Professional Documents

Culture Documents

LW-781 (Cg08) DRL PGM One Page Rev

Uploaded by

mohamed elshemyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LW-781 (Cg08) DRL PGM One Page Rev

Uploaded by

mohamed elshemyCopyright:

Available Formats

05/05/2017 LW-781(Cg08) DRL pgm one page

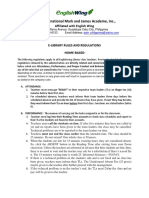

LW-CG08 (LW-781) LOCATION COORDINATES RIG: PERENCO-REP EXPECTED DURATION 10 days

SURFACE TARGET BALOR -25 TOTAL TIME TARGET Liawenda-781 PERENCO DRC

PROSPECT: Ceno E zone X= 199 904,00 199 728,00 Az : 267,07°

Y= 9 359 349,00 9 359 340,00 Inc : 15,40° SAP CODE: DRLWF067 DRILLING PROGRAMME

WELL TYPE: Oil producer. Z RT: 11,36 m Rotary table -mGE = 4,55 m cost estimated: 704 k$ w/frac

Z GE:6,82 m TDceno = +/-1240 m

PROGNOSED LITHOLOGY HOLE MUD TYPES AND LOGGING CASING SIZE BHA CEMENTING DEVIATION BOP's

m MD TVDSS mRKB SIZE PROPERTIES REQUIREMENTS TYPE & DEPTH VOLUME SURVEY

20" CP Hammered set to 13,25 m GE

17,65 120/140 mesh screens 11'' PDC bit(6-5/8 reg pin) Two slurries Varel RS416PDG6HX

Perfos Gel /KCL polymer mud w/LCM+CaCO3+barite Bit sub w/FS ( 6-5/8 reg) back to surface Vertical None Nozzles: 8x12

CIRQUES D=1,14 to 1,32 sg maxi ,FV 60-50. MUD LOGGING 8 5/8" 24 lbs/ft J55 STC 6-1/4 Shock absorber & XO Volumes: WOB= 12 to 25 klbs

50m 20" at 17,65 m VP alap -20<YP<25 -9<YS<11 ; MBT 30-60 kg/m3 Shoe at +/-450 m Landing sub 6-1/4 DC ( 4 IF) Base: theoretical Drop totco 20" x 3M top flange M/up torque:37,1-40,8 klbs-ft

MALEMBO PH=9,5 - 10,5 Nonmagnetic DC 6-1/4(4IF) annulus volume Flowrate min-max:1890-3400 lpm

417m HiVis sweeps with LCM 1 X 6-1/2 DC ( 4 IF) Lead: 40 % excess TFA Max:2,968

11" NB:partial mud losses may occur x/o- Stab 12 -1/4 ( 6-5/8 reg ) -X/O Tail: up to 300 m Recommandation

around 50-280 m 6 X 6-1/2 DC ( 4 IF) 40% excess ann RPM=70 to 80

20<PV<35-30<YP<35-15<YS<16 4 x 4-1/2 HWDP Top job with Flowrate=1000-2500 l/min

LCM will be mixed in active system in case of losses 6-1/2 JAR 1,50 sg + 2% KCL or ClCa2 Anticipated pressure 500psi

If losses occur, refer to the loss decision chart 6 x 4-1/2 HWDP ROP : 10-17 m/h

TERTIARY IABE X/O 4IF X XT39 TFA Max:2,968

4" XT39 DP

8 5/8" csg at 450 m 200/140 mesh screens Mud logging KOP section at 480 mTVD / Tangent section Lead at 1,50 sg MWD survey Kill + Choke line VAREL WM416DG1HX IADC M122

581m Polymer+KCl, fluid loss control.+MI-cide 7 7/8" PDC bit ( 4-1/2 reg) 100m above 8 5//8" shoe; CHH 8 5/8" 2000 PSI Nozzles: 6x12

