Professional Documents

Culture Documents

Hydrodemethlyation of Toluene

Uploaded by

AidonCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrodemethlyation of Toluene

Uploaded by

AidonCopyright:

Available Formats

ACA0809

Hydrodemethlyation of Toluene

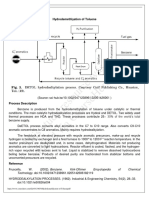

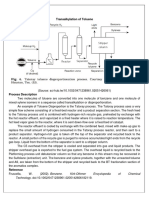

H2 Purification

Benzene Fractionator

Stabilizer

Reactor Flash Drum

(Source: sci-hub.tw/10.1002/0471238961.02051426061 )

Process Description

Benzene is produced from the hydrodemethylation of toluene under catalytic or thermal

conditions. The main catalytic hydrodealkylation processes are Hydeal and DETOL. Two widely used

thermal processes are HDA and THD. These processes contribute 25– 30% of the world’s total

benzene supply.

DeETOL process converts alkyl aromatics in the C7 to C10 range. Also converts C9-C10

aromatic concentrates to C8 aromatics. Mainly requires hydrodealkylation.

The feedstock at elevated pressure with recycle aromatic precursors, make-up and recycle

hydrogen is heated by exchanger and a fired furnace to 1000° to 1200 F° reaction temperature. In the

reactor precursors are dealkylated and, in some cases, dehydrogenated. Materials not producing

aromatics are converted to light hydrocarbons. Reactor effluent is cooled, flashed, and the hydrogen-

rich vapor recycled with excess sent to fuel. Liquid is stabilized to remove dissolved hydrocarbons

boiling below benzene. Products of desired purity are fractionated from stabilizer bottoms and

unconverted precursors are recycled.

Reference

Fruscella, W. (2002). Benzene. Kirk-Othmer Encyclopedia of Chemical

Technology. doi:10.1002/0471238961.0205142606182119

HYDRODEALKYLATION PROCESSES. (1962). Industrial & Engineering Chemistry, 54(2), 28–33.

doi:10.1021/ie50626a004

You might also like

- This Study Resource Was: Hydrodemethlyation of TolueneDocument1 pageThis Study Resource Was: Hydrodemethlyation of TolueneAA0809No ratings yet

- Hydrodemethlyation of Toluene PDFDocument1 pageHydrodemethlyation of Toluene PDFAA0809No ratings yet

- CHE 304 Optional Homework Due Toluene HyDocument9 pagesCHE 304 Optional Homework Due Toluene Hyqurat ul ainNo ratings yet

- Separations Are Ubiquitous in Chemical Industry: Raw MaterialDocument5 pagesSeparations Are Ubiquitous in Chemical Industry: Raw MaterialbcghgfckhNo ratings yet

- Condensation and AdditionDocument4 pagesCondensation and Additionapi-3774614No ratings yet

- 66 Ess16108Document9 pages66 Ess16108Jallu Pratama100% (1)

- Vinyl Chloride Monomer (VCM) Production ProcessDocument11 pagesVinyl Chloride Monomer (VCM) Production ProcessKubra ĖdrisNo ratings yet

- Ethylene Production by Naphtha Cracking TechnologyDocument6 pagesEthylene Production by Naphtha Cracking TechnologyHina IbrahimNo ratings yet

- Super Final PD PapersDocument96 pagesSuper Final PD PapersHarjan Philipp C. GopaldasNo ratings yet

- Production of AcetaldehydeDocument24 pagesProduction of AcetaldehydeAhmed Hassan RashedNo ratings yet

- HPL Summer Training ReportDocument13 pagesHPL Summer Training ReportAmit GangulyNo ratings yet

- Mini Project StyereneDocument25 pagesMini Project StyereneMard Apik100% (1)

- BTX AromaticsDocument6 pagesBTX AromaticsEzekielNo ratings yet

- 2017CHE008 DetailedProcessDescription1Document17 pages2017CHE008 DetailedProcessDescription1Xi Liinett AqkoNo ratings yet

- Church 1951Document8 pagesChurch 1951Evan DulayNo ratings yet

- TOURTON-páginas-37-124-73-88 PDFDocument16 pagesTOURTON-páginas-37-124-73-88 PDFJesús David González CañasNo ratings yet

- Methanol Project PDFDocument50 pagesMethanol Project PDFPaola Nair M ChNo ratings yet

- Hydrodealkylation 12Document2 pagesHydrodealkylation 12khanh11h100% (1)

- A New Method of Low-Temperature Methanol SynthesisDocument4 pagesA New Method of Low-Temperature Methanol SynthesisCarlos Alfonzo Calderón RiveroNo ratings yet

