Professional Documents

Culture Documents

DL310 7 PDF

DL310 7 PDF

Uploaded by

Max RojasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DL310 7 PDF

DL310 7 PDF

Uploaded by

Max RojasCopyright:

Available Formats

Technical Specification

7-6325-E Sandvik DL310-7

2007-11-12

A PPL ICA TION M AIN SPEC IF ICA T ION S

The Sandvik DL310-7 is an electro-hydraulic longhole Carrier 1 x TC 5

drilling rig for small and medium scale production drill- Safety canopy 1 x FOPS (ISO 3449)

ing in underground mines. The rig is capable of drilling Rock drill 1 x HL710S

64 – 102 mm holes up to 38 meters. Drilling module 1 x LF700 / Pito 5

The rig has been designed for vertical and inclined Rod handling system 1 x RC 700 (optional)

plane rings and fans and also for parallel long produc- Boom 1 x ZR 20

tion holes as well as for long single holes. Control system 1 x TPC LH 5

The robust ZR 20 boom has 2 meters parallel drilling Powerpack 1 x HP 555 (55,0 kW)

coverage. The 360° rotation in full parallel coverage Shank lubricating device 1 x SLU 1

area and wide tilt angle ranges forward and backwards Air compressor 1 x CT 10 (7,5 kW)

make the boom suitable to various drilling applications. Water pump 1 x WBP 2 (4,0 kW)

Main switch 1 x MSE-10

Simple and proven technical solutions ensure efficient

and reliable operations. The rigid boom and feed con- Cable reel 1 x TCR 1

struction together with innovative centralizer gives op-

timal drilling accuracy. Good stability characteristics Length 8 450 mm

enables fast tramming even in challenging road condi- Width 1 900 mm

tions. Tramming is done from the operator’s platform Height 2 675 mm

and drilling from a remote panel. Weight 17 000 kg

Tramming speed

The new carrier is designed for better access to the

Horizontal 12,0 km/h

daily service points. 14 % = 1:7 = 8° 5,0 km/h

Gradeability 28 % = 1:3,5 = 15°

Noise level (EN 791, free field condition)

Operator’s platform LpA = 97 dB

Emitted LwA = 115 dB

© 2007 Sandvik Mining and Construction 1/4

Technical Specification

7-6325-E Sandvik DL310-7

2007-11-12

GENERAL DIMENSIONS

30° 30°

2 840 (LF 704)

3 240 (LF 705)

3 550 (LF 706)

Zoom 485

360°

1 615

2 680 3 100 876

9 170

15°

30°

TC 5 CARR IER HL 71 0S ROCK DR ILL

Diesel engine Deutz BF4M 2012 Weight 245 kg

74 kW (99 hp) Length 1 134 mm

Catalyser Height 350 mm

Transmission Hydrostatic Profile height 252 mm

Transfer case Clark-Hurth drop gear

Power class 19,5 kW

Axles Case New Holland D63 Max working pressure

Brakes Percussion 190 bar

Service Hydrostatic transmission Rotation 175 bar

+ positive braking

Max torque

Parking and emergency Hydraulic oil immersed

multiple disc brakes on 200 cm³ motor 860 Nm

both axles Hole size 64 – 102 mm

Hand pump for manual brake release Flushing water pressure 5 – 15 bar

Tyres 12.00 – 20 PR 20 L F7 00 DR IL L ING MODU LE

Steering Frame steering LF70x / Pito 5 x = 4’ / 5’ / 6’

Orbitrol Cuttings collector CC 705

Articulation ± 40°

RC 7 00 ROD HAND L ING SYST EM

Rear oscillation ± 10°

RC 70x, option x = 4’/5’/6’