D=1,02 to 1,10 sg maxi ,FV 40-60. A FIT with 1,62 sg EMW 5 1/2" 15.5 lbs/ft J55 BTC Motor 6"1/4 24-X:7/8-4.8 (4-1/2 regx 4IF) 30% excess. No survey accross 10 3/4" 3M screw on Drilling WOB=4 to 10 klbs . Max 24 klbs

VP alap -14<YP<18-7<YS<9 ; MBT 10-20 kg/m3 after drill 3 m formation shoe at +/- 1240 m String Stabilizer 7-5/8'' (4 IF) turonian reservoir flange 11" 3M M/up torque :16,5-16,7 klbs-ft

PH=9 - 10 ,API filtrate 4-6 down casing shoe 8 5/8 Note : MWD Landing sub 6-1/4(4 IF) Tail at 1,90 sg DSA 11" x 3000 psi Flowrate min-max: 1135-1510 lpm

Previous mud dilution+treatment down to 900 m then will be required Note : casing slips to be Nonmagnetic DC 6-1/4(4IF) 100m above top Shaffer ram BOP 11" 3M btm

CRETACEOUS IABE dump to pit if necessary .Fluid loss < 5 cc in the reservoir CASED HOLE LOG run after cementing job 6 x DC 6"1/2 (4IF) Turo reservoir. Hydrill annular bag type BOP Recommandation

At 900 m quite observation of mud losses w/ differential CCL/GR log down ram BOP. 3 x HWDP 4"1/2(4IF) 30% excess. RPM=40 to 50

sticking risk. PERFORATIONS Setting slips must be handled XO Wellhead secure Flowrate=1180-1360 l/min

Displace new KCL polymer mud at top turonian , keep at 1,03 sg Interval 1175-1202 m carefully Hydr. Jar 4-3/4'' ( 3-1/2IF) Top plug displace by for PERFORATING Anticipated pressure 1000 psi

accross turonian reservor, (12 shot/ft 4" gun w/TCP) XO 1,08 sg KCL Brine WR Tubing head 5 1/2 x 8 5/8 8rd ROP : 15-20 m/h

1017m Viscous mud sweeps with LCM if seepage losses occured 6 x HWDP 4"1/2 top connection

7 7/8"

Use of PacLV for fluid loss control More attention is XO 5 1/2" BTC Btm connection

Z5-1023 m HiVis (Xanthan+Polyplus ) sweeps required by site geogist 4'' DP (XT39) DF 7" 5M top x 8 5/8 8 RD Btm

TURONIAN

Z4-1028 m 50<FV<80-20<YP<25-12<YS<13 while in weak formation as dictated by hole condition possible DSA 7" 5M btm x 11" 3M top

Z3-1029 m NB :Spot pills each 300-400 m as top and under reservoir, change to conventional stabilized BHA+PDC Annular bag-type

Z2-1039 m dictate by hole condition, Follow up ROP/lag BOP 11" 3000 psi 3M btm

Z1-1042 m if gas income weighted mud up to 1,06-1,08 sg (Top ceno E) time,cutting removal 7 7/8"PDC bit xFloat subx Stab 7 5/8 x 1 DC 6 1/2"x Stab 7 9/16 x

Note : keep mud in pill tank at 1,08 sg 3DC 6 1/2 x4 HWDP 4 1/2"x Xo x jar 4 3/4 OD -Xo-

1052 m CaCO3 as plugging agent 2xHWDP 4 1/2 - Xo - DP 4" XT39

Cellulosic fiber for differential sticking prevention

Cretaceous IABE

1119 m

K

1132 m

J

1141 m

1161 m I Completion Brine Cased hole cenomanian 2 7/8" 6.5 lbs/ft J55 Kill string w/ Tubing 2 7/8 Annular bag-type

H 2 7/8" 1.10 sg PERFORATIONS EU 8EU

Rd8with

Rd BOP 11" 3000 psi 3M btm

1175 m

Keep pill brine 1,10 SG in Horizontal white tank E zones tubing shoe at +/- 15 m DSA 7" 5M btm x 11" 3M top

