Professional Documents

Culture Documents

Lm6000 Power Plants: Simple Cycle Efficiency Simple Cycle Output

Uploaded by

Erik Van GroningenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lm6000 Power Plants: Simple Cycle Efficiency Simple Cycle Output

Uploaded by

Erik Van GroningenCopyright:

Available Formats

LM6000 POWER PLANTS

45-58 MW

SIMPLE CYCLE OUTPUT

>41%

SIMPLE CYCLE EFFICIENCY

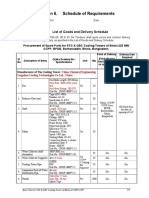

CAPABILITY Simple cycle specifications

(50 Hz and 60 Hz) LM6000 PC LM6000 PG LM6000 PF LM6000 PF+

Achieves various dispatch profiles with 3-minute Net output (MW) 45/50* 55/57* 44/49* 53/58*

synchronization to the grid Net heat rate (Btu/kWh, LHV) 8,651 8,692 8,281 8,271

Net heat rate (kJ/kWh, LHV) 9,127 9,170 8,737 8,726

VERSATILITY Net efficiency (%, LHV) 39.4% 39.3% 41.2% 41.3%

Operates from peaking to baseload with applications in Ramp rate (MW/minute) 50 50 50 50

combined cycle, simple cycle, industrial cogeneration, Startup time (cold iron) (min.) 5 5 5 5

GT min. turn down load (%) 25% 25% 50% 50%

and district heating Combined cycle 1x1 specifications

Net output (MW) 59/66* 73/76* 58/64* 70/77*

SUSTAINABILITY Net heat rate (Btu/kWh, LHV) 6,573 6,535 6,179 6,105

Reduces greenhouse gas emissions as part of the LM6000 Net heat rate (kJ/kWh, LHV) 6,935 6,895 6,520 6441

battery Hybrid EGT offering Net efficiency (%, LHV) 51.9% 52.2% 55.2% 55.9%

Ramp rate (MW/minute) 50 50 50 50

Startup time (cold iron) (min.) 30 30 30 30

With over 40 million operating hours and more than GT min. turn down load (%)

Combined cycle 2x1 specifications

19% 19% 37% 37%

1,300 units shipped, GE’s LM6000 aeroderivative gas Net output (MW) 118/133* 146/153* 117/129* 142/155*

Net heat rate (Btu/kWh, LHV) 6,555 6,516 6,161 6,085

turbine is a leader in the +40 MW space. The LM6000 Net heat rate (kJ/kWh, LHV) 6,916 6,874 6,500 6,420

Net efficiency (%, LHV) 52.1% 52.4% 55.4% 56.1%

offers greater than 99 percent start and operational Ramp rate (MW/minute) 100 100 100 100

Startup time (cold iron) (min.) 30 30 30 30

reliability and 98 percent availability. Its 5-minute fast GT min. turn down load (%) 19% 19% 19% 18%

LM6000 additional specifications

start allows operators to differentiate their dispatch Reliability 99.8% 99.8% 99.8% 99.8%

Availability 98.7% 98.7% 98.7% 98.7%

capability while a simple two-spool design results in Start reliability 99.1% 99.1% 99.1% 99.1%

Fleet operation hours 18.7M 108,000 2.1M 30,000

lower overall maintenance costs. Universal and modular Hot section hours 25,000 25,000 25,000 25,000

Overhaul hours 50,000 50,000 50,000 50,000

packaging gives the LM6000 a smaller footprint and NOx emission (ppm) (@ 15% O2) 25 25 15 15/25

allows for faster installation and commissioning. CO (ppm) (@ 15% O2)

Package noise (dBA average)

89/150**

85

94/150**

85

25/70**

85

25/25**

85

Exhaust temp (°F/°C) 824/440 879/470 861/461 927/491

Exhaust mass flow (lbs) 284.4 315.9 277 927

Exhaust mass flow (Kg/s) 129.0 143.3 125.6 139.4

Combustion SAC SAC DLE DLE

LM6000 LM6000 LM6000 DLE LM6000 DLE

Legacy name (52) (59) (50) (57)

* MW output without SPRINT/with SPRINT

**At baseload/minimum turndown without abatement

NOTE: All ratings are net plant, based on ISO conditions and natural gas fuel. Actual performance will vary with

project-specific conditions and fuel.

gepower.com © 2019 General Electric Company. All rights reserved.