Ground clearance 300 mm

Capacity 20+1 rods / tubes

Fuel tank 150 l

Hydraulic jacks ZR 20 BOO M

Front 2 x Outriggers Parallel coverage 2 000 mm

Rear 2 x Hydraulic jacks Feed extension

Safety canopy FOPS (ISO 3449) LF 704 985 mm

LF 705 1 050 mm

LF 706 1 200 mm

Boom weight, net 2 200 kg

Rotation angle 360°

Stinger extension (rear) 1 500 mm

© 2007 Sandvik Mining and Construction 2/4

Technical Specification

7-6325-E Sandvik DL310-7

2007-11-12

TRAMMING DIMENSIONS

2 145

2 675

2 475

1 945

17° 17°

1 600

2 680 3 100

8 450

R 3 290 40°

R 5 750

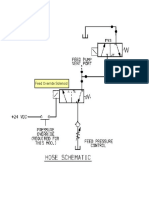

T PC LH 5 CON TRO L SYST EM A IR C IRCUIT

Power control Adjustable full power Compressor type 1 x CT 10 (7,5 kW)

Adjustable collaring power Capacity 1.0 m³/min (7 bar)

Anti-jamming control Adjustable anti-jamming Shank lubricating device 1 x SLU 1

pressure Air consumption 250 – 350 l/min

Rotation control Adjustable rotation speed Oil consumption 200 – 300 g/h

Flushing control Water flushing flow and WAT ER C IRCU IT

pressure control

Air-mist flushing (option) Water pump type 1 x WBP 2 (4,0 kW)

Capacity 100 l/min (12 bar)

H P 5 55 POW ER PACK With 2 bar inlet pressure

Electric motor 1 x 55 kW 3-phase motor Inlet pressure 2 – 7 bar (while drilling)

Pump types Inlet pressure control valve 1 x WP 70

Percussion, feed, boom 1 x 130 l/min variable dis- EL EC TR ICAL SYST EM

and rod handling placement axial piston pump

Rotation 1 x 60 l/min variable dis- Total input power 73 kW

placement axial piston pump Main switch 1 x MSE-10

Filtration Standard voltages 380 – 690 VAC

Pressure 1 x 20 micron 50 or 60 Hz

Return 1 x 12 micron Voltage fluctuation Max ±10 %

Oil tank volume Max. 180 l Lighting

Tank filling 1 x electric filling pump Working lights (24 VDC) Front 2 x 35 W (H.I.D.)

Oil cooling 1 x OW 30 water cooler Portable

Rear 2 x 70 W

Driving lights (24 VDC) Front 2 x 35 W (H.I.D.)

Rear 2 x 70 W

Positioning lights 2 x Laser type

Automatic cable reel 1 x TCR 1

© 2007 Sandvik Mining and Construction 3/4

Technical Specification

7-6325-E Sandvik DL310-7

2007-11-12

COVERAGE AREA

MINIMUM DRIFT SIZE

Drilling 610 WP 775

H W WP HR

module

LF 704 3 140 3 140 1 560 1 620

LF 705 3 440 3 440 1 860 1 620

LF 706 3 650 3 650 2 000 1 620 Optional

Included 100 mm clearance on each side LF705, LF706 2 000

LF704 1 700

MAXIMUM DRIFT SIZE

Drilling

H W WP HR

module

H

LF 704 3 700 4 800 2 000 1 740

HR

LF 705 4 000 5 100 2 000 1 740

LF 706 4 150 5 250 2 000 1 740

With rear stingers in use without optional front stinger

530

775 610

2 000 775

W

30°

Parallel

1 900

610

30°

OPTIONAL EQUIPMENT

DRILLING SYSTEM

• Extra feed swing OTHER OPTIONAL EQUIPMENT

• Fire extinguisher (bottle only)

• Rod handling system RC 700

• Manual fire suppression system, 6 nozzles

• Readiness for double tools system; rods and tubes

• Automatic fire suppression system, 6 nozzles

• Drilling instrumentation TIS, P, D, DP, DDS, DDSP

• Pressure cleaning system (15 bar) with reel

• Data logging for TIS

• High pressure cleaning system with reel and handset

• Front stinger (needed for downholes)

