Professional Documents

Culture Documents

(4.2) HM Manual

Uploaded by

Gỗ MộcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

(4.2) HM Manual

Uploaded by

Gỗ MộcCopyright:

Available Formats

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4. Type ‘HM’ Heavy Duty Slurry Pump Range

4.2 Type HM (hard metal) Slurry Pumps

4.2.1 Product Description

4.2.2 Technical Information

4.2.3 General Arrangement

4.2.4 Tombstone Charts

4.2.5 Performance Curves

4.2.6 Spare Parts

4.0 JLN 09-W23 Edition 8 Page 1/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4. TYPE HM HEAVY DUTY SLURRY PUMP RANGES

The Metso HM Heavy-duty Metal slurry pump range is designed for the toughest pumping

applications. The excellent hydraulic design, with extra thick sections at known points of wear

and the high aspect ratio impeller ensures excellent performance with long wear life.

The modular design technology allows optimum pump and material selection. Pumps can

operate at high efficiency points, thereby reducing both the rate of wear and power

consumed.

The Interchangeability of spares, including material options, ensures minimum stock levels.

TYPICAL PUMP DESIGNATION

HM 100

Pump Range: HM Metal Inlet Size (mm)

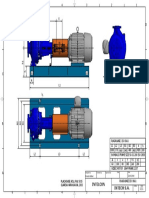

4.2 TYPE “HM” (HEAVY-DUTY METAL) SLURRY PUMP

There are two different frame versions of the HM range of pumps.

Outlet Flange

Shaft Seal Wet End

Bearing Assembly

Shaft

Inlet Flange

Double Adjustment Frame Casing Support

Typical cross sectional view of an HM pump with double adjustment frame.

4.0 JLN 09-W23 Edition 8 Page 2/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Outlet Flange

Bearing Assembly Shaft Seal Wet End

Shaft

Inlet Flange

Single Adjustment Frame

Typical cross sectional view of an HM pump with single adjustment frame.

4.2.1 PRODUCT DESCRIPTION

Details of design features:

Bearing Assembly

The robust steel shaft is carried in grease lubricated oversized adjustable taper roller

bearings in a self-contained cartridge assembly. The cartridge, itself, is housed in a heavy

duty bearing frame and is easily replaced with a minimum of down-time.

Grease Nipple

Taper Roller Bearing

Primary Seal Primary Seal

Shaft Shaft Spacer

DRY END WET END

Secondary Seal Secondary Seal

End Cover Bearing Cylinder Housing End Cover

4.0 JLN 09-W23 Edition 8 Page 3/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Standard Bearing Assembly

Used on all standard pump applications.

Bearing Spacer, Inner

Grease Nipple

Taper Roller Bearing

Primary Seal Primary Seal

Shaft Shaft Spacer

DRY END WET END

Secondary Seal Secondary Seal

End Cover Bearing Spacer, Outer End Cover

Bearing Cylinder Housing

Double Wet End Bearing Assembly used on shafts with high radial loads

Typically, high radial loads are created when pumps are used on installations with high head

and low flow applications.

Bearing Spacer, Inner

Grease Nipple

Taper Roller Bearing

Primary Seal Primary Seal

Shaft Shaft Spacer

DRY END WET END

Secondary Seal Secondary Seal

End Cover Bearing Spacer, Outer End Cover

Bearing Cylinder Housing

Double Dry End Bearing Assembly used on shafts with high axial loads

Typically, high axial loads are created when pumps are used in multi-stage (series pumping)

applications.

4.0 JLN 09-W23 Edition 8 Page 4/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Optional Metric Bearing Assembly for Single Adjust Pumps

This type of bearing assembly is specifically recommended to use for pumps to be installed

with Mechanical Slurry seal. The spherical roller bearing is fixing the shaft to avoid any axial

movement towards the mechanical seal depending on temperature variation on the shaft to

avoid axial clearance changes between the sealing rings. The spherical roller bearing does

also eliminate radial movement of the shaft which can happen with the conical roller

bearings.

4.0 JLN 09-W23 Edition 8 Page 5/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Shaft Seals

The standard pump has a primary high performance hydrodynamic expeller, which seals the

shaft dry when the pump is running. A secondary, grease lubricated, packed gland seal

prevents leakage when the pump is not running. The expeller is not used on flushed seal

assemblies.