G

Clean up hole with tubing up top perfos DF 7" 5M top x 8 5/8 8 RD Btm

1131 m

1202

F string after perfos Frac job & Completion subject WR Tubing head 5 1/2 x 8 5/8 8rd

1219 m

E to well service (PU team) top connection

1225 m

D

1236 m

Rate hole at +/-1240 m 5 1/2" BTC Btm connection

C

TD:1240 m

Potential Hazards - Conduct pit/kick drills every tour until company representative's satisfaction.

NOTES / REMARKS - 7 7/8" PDC BIT must be run under optimum Hydraulic conditions. Drill with minimum

Location compaction around the cellar, must be assured. No fault is expected to be encountered in this well rheology and spot Hi-Vis pill at connections.

The 20" CP set at 13,25 m underground hammered Potential water influx expected 60-110 m and 220-260 m - Function and pressure test of the BOP equipments.

Avoid BOP's shaking during drilling.Start drilling with low parametres to avoid caving ( cellar blowout ) Lost circulation may be experienced around 100-240 m in the Malembo water table and turonian formation - Pressure test casing when bumping the plug (but don't over displace the slurry) and prior

Partial losses are expected in top hole section. Normal pressure regime is expected in the Turonian formation. to drill out the shoe: 1000 psi for the 8 5/8" and 2000 psi for 5 1/2" casing.

If total losses in 11" ( not expected), drill blind to TD with water and HiVis Shale swelling may be experienced around 100-170 m in Malembo formation. - Wiper trips to be done as indicated by hole conditions.

pills. Partial, use gel and LCM sweeps. Gas cup is expected to be encourented in the entrancy of CENOMANIAN K to H zone . - Circulation of HighVis pills as indicated by hole conditions (torque & drag) and prior trips.

The well is to be drilled as a deviated well. 4"/4,5'' liners in both pumps. Be carefully entering turonian /cenomanian,if drag and torque increase POOH,trim down BHA. - Losses will be treated with LCM pills, and cement plugs (1,50 sg) if necessary:

The objectives of the well is the siltstone formation of cenomanian If losses are observed in the cenomanian,POOH ,laydown some DC's.Continu drilling with LCM sweeps in 12 1/4" we will try to drill blind with clear water and pump high visc sweep every 10m.

Calcium carbonate and LCM materials, must be stored on location as contingency. turonian depleted ; do not leave the drill string stationary in front it.Keep slips in rotary while change - Short trip to 8 5/8" casing shoe before to run 5 1/2" casing.

connections.Special care in the entrancy of gas cup H zone, - Expected reservoir pressure = 1540 PSI at 1033 m ( EMG : 1,04 sg ) PREPARED BY: R.MBUMBA

CHECKED BY: H.CHEVRE

APPROVED BY: A.BROCHE

DATE:05/05/2017

Perenco Confidential 05/05/2017

05/05/2017 LW-781(Cg08) DRL pgm one page

Perenco Confidential 05/05/2017

You might also like

- New Uhf Rfid ReaderDocument2 pagesNew Uhf Rfid ReaderLaurence HasanNo ratings yet

- fs19 Dedicated Server InfoDocument10 pagesfs19 Dedicated Server InfostefaanNo ratings yet

- DATA COMMS AND NETWORKS Assignment 1Document23 pagesDATA COMMS AND NETWORKS Assignment 1farai nyakudangaNo ratings yet

- Kutum vs. Novuer CalculatorDocument20 pagesKutum vs. Novuer CalculatorAlyson Cua0% (1)

- Swissborg Cryptocurrencies Outlook 2018Document27 pagesSwissborg Cryptocurrencies Outlook 2018Rafael Tadeu TegaNo ratings yet

- Guide To Firewalls and Network Security: Chapter 5 SolutionsDocument3 pagesGuide To Firewalls and Network Security: Chapter 5 Solutionssignup001No ratings yet