• Water hose 1½” (30 m)

• Air mist flushing with outer compressed air feed

• Greasing system (Lincoln) with pump, reel and nozzle

• Power extractor for HL710S

• Centralized greasing

• *) HL800S rock drill with stabilizer

• Automatic greasing system (Lincoln)

• *) KVL 10-1 shank lubrication system instead of SLU 1

• Biodegradable oils

ELECTRICAL SYSTEM

• Electric cable rubber or PUR • Fast filling and evacuation system (Wiggins) for fuel

• Ground fault and over current unit VYK • Fast filling and evacuation system (Wiggins) for fuel,

transmission, engine and hydraulic oil

• *) 1 000 V electric system

• * EU, UL, CSA, AUS norms package

• Star-Delta starting (380 – 690 VAC only)

• 230 VAC power outlet max 4 500 VA *) = Replaces standard component

• 3-phase outlet network voltage

CARRIER

• Exhaust scrubber

• Complete spare wheel

Sandvik Mining and Construction reserves the right to change this specification without further notice.

Sandvik Mining and Construction Oy

P.O.Box 100, FIN–33311 Tampere, Finland

© 2007

Tel. Sandvik

+358 205 44Mining and Construction

121, Telefax +358 205 44 4771 4/4

www.sandvik.com

You might also like

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Biochemistry Free For All FinalDocument3,578 pagesBiochemistry Free For All Finalharsh100% (1)

- WSET Welcome Pack 22-23Document33 pagesWSET Welcome Pack 22-23zeus izzy yeeNo ratings yet

- Affidavit Complaint LanderoDocument4 pagesAffidavit Complaint LanderoUndo ValenzuelaNo ratings yet

- DL420 15c SpecificationsDocument4 pagesDL420 15c Specificationsesteban muñozNo ratings yet

- Sandvic DD420 60C SpecDocument4 pagesSandvic DD420 60C SpecAlterSon Grafi KalayNo ratings yet

- Introduction To Blast Hole DrillingDocument38 pagesIntroduction To Blast Hole DrillingMax Rojas75% (4)

- Heavy Duty Personalized Nutrition and Recovery PlanDocument24 pagesHeavy Duty Personalized Nutrition and Recovery Plansafar benceNo ratings yet

- Raptor 44 ReseminDocument6 pagesRaptor 44 ReseminlucasmaltaNo ratings yet

- Service PartsDocument6 pagesService PartsMax RojasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Especificaciones Del Jumbo DD 311Document4 pagesEspecificaciones Del Jumbo DD 311RimbertNo ratings yet

- dd210 Specification Sheet English PDFDocument4 pagesdd210 Specification Sheet English PDFGerson Dario Rojas TorresNo ratings yet

- Espec DL311-7 7 - 6328-EDocument4 pagesEspec DL311-7 7 - 6328-EFranklin LabbeNo ratings yet

- SLU 1 Shank Lubricator PDFDocument2 pagesSLU 1 Shank Lubricator PDFMax RojasNo ratings yet

- Jumbo Dd421Document4 pagesJumbo Dd421Anonymous Iu8A4JC100% (2)

- D90KS Commissioning PDFDocument20 pagesD90KS Commissioning PDFMax Rojas100% (1)

- DM901HDE: Diesel Driven & Electric DrillerDocument6 pagesDM901HDE: Diesel Driven & Electric DrillerEnzo VanderlindenNo ratings yet

- DL311 7Document4 pagesDL311 7Vanessa Astudillo RNo ratings yet

- Circuit DiagramsDocument63 pagesCircuit DiagramsMax RojasNo ratings yet

- Sandvik Dd311 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd311 Development Drill: Technical SpecificationJuan David Rondinel BulejeNo ratings yet

- 2017 Vol 2 CH 3 AnsDocument17 pages2017 Vol 2 CH 3 AnsJohn Lloyd YastoNo ratings yet

- Sandvik DD210Document4 pagesSandvik DD210Lener Elvin Lopez LavadoNo ratings yet

