQR SHALL [PS] be approved by the Company welding TA-2 for each

project.

All welding procedure qualification shall be done in Oman only and shall be witnessed by the

Company welding Inspector under simulated site conditions.

Previously qualified welding procedures by the same contractor may be used subject to the

following:

The PQR is fully in accordance with this specification.

The WPS is amended to reflect the project specific details.

WPS proposals for qualification shall be submitted to the Company a minimum of two

weeks prior to the proposed date of test welding. The WPS proposals shall be endorsed and

signed by the Contractors authorised representative prior to submission. The Authorised

Company welding Engineer shall endorse “APPROVED FOR QUALIFICATION", the

contract number, the date and signature. Only WPSs endorsed shall be used for test welding.

5.2 Record

Add the following:

The PQR shall include the following Documents:

The WPS Approved for Qualification with all the details specified in clause 5.3.

The actual welding details with all the details specified in clause 2.3

Material certificates.

Consumables certificates.

PAMS printout of the welding parameters*.

Summary of welding parameters including heat input calculation

Visual inspection report.

NDT reports.

Laboratory test report.

* Welding parameters shall be recorded by means of a calibrated portable arc monitoring system with printout

facility.

5.3 Welding Procedure Specification

5.3.1 General

Add the following:

The WPS shall show the following non-technical information:

Date

Contractor’s logo

Revision number

Contract number

Project title

Contractors signature and endorsement

September 2018 Page 10 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

MDMT

Service (Sour/non-sour)

Client: PDO

5.3.2 Specification Information

5.3.2.2 Materials

Replace existing section as follows:

UNS number of material specification and grade of pipe or fittings or flanges shall be stated.

5.3.2.3 Diameters and wall thicknesses

Replace existing section as follows:

The following limits shall apply for all diameters and thicknesses:

Qualified diameter range; when D <323mm, 0.5D to 2 D; when D > 323mm; 0.5D to

maximum to be welded.

Qualified wall thickness range, 0.75t to 1.5t. but not < 5mm. For t < 5mm, a change

outside the range t to 1.5t

Qualified throat thickness, (fillet weld), 0.75a to 1.5a.

Nominal thickness, t, is dependent on weld configuration and is defined in Appendix A of

this specification.

Welds made using fully automatic equipment shall be separately qualified for each

combination of pipe diameter and wall thickness.

5.3.2.4 Joint design

Add the following:

The WPS shall indicate the allowable tolerances on each of the joint design details.

Where automatic welding is specified, a U-groove preparation without root gap shall be

used.

5.3.2.5 Filler metal, Flux and number of beads

Add the following:

Details of the filler metal manufacturer and brand name shall be stated on the WPS for each

pass.

For SMAW, maximum bead width shall be restricted to 2.5 times the electrode diameter.

Based on the minimum line pipe thickness of 4.8 mm normally specified for pipelines, joints

shall be completed with a minimum of three passes.

5.3.2.6 Electrical characteristics

Add the following:

Where applicable, electrode stick-out, contact tube-to-work distance, and wire feed speed

shall be specified for each bead. If pulse welding is used, background current and pulse

parameters shall also be specified or a unique program reference included.

September 2018 Page 11 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

5.3.2.7 Flame characteristics

Delete this section: Replace existing section as follows:

Oxyfuel gas welding shall not be used.

5.3.2.8 Position

Add the following:

WPSs for manually welded line pipe butt joints shall be qualified in the 5G position to cover

production welding 5 G positions. Automatic welds shall be qualified for each position to be

used in production. Branches, attachment welds and ancillary piping may be qualified in the

production welding position or, to cover all positions, in the 6G position, at the option of the

Contractor.

5.3.2.9 Direction of welding

Add the following:

Except where an automatic process is specified, all positional welds shall be deposited by

uphill progression only.

5.3.2.11 Type and removal of line-up clamp

Replace last sentence as follows:

An internal or external line-up clamp shall be used for all girth welds except where it is

demonstrated that to do so would be impractical, in which case tack welding may be

permitted by Company authorised welding engineer

An internal line-up clamp shall not be removed until deposition is completed of the first two

passes. An external line-up clamp shall not be removed until the root bead is at least 50%

complete, equally distributed around the joint.

The minimum number of passes to be deposited before the pipe is lowered off shall be

stated.

See also clause 7.3 of this specification.

5.3.2.13 Pre- and post-Weld heat treatment (PWHT)

Add the following:

The maximum interpass temperatures shall also be specified.

5.3.2.14 Shielding gas and flow rate

Change title to:

Shielding/backing gas and flow rate

Add the following:

For root welding of single-sided joints, gas back purge shall be specified. The WPS shall

include requirements for flushing prior to commencement of welding and for monitoring of

exit gas oxygen content, (see section 7.17 of this specification).

September 2018 Page 12 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

5.3.2.15 Shielding flux

Add the following:

AWS flux classification, the manufacturer, brand name and the type of flux shall also be

specified.

5.3.2.16 Speed of travel

Replace existing section as follows:

Speed of travel shall be shown in millimetres per minute or millimetres per second.

5.3.2.17 Method of cooling after welding

Delete this title and add the following new sections, 5.3.2.17 – 5.3.2.21:

5.3.2.18 Heat input range

Heat Input (kJ/mm) = (Volts x Amps x 60) / (1000 x Welding Speed (mm/min.))

The allowable range of heat input rates to be applied by each welding process for each bead

shall be specified.

5.3.2.19 Number of welders

The WPS shall designate the number of root pass welders and hot pass (second pass)

welders.