- Black BookDocument21 pagesBlack Bookदेवेश सिंह राजपूतNo ratings yet

- Chapter - 1 General: Fig. 1.1 Industrial RobotDocument40 pagesChapter - 1 General: Fig. 1.1 Industrial RobotArunNo ratings yet

- BGSDocument328 pagesBGSDorin PaslaruNo ratings yet

- VendorNew3Document40 pagesVendorNew3anonymousaccoun9526No ratings yet

- US5320019 Hammer JammerDocument8 pagesUS5320019 Hammer JammerDuane BlakeNo ratings yet

- Gas Chromatograph Series 8900Document2 pagesGas Chromatograph Series 8900RobertNo ratings yet

- Seminar ReportDocument14 pagesSeminar ReportAlok ShubhamNo ratings yet

- Development of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional TechniquesDocument5 pagesDevelopment of Hybrid BT Cotton in China A Successful Integration of Transgenic Technology and Conventional Techniqueszhongshunmao1541No ratings yet

- Tech Tip: Si CarburettorDocument2 pagesTech Tip: Si CarburettorcesarecontoNo ratings yet

- The Book of Combat - A Complete Guide To BDO PVP MechanicsDocument84 pagesThe Book of Combat - A Complete Guide To BDO PVP MechanicsMichaelOrdoñaNo ratings yet

- Trade Oil Offer NEW OffferDocument7 pagesTrade Oil Offer NEW Offfererick tafurNo ratings yet

- Secure Data Exchange Via HSMDocument3 pagesSecure Data Exchange Via HSMLayer7TechNo ratings yet

- Bit TechnologyDocument1 pageBit TechnologyEkwoh Okwuchukwu ENo ratings yet

- Layer by Layer Troubleshooting With A Cisco RouterDocument5 pagesLayer by Layer Troubleshooting With A Cisco Routerpete555No ratings yet

- Keeping Up With: Financial Investigations Crypto AgeDocument19 pagesKeeping Up With: Financial Investigations Crypto AgeTocel PerezNo ratings yet

- Online Reservation System For RailwayDocument16 pagesOnline Reservation System For RailwaySubhash SagarNo ratings yet

- Paper Sabria TunisiaDocument12 pagesPaper Sabria TunisiaRani Juliarini RahayuNo ratings yet

- Save Computers From Hackers Save Computers From Hackers Attacks AttacksDocument18 pagesSave Computers From Hackers Save Computers From Hackers Attacks AttacksAsif ANo ratings yet

- Transaction Analysis On Ethereum Network Using Machine Learning A Proposed SystemDocument6 pagesTransaction Analysis On Ethereum Network Using Machine Learning A Proposed SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Paris-Turf HACK - MOD: Taispeántar An Nasc Íoslódála Thíos Dara!Document3 pagesParis-Turf HACK - MOD: Taispeántar An Nasc Íoslódála Thíos Dara!Aigle NoirNo ratings yet

- Industry Decanter Centrifuge: Hebei GN Solids Control Co.,LtdDocument16 pagesIndustry Decanter Centrifuge: Hebei GN Solids Control Co.,LtdlauNo ratings yet

- Unit 1Document44 pagesUnit 1Gaurav AgrawalNo ratings yet

- PVP Form 1-Application FormDocument7 pagesPVP Form 1-Application FormJoeluntalanNo ratings yet

- HistoryDocument20 pagesHistoryAlexandru RomînuNo ratings yet

- WhatsApp Security WhitepaperDocument9 pagesWhatsApp Security WhitepaperRon G'sNo ratings yet

- Methods of Determining Initial Fluid Contacts-Abbas Radhi-2022Document12 pagesMethods of Determining Initial Fluid Contacts-Abbas Radhi-2022M MohammedNo ratings yet

- Promax SoftwareDocument2 pagesPromax SoftwareSanthosh Kumar PeapalyNo ratings yet