- JumboDocument4 pagesJumboWilliam Valeriano100% (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Dd321 Specification Sheet EnglishDocument4 pagesDd321 Specification Sheet EnglishNelson Valles AvilaNo ratings yet

- Implementing Quality MGMT System at Hyundai MotorsDocument2 pagesImplementing Quality MGMT System at Hyundai MotorsDevspring0% (1)

- Sandvik Dt1231 Tunneling Drills: Technical SpecificationDocument4 pagesSandvik Dt1231 Tunneling Drills: Technical SpecificationKevin QFNo ratings yet

- Sandvik DD2710Document4 pagesSandvik DD2710lorenzo henerNo ratings yet

- Dev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishDocument4 pagesDev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishBBBBBBNo ratings yet

- DS421 8-4301-ADocument4 pagesDS421 8-4301-AchristianNo ratings yet

- Manual Sandvik Ds 421-cDocument4 pagesManual Sandvik Ds 421-cchristian100% (1)

- SandvikDocument4 pagesSandvikBenjamin Musa ダNo ratings yet

- Manual de Operación: 5.4.7. Control Remoto InalámbricoDocument25 pagesManual de Operación: 5.4.7. Control Remoto InalámbricoMax RojasNo ratings yet

- DS2711 Narrow Vein Bolter: Technical SpecificationDocument4 pagesDS2711 Narrow Vein Bolter: Technical SpecificationMarioNo ratings yet

- Sandvik DD321Document4 pagesSandvik DD321Anonymous Dm7iMmt0% (2)

- Ds311-Ficha Tecnica PDFDocument4 pagesDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNo ratings yet

- Ds421 Specification Sheet EnglishDocument4 pagesDs421 Specification Sheet EnglishmegamNo ratings yet

- DS312 Specification Sheet EnglishDocument4 pagesDS312 Specification Sheet EnglishAntonio BocanegraNo ratings yet

- Dd421 Specification Sheet EnglishDocument4 pagesDd421 Specification Sheet Englisheduama0% (1)

- Espec DL310 PDFDocument4 pagesEspec DL310 PDFFranklin LabbeNo ratings yet

- (Solo 5-7C) SANDVIKDocument4 pages(Solo 5-7C) SANDVIKCesar Gabriel Valdez SotoNo ratings yet

- Sandvik DT1130-C Data: Application Main SpecificationsDocument4 pagesSandvik DT1130-C Data: Application Main SpecificationsLuis JaimesNo ratings yet

- Axera 7260t Sandvik Mining and ConstructionDocument4 pagesAxera 7260t Sandvik Mining and ConstructiondaniloNo ratings yet

- Jumbo Dl420 7cDocument4 pagesJumbo Dl420 7cRodrigo ContrerasNo ratings yet

- Jumbo Ficha TecnicaDocument4 pagesJumbo Ficha TecnicaRodrigo FooNo ratings yet

- Specifications JumboDocument4 pagesSpecifications JumboChristianM.LeandroYauriNo ratings yet

- 6-9660-F (DD320-40) PDFDocument4 pages6-9660-F (DD320-40) PDFlorenzo henerNo ratings yet

- 6-9520-F (Axera 7-260) PDFDocument4 pages6-9520-F (Axera 7-260) PDFADRIAN MENDEZ RICARIONo ratings yet

- 6 9500 F Axera 7 240 PDFDocument4 pages6 9500 F Axera 7 240 PDFsegomezpNo ratings yet

- SpecificationsDocument4 pagesSpecificationsvipulNo ratings yet

- AXERA 6-226: Technical Specification 6-9650-B 2004-07-02Document4 pagesAXERA 6-226: Technical Specification 6-9650-B 2004-07-02cristianNo ratings yet

- Sandvik Dd321 Development Drill: Technical SpecificationDocument4 pagesSandvik Dd321 Development Drill: Technical SpecificationFERNANDO INOCENTE TRINIDAD GUERRANo ratings yet