5.3.2.20 Partially completed joint

The minimum number of passes before the joint is allowed to cool to ambient temperature

shall be specified. The minimum shall be three passes or one third of the joint whichever is

greater.

See also clause 7.14 of this specification.

5.3.2.21 Tungsten electrode for GTAW welding

The AWS electrode class shall be specified in the WPS.

5.3.2.22 Welding technique

For automatic welding, the following shall be specified:

- amplitude of weave;

- frequency of weave; and

- dwell time.

5.4 Essential Variables

5.4.2 Changes requiring requalification

5.4.2.1 Welding process or Method of application

Replace as follows,

Any change in process or combination of processes. Any change in equipment type and

model for mechanised or automatic welding.

September 2018 Page 13 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

5.4.2.2 Base material

Replace as follows:

Any change in UNS number. A change in the PREN exceeding –1.5 or +2.5.

For super-duplex grades the following shall be considered an essential variable:

Any change in manufacturer

Any change in product form (casting, forging) for pipes and fittings. A procedure

qualified by welding together products from different manufacturers or different

product forms shall qualify both the combination and welds between each product.

5.4.2.3 Joint Design

Delete existing section and replace by:

Any change in bevel dimension outside the tolerance stated in the approved WPS, Branch

welds shall require separate qualification in accordance with Section 5.7.

5.4.2.4 Position

Add the following:

Any change in the angle of the axis of the pipe greater than 25 from that used for

qualification shall constitute an essential variable.

5.4.2.6 Filler metal

Replace existing section, including Table 1, as follows:

The following changes in the qualified WPS shall be considered as essential variables:

A change in the diameter of electrode or filler wire.

A change in filler metal classification.

For super duplex material: a change of filler metal trade name

5.4.2.10 Shielding gas and flow rate

Change title to:

Shielding/backing gas and flow rate

Add the following:

A change of shielding or backing gas flow rate to one outside the range ± 20% of the

average value qualified and specified shall also constitute an essential variable.

Any increase in the oxygen content of the effluent backing gas beyond that qualified shall

necessitate re-qualification.

Any decrease in the number of passes before cessation of backing gas flow shall constitute

an essential variable.

5.4.2.11 Shielding flux

Replace existing section as follows:

September 2018 Page 14 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Any change in classification or trade name constitutes an essential variable.

5.4.2.12 Speed of travel

Add the following:

Any change in the range of qualified speed of travel, or electrode run out length, outside the

range ± 15% of that qualified shall constitute an essential variable. See also 5.4.2.13,

following.

5.4.2.14 PWHT

Delete this section and replace with the following new sections, 5.4.2.14 – 5.4.2.19:

5.4.2.15 Welding current or heat input

Any change in average welding heat input per pass outside the range ± 10% of that qualified

and the addition or deletion of pulsating current shall be considered essential variables.

5.4.2.16 Interpass temperature

Any increase in maximum interpass temperature shall constitute an essential variable.

5.4.2.17 Number and sequence of weld beads

Any change in the sequence of deposition shall constitute an essential variable.

5.4.2.18 Removal of line-up clamp

Removal of the line-up clamp at a stage earlier than stated in the approved for construction

WPS shall constitute an essential variable.

5.4.2.19 Partially completed joint

Any change in the minimum number of runs before the joint is allowed to cool shall

constitute an essential variable.

5.4.2.20 Diameter

See clause 5.3.2.3 of this specification.

5.5 Welding of Test Joints - Butt Welds

Replace existing section as follows:

Test welding shall be performed under simulated site conditions using full pipe lengths as

appropriate In order that root oxidation can be assessed under ‘worst case’ conditions,

welding should commence as soon as the maximum specified back purge oxygen level is

reached.

Test welding shall be witnessed by a authorised Company representative. The Contractor

shall give the Company a minimum of 48 hours' notice of the intention to proceed with test

welding.

Immediately prior to test welding, the Contractor shall have available at the test site for

Company inspection, the following documents:

WPS endorsed "Approved for Qualification".

Materials certificates, or verified copies, traceable to the items to be welded.

September 2018 Page 15 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Batch certificates, or verified copies, traceable to the welding consumables.

The approved consumable handling procedure.

No test welding is permissible without recording the welding parameters using a calibrated

portable arc monitor.

5.6 Testing Of Welded Joints - Butt Welds

5.6.1 Preparation

Delete the existing section and replace as follows:

Test welds shall be subjected to NDT as detailed in 5.6.1.1, before sectioning for destructive

testing in accordance with 5.6.1.2.

5.6.1.1 Non-destructive testing of test welds

NDT shall be witnessed by a authorised Company inspector.

The NDT shall consist of the following:

Visual examination

Liquid penetrant testing

Radiographic testing

The acceptance criteria shall be as stated in Section 6 of this specification. Any weld that

fails to meet the acceptance criteria shall not be offered for destructive testing. Visual

examination of all butt welds shall include the pipe bore surfaces. The degree of oxidation

present on these surfaces following welding shall be within the visual acceptance criteria of

DEP 30.10.60.31-GEN.

5.6.1.2 Destructive testing of test welds

Following Company approval of the NDT, all test welds shall be sectioned at the locations

shown in Figure 3 of API Std 1104 and Figure A of this specification. Sectioning and

testing shall be performed at a Company-approved test laboratory.

All test reports shall be endorsed and signed by the testing organisation, the Contractor, and

the Company Inspector who witnessed the testing.

5.6.3 Nick-break test

Delete this section.