- Carding: A Fi RST GlanceDocument6 pagesCarding: A Fi RST GlanceMohamed NaeimNo ratings yet

- Elastec TDS-118 Skimmer BrochureDocument2 pagesElastec TDS-118 Skimmer BrochureGiorgiana Rosu100% (1)

- Seminar On 3g Vs WifiDocument36 pagesSeminar On 3g Vs Wifisahil_sharma437100% (6)

- Spining Card Clothing Broucher TCC Spin GBDocument36 pagesSpining Card Clothing Broucher TCC Spin GBMuhammad Farooq KokabNo ratings yet

- Christmas Tree: The Conductor CasingDocument5 pagesChristmas Tree: The Conductor CasingBakhtyar AhmedNo ratings yet

- Core OperationsDocument10 pagesCore Operationsdeyaa SadoonNo ratings yet

- LINERDPDocument1 pageLINERDPscrbdgharaviNo ratings yet

- 192.168.100.1 RgCmConfigurationDocument10 pages192.168.100.1 RgCmConfigurationTravis MosleyNo ratings yet

- Germansportguns Gsg5Document34 pagesGermansportguns Gsg5Justin100% (1)

- DTC550 Service Manual Rev. 2.8Document614 pagesDTC550 Service Manual Rev. 2.8kuvalda2000No ratings yet

- Theory Slides 1Document82 pagesTheory Slides 1AboZaidNo ratings yet

- Beware 23122019-1enDocument3 pagesBeware 23122019-1enmarcell ribeiroNo ratings yet

- Brass Shear Screws Data PDFDocument2 pagesBrass Shear Screws Data PDFBella cedricNo ratings yet

- Oil Tender Part 3Document40 pagesOil Tender Part 3Dhrubajyoti SonowalNo ratings yet

- PCS7 V7 Compatibility List DDocument8 pagesPCS7 V7 Compatibility List DAlexReynagNo ratings yet

- MySep Software Brochure PDFDocument7 pagesMySep Software Brochure PDFoverlord5555No ratings yet

- DDR 27-10Document1 pageDDR 27-10GPCNo ratings yet

- Salamat-1 Mud Report 54-28092012Document4 pagesSalamat-1 Mud Report 54-28092012mega87_2000No ratings yet

- FreetDocument32 pagesFreetHamed GeramiNo ratings yet

- Shaped Charges UCRL JC 135302Document10 pagesShaped Charges UCRL JC 135302warrior_2008No ratings yet

- 常见石油英文缩写对照表 Abbreviations Petroleum OperationDocument31 pages常见石油英文缩写对照表 Abbreviations Petroleum OperationEvence ChenNo ratings yet

- Biometrics in Secure E-TransactionDocument4 pagesBiometrics in Secure E-TransactionREx Ethics100% (1)

- Literature Review On Design & Fabrication of Oil Measuring & Despensing MachineDocument2 pagesLiterature Review On Design & Fabrication of Oil Measuring & Despensing MachineIJIRSTNo ratings yet

- Properties of Reservoir Fluids PDFDocument30 pagesProperties of Reservoir Fluids PDFLawNo ratings yet

- BRINE-PAC 3N1 - ProductBulletinDocument1 pageBRINE-PAC 3N1 - ProductBulletinhungcandinh100% (1)

- Kahraman C-181 (ST-1)Document3 pagesKahraman C-181 (ST-1)Islam AtifNo ratings yet

- Herunefer W 13Document3 pagesHerunefer W 13Islam AtifNo ratings yet

- Chapter 1Document173 pagesChapter 1mohamed elshemyNo ratings yet

- ENI - Completion Design ManualDocument295 pagesENI - Completion Design ManualKingsley Okenyi100% (1)

- Petroleum SystemsDocument20 pagesPetroleum Systemsmohamed elshemyNo ratings yet

- Mitchell-Advanced Oil Well Drilling EngineeringDocument626 pagesMitchell-Advanced Oil Well Drilling EngineeringYASSER_MANo ratings yet

