Professional Documents

Culture Documents

2.02.00 - CG - Prod and Gen - Manufacturing Development Specialist PDF

Uploaded by

BRUCEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.02.00 - CG - Prod and Gen - Manufacturing Development Specialist PDF

Uploaded by

BRUCECopyright:

Available Formats

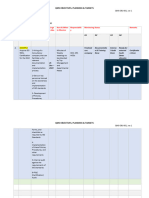

DOCUMENT NO: 2.02.

00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

LEARNER: MANAGER: DATE:

PURPOSE STATEMENT: To identify, co-ordinate and actively participate in strategic and systemic level SIGNED SIGNED

C NYC

departmental improvement initiatives to achieve the Business Strategy LEARNER MANAGER

UNIT 1: FACILITATE DEPARTMENTAL ACHIEVEMENT OF THE MANUFACTURING STRATEGY

1.1 IMPLEMENT DEPARTMENTAL PLANS TO SUPPORT THE MANUFACTURING WAY

1.2 IMPLEMENT MANUFACTURING WORK PRACTICES/PRINCIPLES

1.3 PROVIDE LEADERSHIP FOR ONGOING MANUFACTURING DEVELOPMENT STRATEGIES

1.4 PROMOTE KNOWLEDGE MANAGEMENT PROCESSES

UNIT 2 : FACILITATE THE IDENTIFICATION AND IMPLEMENTATION OF DEPARTMENTS IMPROVEMENT PROJECTS

2.1 VALUE CHAIN AND IMPROVEMENT TOOLS APPLIED

2.2 EVALUATE APPLICABLE CRITICAL TO CUSTOMER REUIREMENTS

2.3 CONDUCT APPROPRIATE BENCHMARKING

2.4 FACILITATE & CO-ORDINATE THE DEPARTMENTAL PROJECT SELECTION PROCESS

UNIT 3 : FACILITATE, CO-ORDINATE AND/OR LEAD DEPARTMENTAL IMPROVEMENT PROJECTS

3.1 ENSURE INTEGRITY OF THE DMAIC PROBLEM SOLVING PROCESS

3.2 LEAD PROJECTS

3.3 FACILITATE THE SOP LEARNING PROCESS

3.4 PROVIDE INDUSTRIAL ENGINEERING SUPPORT

3.5 CONDUCT ADMINISTRATION

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 1 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

UNIT 1: FACILITATE DEPARTMENTAL ACHIEVEMENT OF THE MANUFACTURING STRATEGY

OUTCOME 1.1: IMPLEMENT DEPARTMENTAL PLANS / STRATEGIES TO SUPPORT THE MANUFACTURING WAY

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

1.1.1 Departmental strategies are implemented and

their progress monitored to track progress

1.1.2 Departmental goals are developed in line with • The Manufacturing 1. Explain how departmental plans are monitored

the strategy and reviewed regularly to ensure Way 2. Describe the process used to develop

ongoing alignment • Performance departmental goals

1.1.3 Accountability for the successful implementation Management

of the plan is documented and agreed to by all

team members

OUTCOME 1.2 : IMPLEMENT MANUFACTURING WORK PRACTICES / PRINCIPLES

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

1.2.1 Team leaders and team members are coached

on WCM principles and work practices to • CCI 1. Explain how work practices are communicated

ensure effective application thereof • TRACC 2. Demonstrate how you would coach a team

1.2.2 Development of appropriate work practices, member

roles and responsibilities relating to 3. Discuss how you would facilitate manufacturing

manufacturing change initiatives are change initiatives

implemented and tracked for successful 4. Provide evidence of an audit

application 5. Explain how you would ensure that work

1.2.3 Application of WCM principles and work instructions are valid

practices are audited to identify compliance and

improvement opportunities

1.2.4 Work Instructions and SOP’s are regularly

reviewed to ensure relevance, accuracy and

compliance

1.2.5 New staff are inducted on the manufacturing

strategy to ensure alignment

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 2 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