- Arrieta Ethylene GlycolDocument8 pagesArrieta Ethylene GlycolNguyen VietNo ratings yet

- Hda Process Flow Diagram PDFDocument2 pagesHda Process Flow Diagram PDFadnan mukhtar50% (2)

- Act 6 Benzene PDFDocument5 pagesAct 6 Benzene PDFDulce Wendolyn BollásNo ratings yet

- 2-Eha PRCS1Document45 pages2-Eha PRCS1MARISSE LYN DORADONo ratings yet

- Butyraldehyde Production DesignDocument18 pagesButyraldehyde Production DesignLuisMPortillaBenavidesNo ratings yet

- Hoja Tecnica Monoxido de CarbonoDocument6 pagesHoja Tecnica Monoxido de CarbonoLuna ArboledaNo ratings yet

- Butynediol: Bis (Magnesium Bromide) With ParaformaldehydeDocument4 pagesButynediol: Bis (Magnesium Bromide) With ParaformaldehydeMirna SantiaNo ratings yet

- HPCL IT DHDS Block OverviewDocument37 pagesHPCL IT DHDS Block OverviewSrija Mummidi100% (1)

- Hydrodeoxygenation of Pyrolysis OilDocument15 pagesHydrodeoxygenation of Pyrolysis OilThuan HuynhNo ratings yet

- Mthanol ProductionDocument61 pagesMthanol Productionvv vvNo ratings yet

- 2 Ethyl 2520hexanol Methods 2520of 2520 ProductionDocument10 pages2 Ethyl 2520hexanol Methods 2520of 2520 Productionapi-3714811No ratings yet

- Production of Pure Hydrogen by Ethanol DehydrogenationDocument9 pagesProduction of Pure Hydrogen by Ethanol DehydrogenationAbdulwahid SultanNo ratings yet

- MNIT Hydro De-Alkylation: Toluene to BenzeneDocument15 pagesMNIT Hydro De-Alkylation: Toluene to Benzeneanon_429955241No ratings yet

- H2 ProductionDocument25 pagesH2 ProductionMohini SharmaNo ratings yet

- Boosting Energy Efficiency in Aromatics ProcessingDocument4 pagesBoosting Energy Efficiency in Aromatics Processing김태현No ratings yet

- Acetaldehyde Methods 2520of 2520 ProductionDocument6 pagesAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- SKKC4723 Refinery and Petrochemical Technology 2018/2019-SEM 1Document10 pagesSKKC4723 Refinery and Petrochemical Technology 2018/2019-SEM 1Dinesh RajuNo ratings yet

- Manufacture of Styrene PDFDocument3 pagesManufacture of Styrene PDFmohit kumarNo ratings yet

- MANUFACTURING TOLUENE PROCESSESDocument4 pagesMANUFACTURING TOLUENE PROCESSESMiko Yee Teng100% (1)

- PARTE2GasProcessHandbook - 2006 (PDF - Io)Document40 pagesPARTE2GasProcessHandbook - 2006 (PDF - Io)ganimedes100% (1)

- Production Of Methanol From Natural GasDocument219 pagesProduction Of Methanol From Natural GasMary Grace VelitarioNo ratings yet

- Production of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationDocument14 pagesProduction of Vinyl Chloride From Ethylene Dichloride by Pyrolysis Aspen Model DocumentationParaiba da Paraiba100% (2)

- EthyleneDocument4 pagesEthyleneashutosh kumarNo ratings yet

- Technoeconomic Assessment of Ethanol ProductionDocument12 pagesTechnoeconomic Assessment of Ethanol ProductionsumitrochakrabortiNo ratings yet

- Water-Gas Shift Reaction Catalysts and ApplicationsDocument68 pagesWater-Gas Shift Reaction Catalysts and Applicationsdejla670% (1)

- Petrochem 10 - SEM 1 12-13Document40 pagesPetrochem 10 - SEM 1 12-13Saifuddin AzizNo ratings yet

- CATALYSTSDocument21 pagesCATALYSTSJhon Jairo Rico CerqueraNo ratings yet

- Dehydrogenation Process Description المشروعDocument5 pagesDehydrogenation Process Description المشروعsaeed909909No ratings yet

- CPT PresentationDocument15 pagesCPT PresentationNavket JhaNo ratings yet

- Separation ChainDocument2 pagesSeparation ChainKaleem UllahNo ratings yet

- Ethylene UnitsDocument20 pagesEthylene UnitsLindah Turson100% (3)

- Iffco: Indian Faremrs Fertiliser Cooperative LimitedDocument26 pagesIffco: Indian Faremrs Fertiliser Cooperative LimitedArslanQureshi100% (1)