Add the following new sections, 5.6.6 – 5.6.11:

5.6.6 Macroscopic examination and hardness test

5.6.6.1 Preparation

Specimens shall be prepared for macroscopic examination by grinding or other suitable

method to a 600 grit paper finish. The prepared surfaces shall be etched using a suitable

etchant to reveal the pass sequence, HAZ, defects etc. Metallographic examination of

representative sections shall also be carried out and observations included with the

macroscopic examination report to confirm the microstructure of the weld/HAZ and the

absence of deleterious phases.

September 2018 Page 16 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

The sections of the weld taken for macroscopic examination and hardness testing shall also

be used for ferrite measurement as required in clause 5.6.7 of this specification.

5.6.6.2 Method

The macro sections shall be examined at a minimum magnification of x5. Macro-

photographs showing the hardness indentations shall be included in the PQR.

The hardness shall be measured in accordance with ASTM E92, using HV10. For pipe butt

welds, the hardness indentations shall be as shown in Figure C of this specification. For pipe

of t less than 10 millimetres, the mid-thickness traverse may be omitted.

5.6.6.3 Requirements

The macro sections shall not show defects exceeding the acceptance standards given in

Section 6 of this specification. Each specimen shall exhibit a smooth and regular profile and

the reinforcement shall blend smoothly with the parent metal. Slight intermittent undercut

with a maximum depth of 10% of the pipe wall thickness or 0.4 millimetres, whichever is

the smaller, shall be deemed acceptable. Excess penetration shall not exceed the

requirements of clause 9.3.6.4 of this specification. Joint misalignment shall not exceed 1.6

millimetres.

The maximum hardness values from each traverse shall not exceed 325 HV10.

5.6.7 Ferrite measurement

5.6.7.1 Preparation

Measurements of ferrite level shall be made on the prepared sections used for macro-

examination and hardness measurements.

5.6.7.2 Method

The ferrite content shall be determined by microscopic point counting in accordance with

ASTM E562 and magnetic measurement technique using an instrument calibrated to AWS

4.2 (for DSS only). Ferrite determinations shall be made in the weld metal and both HAZ

areas at a depth of 1mm from the inside and from the outside surfaces, or for magnetic

techniques, as close to the surface as is practicable. Additional checks shall be made in the

centre of the unaffected base material on each side of the weld.

5.6.7.3 Requirements

Ferrite content determined by microscopic point counting shall be in the range 40 - 60% for

the parent material and 35 - 65% in the weld/HAZ regions. The ferrite range for magnetic

measurements shall be between 30 – 70 FN. In the event that borderline unacceptable or

otherwise doubtful results are obtained using magnetic measurement, a check point-counting

determination may be made. If the results of these repeat tests are satisfactory, the ferrite

content shall be considered to be acceptable.

5.6.8 Charpy V-Notch Impact Testing

5.6.8.1 Preparation

Each procedure qualification shall include impact testing unless the nominal pipe wall

thickness is less than 4.8 mm.

One set of three specimens shall be taken at each of the following positions:

root weld centre line

September 2018 Page 17 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

root fusion line (50% intersection of notch)

root fusion line + 2 millimetres

When the wall thickness exceeds 20 millimetres, an additional set of three specimens shall

be taken at each of the following positions:

cap weld centre line

cap fusion line (50% intersection of notch)

cap fusion line + 2 millimetres

These requirements are summarised in Figure B of this specification.

Specimens shall be 10 x 10 millimetres full size wherever possible. Where these dimensions

are not possible, the largest obtainable standard sub-size specimens shall be extracted.

5.6.8.2 Test temperatures and acceptance criteria

Testing in accordance with ASTM A370 and this specification shall be conducted at -46

Deg.C.

For each set of three specimens, only one of the individual values may be below the

minimum average energy requirement with an absolute minimum as defined by the

minimum individual acceptance criterion.

The acceptance criteria are detailed in the Table below. For other standard specimen

dimensions, the acceptance criteria shall be applied pro rata.

Specimen Size, mm Charpy Energy, Joules

Minimum Average Minimum Single

10 x 10 50 40

10 x 7.5 40 32

10 x 5 33 26

5.6.9 Corrosion Testing

5.6.9.1 Preparation

A coupon specimen of dimensions 5 cm x 5 cm x full wall thickness shall be prepared in

accordance with ASTM G48. No flattening of the coupon material shall be carried out. The

weld seam shall be located centrally and parallel to one axis. The edges of the specimen

shall be rounded to minimise edge effects and the sides ground to 600 grit finish or better.

Other surfaces shall be in the "as-finished" condition.

5.6.9.2 Method

A pitting corrosion resistance test shall be conducted in accordance with ASTM G48,

Method A using the total immersion ferric chloride test. The specimen shall be degreased,

dried and weighed to three decimal places and the weight recorded.

The specimen shall be held in the solution at an angle of 45, with inside surface uppermost.

Unless otherwise directed, the test shall be conducted for a period of 24 hours at a

temperature of 22C ± 2C. For 'super duplex' grades the test temperature shall be 35C -

37C.

September 2018 Page 18 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

On completion of the test period the specimen shall be rinsed, cleaned, dried and weighed

using the procedures specified in ASTM G48A.

5.6.9.3 Requirements

The specimen shall be examined at a magnification of x20. No pitting shall be visible.

Weight loss shall be presented as total weight loss and weight loss per unit area. The latter

shall not exceed 4gm/m2

All samples shall be made available for inspection by the Company.

5.6.9.4 Other corrosion testing

Further testing may be required by the Company where duplex stainless steels are specified

for service in environments containing H2S.

5.6.10 Chemical analysis

Chemical analysis shall be conducted of the root run weld metal. The weld metal sample

shall be taken from an adjacent or equivalent location to that shown for the impact test

specimens in Figure A. The elements required for calculation of the PRE (see Section

4.2.2.1) shall be determined. The PRE value shall exceed the minimum specified for the

base material to be welded.

