Professional Documents

Culture Documents

HSS86 2-Phase Hybrid Stepper Servo Driver

HSS86 2-Phase Hybrid Stepper Servo Driver

Uploaded by

dreman13Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSS86 2-Phase Hybrid Stepper Servo Driver

HSS86 2-Phase Hybrid Stepper Servo Driver

Uploaded by

dreman13Copyright:

Available Formats

HSS86

2-Phase Hybrid Stepper Servo Driver

1. Instruction

1.1 Overview

HSS86 is 2 phase nema 34 series hybrid stepper servo driver. It adopts new generation 32 bit DSP and vector control technology,

which can avoid the stepper motor losing steps and ensure the accuracy of the motor. The torque reducing is much lower than open

loop stepper motor when it is at higher speed. The high speed performance and torque are enhanced in a great extent. Meanwhile

the current control is based on the load, that can reduce the motor temperature ri

sing effectively, then can extend the using life of the motor. The build-in place in position and alarm output signal can help the

upper monitor to monitor and control. The function of position ultra difference alarm can ensure the machine work safely. The

closed loop system is an ideal improvement and a good replacement of open loop system, Besides that, it also have some function

of AC servo motors, but price is just half of AC servo.

1.2 Features

1.2.1 Stepper motor closed loop system, never lose step.

1.2.2 Improve motor output torque and working speed.

1.2.3 Automatic current adjustment based on load, lower temperature rising.

1.2.4 Suitable for all mechanical load conditions (include low rigidity belt pulley and wheel), no need to adjust gain parameter.

1.2.5 Motor work smoothly and low vibration, high dynamic performance at acceleration and deceleration.

1.2.6 No vibration from high speed to zero speed

1.2.7 Drive nema 34 series closed loop stepper motor.

1.2.8 Pulses response frequency can reach 200KHZ

1.2.9 16 kinds microsteps choice, highest 51200microsteps/rev.

1.2.10 Voltage range: AC24~70V or DC30V~100V

1.2.11 Over-current, over-voltage and position ultra difference protection function.

1.3 Applications

Closed loop stepper system can be applied to all kinds small automatic equipment and instrument. Such as engraving machine,

special industrial sewing machine, stripping machine, marking machine, cutting machine, laser phototypesetting, graph plotter, cnc

machine, automatic assembly equipment and so on.

2. Electrical, mechanical, environment Parameter

2.1 Electrical Parameter

Voltage range AC24~70V or DC30~100V

Peak current Peak 8.0A(current change according to load)

Logic input current 7~20mA

frequency 0~200KHz

Suitable motor 86HSE118,86HSE82

Encoder lines 1000

Insulation resistance >=500MΩ

2.2 Environment Parameter

Cooling method Natural or radiator

Operating environment Operating Occasions try to avoid dust, oil, corrosion gas

Operating temprature 0~50℃

Operating humidit 40~90%RH

virbration 5.9m/s2Max

Storage temperature 0~50℃

Weight 560g

2.3 Installation Dimension

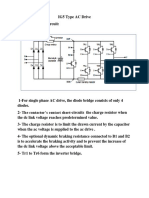

3. Driver connector, indicator and wiring diagram

3.1 motor and power supply input port

Port NO. Motor Wire color

1 A+ A phase winding + red

2 A- A phase winding - green

3 B+ B phase winding + yellow

4 B- A phase winding - blue

5 AC1 Input voltage AC24~70V or DC30~100V

6 AC2

3. 2. Encoder input port

Port NO. Encoder Wire color

1 EB+ Encoder B phase input+ yellow

2 EB- Encoder B phase input- green

3 EA+ Encoder A phase input+ black

4 EA- Encoder A phase input- blue

5 VCC Encoder voltage(+5V) red

6 EGND Encoder Grand(0V) white

(The encoder wires disconnected will lead to the damage of driver or encoder.)

3.3. Signal controller port

Port NO.

1 PUL+ Pulse input + If the signal control voltage is +5V, then the signal

control input port do not need to connect an extra

2 PUL- Pulse input -

resistance. If the signal control voltage is +12V, then

the signal control input port need to connect to a 1K

3 DIR+ Direction input +

resistance. If the signal control voltage is +12V, then

4 DIR- Direction input - the signal control input port need to connect to a 2K

resistance.