- Syrene Production by Dow Process RTDocument22 pagesSyrene Production by Dow Process RTAnonymous Ksq1dyPRhNo ratings yet

- Toluenediamine PDFDocument15 pagesToluenediamine PDFAmalia RizkaNo ratings yet

- 3Document11 pages3deboNo ratings yet

- Thermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerFrom EverandThermochemical Processing of Biomass: Conversion into Fuels, Chemicals and PowerNo ratings yet

- Advanced Pharmaceutical analysisFrom EverandAdvanced Pharmaceutical analysisRating: 4.5 out of 5 stars4.5/5 (2)

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Gas Hydrates 1: Fundamentals, Characterization and ModelingFrom EverandGas Hydrates 1: Fundamentals, Characterization and ModelingDaniel BrosetaNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Cash Card Updating Form Legal Fillable 5 PagesDocument5 pagesCash Card Updating Form Legal Fillable 5 PagesAidonNo ratings yet

- Craft Beer ProductionDocument567 pagesCraft Beer ProductionmcantaruttiNo ratings yet

- Material Safety Data SheetDocument6 pagesMaterial Safety Data SheetAidonNo ratings yet

- Paints Pigment Handout Class PDFDocument16 pagesPaints Pigment Handout Class PDFAidonNo ratings yet

- Energies 12 02337Document22 pagesEnergies 12 02337Fitriatul UntsiNo ratings yet

- MSDS PhenolphthaleinDocument6 pagesMSDS PhenolphthaleinAstri Aisyah RahmiNo ratings yet

- Visions:: Department of EducationDocument2 pagesVisions:: Department of EducationAidon100% (4)

- ASTM C59-C59M - 00 (Reapproved 2011)Document2 pagesASTM C59-C59M - 00 (Reapproved 2011)Black GokuNo ratings yet

- Msds Natrium HidroksidaDocument6 pagesMsds Natrium HidroksidaTrisno AfandiNo ratings yet

- HM0 0Document7 pagesHM0 0Diego Vargas DNo ratings yet

- Gypsum Plasters: Standard Specification ForDocument4 pagesGypsum Plasters: Standard Specification ForGrato Jr SingcoNo ratings yet

- Bolt Anchorage With Gypsum-Plaster Water Capsule CartridgesDocument28 pagesBolt Anchorage With Gypsum-Plaster Water Capsule CartridgesAidonNo ratings yet

- Palsson K. - Plant Products Used As Mosquito Repellents in Guinea Bissau West Africa - 1999Document15 pagesPalsson K. - Plant Products Used As Mosquito Repellents in Guinea Bissau West Africa - 1999AidonNo ratings yet

- Standard Test Methods For Physical TestiDocument8 pagesStandard Test Methods For Physical TestiAidonNo ratings yet

- Thermal Radiation Heat TransferDocument372 pagesThermal Radiation Heat Transferdarkknight77100% (1)

- Msds PDFDocument6 pagesMsds PDFAidonNo ratings yet

- Writing A PaDocument2 pagesWriting A PaSalim AngoNo ratings yet

- 219 - EWG - APEC Energy Demand and Supply Outlook 7th Edition - Vol I PDFDocument208 pages219 - EWG - APEC Energy Demand and Supply Outlook 7th Edition - Vol I PDFAlvin SyukroNo ratings yet

- GooglepreviewDocument33 pagesGooglepreviewAidonNo ratings yet

- Standard Methods For Testing Mosquito Repellents: January 2007Document9 pagesStandard Methods For Testing Mosquito Repellents: January 2007Pemdansert Subdit Pembakuan dan SertifikasiNo ratings yet

- HydrolysisH PDFDocument12 pagesHydrolysisH PDFEuwan Tyrone PriasNo ratings yet

- Floralwhite Blue Jasmin Flower Vow Renewal Invitation PDFDocument1 pageFloralwhite Blue Jasmin Flower Vow Renewal Invitation PDFAidonNo ratings yet

- Energies 12 02337Document22 pagesEnergies 12 02337Fitriatul UntsiNo ratings yet

- C5 Hydrocarbon: Isoprene 1. HistoryDocument11 pagesC5 Hydrocarbon: Isoprene 1. HistoryAidonNo ratings yet

- Metro Clark Waste Management Landfill GuideDocument21 pagesMetro Clark Waste Management Landfill GuideAidonNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Catalytic Reforming: Debutanizer Reactor Regeneration TowerDocument2 pagesCatalytic Reforming: Debutanizer Reactor Regeneration TowerAidonNo ratings yet

- Transalkylation of Toluene PDFDocument2 pagesTransalkylation of Toluene PDFAidonNo ratings yet

- Transalkylation of TolueneDocument2 pagesTransalkylation of TolueneAidonNo ratings yet