- Ds311de Specification Sheet EnglishDocument4 pagesDs311de Specification Sheet EnglishFORMINNo ratings yet

- Axera6 226 FichaDocument3 pagesAxera6 226 FichaFer GarciaNo ratings yet

- Axera6 226Document3 pagesAxera6 226Jesinaldo DantasNo ratings yet

- dd321 Specification Sheet EnglishDocument4 pagesdd321 Specification Sheet Englishgkqztsy9skNo ratings yet

- Sandvik DP1100: ApplicationDocument4 pagesSandvik DP1100: ApplicationAnbarasanNo ratings yet

- SpecificationsDocument4 pagesSpecificationsSebastian VasquezNo ratings yet

- DT821-SC - Ficha TécnicaDocument4 pagesDT821-SC - Ficha TécnicaAlexandra chata monsalve momsalveNo ratings yet

- Frontonero SANDVIK DD311Document4 pagesFrontonero SANDVIK DD311Arturo And100% (1)

- ds311 Specification Sheet EnglishDocument4 pagesds311 Specification Sheet EnglishKhánhNamNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishFORMINNo ratings yet

- DT621 - Teknik KatalogDocument4 pagesDT621 - Teknik KatalogEmrah MertyürekNo ratings yet

- dt820 Specification Sheet EnglishDocument4 pagesdt820 Specification Sheet Englishburak tiryakiNo ratings yet

- Slim Tyre Handler: Benefits Technical CharacteristicsDocument3 pagesSlim Tyre Handler: Benefits Technical Characteristicsmayadin yadinNo ratings yet

- Ds311 Specification Sheet EnglishDocument4 pagesDs311 Specification Sheet EnglishYonatan Tarazona HilarioNo ratings yet

- sd110 en AsiapacificDocument2 pagessd110 en AsiapacificsakoequipmentNo ratings yet

- Dl422ie Technical Specification EnglishDocument8 pagesDl422ie Technical Specification EnglishPiero Fabrizzio Mendoza FuenteNo ratings yet

- Surface Drills: Commando DC300Ri S5Document4 pagesSurface Drills: Commando DC300Ri S5Agus purwantoNo ratings yet

- Sandvik DD310-26XDocument3 pagesSandvik DD310-26XMep RoleroNo ratings yet

- Main AssemblyDocument8 pagesMain AssemblyMax RojasNo ratings yet

- Equipment: Unit Identification CardDocument7 pagesEquipment: Unit Identification CardMax Rojas100% (1)

- TIS For DL310 and DL320 Models: Technical Specification 5-9250-B 2007-10-26Document2 pagesTIS For DL310 and DL320 Models: Technical Specification 5-9250-B 2007-10-26Max RojasNo ratings yet

- SOLO 5 - 7P: Serial Number: 107A10770 - 1 Main Assembly Id: 550 798 65Document7 pagesSOLO 5 - 7P: Serial Number: 107A10770 - 1 Main Assembly Id: 550 798 65Max RojasNo ratings yet

- LF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Document2 pagesLF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Max RojasNo ratings yet

- ZR 20 / 32 P Boom: C 44120 - 2 en 0507/LHDocument41 pagesZR 20 / 32 P Boom: C 44120 - 2 en 0507/LHMax RojasNo ratings yet

- ZR 20 Boom: Technical Specification 4-1820 2005-01-11Document2 pagesZR 20 Boom: Technical Specification 4-1820 2005-01-11Max RojasNo ratings yet

- TPC LH 5Document2 pagesTPC LH 5Max RojasNo ratings yet

- Interlock D40KX PDFDocument2 pagesInterlock D40KX PDFMax RojasNo ratings yet

- LF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Document2 pagesLF 700 Cylinder Rope Feed: Technical Specification 3-1545 2005-01-11Max RojasNo ratings yet

- Entrenamineto OperacionDocument53 pagesEntrenamineto OperacionMax Rojas100% (1)