Expeller Ring Seal

Expeller Ring

Grease Connection

Expeller

Gland Follower

Shaft Sleeve

Impeller Gasket

Shaft Sleeve Gasket

Shaft Sleeve Gasket

Packings

Lantern Ring

Standard Expeller Shaft Seal

4.0 JLN 09-W23 Edition 8 Page 6/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Optional adjustable water flushed seals are available with packing and a lantern ring, running

on a renewable High Chrome sleeve. These can be supplied as either “full flow” or “low flow”

flush.

Stuffing Box

Flush Water Connection

Gland Follower

Impeller Spacer Shaft Sleeve

Shaft Sleeve Spacer Impeller Gasket

Gland Seal

Shaft Sleeve Gasket

Lantern Ring

Packings

Stuffing Box Seal

“Full Flow” Shaft Seal Assembly

Typically, a “full flow” gland seal is used when dilution of the slurry being pumped is not

critical.

4.0 JLN 09-W23 Edition 8 Page 7/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Stuffing Box

Flush Water, IN

Gland Follower

Impeller Spacer Shaft Sleeve

Shaft Sleeve Spacer Impeller Gasket

Gland Seal

Shaft Sleeve Gasket

Lantern Ring

Packings

Flush Water, OUT Stuffing Box Seal

“Low Flow” Shaft Seal Assembly

Typically, a “low flow” gland seal is used to minimise dilution of the

Slurry being pumped. The Flush Water,OUT is for connection of flush water circulating

control device required when absolutely no water dilution of the slurry is accepted. In most

cases, when a minimal, dilution is accepted, is the connection plugged !

Various options of mechanical seals are available. You are advised to consult with the Pump

Technical Support Group on Metso Mechanical Slurry seal selection.

4.0 JLN 09-W23 Edition 8 Page 8/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Wet end

The materials used are the very best available, providing both excellent wear properties and

corrosion resistance.

The wet end comprises:

Back liner, Casing (full volute) and Impeller are all available in High Chrome, a wear

resistance chrome white iron with a hardness of 600 – 650 BHN, which can be used at pH

values down to 2.5. It is the standard material for most hard metal pump ranges.

Typical cross sectional view of an HM Pump Wet End

4.0 JLN 09-W23 Edition 8 Page 9/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Double adjustment

The total impeller wear clearance adjustment is a patented external double adjustment

feature. The procedures of closing the back and front impeller clearances permits

continuous perfomance of the pump throughout the normal wear life of all components. This

simple operation is illustrated in the two steps shown below and can be performed on an

installed pump without disassembly.

Step 1

ADJUST IMPELLER BACK-SIDE CLEARANCE.

Impeller back clearance and centrifugal seal adjustment is achieved by adjusting the screw

on the bearing cylinder housing. The bearing cylinder housing, shaft and impeller move back

in order to close the impeller back clearance.

Step 2

ADJUST IMPELLER FRONT-SIDE

CLEARANCE.

Impeller front clearance is adjusted by removal of casing half-shims and re-tightening casing

bolts. This also acts as a visual wear indicator. The entire power fame moves forward to

close the impeller front-side clearance.

4.0 JLN 09-W23 Edition 8 Page 10/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Hydraulics

The compact arrangement is of end suction design, with a thick sectioned, one piece, hard

metal volute casing providing smooth, high efficiency, hydraulic flow and minimum radial

loading. Carefully matched to the casings, the large diameter, high aspect ratio, impellers

are solids handling with back and front pump-out vanes generating minimum turbulence, low

NPSH and extended wear life.

Frame and base

The frame supports the bearing cartridge assembly, shaft seal and overhead motor mounting

(if fitted). The base supports the frame and wet end assembly.

All parts can be identified in the sectional view drawing at the front of Section 4.2.

Motor mounting

There are several options of motor mountings, these are:

Overhead, Reverse overhead, Side (left or right) for V-belt drive, and Direct in line.

Illustrations of the various types of motor mounts can be found in

Section 4.2.3 “Dimensional Drawings of Pumps”.