GEA34350 (09/2019)

You might also like

- Lm6000 Power Plants: MW Up To MinuteDocument1 pageLm6000 Power Plants: MW Up To Minutejing qiangNo ratings yet

- Sheet Product S 2019Document1 pageSheet Product S 2019Anonymous XgX8kTNo ratings yet

- Lm6000 Power Plants: Simple Cycle Efficiency Simple Cycle OutputDocument1 pageLm6000 Power Plants: Simple Cycle Efficiency Simple Cycle OutputFred PachecoNo ratings yet

- Lm2500 Power Plants: Up To Million MWDocument1 pageLm2500 Power Plants: Up To Million MWZakaria ZelmatNo ratings yet

- Lm2500 Fact Sheet Product SpecificationsDocument1 pageLm2500 Fact Sheet Product SpecificationsFrankNo ratings yet

- Lm6000 Power PlantsDocument2 pagesLm6000 Power PlantsAdianta GeorNo ratings yet

- TM2500 60Hz Fact Sheet 2016Document2 pagesTM2500 60Hz Fact Sheet 2016gustiramadaniNo ratings yet

- 9HA.01 .02 Fact Sheet 2016 PDFDocument2 pages9HA.01 .02 Fact Sheet 2016 PDFHi BlackNo ratings yet

- 9ha Fact Sheet Oct15Document2 pages9ha Fact Sheet Oct15Zulfiqar AliNo ratings yet

- 9e03 04 Fact Sheet April 2015Document2 pages9e03 04 Fact Sheet April 2015AniNo ratings yet

- tm2500 Fact Sheet Product SpecificationsDocument1 pagetm2500 Fact Sheet Product SpecificationsRostom BachaNo ratings yet

- GE 7ha-Fact-Sheet-Oct15 PDFDocument2 pagesGE 7ha-Fact-Sheet-Oct15 PDFTan Nguyen HuuNo ratings yet

- 7f Fact Sheet Product SpecificationsDocument1 page7f Fact Sheet Product SpecificationsFerdinandjaNo ratings yet

- 7ha Power Plants: Combined Cycle Efficiency Simple Cycle OutputDocument1 page7ha Power Plants: Combined Cycle Efficiency Simple Cycle Outputabhisheks5987No ratings yet

- 6f 03 Fact Sheet Product SpecificationsDocument1 page6f 03 Fact Sheet Product SpecificationsMd. MobenNo ratings yet

- 9f - Fact Sheet Product SpecificationsDocument1 page9f - Fact Sheet Product SpecificationsamineNo ratings yet

- 9ha Power Plants: Combined Cycle Efficiency Simple Cycle OutputDocument1 page9ha Power Plants: Combined Cycle Efficiency Simple Cycle OutputumerNo ratings yet

- GE Energy: Gas Turbine (50Hz)Document2 pagesGE Energy: Gas Turbine (50Hz)Rolando Antonio Cuenca PironaNo ratings yet

- E3 Modelling Inputs For New CHP Built in 2008 and 2020 (HHV Without Supplemental Firing)Document2 pagesE3 Modelling Inputs For New CHP Built in 2008 and 2020 (HHV Without Supplemental Firing)ahmedNo ratings yet

- GE Energy: Gas Turbine (50hz)Document2 pagesGE Energy: Gas Turbine (50hz)Rolando Antonio Cuenca PironaNo ratings yet

- Gt13e2 Fact Sheet Product SpecificationsDocument1 pageGt13e2 Fact Sheet Product SpecificationsLotfiNo ratings yet