OUTCOME 1.3 : PROVIDE LEADERSHIP FOR ONGOING MANUFACTURING DEVELOPMENT STRATEGIES

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

1.3.1 Conceptual frameworks are integrated and 1. Provide evidence of how communication of

communicated to all levels to ensure common • Communication conceptual frameworks are undertaken

understanding and acceptance principles 2. Discuss how you ensure that the Manufacturing

1.3.2 WCM and related philosophies are promoted • Decision making Way philosophy is promoted

through structured meetings and decision

making processes with the departmental team

OUTCOME 1.4: PROMOTE KNOWLEDGE MANAGEMENT PROCESSES

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

1.4.1 Manufacturing development initiatives are 1. Demonstrate how information is disseminated

shared using appropriate channels 2. Discuss how shared learnings are implemented

1.4.2 Shared learning processes are promoted and

driven in the region

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 3 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

UNIT 2: IDENTIFY DEPARTMENTS IMPROVEMENT PROJECTS

OUTCOME 2.1: VALUE CHAIN AND IMPROVEMENT TOOLS APPLIED

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

2.1.1 Department understanding of the value chain is 1. Demonstrate how you would facilitate an

facilitated by using tools such as Value Stream understanding of the value chain

Mapping (VSM) 2. Provide examples of where you have used the

2.1.2 Theory of Constraints as it relates to the value Theory of Constraints to improve process/s in the

chain are identified and initiatives to value chain

reduce/remove them are implemented and 3. Explain how you would use ‘Lean Manufacturing’

monitored philosophies and principles to improve process

2.1.3 Lean Manufacturing’ philosophies and principles

are appropriately applied to ensure ongoing

improvement in operating efficiencies

2.1.4 Six sigma principles are applied to improve

process constraints

OUTCOME 2.2: CUSTOMER REQUIREMENTS EVALUATED

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

2.2.1 Factors that are critical to quality, delivery and 1. Provide examples of where solutions to customer

cost are evaluated for improvement and requirements have been formulated

solutions formulated 2. Demonstrate how critical to customer parameters

2.2.2 Critical to customer parameters are monitored are determined and monitored

to ensure improved and sustained capability

OUTCOME 2.3: CONDUCT APPROPRIATE BENCHMARKING

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

2.3.1 Benchmarking against ‘best in class’ is 1. Conduct a benchmarking exercise and make

conducted for a value stream or process to recommendations for gap closure

identify improvement opportunities

2.3.2 Benchmarking against other industries is

conducted to ensure ongoing alignment of the

business strategy

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 4 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

OUTCOME 2.4: FACILITATE AND CO-ORDINATE THE DEPARTMENTAL PROJECT SELECTION PROCESS

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

2.4.1 Identification of potential projects is facilitated 1. Demonstrate how you would facilitate the

through the application of Value stream identification of potential projects

mapping, brain storming and other appropriate 2. Provide evidence of where risk assessment has

methods to ensure comprehensive analysis been done for each potential project in the

2.4.2 Impact on organisational goals and financial following areas:

issues based on NPV/EVA calculations are - Strategic: Impact on organisational goals

determined and analysed for the purpose of - Customer focussed: Impact on ‘critical to’ factor

assessing risk. - Value: Financial impact based on NPV/EVA

2.4.3 Short-listed projects are managed and calculations

motivated for input into the regional project 3. Explain how you would motivate a particular project

hopper process through a formal process

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 5 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

UNIT 3: FACILITATE, CO-ORDINATE AND/OR LEAD DEPARTMENTAL IMPROVEMENT PROJECTS

OUTCOMES 3.1: ENSURE INTEGRITY OF THE DMAIC PROBLEM SOLVING PROCESS

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

3.1.1 Project milestones are monitored to ensure

adherence to the DMAIC approach

3.1.2 Project tools, templates etc are applied

consistently to ensure a successful outcome

3.1.3 DMAIC methodology is consistently applied to

lead projects

OUTCOME 3.2: LEAD PROJECTS

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

3.2.1 SOP project portal protocols are adhered to by Demonstrate knowledge of

formal project teams

3.2.2 Sub-activities of the projects are co-ordinated and

corrective action taken to address any deviations

3.2.3 Appropriate change management processes are

applied to ensure

3.2.4 Team and team dynamics are managed to ensure

project success

3.2.5 Appropriate statistical techniques are consistently

applied to the DMAIC process

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 6 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