5 ENA+ Enable input +

6 ENA- Enable input -

7 Pend+ Position signal output+ OC output, closed indicate finish the position, open

circuit indicate position is not finished.

8 Pend- Position signal output-

9 ALM+ Alarm signal output+ OC output, there is alarm signal when closed, no

alarm signal when open circuit.

10 ALM- Alarm signal output+

3.4. Switch setting

SW1:The choice of the motor. ON--86HSE118,OFF—86HSE82.

SW2:Rotate direction setting. ON--CW,OF—CCW。

SW3、SW4、SW5、SW6:Microstep setting

Micorstep/rev SW3 SW4 SW5 SW6

Default(400) ON ON ON ON

800 OFF ON ON ON

1600 ON OFF ON ON

3200 OFF OFF ON ON

6400 ON ON OFF ON

12800 OFF ON OFF ON

25600 ON OFF OFF ON

51200 OFF OFF OFF ON

1000 ON ON ON OFF

2000 OFF ON ON OFF

4000 ON OFF ON OFF

5000 OFF OFF ON OFF

8000 ON ON OFF OFF

10000 OFF ON OFF OFF

20000 ON OFF OFF OFF

40000 OFF OFF OFF OFF

3.5.Status indication

PWR:power indicator light : When power is on, the green light is on.

ALM:Alarm indicator light: If the red light is flicker one time within 3 seconds, that means over current or interphase short circuit;

If the red light is flicker twice within 3 seconds, that means over voltage;

if the red light is flicker three times within 3 seconds, that means position ultra difference .

3.6.Wire diagram

HSS86

+5V

PUL+ R 1 4

EB- yellow

PUL- 2 3

EB- green

DIR+ R 1 4

EA+ black

encoder

DIR- 2 3

ENA+ R

EA- blue

1 4

VCC red

controller ENA- 2 3

EGND white

Pend+ 4 1

Pend- 3 2

A+ red

ALM+ 1

4

A- green motor

ALM- 3 2 B+ yellow

Power supply B- blue

AC24~70V

AC1

or DC30~100V AC2

You might also like

- RYC TB6600-T4 ManualDocument3 pagesRYC TB6600-T4 ManualFernando Queiroz100% (1)

- Continuity & Insulation Resistance Test - CablesDocument8 pagesContinuity & Insulation Resistance Test - Cablesamer_arauf85% (20)

- Easy Servo Driver JK-HSD86Document7 pagesEasy Servo Driver JK-HSD86Renato KristićNo ratings yet

- Invt gd100 User ManualDocument111 pagesInvt gd100 User ManualRaison Automation0% (2)

- TB6600 User Guide V1.2Document11 pagesTB6600 User Guide V1.2apic20No ratings yet

- Dq420ma English PDFDocument6 pagesDq420ma English PDFAnderson RovaniNo ratings yet

- Electronic Governor For HEP Operation Manual, Schematic & Wiring DiagramsDocument40 pagesElectronic Governor For HEP Operation Manual, Schematic & Wiring DiagramsPritam Singh100% (4)

- Braking Resistor For FRENIC-Lift - ECOMSADocument5 pagesBraking Resistor For FRENIC-Lift - ECOMSAsd23100% (1)

- Differential Protection HistoryDocument7 pagesDifferential Protection HistoryRitish Amal100% (1)

- HSS60Document6 pagesHSS60Abraham GutierrezNo ratings yet

- Servo Stepper Driver UK 2 HSS86Document7 pagesServo Stepper Driver UK 2 HSS86Mimo AbduNo ratings yet

- HBS86H Hybrid Stepper Servo Drive ManualDocument22 pagesHBS86H Hybrid Stepper Servo Drive ManualPhúc Phan TiếnNo ratings yet

- 2dm2280 Digital Step DriverDocument22 pages2dm2280 Digital Step DrivermuhammedasifNo ratings yet

- TB6600 User GuideDocument11 pagesTB6600 User GuideRudyardo MartinezNo ratings yet