- 7-6325-E (DL310-7) PDFDocument4 pages7-6325-E (DL310-7) PDFMax RojasNo ratings yet

- Electridad Gator InglesDocument16 pagesElectridad Gator InglesMax RojasNo ratings yet

- Table of Contents - Book 1: Revised 1 - 05Document51 pagesTable of Contents - Book 1: Revised 1 - 05Max Rojas100% (1)

- Respiration LabDocument4 pagesRespiration LabLogan Parkison100% (1)

- Module MCQ PracticeDocument35 pagesModule MCQ PracticeAkash KumarNo ratings yet

- UPVC PipesDocument1 pageUPVC PipesIbnu SenaNo ratings yet

- E3 ShelterDocument17 pagesE3 ShelterChhotuNo ratings yet

- Date: 01-06-2017 To 30-06-2017 S.N Date 7 Am To 1.30 PM 1.30 PM To 8.30 PM 8.30 PM To 7.00 AmDocument3 pagesDate: 01-06-2017 To 30-06-2017 S.N Date 7 Am To 1.30 PM 1.30 PM To 8.30 PM 8.30 PM To 7.00 Ampriya selvarajNo ratings yet

- Pharmaceutical Emulsions: Iqra Zulfiqar (R#33)Document51 pagesPharmaceutical Emulsions: Iqra Zulfiqar (R#33)MalekLeeNo ratings yet

- Single 2013 MI 3102 BT EurotestXE Ang PDFDocument2 pagesSingle 2013 MI 3102 BT EurotestXE Ang PDFDejanTomasevicNo ratings yet

- Contrast MediaDocument6 pagesContrast MediardmdelarosaNo ratings yet

- Lesson PlanDocument3 pagesLesson PlanAbbygale VittoNo ratings yet

- Polypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetDocument2 pagesPolypropylene Homo Polymer Injection Molding: Provisional Technical DatasheetMohit MohataNo ratings yet

- Science 9 W AnswerDocument62 pagesScience 9 W AnswerAstrande KevinNo ratings yet

- Grundfos MTS Screw Spindle PumpDocument68 pagesGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Eportfolio ResumeDocument1 pageEportfolio Resumeapi-451776993No ratings yet

- ValidaDocument1 pageValidaMarcela Jarpa ParraNo ratings yet

- November 16, 2018Document15 pagesNovember 16, 2018Anonymous KMKk9Msn5100% (1)

- Menard CasesDocument9 pagesMenard CasesMenard BiasuraNo ratings yet

- WAI Recognized For Revenue Growth: in This IssueDocument12 pagesWAI Recognized For Revenue Growth: in This IssueBen ThompsonNo ratings yet

- Acute Abdomen - DR Raya Batubara, SP.BDocument39 pagesAcute Abdomen - DR Raya Batubara, SP.BGJMasterNo ratings yet

- PDF Version of DemeterDocument8 pagesPDF Version of Demeterpierrette1No ratings yet

- PRE NE HA HANDBOOK V8 20200827 With Answer PDFDocument123 pagesPRE NE HA HANDBOOK V8 20200827 With Answer PDFtok janggutNo ratings yet

- Assessment 2 Cluster SITXMGT001, SITXMGT002 PerformanceDocument16 pagesAssessment 2 Cluster SITXMGT001, SITXMGT002 PerformanceBoban Gorgiev0% (2)

- 16127-Underground Ducts and Utility StructuresDocument5 pages16127-Underground Ducts and Utility StructuresYousif AbdalhalimNo ratings yet

- COLLEGE OF HEALTH SCIENCE Department of Anesthesia Research ProposalDocument29 pagesCOLLEGE OF HEALTH SCIENCE Department of Anesthesia Research Proposalmihret tedla100% (1)

- Systematic Yoga: Alan Nash Revised: June 14, 1999Document12 pagesSystematic Yoga: Alan Nash Revised: June 14, 1999sidheshNo ratings yet