5.6.11 Retests

5.6.11.1 General

If the results of destructive testing are unsatisfactory owing to defective specimen

preparation or a localised weld defect, the Contractor shall inform the Company and obtain

approval to proceed with retests as detailed below.

5.6.11.2 Tensile tests and bend tests

If only one tensile or bend specimen does not meet the acceptance criteria, two additional

specimens shall be tested. Both of the additional specimens shall meet the acceptance

criteria.

5.6.11.3 Hardness tests

If only one hardness result exceeds the specified maximum then three further impressions

shall be made in close proximity to that which failed such that they do not mutually

interfere. If all of the further tests are below the specified maximum then the test shall be

accepted.

5.6.11.4 Charpy v-notch impact tests

If the specified minimum average value has been achieved and more than one specimen is

below the specified average value, or one specimen is below the specified minimum

individual value, a retest of three further specimens shall be made. All three individual

retest values shall equal or exceed the specified minimum average value.

5.6.11.5 Corrosion tests

Re-testing shall not be allowed.

September 2018 Page 19 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

5.6.11.6 New procedure requirement

If the test joint fails to meet the minimum requirements, a new WPS proposal shall be

established and re-qualified.

5.7 Welding of Test Joints - Fillet Welds

Change title as follows:

Welding of Test Joints - Fillet Welds and Branch Welds

Delete existing section and replace as follows:

The configuration of fillet weld and branch weld test joints shall be in accordance with the

weld details to be used in production and the limitations of section 5.3 of this specification.

See also the note under section 5.1.

Test welding shall be witnessed by the Company and shall only commence after the WPS

proposal has been approved by the Company and endorsed "APPROVED FOR

QUALIFICATION".

5.8 Testing Of Welded Joints - Fillet Welds

Change title as follows:

Testing of Welded Joints - Fillet Welds and Branch Welds

5.8.1 Preparation

Replace existing section as follows:

Prior to cutting, test welds shall be visually inspected and liquid-penetrant tested. If the

weld is deemed acceptable in accordance with the acceptance criteria detailed in Section 6 of

this specification it may be offered for destructive testing

Test specimens for macroscopic examination and hardness testing shall be cut from the joint

at the locations shown in Figure 10 of API Std 1104. The specimens should be machine cut

and one face shall be prepared for macroscopic examination by grinding or other suitable

method to a 600 grit paper finish. The prepared surfaces shall be etched using a suitable

etchant to reveal the pass sequence, HAZ, defects etc.

5.8.2 Method

Replace existing section as follows:

Macroscopic examination and hardness measurement shall be carried out in accordance with

section 5.6.6.2 of this specification. On full penetration branch welds, ferrite checks shall

also be conducted in accordance with section 5.6.7.2 of this specification.

5.8.3 Requirements

Replace existing section as follows:

Macroscopic examination, hardness and ferrite requirements shall be in accordance with

clauses 5.6.6.3 and 5.6.7.3 of this specification.

September 2018 Page 20 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Add the following new sections5.9 – 5.11:

5.9 Welding of Test Repair Welds

Repair welding procedures shall be prepared and qualified for each type of repair to be

performed in accordance with sections 5 and 10 of this specification. The initial girth weld

shall be welded to the appropriate qualified WPS. The maximum depth of partial

penetration repair welds shall the lesser of 0.5t or t-6 mm, (see also section 10.16). Where

the execution of single run repairs has been agreed (see section 10.1.1) separate qualification

shall be made. Back-welded repairs or root weld repair are not permitted. Test repair weld

excavations shall be located as shown by the appropriate diagram in Figure 1 of BS 4515 Pt.

2.

5.10 Testing of Repair Welds

5.10.2 Preparation

Non-destructive and destructive testing of the repair weld shall be performed as required in

(5.6) and (10.1.3) except where modified below.

5.10.3 Method

Provided the repair weld procedure is representative of the original weld qualification,

destructive tests shall be as listed below. Otherwise full procedure qualification tests shall

apply as specified in section 5.6 of this specification’.

- 1 transverse tensile, (5.6.2);

- bend test, (5.6.4 or 5.6.5);

- 1 macro-hardness test, (5.6.6) at the locations shown in Figure 8 of BS 4515 Part 2;

- Ferrite measurement (5.6.7), which for partial penetration repairs shall include

measurements made in the new HAZ formed in the original weld;

- Charpy testing (5.6.8) at the locations shown in Figure 4

- Corrosion testing (5.6.9), to include the junction of new and original weld metal.

5.10.4 Requirements

The acceptance criteria shall be as for the original welding procedure qualification.

5.11 Records

The procedure qualification record shall include the following:

Approved for qualification WPS

Print-outs from the portable arc monitoring system for each pass

Visual inspection and NDT reports

Heat treatment reports

Original laboratory test certificates, including macrophotographs

Original or verified copies of materials certificates for the test coupon materials

Original or verified copies of batch certificates for the filler materials and

shielding/backing gases employed for test welding.

The PQR shall be submitted to the Company for review and approval with the revised WPS

for production welding.

September 2018 Page 21 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

6 Qualification of Welders

6.1 General

Add the following:

Welders who weld the procedure qualification test coupons, which are satisfactory, shall be

deemed as being qualified.

Welders shall have a valid Company qualification within the validity defined in this

specification or they shall be qualified using the Approved For Construction WPS.

Qualification shall be valid for a period of six months. This period may be extended by a

further six months when it can be shown by NDT from production welding that the welder

has produced satisfactory welds using the approved for construction WPS. After 12 months

the welder shall be re-qualified, unless otherwise agreed by the Company’.