- Dq2611m ManualDocument7 pagesDq2611m ManualTawanda MandazaNo ratings yet

- AP358 DatasheetDocument13 pagesAP358 DatasheetRafael OliveiraNo ratings yet

- HBS57 Closed Loop Driver Instructions: 1. FeaturesDocument6 pagesHBS57 Closed Loop Driver Instructions: 1. Featuresbayu ajiNo ratings yet

- Stepper Driver Spec. of FMDD50D40NOM (FUYU)Document5 pagesStepper Driver Spec. of FMDD50D40NOM (FUYU)Ronald SalloNo ratings yet

- Lcda 608s Digital DC Servo ManualDocument22 pagesLcda 608s Digital DC Servo ManualHoàng NguyễnNo ratings yet

- Operation Manual of EX9065 65A 65B Series 20161004 FinalDocument37 pagesOperation Manual of EX9065 65A 65B Series 20161004 FinalphachayoNo ratings yet

- New Step Servo Driver-DL86H Manual: CatalogDocument7 pagesNew Step Servo Driver-DL86H Manual: CatalogKacper GorajNo ratings yet

- DQ542MA English Manual PDFDocument6 pagesDQ542MA English Manual PDFSteven MillerNo ratings yet

- Instruction Manual PDFDocument10 pagesInstruction Manual PDFАнгел МиладиновNo ratings yet

- TB6500 ManualDocument11 pagesTB6500 ManualEnrique BautistaNo ratings yet

- TB6600 User Guide V1.2Document11 pagesTB6600 User Guide V1.2Anonymous gdJiDHNo ratings yet

- Manual Driver de CorrientrDocument8 pagesManual Driver de CorrientrRonald Sarzuri VargasNo ratings yet

- TB6600 Stepper Motor Driver BM3D v1.1Document8 pagesTB6600 Stepper Motor Driver BM3D v1.1cristian_floric5702No ratings yet

- 12-Tapgggered Roller BearingsDocument20 pages12-Tapgggered Roller BearingsRafik Mohamed AlhajiNo ratings yet

- Monolithic IC MM1089: Sensor AmplifierDocument9 pagesMonolithic IC MM1089: Sensor AmplifierBenny AlconnNo ratings yet

- TB6600 UpgradeDocument3 pagesTB6600 UpgradeGiuliano Alves SantanaNo ratings yet

- Driver ZDM-2HA865 Manual SpecificationDocument10 pagesDriver ZDM-2HA865 Manual SpecificationEvan HaasjesNo ratings yet

- T6 Servo Quick StartDocument18 pagesT6 Servo Quick StartmNo ratings yet

- User'S Manual: Ipower SeriesDocument20 pagesUser'S Manual: Ipower SeriesSilvio SantosNo ratings yet

- 中文 English Deutsch Pусский язык: Home Page About us Products News Services Contact usDocument15 pages中文 English Deutsch Pусский язык: Home Page About us Products News Services Contact usHOLDORFNo ratings yet

- JDSM2505M DatasheetDocument20 pagesJDSM2505M DatasheetArmando SandersNo ratings yet

- PV PanelDocument17 pagesPV PanelMuhammad RiazNo ratings yet

- Transmisor de Temperatura Omegaette TXDIN70Document8 pagesTransmisor de Temperatura Omegaette TXDIN70Josue ConstenlaNo ratings yet

- VDB3722MA Driver With Microstep Série NovaDocument16 pagesVDB3722MA Driver With Microstep Série NovaJefferson Alcantara GomesNo ratings yet

- Lect 4 PDFDocument14 pagesLect 4 PDFSaif AlabdullahNo ratings yet

- Manual: Digital Stepper DriveDocument23 pagesManual: Digital Stepper Driverenato vitaliNo ratings yet

- 2HSS57 KH XX - JMC Nema 57 Closed Loop Stepper Driver Eng 451294Document23 pages2HSS57 KH XX - JMC Nema 57 Closed Loop Stepper Driver Eng 451294Ardiansyah AndryNo ratings yet

- Altivar 61 - ATV61HC13N4Document5 pagesAltivar 61 - ATV61HC13N4muhammad sholeh0% (1)

- SD-2H086MB User ManualDocument10 pagesSD-2H086MB User ManualJohn MiltonNo ratings yet

- Stepper Motor 23HS45 For GrinderDocument5 pagesStepper Motor 23HS45 For GrindercendrezNo ratings yet