- MGS-BC_50_1000C Technical SpecificationDocument12 pagesMGS-BC_50_1000C Technical SpecificationFalgon IslamNo ratings yet

- Cooling of 1103A-33GDocument2 pagesCooling of 1103A-33GMd ShNo ratings yet

- Star 270 Watt PC ModuleDocument2 pagesStar 270 Watt PC ModuleTelecomMasterNo ratings yet

- HJT-210-120-20BBDocument2 pagesHJT-210-120-20BBeiszNo ratings yet

- GE Energy: Gas Turbine (60Hz)Document2 pagesGE Energy: Gas Turbine (60Hz)Rolando Antonio Cuenca PironaNo ratings yet

- Technical Specification OF Mitsubishi Basic Diesel Generator SetDocument12 pagesTechnical Specification OF Mitsubishi Basic Diesel Generator SetFalgon IslamNo ratings yet

- Astronergy CHSM6612P 3BB 40mm Frame 20151014Document2 pagesAstronergy CHSM6612P 3BB 40mm Frame 20151014J AANo ratings yet

- Equipment Data Sheet: Diesel Generating Set 50Hz 60kVA 60Hz 50kWDocument3 pagesEquipment Data Sheet: Diesel Generating Set 50Hz 60kVA 60Hz 50kWMateen YounasNo ratings yet

- MGS-BC diesel generatorDocument12 pagesMGS-BC diesel generatorFalgon IslamNo ratings yet

- Catálogo de Panel Solar de Mono Bifásico - Tai Energy PARA INSTALACIONDocument2 pagesCatálogo de Panel Solar de Mono Bifásico - Tai Energy PARA INSTALACIONLenin RolandNo ratings yet

- GE Energy: Gas Turbine (60Hz)Document2 pagesGE Energy: Gas Turbine (60Hz)Rolando Antonio Cuenca PironaNo ratings yet

- NOARK 210-650-670MH8-66 Mono Solarni PanelDocument2 pagesNOARK 210-650-670MH8-66 Mono Solarni PanelMary DunlapNo ratings yet

- Manual Motor Perkins PDFDocument8 pagesManual Motor Perkins PDFRobertoSoares0% (1)

- CHSM60M-HC (BL) 158 Asm (En) 20201210Document2 pagesCHSM60M-HC (BL) 158 Asm (En) 20201210Unique EngineeringNo ratings yet

- Astro: Monocrystalline PV Module CHSM66M-HC SeriesDocument2 pagesAstro: Monocrystalline PV Module CHSM66M-HC Seriesabdalrhman alqatawnehNo ratings yet

- 7ha.03 Power Plants Fact Sheet PDFDocument1 page7ha.03 Power Plants Fact Sheet PDFWanNurieman AshraffNo ratings yet

- Data Sheet: Three Phase Induction Motor - Squirrel CageDocument3 pagesData Sheet: Three Phase Induction Motor - Squirrel CageKamil KościelakNo ratings yet

- 9ha Fact Sheet Product SpecificationsDocument1 page9ha Fact Sheet Product SpecificationsDangolNo ratings yet

- SpecsDocument10 pagesSpecsphtzwzvnhkNo ratings yet

- Tekhnicheskaya Spetsifikatsiya Perkins 1103d 33g3Document8 pagesTekhnicheskaya Spetsifikatsiya Perkins 1103d 33g3Pieter JanssensNo ratings yet

- GT36Document2 pagesGT36John_J2012No ratings yet

- M3 Mono 72cells 390-405WDocument2 pagesM3 Mono 72cells 390-405WIsmael YahmiNo ratings yet

- Technical Specification - MGS-BC - 1500B - 2Document11 pagesTechnical Specification - MGS-BC - 1500B - 2DodongNo ratings yet