Inlet and outlet connections

Inlet and outlet connections are loose two-piece flanges and can be provided in either DIN or

ANSI standards, to suit customer requirements. Available outlet positions are detailed at

Section 4.2.2 - Technical data - CASING/LINER DATA.

Ease of maintenance

The casing arrangement makes maintenance extremely simple. The back pull-out feature

provides ready access to the rotating assembly without disturbing inlet and outlet

connections. Alternatively, the front pull-out feature requires the casing to be removed and

the rotating assembly can be withdrawn through the bearing frame.

4.0 JLN 09-W23 Edition 8 Page 11/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Back Pull-out Design (Double adjustment frame)

For normal routine inspection or repair, the bearing frame and rotating element can be -

removed as a unit. Impeller and gland seal component renewal can be carried out rapidly.

Front Pull-out Design

For casing only renewal, or if back pull-out is not convenient, the front pull-out feature can be

used after pipe work removal.

Summary of options

Motor mountings:

Over head, Reverse over head, Side (left or right) and Direct in line

Shaft seals:

Expeller, Full / Low flow packed gland, Mechanical Slurry Seal

Bearing assemblies:

Standard, Double wet end, Double dry end

Flanged connections and outlet positions:

Flanges to DIN or ANSI standards.

See Section 4.2.2 - Technical Data -CASING/LINERS DATA for available outlet positions

4.0 JLN 09-W23 Edition 8 Page 12/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.2 HM Technical information - KEY DIMENSIONS

PUMP SIZE HM50 HM75 HM100 HM150 HM200 HM250 HM300

INLET DIAMETER (mm) 50 75 100 150 200 250 300

OUTLET DIAMETER (mm) 32 50 75 100 150 200 250

STUFFING BOX (EXPELLER TYPE)

EXPELLER DIAMETER (mm) 175 175 210 280 346 418 580

INSIDE DIAMETER 78.3 78.3 105 127 143 162 180

DEPTH 44 44 42.5 51 55 62.8 64

PACKING SIZE (mm x mm) 9.5 9.5 11 13 14 16 16

NUMBER OF RINGS 3 3 3 3 3 3 3

WIDTH OF LANTERN RING 8.5mm 8.5mm 10mm 12mm 13mm 16mm 16mm

GREASE NIPPLE CONNECTION 1/8” 1/8” 1/8” 1/8” 1/8” 1/8” 1/8”

STUFFING BOX (WATER FLUSH GLAND

TYPE)

INSIDE DIAMETER (mm) 78.3 78.3 105 127 143 162 180

DEPTH (mm) 56 56 65 77 83 96 111.4

PACKING SIZE (mm x mm) 9.5 9.5 11 13 14 16 16

NUMBER OF RINGS 4 4 4 4 4 4 4

WIDTH OF LANTERN RING 8.5mm 8.5mm 10mm 12mm 13mm 16mm 16mm

WATER FLUSH CONNECTION ½” ½” ½” ½” ½” ½” ½”

GLAND FLOW:

LOW FLOW (L/MIN) 3 3 6.5 9 11.5 13.5 16

FULL FLOW (L/MIN) 13 13 18.5 23 28 32 36

SHAFT:

IMPELLER OVER HANG (mm) 240 248 278 322 398 452 523

IMPELLER THREAD SIZE 1¼” 7 T.P.I. 1¼” 7 T.P.I. 1¾ 5 T.P.I. 2¼” 4 T.P.I. 2½ 4 T.P.I. 3” 3.5 T.P.I. 4” 3 T.P.I.

4.0 JLN 09-W23 Edition 8 Page 13/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Pump Size HM50 HM75 HM100 HM150 HM200 HM250 HM300

Frame Size 250 250 300 400 500 600 750

Diameter between bearings 70 70 85 90 130 130 160

Distance between bearings centres 206 206 244.5 286 339.5 408 370

Diameter under shaft sleeve 47.55 47.55 63.00 75.00 95.00 111.70 120.00 Diameter at

drive end 49.95 - 49.95 - 60.00 - 70.00 - 80.00 - 100.0 - 100.0 -

49.90 49.90 59.97 69.97 79.95 99.95 99.78

Drive End Tolerance +-0.05 +-0.05 +-0.05 +-0.05 +-0.05 +-0.05 +-0.05 Drive key

size 14 x 9 mm 14 x 9 mm 18 x 11 mm 20 x 12 mm 22 x 14 mm 28 x16 mm 28 x 16 mm

Distance to allow for

back pull out feature (mm) 158 164 176 203 308 357 370

Standard Bearing Assembly

Impeller and Drive End Type: Taper Roller Taper Roller Taper Roller Taper Roller Taper Roller Taper Roller Taper Roller