Welders shall be re-qualified when the Company has reason to question the welder's ability

to make welds that meet this specification.

For butt welds, welders shall be qualified by visual examination, radiographic testing, bend

testing and macro-examination.

For branch welds and fillet welds, welders shall be qualified by visual examination, liquid

penetrate testing, and macro-examination.

6.2 Single Qualification

6.2.1 General

Delete first sentence and replace as follows:

The use of segments of pipe nipples shall not be permitted. Each of the two pipe nipples

used to make the test weld shall be a minimum length of D or they shall be of sufficient

length to accommodate the alignment device being used, whichever is greater.

6.2.2 Scope

Delete items a., b., c., d., e., f., and g. and replace with the following:

For sour service/critical applications, as determined by the Company in the Contract

document, the limits of welder qualification are the essential variables of the WPS. In such

cases, any change that necessitates re-qualification of the WPS shall cause for re-

qualification of welders to the new, approved WPS. The following essential variables shall

be applied for welder qualification:

(a) A change from one welding process to another or a change from manual to automatic or

vice versa.

(b) A change in joint thickness to more than twice the thickness of the test joint.

(c) A change in pipe or branch diameter outside the range 0.5D to 2 D, where D is the test

pipe diameter.

(d) A major change in joint configuration, e.g. ‘U’ to ‘V’ preparation

(e) Any change in welding position, except that qualification in the 6G position shall

qualify all positions.

(f) A change in welding progression from uphill to downhill or vice versa.

(g) For manual welding electrodes, a change from one coating type to another

(h) Any change in the nominal composition of the shielding gas.

September 2018 Page 22 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

6.3 Multiple Qualification

6.3.1 General

This clause of API Std 1104 shall not be applicable.

6.3.2 Scope

This clause of API Std 1104 shall not be applicable.

6.4 Visual Examination

Delete existing section and replace with the following:

Performance of visual examination and the acceptance criteria shall be as defined in section

9 of this specification.

6.5 Destructive Testing

6.5.1 Sampling of test butt welds

Delete existing section, including Table 3, and replace with the following:

After satisfactory radiographic testing, the test weld shall be sectioned for macro-

examination in accordance with Section 5.6.6. Hardness testing may be omitted. The

number of macro-sections shall be two per welder's portion. The acceptance criteria shall be

as defined in Section 9.

6.5.2 Tensile strength, nick-break and bend test procedures for butt welds

: Add the following:

The specified tensile strength and nick-break tests may be omitted.

6.5.6 Sampling of test fillet welds

Change title as follows:

Sampling of Test Fillet Welds and Branch Welds

Add the following:

See also the note in section 5.1 of this specification.

Prior to cutting, in addition to the visual examination specified in clause 6.4, the test welds

shall be liquid penetrant tested and shall meet the requirements of section 9 of this

specification.

6.5.7 Test methods and requirements for fillet welds

Change title as follows:

Test Methods and Requirements for Fillet Welds and Branch Welds

Replace existing section as follows:

The fillet weld samples shall be prepared and subjected to macro-examination in accordance

with section 5.8 of this specification.

September 2018 Page 23 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

6.6 Non-destructive Testing (Radiography) - Butt Welds Only

6.6.1 General

Replace existing section as follows:

The qualification butt weld shall be examined by radiography in addition to the destructive

testing specified in API Std 1104 section 6.5 and this specification.

6.6.2 Inspection requirements

Add the following:

The test weld shall meet the requirements of API Std 1104 as modified by this specification.

6.7 Retesting

Replace existing section as follows:

If the test weld does not meet the specified acceptance criteria, the welder may carry out two

repeat tests. Both of the repeat welds shall meet the specified acceptance criteria. Failure of

one or both repeat welds shall result in disqualification of the welder until such time as the

Contractor can demonstrate to the Company by records that satisfactory training has been

received. The welder may then be presented for further qualification testing.

6.8 Records

Add the following:

The Contractor shall maintain the records of the tests and test results of each welder. The

Contractor shall assign each welder a unique identification number, letter, or symbol to

ensure traceability to specific welds. If a welder ceases to work for the Contractor, the

unique identification shall not be re-assigned to another welder.

September 2018 Page 24 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

7 Design and Preparation of a Joint for Production

Welding

Change title as follows:

Production Welding

7.1 General

Replace existing section as follows:

No production welding shall be carried out before the WPSs have been endorsed as

'Approved for Construction' by the Company and the welders qualified to weld using the

approved WPSs.

The approved WPSs shall be available at the construction site.

The preparation and welding of pipeline shall be in accordance with the qualified and

approved WPS.

Fusion faces and the surrounding surfaces within a minimum of 25 millimetres of the joint

shall be free from heavy scale, moisture, oil, paint, or any other substance which may have a

deleterious effect on the weld quality or progress.

Stray arc strikes shall be removed by grinding. The ground area shall be liquid penetrant

tested and thickness checked. Where the thickness is below the specified minimum, the

section of pipe shall be removed. Any arcing from a poor connection shall be treated as an

arc strike. Connections shall be made to the work by clamps having stainless steel contact

surfaces. Earth cables shall not be welded to pipeline components.

7.1.1 Handling and storage

7.1.1.1 General

All precautions shall be taken throughout fabrication to minimise contamination of duplex

stainless steel materials resulting from direct contact with carbon steels, exposure to ferrous

dust, swarf or other debris and from residual deposits on or near fusion faces. Equipment

used for grinding and cleaning of edge preparations shall be dedicated for stainless steel

work. Wire brushes shall be of stainless steel. Precautions required for handling equipment

and line-up clamps are included in Clause 4.1 of this specification. General precautions to

be applied during the storage of duplex stainless steels and in handling line pipe are outlined

in Clauses 7.1.1.2 and 7.1.2.3, following.