- Drilling Rig Operations & A To Z Rotary Drilling Rig ComponentsDocument130 pagesDrilling Rig Operations & A To Z Rotary Drilling Rig ComponentsOmar Santamaría Castillo100% (1)

- Surface Mining MethodsDocument15 pagesSurface Mining MethodsMatthew Butler50% (2)

- Chapter 6Document175 pagesChapter 6mohamed elshemyNo ratings yet

- Eni Drilling Design ManualDocument230 pagesEni Drilling Design Manualbweimar2100% (1)

- Determination of Flow Units Carbonate ReservoirsDocument165 pagesDetermination of Flow Units Carbonate ReservoirsRonald ChevalierNo ratings yet

- 13 Volume Calculations For Primary Cementing - QuartzDocument4 pages13 Volume Calculations For Primary Cementing - QuartzRebarNo ratings yet

- Reserve Estimation Methods 02 VolumetricDocument8 pagesReserve Estimation Methods 02 VolumetricsiriuslotNo ratings yet

- Geolog BrochureDocument63 pagesGeolog Brochuremohamed elshemyNo ratings yet

- B - Fluids and Fluid Types 1-6-04Document20 pagesB - Fluids and Fluid Types 1-6-04Bladimir Soliz PardoNo ratings yet

- 4 Silica Sand PDFDocument1 page4 Silica Sand PDFmohamed elshemyNo ratings yet

- Acoustic Waves and Tools: Baker Atlas Montrose Training CentreDocument34 pagesAcoustic Waves and Tools: Baker Atlas Montrose Training Centremohamed elshemyNo ratings yet

- Geolog BrochureDocument63 pagesGeolog Brochuremohamed elshemyNo ratings yet

- Silica Sand Manufacturers in RajasthanDocument1 pageSilica Sand Manufacturers in Rajasthanmohamed elshemyNo ratings yet

- Pnacs707 2Document173 pagesPnacs707 2mohamed elshemyNo ratings yet

- Pnacs707 2Document173 pagesPnacs707 2mohamed elshemyNo ratings yet

- 2111 PDFDocument222 pages2111 PDFmohamed elshemyNo ratings yet

- Geophysical Methods & ApplicationsDocument10 pagesGeophysical Methods & ApplicationsmlakkissNo ratings yet

- 2013-01-01-R-543 (NP - GE31) - Rumaila DORDocument2 pages2013-01-01-R-543 (NP - GE31) - Rumaila DORmohamed elshemyNo ratings yet

- Pnacs707 2Document173 pagesPnacs707 2mohamed elshemyNo ratings yet

- Module I PDFDocument43 pagesModule I PDFkishorNo ratings yet

- Mechatronics 2Document41 pagesMechatronics 2Shruthi SuryanarayanNo ratings yet

- Mechatronics 2Document41 pagesMechatronics 2Shruthi SuryanarayanNo ratings yet

- Gemston Es: in EgyptDocument1 pageGemston Es: in Egyptmohamed elshemyNo ratings yet

- Pnacs707 2Document173 pagesPnacs707 2mohamed elshemyNo ratings yet

- Intro To MechatronicsDocument33 pagesIntro To MechatronicscorozcogarciaNo ratings yet

- E-LIBRARY RULES - Home-BasedDocument5 pagesE-LIBRARY RULES - Home-BasedBeverly Ann GonzalesNo ratings yet

- LHD Isuzu MU-X 2017+ - Anti-Lock BrakeDocument1 pageLHD Isuzu MU-X 2017+ - Anti-Lock BrakeMuhammed DoumaNo ratings yet

- Select and Answer 10 Problems Correctly To Obtain Perfect Score (10 Points Per Problem) - You May Answer More Than 10 Problems. However, Maximum Score Is Limited To 100 PointsDocument9 pagesSelect and Answer 10 Problems Correctly To Obtain Perfect Score (10 Points Per Problem) - You May Answer More Than 10 Problems. However, Maximum Score Is Limited To 100 PointsKRISTINE MIRANDANo ratings yet