OUTCOME 3.3: FACILITATE THE SOP LEARNING PROCESS

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

3.3.1 Appropriate training methodologies are applied to Provide department specific examples or

ensure successful application of the SOP learning input with respect to Six Sigma, Lean, TOC

3.3.2 Coaching of team members occurs to facilitate the and other relevant methodologies for

transfer of learning training and/or coaching purposes

3.3.3 Evaluation (stage 5/6) of the training is done for all Coach and facilitate training projects (e.g.

team members, and any shortfalls addressed Green Belt Projects)

Assess effective application of the training

(e.g. Project delivery, ROI) – monitor

departmental outputs related to training,

coaching or project objectives

OUTCOME 3.4: PROVIDE INDUSTRIAL ENGINEERING SUPPORT

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

3.4.1 Production planning and scheduling systems are Department specific production planning and

evaluated for effectiveness and recommendations scheduling systems or logistics subsystems are

for improvement provided evaluated and/or implemented

3.4.2 Industrial Engineering support is given through the Provide general IE support. RofV scheduling and

application of a variety of techniques such as materials/inventory management philosophies and

scheduling, materials inventory, work and time processes, work and time studies, simulation,

studies, simulation and operations research to operations research.

assist in process improvements Support is provided to evaluating, specifying and/or

3.4.3 Support is provided in evaluating, specifying implementing Manufacturing Information Systems

and/or implementing Manufacturing Information Support is provided to introducing Advanced

Systems Manufacturing technologies as appropriate. RofV

3.4.4 Advice and recommendations are provided to artificial intelligence etc

assist with the introducing of advanced Departmental capacity constraints are evaluated

manufacturing technologies, artificial intelligence with respect to Regional Capacity Plans and provide

etc input into the Regional Capacity Planning process.

3.4.5 Departmental capacity constraints are evaluated

with respect to Regional Capacity Plans and

provide input into the Regional Capacity Planning

process.

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 7 of 8

DOCUMENT NO: 2.02.00

COMPETENCE GUIDE:

REVISION NO: 0

MANUFACTURING DEVELOPMENT

SPECIALIST DATE ISSUED: FEBRUARY 2009

OUTCOME 3.5: CONDUCT ADMINISTRATION

ASSESSMENT CRITERIA LEARNER GUIDE LEARNING OBJECTIVES C NYC

3.5.1 Relevant regional and divisional audits are

conducted and communicated

3.5.2 Relevant reports and scoreboards are maintained

and communicated to ensure progress, monitoring

and for future learning

3.5.3 Network capabilities both internally and externally

are developed. RofV consultant, universities and

other professional bodies.

Date of Issue: February 2009 2009 SABMiller Africa & Asia

Page 8 of 8

You might also like

- Evaluation in Agricultural Extension PDFDocument118 pagesEvaluation in Agricultural Extension PDFDhea Erika Dyah PutriNo ratings yet

- Project Management Fundamentals: Key Concepts and MethodologyFrom EverandProject Management Fundamentals: Key Concepts and MethodologyRating: 5 out of 5 stars5/5 (5)

- 3 - Pillar Two-20170102Document26 pages3 - Pillar Two-20170102AhmadNo ratings yet

- Establishing A CGMP Laboratory Audit System: A Practical GuideFrom EverandEstablishing A CGMP Laboratory Audit System: A Practical GuideNo ratings yet