Surface oxidation or metallic contamination which will not respond to washing or

degreasing treatments shall be removed using power tools or by a pickling treatment.

Pickling procedures shall be subject to prior approved by the Company. Washing shall be

performed with potable water.

7.1.1.2 Storage

a) Components stored in an open site or within a fabrication workshop shall be protected from

environmental contamination.

b) Duplex stainless steels shall be clearly identified and segregated from other stored materials.

7.1.1.3 Pipe handling

c) Supports, rollers and other pipe handling equipment shall be of compatible material or shall be

suitably lined to prevent damage or contamination of the pipe work.

September 2018 Page 25 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

d) Slings and supports for lifting duplex stainless steel pipe and assemblies shall be of Nylon or

similar compatible material.

e) Pipe handling by means of hooks in pipe ends shall not be permitted.

7.1.2 Weather protection

f) Work shall not be performed when the weather and/or degree of protection does not permit

satisfactory workmanship.

g) Enclosures giving adequate protection to the weld area at all times from wind, rain and

moisture shall be provided. In windy conditions the pipe ends shall be sealed to prevent

through draughts.

h) Weld surfaces shall be thoroughly cleaned and dried before welding. Moisture shall be

removed by means of blowers, or in exceptional cases a heating torch may be used provided no

signs of surface oxidation are allowed to develop.

7.2 Alignment

Replace existing section as follows:

No welding shall be carried out until the alignment specified in the approved WPS has been

achieved.

Hammering or heating of the pipe shall not be permitted.

Joint design shall be in accordance with ASME B31.4 or B31.8. Any taper shall not be

steeper than 1 in 4.

When a pipe with one longitudinal seam is used, this seam shall be within the top 120 of the

circumference. The longitudinal seams of consecutive pipes shall be offset by at least 45.

7.3 Use of Line-Up Clamp for Butt Welds

Replace existing section as follows:

Internal line-up clamps shall be used wherever possible and their design shall be such as to

allow the introduction and containment of root purging gases, as required in clause 7.17.

External line-up clamps may be used for line pipe less than 150 NB, for tie-in welds and for

special welds, such as connections to valves, flanges and fittings.

Pipe shall not be moved or lowered off until the second pass has been completed. An internal

line-up clamp shall not be removed until deposition is completed of the first two passes. An

external line-up clamp shall not be removed until the root bead is at least 50% complete,

equally distributed around the joint.

Where an internal or external line-up clamp cannot be used, alignment may be achieved

using tack welds. Tack welds shall be temporary bridge or bullet tacks using suitable duplex

stainless steel material. Welding parameters shall be in accordance with the appropriate fill

pass. Tack welding shall be performed only by welders qualified to weld with the WPS. The

tack welds shall be removed by grinding as welding progresses around the joint.

Fully penetrating root tacks shall not be allowed.

7.4 Bevel

7.4.2 Field bevel

Replace existing section as follows:

September 2018 Page 26 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Component ends shall normally be bevelled by machining or grinding. Preparation of weld

edges by plasma cutting is permissible provided a machine guided torch is used. Edges shall

be ground to a smooth bright uniform finish with the removal of a minimum of 0.5

millimetres of metal.

The new bevel shall be visually examined Burns, small score marks, indentations, other

imperfections, and linear indications shall be unacceptable and the bevel shall be re-

prepared. Repair by welding shall not be permitted. Edges shall be free from slag, spatter,

dirt, grease or other foreign matter which may affect weld quality. Acetone may be used for

surface cleaning.

Where pipes are cut, pipe markings shall be transferred to the off-cut in order to maintain

identification.

7.7 Cleaning Between Beads

Delete, ‘When automatic or semi-automatic welding is used’ and replace with the following:

‘For all types of welding’

7.8 Position Welding

7.8.2 Filler and finish beads

Replace last sentence of first paragraph as follows:

The weld metal reinforcement at the cap shall not exceed the requirements of clause 9.3.13

of this specification.

7.10 Identification of Welds

Replace existing section as follows:

Prior to commencing the root pass, the welder shall clearly mark the pipe adjacent to the

weld with the symbol or identification assigned to him. Where tack welding has been

approved by the Company, no marks shall be made for the tack welding.

Marking shall be made with weather-proof chalk, paint, chloride-free crayon, or pen. Die

stamps shall not be used. The root pass welder shall make a mark at the top of the pipe.

Where two welders make the root pass, they shall each make a mark at the top of the pipe on

the side where they are about to weld. Subsequent welders shall mark the pipe below the

first code in the sequence which they work. The identification marks shall not be removed

until the welds have been inspected both visually and non-destructively.

7.11 Pre- and Post-Heat Treatment

Replace existing section as follows:

7.11.1 Preheat and interpass temperature control and measurement

If welding is likely to be performed below 15C or condensation of moisture on the weld

area is possible a minimum preheat of 50C shall be applied to a minimum bandwidth of

75mm either side of the joint. Welding or cutting torches shall not be used.

The maximum preheats and interpass temperature shall be 150C. Temperature

measurement shall be by thermocouple, thermo melt crayon, contact pyrometer or a

combination of these. Thermo melt crayons shall not be applied within the bevel area.

September 2018 Page 27 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Add the following new sections, 7.13– 7.16:

7.13 Weld Interruption

Where interruption is unavoidable, a minimum of three passes or one third of the joint

thickness, whichever is greater, shall have been deposited. On resumption of welding any

preheat requirements specified in the approved WPS shall be applied.