- 9ha Power Plants PDFDocument2 pages9ha Power Plants PDFmead6356No ratings yet

- 9ha Power PlantsDocument2 pages9ha Power PlantsIzzadAfif1990No ratings yet

- 620KVA Chienese GensetDocument4 pages620KVA Chienese GensetAbdus SalamNo ratings yet

- Datasheet Astronergy CHSM72M-HC-360... 380Document2 pagesDatasheet Astronergy CHSM72M-HC-360... 380Fernando VieiraNo ratings yet

- 9e Fact Sheet Product SpecificationsDocument1 page9e Fact Sheet Product Specificationskarim karimNo ratings yet

- Combat Harsh Weather with Emmvee's Solar ModulesDocument8 pagesCombat Harsh Weather with Emmvee's Solar ModulesaniketNo ratings yet

- Perkins 1300 Technical DataDocument12 pagesPerkins 1300 Technical DataAbdul Khaliq100% (1)

- Technical Data: @perkinsDocument8 pagesTechnical Data: @perkinsdfheardNo ratings yet

- FVG60156M 1Document2 pagesFVG60156M 1Katherine Morales aNo ratings yet

- Mitsubishi Diesel Generator Technical SpecificationDocument13 pagesMitsubishi Diesel Generator Technical SpecificationgondrayNo ratings yet

- Big On Performance, Small On Space.: DigitalDocument8 pagesBig On Performance, Small On Space.: DigitalfarrelsyafiraNo ratings yet

- Bifacial Transparent Half-Cell Mono PERC Module: Linear Performance WarrantyDocument2 pagesBifacial Transparent Half-Cell Mono PERC Module: Linear Performance WarrantyThales CamposNo ratings yet

- Ovation GE LM6000 Control System Retrofit: FeaturesDocument5 pagesOvation GE LM6000 Control System Retrofit: FeaturesErik Van GroningenNo ratings yet

- N8600403-032020 IPLEX NX Brochure EN WebDocument12 pagesN8600403-032020 IPLEX NX Brochure EN WebErik Van GroningenNo ratings yet

- Iplex Videoscopes: Flexible Options For Your RVI ApplicationsDocument1 pageIplex Videoscopes: Flexible Options For Your RVI ApplicationsErik Van GroningenNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Mentor Visual Iq Videoprobe: Put The Power of Productivity in Your HandsDocument12 pagesMentor Visual Iq Videoprobe: Put The Power of Productivity in Your HandsErik Van GroningenNo ratings yet

- Mentor Visual Iq Videoprobe: Portable, Connected HD Borescope With 3D MeasurementDocument7 pagesMentor Visual Iq Videoprobe: Portable, Connected HD Borescope With 3D MeasurementErik Van GroningenNo ratings yet

- Novel Coronavirus Landscape Covid 95 PDFDocument6 pagesNovel Coronavirus Landscape Covid 95 PDFErik Van GroningenNo ratings yet

- Astra Owners Manual July 2013 PDFDocument327 pagesAstra Owners Manual July 2013 PDFNico IoanaNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Stand Out: Easy-Setup 18/7 DisplayDocument3 pagesStand Out: Easy-Setup 18/7 DisplayErik Van GroningenNo ratings yet

- JaarverslagCOM KPN Jaarverslag 2017Document166 pagesJaarverslagCOM KPN Jaarverslag 2017Erik Van GroningenNo ratings yet

- DTM COVID19 20200322 MRM EuropeDocument1 pageDTM COVID19 20200322 MRM EuropeErik Van GroningenNo ratings yet

- Productivity ImprovementDocument262 pagesProductivity ImprovementOwais MalikNo ratings yet

- 1629213726technology GK EbookDocument394 pages1629213726technology GK EbookDebrajNo ratings yet

- Swiss ChallengeDocument4 pagesSwiss ChallengeRamith De SilvaNo ratings yet

- Job Description Shift Charge EngineerDocument4 pagesJob Description Shift Charge EngineerHumayun Rashid KhanNo ratings yet