- UNIDO GuidelinesDocument146 pagesUNIDO Guidelineszimitaw yibekalNo ratings yet

- Tailoring Projects 2022 - GROUP 8Document35 pagesTailoring Projects 2022 - GROUP 8aihalNo ratings yet

- CMMI V2 0 Quick Reference GuideDocument15 pagesCMMI V2 0 Quick Reference Guidemaria clara lopezNo ratings yet

- CBC - Buko Pie MakingDocument36 pagesCBC - Buko Pie Makingrobelyn veranoNo ratings yet

- Development Workplace - Chccom003 - r2Document4 pagesDevelopment Workplace - Chccom003 - r2Manik KumariNo ratings yet

- Project Scope ManagementDocument112 pagesProject Scope ManagementKelvin TingNo ratings yet

- RIBA Quality Management System - Procedures ManualDocument94 pagesRIBA Quality Management System - Procedures ManualbrunoNo ratings yet

- INFINITY - PMP 02 - ScopeDocument24 pagesINFINITY - PMP 02 - ScopeOmar KhaledNo ratings yet

- Supervised Templates of Bookkeeping NCIIIDocument54 pagesSupervised Templates of Bookkeeping NCIIILovely Rose Bacolcol100% (1)

- BSCC SBCC As A Planned ProcessDocument21 pagesBSCC SBCC As A Planned ProcessKoolet GalNo ratings yet

- IRCA 9K - LA Exercise WorkbookDocument40 pagesIRCA 9K - LA Exercise WorkbookAditya NaiduNo ratings yet

- Leading by Example ReportDocument12 pagesLeading by Example ReportLe minhNo ratings yet

- Forms 1.1-1.4Document12 pagesForms 1.1-1.4Latifah EmamNo ratings yet

- Project Management Improvement ProcessDocument13 pagesProject Management Improvement Processpravinepatil3426No ratings yet

- Saep 1161Document51 pagesSaep 1161Anonymous 4IpmN7OnNo ratings yet

- StepUsersGuide 09Document51 pagesStepUsersGuide 09Yixuan ZhongNo ratings yet

- Food Processing NC IVDocument119 pagesFood Processing NC IVCharo GironellaNo ratings yet

- Practical Project Management 101: Unit StandardsDocument109 pagesPractical Project Management 101: Unit StandardsHrh Charmagne Thando NkosiNo ratings yet

- Competency - Based Learning MaterialsDocument60 pagesCompetency - Based Learning Materialsanna victoria salamatNo ratings yet

- B94 PQP Seksyen 28Document42 pagesB94 PQP Seksyen 28Roif Samsul100% (1)

- SW Development Process Audit Procedure ATTDocument7 pagesSW Development Process Audit Procedure ATTReshma KharatNo ratings yet

- Quality PlanDocument44 pagesQuality PlanAbhishek SharmaNo ratings yet

- Beverly Wood Swe440 Ip3Document36 pagesBeverly Wood Swe440 Ip3Beverly WoodNo ratings yet

- TR Die Designing NC IVDocument140 pagesTR Die Designing NC IVJefferson MoralesNo ratings yet

- IMS Checklist 3 - Mod 2Document10 pagesIMS Checklist 3 - Mod 2Febin C.S.100% (1)

- Unisdrmeframeworkver1.0Document26 pagesUnisdrmeframeworkver1.0Joeban R. Paza100% (1)

- Project Scope Management FinalDocument18 pagesProject Scope Management FinalAbdullah SahiNo ratings yet

- Assessment GuideDocument30 pagesAssessment GuideMarius BuysNo ratings yet

- CDRF PaperDocument100 pagesCDRF PaperDavid BriggsNo ratings yet

- 2 - What Is Project Management - Part 1Document8 pages2 - What Is Project Management - Part 1Ahmad JalamnehNo ratings yet

- BDA Audit Handbook - v2.1Document11 pagesBDA Audit Handbook - v2.1Muhammad A El-Mun'emNo ratings yet

- Tranning RegulationDocument19 pagesTranning RegulationMargaret lian Celeste BisaresNo ratings yet