7.14 Weld Finishing

Welds shall be left in as welded condition and shall not be peened.

When fabrication is completed, all surfaces adjacent to the welds shall be cleaned of spatter,

burrs, and other imperfections which could interfere with radiographic or ultrasonic

inspection.

7.15 Shielding and Backing Gas

Argon, Helium or Argon/Helium mixtures of at least 99.995% purity shall be used as

shielding and backing gas. Gas mixtures containing nitrogen additions may be used subject

to the approval of the Company. Hydrogen additions are not permitted.

Gas back purge shall be maintained during the welding of all full penetration butt joints until

a minimum of 6 mm thickness of weld metal has been deposited. The same criteria shall be

applied to confirm the acceptable maximum depth of partial penetration repair welds.

Flushing with backing gas shall be carried out before welding. The oxygen content of the

exit gas shall be monitored using suitable oxygen measuring equipment and welding shall

not commence until a level that is qualified in the PQR but shall not be more than 0.2%.

Monitoring shall be continued during welding to ensure that this limit is not exceeded.

8 Inspection and Testing of Production Welds

8.2 Methods of Inspection

Add the following:

Welds shall be evaluated to the requirements of Section 9 of API Std 1104 and this

specification. Manual Ultrasonic testing of welds is not acceptable and specialized UT

techniques require company NDT TA2 approval. A Written NDT procedure in accordance

with Section 11 of API Std 1104 shall be approved by the Company prior to production

welding as applicable. The procedures shall be in accordance with Section 11 of API Std

1104 and this specification.

The primary NDT method shall be X-ray radiography using film types classified C1, C2 or

C3 according to EN 584-1.

The use of a crawler camera or other remote system shall be used for diameters greater than

8 inch.

8.3 Qualification of Inspection Personnel

Replace existing section as follows: Add the following:

Welding inspection personnel shall hold a valid qualification of one of the following:

September 2018 Page 28 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

CSWIP 3.2 with minimum of 2 years in DSS welding inspection after

certification (or)

AWS SCWI with minimum of 2 years in DSS welding inspection after

certification

Other qualifications shall be agreed by the company as equivalent to above.

8.4 Certification of Non-Destructive Testing Personnel

Add the following new sections, 8.5 and 8.6:

8.5 Extent of Inspection and Testing

During production welding the welding parameters shall be monitored and recorded as per

ITP.

Radiographic frequency for all pressure rating butt welds shall be 100%. The frequency for

class less than 600 rating can be optimised if the contractor can produce statistical analysis

to demonstrate performance over 3 years period.

All fillet welds shall be examined by liquid penetrant examination.

The Company authorised inspector shall inspect all the welds and verify compliance to the

specification.

8.6 Records

The Contractor shall generate a weld history sheet for every weld which shall contain the

following information:

Weld number

Isometric and line number

Materials specification and identification

The WPS employed

The welder(s)' identity symbols

Date welded

Visual inspection disposition

NDT reports where applicable (to be attached to the weld history sheet)

Type of repair, if applicable, and WPS

NDT reports for repairs (to be attached to the weld history sheet)

PWHT if applicable (chart to be attached to the weld history sheet)

Batch number of consumables employed

9 Acceptance Standards for Non-Destructive Testing

9.1 General

Add the following:

Wherever accessible, the extent of oxidation on the root and HAZ surfaces of single-sided

welds shall be assessed for comparison with the visual acceptance criteria of DEP

30.10.60.31-Gen.

September 2018 Page 29 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

9.3 Radiographic Testing

9.3.1 Inadequate Penetration without High-Low (IP)

Replace existing section as follows:

This type of defect shall not be acceptable regardless of the length.

9.3.2 Inadequate penetration due to high-low (IPD)

Replace existing section, including Figure 14, as follows:

This type of defect shall not be acceptable regardless of the length.

9.3.3 Inadequate cross penetration ( ICP)

Replace existing section as follows:

This type of defect shall not be acceptable regardless of the length.

9.3.7 Burn-Through (BT)

Delete sub-sections 9.3.7.2 and 9.3.7.3. Replace with new sub-section 9.3.7.2.

9.3.7.2 Acceptance Criteria

Replace existing section as follows:

Any amount of burn-through shall be unacceptable, irrespective of pipe diameter.

9.3.8 Slag Inclusions

9.3.8.1 General

Add the following

Tungsten and copper inclusions shall be treated as slag inclusions for the

purposes of assessment.

9.3.10 Cracks

Replace existing section as follows:

Cracks of any type shall not be accepted and repair of weldment crack approval shall be

obtained approval from company welding TA2.

Add the following new section:

9.3.14 Excess Reinforcement and Penetration

Weld reinforcement, when measured from the adjacent parent material surface, shall not

exceed the following values:

Wall thickness External weld reinforcement

(mm) (mm)

6.4 and under 1.6

6.4 - 12.7 2.5

Over 12.7 3.0

September 2018 Page 30 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Internal protrusion of the weld root shall not exceed 1.5mm. When measuring internal

protusion, the line of the pipe bore outside the HAZ should be taken as the reference. Local

profile changes adjacent to the fusion line should be discounted.

9.4 Magnetic Particle Testing

Delete this section.

9.5 Liquid Penetrant Testing

9.5.2 Acceptance standards

Delete existing section and replace with the following:

Any relevant linear indications shall be unacceptable.

10 Repair and Removal of Weld Defects

10.2.1 Company Authorisation

Replace existing section as follows:

Cracked weld joints shall be cut out and not to be repaired. A weld with other unacceptable

defects may be repaired only once. If the repair is unacceptable then the complete weld and

HAZ shall be removed.