- Huong Dan REC DPR2700Document16 pagesHuong Dan REC DPR2700Chim ConNo ratings yet

- Smartcon 4000Document20 pagesSmartcon 4000செல்வமாரியப்பன் சீனிவாசன்No ratings yet

- TSXCTY4ADocument7 pagesTSXCTY4Att cheneyNo ratings yet

- DQ860MA EnglishDocument16 pagesDQ860MA Englishnicolascarlao notareNo ratings yet

- API DC Input SplittersDocument6 pagesAPI DC Input SplittersAnonymous zdCUbW8HfNo ratings yet

- TCS7191B: General Description FeaturesDocument14 pagesTCS7191B: General Description FeaturesJesus SanchezNo ratings yet

- Dq860ma PDFDocument7 pagesDq860ma PDFTrentoNo ratings yet

- Ulv602 UtcDocument6 pagesUlv602 Utcruslan futkaradzeNo ratings yet

- Model No.: SC + R9: RF 2.4G RGB/RGBW LED SPI Controller SetDocument4 pagesModel No.: SC + R9: RF 2.4G RGB/RGBW LED SPI Controller SetkujaautumnNo ratings yet

- DVC700 Series Programmable System Controller DVC710 DVC710LC Programmed With HCT's Intella Software Suite™Document8 pagesDVC700 Series Programmable System Controller DVC710 DVC710LC Programmed With HCT's Intella Software Suite™Derik Carela DiazNo ratings yet

- Op Amp PresentationDocument23 pagesOp Amp Presentationboomadev6321No ratings yet

- GD200A Manual EnglishDocument269 pagesGD200A Manual Englishtran dieuNo ratings yet

- SJ100 QRG NB5821XDDocument24 pagesSJ100 QRG NB5821XDFiq GanuNo ratings yet

- VACON DRIVE Local Remote Application ManualDocument52 pagesVACON DRIVE Local Remote Application ManualRodrigoNo ratings yet

- 170C Electric Steering Motor User ManualDocument20 pages170C Electric Steering Motor User ManualDavid FernándezNo ratings yet

- 84-NJM2624AD Motor Aire AcondicionadoDocument8 pages84-NJM2624AD Motor Aire AcondicionadonorbertoNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Real Time Clock Timer Relay.: User ManualDocument4 pagesReal Time Clock Timer Relay.: User ManualRafik Mohamed AlhajiNo ratings yet

- Installation Guide: Safety WarningDocument1 pageInstallation Guide: Safety WarningRafik Mohamed AlhajiNo ratings yet

- Het01 User Guide: Safety WarningDocument2 pagesHet01 User Guide: Safety WarningRafik Mohamed AlhajiNo ratings yet

- 12-Tapgggered Roller BearingsDocument20 pages12-Tapgggered Roller BearingsRafik Mohamed AlhajiNo ratings yet

- Magnabend 2500E Quote PDFDocument1 pageMagnabend 2500E Quote PDFRafik Mohamed AlhajiNo ratings yet

- Myplasmcnc enDocument16 pagesMyplasmcnc enRafik Mohamed AlhajiNo ratings yet

- LS600-305 JZJ-190225 PDFDocument7 pagesLS600-305 JZJ-190225 PDFRafik Mohamed AlhajiNo ratings yet

- The MK.2 DIY Sheet Metal Self-Loading Pistol (ProfessorParabellum) PDFDocument26 pagesThe MK.2 DIY Sheet Metal Self-Loading Pistol (ProfessorParabellum) PDFRafik Mohamed AlhajiNo ratings yet

- ZK Motion User ManualDocument33 pagesZK Motion User ManualRafik Mohamed Alhaji100% (1)

- SteelDesign Torsion Fu NewDocument6 pagesSteelDesign Torsion Fu NewRafik Mohamed AlhajiNo ratings yet

- Cut 65Cnc: Modern, Effective, Industrial Plasma CutterDocument2 pagesCut 65Cnc: Modern, Effective, Industrial Plasma CutterRafik Mohamed AlhajiNo ratings yet

- Sabm SX (500-205) ElectricalDocument10 pagesSabm SX (500-205) ElectricalRafik Mohamed AlhajiNo ratings yet