- Competency Based Learning Material: S: P F & B Q: F P NC Ii U C: I G M P P M T: I G M P PDocument66 pagesCompetency Based Learning Material: S: P F & B Q: F P NC Ii U C: I G M P P M T: I G M P PErethro CytesNo ratings yet

- Project HSE Performance Monitoring ProcedureDocument12 pagesProject HSE Performance Monitoring ProcedureWinnie Eldama0% (1)

- Mominnovation Sdn. BHD.: Table of ContentsDocument41 pagesMominnovation Sdn. BHD.: Table of ContentsRoif SamsulNo ratings yet

- Training & DDocument5 pagesTraining & DEDWARD ACHEAMPONGNo ratings yet

- 6.2 Objectives and Planning FormatDocument3 pages6.2 Objectives and Planning FormatSirajuddin KhowajaNo ratings yet

- Evaluation GuidelinesDocument26 pagesEvaluation GuidelinesJohanNo ratings yet

- Objectives Targets and ProgramsDocument5 pagesObjectives Targets and ProgramsKoshalNo ratings yet

- Construction Curriculum L - 4Document99 pagesConstruction Curriculum L - 4MeriedNo ratings yet

- Establish Quality StandardDocument9 pagesEstablish Quality Standardmahad mohamedNo ratings yet

- Module 2 - Decision MakingDocument23 pagesModule 2 - Decision MakingNicole NimoNo ratings yet

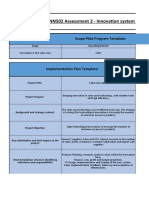

- BSBINN502 Assessment 2 - Innovation System Pilot ProjectDocument5 pagesBSBINN502 Assessment 2 - Innovation System Pilot ProjectIvson SilvaNo ratings yet

- Apqp Report2Document32 pagesApqp Report2Angel MuruetaNo ratings yet

- Central Pacific April 2 2023Document11 pagesCentral Pacific April 2 2023api-635030783No ratings yet

- Hhog PHC PD 2023 118 CDPNL Technical Tender Form K 1.8 Training and Manpower DevelopmentDocument7 pagesHhog PHC PD 2023 118 CDPNL Technical Tender Form K 1.8 Training and Manpower DevelopmentCHRISTOPHER WEALTHNo ratings yet

- 30 60 90 Days QHSE Plan SxvysiDocument4 pages30 60 90 Days QHSE Plan SxvysiAlmerindo DOS SANTOSNo ratings yet

- Audit in PracticeDocument56 pagesAudit in PracticeRached LazregNo ratings yet

- 2023-24 MMS 7201 Lecture 5 - Design and Devt (Product Realization and DFMA)Document52 pages2023-24 MMS 7201 Lecture 5 - Design and Devt (Product Realization and DFMA)mulamuziisacNo ratings yet

- Commissioning StepsDocument15 pagesCommissioning StepsZahid RasoolNo ratings yet

- DT1-PCI&CHEC-PMT-PLA - 0003 - Manufacturing Management PlanDocument36 pagesDT1-PCI&CHEC-PMT-PLA - 0003 - Manufacturing Management PlanMinh Thức XdNo ratings yet

- 2201 Engagement PlanningDocument7 pages2201 Engagement PlanningdeeptimanneyNo ratings yet

- CMMI Quick Reference GuideDocument19 pagesCMMI Quick Reference GuideVenky SreeNo ratings yet

- Competency Based Learning Material: S: P F & B Q: F P NC Ii U C: I E P P M T: I E P PDocument51 pagesCompetency Based Learning Material: S: P F & B Q: F P NC Ii U C: I E P P M T: I E P PErethro CytesNo ratings yet

- Pip Adg001 Specification For Developing Practices: Work ProcessesDocument21 pagesPip Adg001 Specification For Developing Practices: Work ProcessesJohn BuntalesNo ratings yet