10.2.3 Repair of Defects other than Cracks

Delete this section, including items a., b., c., d., e and replace with the following:

All repairs shall be performed in accordance with a separately qualified repair welding WPS.

The repair welding procedure shall be qualified in accordance with sections 5.9 and 5.10 of

this specification on a full-thickness girth weld. For qualification of repair welding

procedure, original welding procedure impact and hardness test requirements shall be met.

10.2.5 Back Weld Repairs

Delete this section and replace with the following:

Back weld repairs are not acceptable.

10.2.6 Welded Double repairs

Delete this section and replace with the following:

Weld double repairs are not acceptable.

10.2.7 Repair Area length

10.2.7.1 Large Diameter Pipe

Delete this section and replace with the following:

The total repair length shall not exceed 40% of the total weld length. For partial penetration

repairs, the maximum length of a single repair portion shall be 30% of the total weld length.

September 2018 Page 31 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

For full penetration repairs, the maximum length of a single repair portion shall be 20% of

the total weld length. Groove taper shall be included in the measurements.

11 Procedures for Non-Destructive Testing (NDT)

11.1 Radiographic Test Methods

11.1.1 General

Add the following:

The radiation shall be X-ray for penetrated thickness up to 25mm. The technique shall be

film outside, source of radiation inside. Where the source of radiation cannot be located

inside the pipe, the Company may agree to use of the film and source of radiation outside:

double wall single image technique.

The Contractor shall qualify a radiographic testing procedure prior to testing production

welds by producing radiographs that comply with this specification. These shall be retained

for reference during production and should be suitable both for confirmation of radiographic

quality and for assessment of questionable root profile features (weld protrusion, concavity

etc.) from density measurements. Note: Radiographic testing procedure qualification may be

undertaken on test welds produced for welding procedure qualification.

11.1.2.3 Other imaging media

Delete this section.

11.1.5 Selection of IQIs

Replace the note with the following,

NOTE: For the purpose of IQI selection, the thickness of the weld means specified wall

thickness plus weld reinforcement (internal plus external combined) and shall be applicable

for all type of exposures

Add the following,

For radiographic procedure qualification, IQIs shall also be placed on the surface facing the

source of radiation. The specified sensitivity requirement shall be achieved on the source

side IQIs. The sensitivity achieved on the film side IQIs shall be recorded for comparison

and used for evaluating production radiographs.

11.1.6.2 Other imaging media

Delete this section.

11.1.9.2 Other imaging media

Delete this section.

11.1.10 Film density

11.1.10.1 General

Replace existing section as follows:

The minimum density shall be 2.0. The maximum density shall be 3.5 where adequate

interpretation can be achieved with the viewing screen.

September 2018 Page 32 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

11.2 Magnetic Particle Test Method

Delete this section.

12 Mechanized welding with filler wire additions

Replace existing section as follows:

Requirements for Mechanized welding with filler wire additions are included in the

preceding sections of this specification.

13 Automatic Welding Without Filler-Metal Additions

Replace existing section as follows:

Welding without filler metal addition is not permitted.

Add the following new section:

14 Documentation

14.1 General

The Contractor shall maintain a record system which ensures weld traceability. The

Contractor shall be responsible for compiling the following document packages which shall

be submitted to the Company upon completion of the works:

(a)

Copy of approved Welding Procedure Register

Copies of approved WPSs

Copies of approved repair WPSs

Copies of all supporting PQRs

List of approved welders and their identification

List of Company welders' cards

Copies of the Company welders' cards

List of approved NDT operators

Copies of NDT operator qualification certificates

List of Company-approved deviations to the Code and this specification

Copies of Company-approved deviations to the Code or this specification

List of consumable batch certificates

Copies of consumable batch certificates

List of materials certificates

Copies of materials certificates

List of test equipment

Copies of calibration certificates

(b)

Certificate of Compliance

List of as-built drawings

As built drawings showing unique weld numbers

List of weld history sheets

Copies of weld history sheets which shall show for each weld

weld number

isometric and line number

material specifications and identification

the WPS employed

September 2018 Page 33 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

the welders' identity symbols

date welded

visual inspection disposition

NDE reports where applicable (to be attached to weld history sheet)

type of repair, if applicable, and WPS

NDE reports for repairs (to be attached to weld history sheet)

PWHT if applicable (chart to be attached to weld history sheet)

batch number of consumables employed

Radiographs - indexed and stored in a fireproof container

List of site test records

Copies of site test records

List of non-conformances/corrective actions issued during external or internal audits

Copies of non-conformances/corrective actions issued during external or internal audits

Annexure to API 1104

A Alternative Acceptance Standards for Girth Welds

A.1 General

Add the following:

This Appendix shall be applied only when specified by the Company.

B In-Service Welding

Delete this Appendix in its entirety.

September 2018 Page 34 SP-1097

Specification for Welding of Duplex and Super Duplex Stainless Steel Pipelines Version 3.0

Figure A - Location of Macro section and Impact Test Specimens

Top of pipe

Mac rosection/hardness

Weld metal

Impact

Fusi on line

A spec imens

Fusi on line + 2mm

Mac rosection/hardness

( a ) . Pip e d ia me te r s u p to

a n d in c lu d in g 4 in c h e s ( 1 1 4 .3 mm)

Top of pipe

Mac rosection/hardness

Mac rosection/hardness

Weld metal

Impact

Fusi on line

spec imens

Fusi on line + 2mm

Mac rosection/hardness

( b ) . Pip e d ia me te r s g r e a te r

th a n 4 in c h e s ( 1 1 4 .3 mm)