- Magnabend BrochureDocument1 pageMagnabend BrochureRafik Mohamed AlhajiNo ratings yet

- Cut 65Cnc: Modern, Effective, Industrial Plasma CutterDocument2 pagesCut 65Cnc: Modern, Effective, Industrial Plasma CutterRafik Mohamed AlhajiNo ratings yet

- Avc118 ADocument27 pagesAvc118 ARafik Mohamed AlhajiNo ratings yet

- PlasmaOxy Operators ManualDocument31 pagesPlasmaOxy Operators ManualRafik Mohamed AlhajiNo ratings yet

- Controlled RectifiersDocument78 pagesControlled RectifiersAnonymous TJRX7CNo ratings yet

- Est Module: 1Document8 pagesEst Module: 1YisobiNo ratings yet

- Lecture.7electronic Circuits 2Document17 pagesLecture.7electronic Circuits 2eafc2444No ratings yet

- Catalogo RWGDocument8 pagesCatalogo RWGFolpoNo ratings yet

- BS88 PDFDocument10 pagesBS88 PDFashley_moseley1918No ratings yet

- 5.0 - P34x - EN TDS - E22 PDFDocument56 pages5.0 - P34x - EN TDS - E22 PDFDiana Vanessa VelCruzNo ratings yet

- V02D1220X3K1-0000-1-QuickPrint OEM - Spike RK Introduction F 2 - BH CheckedDocument10 pagesV02D1220X3K1-0000-1-QuickPrint OEM - Spike RK Introduction F 2 - BH CheckedBrian HuynhNo ratings yet

- Eaton PRC Lighting Control Design Guide Dg144001enDocument42 pagesEaton PRC Lighting Control Design Guide Dg144001enBrian PompeiNo ratings yet

- Ar2 Doc 002 0004 00 PV Inverter Sizing Study Rev BDocument4 pagesAr2 Doc 002 0004 00 PV Inverter Sizing Study Rev BmbnuguidNo ratings yet

- SubstationDocument2 pagesSubstationfahamida joyaNo ratings yet

- AC MotorsDocument52 pagesAC Motorsjennybunnyomg50% (6)

- Designing of MOS Transistors in Two Stage OTA With Miller CompensationDocument7 pagesDesigning of MOS Transistors in Two Stage OTA With Miller CompensationjitendraNo ratings yet

- TRIO-TM-50.0 60.0 BCD.00658 EN RevGDocument4 pagesTRIO-TM-50.0 60.0 BCD.00658 EN RevG'Julius OrpiaNo ratings yet

- Yageo 2010Document8 pagesYageo 2010andreiblinduNo ratings yet

- Dar & Gib Dar LockoutDocument2 pagesDar & Gib Dar Lockoutcaroline_young3682No ratings yet

- Masterseal Plus CatalogueDocument8 pagesMasterseal Plus CataloguePeter ManNo ratings yet

- Electrical Drive Systems 324: OvervievDocument12 pagesElectrical Drive Systems 324: OvervievJovenlou BihagNo ratings yet

- Animal JpegDocument189 pagesAnimal Jpegglennell castillanoNo ratings yet

- Open Neturals OctFAI2013Document6 pagesOpen Neturals OctFAI2013david23281dNo ratings yet

- P94-6009 Harness 379Document11 pagesP94-6009 Harness 379Keith Vest83% (6)

- CA3046Document6 pagesCA3046erdem10139No ratings yet

- MJ1000-Motorola IncDocument4 pagesMJ1000-Motorola IncFrancisco DiazNo ratings yet

- E1 1a Example StringDocument1 pageE1 1a Example StringSAEL SOLARNo ratings yet

- F600 Low Pass Filter Kit Assembly InstructionsDocument4 pagesF600 Low Pass Filter Kit Assembly InstructionsmanuelNo ratings yet

- STS - (3000K, 6000K) - H1 Smart Transformer Station Installation Guide (Malaysia, BGMC)Document79 pagesSTS - (3000K, 6000K) - H1 Smart Transformer Station Installation Guide (Malaysia, BGMC)Miguel Bejarano PrudencioNo ratings yet

- Field-Wireable Connectors: Your Global Automation PartnerDocument19 pagesField-Wireable Connectors: Your Global Automation Partners doraiNo ratings yet