- Bamboo People - An Interdisciplinary Unit For High SchoolDocument6 pagesBamboo People - An Interdisciplinary Unit For High SchoolChipo Jean MarundaNo ratings yet

- Schmidt Hammer TestDocument5 pagesSchmidt Hammer Testchrtrom100% (1)

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Why We Need A Flying Amphibious Car 1. CarsDocument20 pagesWhy We Need A Flying Amphibious Car 1. CarsAsim AhmedNo ratings yet

- (Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupDocument3 pages(Ug, PG & PHD) Fellowship: Tih-Iot Chanakya GroupVijay M.MNo ratings yet

- Be and Words From The List.: 6B Judging by Appearance Listening and ReadingDocument3 pagesBe and Words From The List.: 6B Judging by Appearance Listening and ReadingVale MontoyaNo ratings yet

- Bilateral Transfer of LearningDocument18 pagesBilateral Transfer of Learningts2200419No ratings yet

- IU IIDC Time Management and Organizational SkillsDocument40 pagesIU IIDC Time Management and Organizational SkillsAsger HamzaNo ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Research Project Presentation of Jobairul Karim ArmanDocument17 pagesResearch Project Presentation of Jobairul Karim ArmanJobairul Karim ArmanNo ratings yet

- Customer Service Metrics CalculatorDocument28 pagesCustomer Service Metrics CalculatorSelma Regita MahardiniNo ratings yet

- Kat-A 4102 Rotovalve Edition3!12!02-2013 enDocument4 pagesKat-A 4102 Rotovalve Edition3!12!02-2013 enWalter PiracocaNo ratings yet

- Davis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersDocument8 pagesDavis A. Acclimating Pacific White Shrimp, Litopenaeus Vannamei, To Inland, Low-Salinity WatersAngeloNo ratings yet

- MidsemDocument6 pagesMidsemAravind SomasundaramNo ratings yet

- Headlight Washer System: Current Flow DiagramDocument3 pagesHeadlight Washer System: Current Flow DiagramLtBesimNo ratings yet

- Surge Protection Devices CatalogueDocument134 pagesSurge Protection Devices CatalogueNguyen Doan QuyetNo ratings yet

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNo ratings yet

- NCRA Membership InformationDocument1 pageNCRA Membership Informationbkharkreader1301No ratings yet

- Causal Emergence - HoelDocument18 pagesCausal Emergence - HoelFelipe LopesNo ratings yet

- I. Objectives Ii. Content Iii. Learning ResourcesDocument13 pagesI. Objectives Ii. Content Iii. Learning ResourcesZenia CapalacNo ratings yet

- (14062020 0548) HF Uniform Logo GuidelinesDocument4 pages(14062020 0548) HF Uniform Logo GuidelinesBhargaviNo ratings yet

- Diltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486Document5 pagesDiltoids Numberletter Puzzles Activities Promoting Classroom Dynamics Group Form - 38486sinirsistemiNo ratings yet

- Kowalkowskietal 2023 Digital Service Innovationin B2 BDocument48 pagesKowalkowskietal 2023 Digital Service Innovationin B2 BAdolf DasslerNo ratings yet

- Solar-range-brochure-all-in-one-Gen 2Document8 pagesSolar-range-brochure-all-in-one-Gen 2sibasish patelNo ratings yet

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaNo ratings yet

- Stress: Problem SetDocument2 pagesStress: Problem SetDanielle FloridaNo ratings yet

- 1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Document880 pages1988 Mazda 323 Workshop Manual V1.0 (Turbo Only)Mike Marquez100% (2)

- Practice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDDocument8 pagesPractice Test - Math As A Language - MATHEMATICS IN THE MODERN WORLDMarc Stanley YaoNo ratings yet

- JVC tm1010pnDocument4 pagesJVC tm1010pnPer VigiloNo ratings yet

- Storage Tanks Overfill Prevention Better PracticesDocument2 pagesStorage Tanks Overfill Prevention Better PracticesRicardo Bec100% (1)