- +91 9001113984 WWW - Rajlandbank.com RAJ LANDSCAPE PVT LTDDocument176 pages+91 9001113984 WWW - Rajlandbank.com RAJ LANDSCAPE PVT LTDrajlandscapepvtltdNo ratings yet

- A. List of Goods and Delivery ScheduleDocument3 pagesA. List of Goods and Delivery ScheduleAbdul Aziz FahadNo ratings yet

- EPIA Sunbelt ReportDocument29 pagesEPIA Sunbelt ReportFélix Arroyo WoessnerNo ratings yet

- A Study of The Colors of Contamination in Used OilsDocument11 pagesA Study of The Colors of Contamination in Used OilsВалерия КорнееваNo ratings yet

- LR NGCC FR 20110325 PDFDocument167 pagesLR NGCC FR 20110325 PDFAlex TopNo ratings yet

- Steam Turbine Code TypesDocument140 pagesSteam Turbine Code Typesfreehandbook286% (7)

- A Tutorial On Power Generation From Thermal Power PlantsDocument326 pagesA Tutorial On Power Generation From Thermal Power Plantslaloo01No ratings yet

- Shell Turbo Family BrochureDocument4 pagesShell Turbo Family BrochureLuqman Cuopreakt'zNo ratings yet

- Final Criteria - Jps 2019-2024 Rate Review ProcessDocument137 pagesFinal Criteria - Jps 2019-2024 Rate Review Processcsf571No ratings yet

- BEMCO's Commitment to Quality and Project ExcellenceDocument19 pagesBEMCO's Commitment to Quality and Project ExcellenceVenkatesh LakshminarayananNo ratings yet

- Mohammad Shoaibul HaqueDocument4 pagesMohammad Shoaibul HaqueIshtiak KabirNo ratings yet

- Various Applications of High-Efficiency H-25 Gas TurbineDocument6 pagesVarious Applications of High-Efficiency H-25 Gas Turbinehar keramasanNo ratings yet

- 1 1 PDFDocument74 pages1 1 PDFAbigor45No ratings yet

- Gas Turbine Power GenerationDocument4 pagesGas Turbine Power GenerationEdzwan RedzaNo ratings yet

- Topping and Bottoming Cycle PlantDocument26 pagesTopping and Bottoming Cycle PlantRaghav patelNo ratings yet

- Gas Turbine Training MaterialDocument141 pagesGas Turbine Training MaterialVikas Yerramsetty100% (9)

- Wingd X DF Power Plant SolutionDocument16 pagesWingd X DF Power Plant Solutionthomas pierreNo ratings yet

- Combined Cycle Power Plant Generates Electricity Using Gas & Steam TurbinesDocument13 pagesCombined Cycle Power Plant Generates Electricity Using Gas & Steam TurbinesPrashant KumarNo ratings yet

- Nuovo Pignone Gas Turbines GuideDocument47 pagesNuovo Pignone Gas Turbines Guideabraham lovera100% (1)

- Heavy-Duty Gas Turbine Calculation Program: TrainingDocument40 pagesHeavy-Duty Gas Turbine Calculation Program: Trainingbiranchi satapathyNo ratings yet

- Marine Power Plants PDFDocument55 pagesMarine Power Plants PDFaleksandar_djordjic100% (7)

- Design and Analysis of Fire Tube Boiler With Heat Flow AnalysisDocument3 pagesDesign and Analysis of Fire Tube Boiler With Heat Flow Analysisbez100% (1)

- Topping & Bottoming CycleDocument28 pagesTopping & Bottoming CycleNadeem TanwariNo ratings yet

- Futtsu Thermal Power StationDocument18 pagesFuttsu Thermal Power StationJOVAN HILMANSYAHNo ratings yet

- 500MW San Lorenzo CCGT Power PlantDocument3 pages500MW San Lorenzo CCGT Power PlantChristian Denric CosinasNo ratings yet

- Gas TurbineDocument31 pagesGas TurbineŞansal Dikmener100% (1)