- Shakira Waka Waka (Blu Ray From Africa) 1080P x264 2010 CeasPDocument1 pageShakira Waka Waka (Blu Ray From Africa) 1080P x264 2010 CeasPceaspNo ratings yet

- Data Warehousing ComponentsDocument5 pagesData Warehousing ComponentsVaishu SriniNo ratings yet

- Astm A928Document6 pagesAstm A928maniyarasan100% (1)

- Sany Part ManualDocument467 pagesSany Part ManualKumlachew Ali86% (7)

- Hibridni Oblak Una - Modul 4Document35 pagesHibridni Oblak Una - Modul 4Una DrakulićNo ratings yet

- Poisoning The WellDocument20 pagesPoisoning The WellJoshua HockadayNo ratings yet

- Comparative Study of Cloud Services Offered by Amazon, Microsoft and GoogleDocument5 pagesComparative Study of Cloud Services Offered by Amazon, Microsoft and GoogleEditor IJTSRDNo ratings yet

- IT AssignmentDocument3 pagesIT AssignmentKanthi Rekha VardhiNo ratings yet

- Manual Kyocera FS 1016MFPDocument92 pagesManual Kyocera FS 1016MFPToño Carbajal RiosNo ratings yet

- 17.02.SI.0009. Princess Etab Ben Jalawi A'al Saud Villa 1Document2 pages17.02.SI.0009. Princess Etab Ben Jalawi A'al Saud Villa 1Arafat BauntoNo ratings yet

- Scaffolding CatalogDocument32 pagesScaffolding CatalogNurmiswari Abdullah SarongNo ratings yet

- Assignment No.1 Title-Case Study Based Assignment On Method StudyDocument4 pagesAssignment No.1 Title-Case Study Based Assignment On Method Studyshreyas mithariNo ratings yet

- Actuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualDocument160 pagesActuator Controls Ac 01.2/acexc 01.2: Operation and Setting ManualJorge Antonio Lovera CastroNo ratings yet

- Traffic Mechanical Supervisor NotificationsDocument4 pagesTraffic Mechanical Supervisor NotificationsPrasad KvNo ratings yet

- 1.service Management WorkshopDocument34 pages1.service Management WorkshopWill RedNo ratings yet

- Lecture 0 Rule and SylabusDocument13 pagesLecture 0 Rule and SylabusStyNo ratings yet

- GPON - Fundamentals: Technical Team From FTTHDocument56 pagesGPON - Fundamentals: Technical Team From FTTHDaniel VieceliNo ratings yet

- Xspider ManualDocument236 pagesXspider Manualady_marinescuNo ratings yet

- Ams Iii GDocument4 pagesAms Iii Ghemang_nsNo ratings yet

- VP Marketing Product Development in NYC Resume Sherri SwihartDocument2 pagesVP Marketing Product Development in NYC Resume Sherri SwihartSherriSwihartNo ratings yet

- 020 UsDocument16 pages020 UsanthonypardoNo ratings yet

- ComponentsDocument28 pagesComponentsGyan Swaroop TripathiNo ratings yet

- BS-976 1Document14 pagesBS-976 1ExtracoNo ratings yet

- SDK-Python Interface ENG V1.0Document32 pagesSDK-Python Interface ENG V1.0Chandru ChristurajNo ratings yet

- JText FieldDocument45 pagesJText FielddrsolicNo ratings yet

- Submersible Sewage Ejector Pump: Pump Installation and Service ManualDocument8 pagesSubmersible Sewage Ejector Pump: Pump Installation and Service Manualallen_worstNo ratings yet

- Certificate in IT Syllabus: Software Development RationaleDocument4 pagesCertificate in IT Syllabus: Software Development RationaleNaziya BocusNo ratings yet