No specific thrust bearing fitted

Bearing Reference: TIMKEN TIMKEN TIMKEN TIMKEN TIMKEN TIMKEN TIMKEN

Impeller End 4595/4535 4595/4535 HM212047 748S/742 861/854 938/932 HH228349

Drive End 4595/4535 4595/4535 HM212047 748S/742 861/854 938/932 HH228349

Back Pull Out Feature YES YES YES YES YES YES YES

Front Pull Out Feature YES YES YES YES YES YES YES

(with case removed) YES YES YES YES YES YES YES

Optional Metric Bearing Assembly

For Single Adjust Pumps

Impeller End Roller Bearings Spherical Spherical Spherical Spherical Spherical Spherical Spherical

Drive End Roller Bearings Cylindrical Cylindrical Cylindrical Cylindrical Cylindrical Cylindrical Cylindrical

Bearing Reference: SKF SKF SKF SKF SKF SKF SKF

Impeller End 22211E 22211E 22213E 22215E 21319E 22224E 22228CC/W33

Drive End NU221ECP NU221ECP NU2215ECP NU315ECP NU319ECP NU2224ECP NU322ECP

Impeller Release Mechanism NO NO NO YES YES YES YES

Bearing Assembly Lubrication Grease Grease Grease Grease Grease Grease Grease

4.0 JLN 09-W23 Edition 8 Page 14/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

PUMP SIZE HM50 HM75 HM100 HM150 HM200 HM250 HM300

NORMAL MAX OPERATING SPEED (RPM) 3000 3000 2600 1800 1400 1200 1000

BACK LINER YES YES YES YES YES YES YES

HARD METAL

SLIDE BASE NO NO NO OPTIONAL OPTIONAL OPTIONAL OPTIONAL

WEIGHTS: (KG)

BACK PULL OUT (EXCLUDING DRIVE, 137 148.5 238 470 902 1426 2025

GUARD, MOTOR AND MOUNTING PLATE)

BEARING/SHAFT ASSEMBLY 31 31 44 80 144 244 330

HARD METAL CASE 28 48.5 77 132 318 612 887

4.0 JLN 09-W23 Edition 8 Page 15/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.2 HM Technical information - IMPELLER DATA

PUMP SIZE HM50 HM75 HM100 HM150 HM200 HM250 HM300

FRAME SIZE 250 250 300 400 500 600 750

STANDARD PUMP IMPELLER

MATERIAL:

SEMI OPEN HIGH

CHROME

CLOSED HIGH HIGH HIGH HIGH HIGH HIGH

CHROME CHROME CHROME CHROME CHROME CHROME

INDUCED FLOW HIGH HIGH HIGH HIGH HIGH HIGH HIGH

CHROME CHROME CHROME CHROME CHROME CHROME CHROME

OTHER MATERIAL OPTIONS

SEMI OPEN YES

CLOSED YES YES YES YES YES YES

INDUCED FLOW YES YES YES YES YES YES YES

NUMBER OF VANES

SEMI OPEN 4

CLOSED 4 5 5 5 5 5

INDUCED FLOW 9 9 9 9 9 9 9

MAIN VANE DIAMETER (mm) 240 250 300 400 500 600 905

SHROUD DIAMETER (mm) 250 250 300 400 500 600 905

DIAMETER OF IMPELLER EYE (mm) N/A 81 112 162 200 264 345

CLOSED IMPELLER ONLY

DISTANCE BETWEEN SHROUDS N/A 27 36 51 75 95 105

BACK PUMP OUT VANES YES YES YES YES YES YES YES

FRONT PUMP OUT VANES N/A YES YES YES YES YES YES

4.0 JLN 09-W23 Edition 8 Page 16/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

PUMP SIZE HM50 HM75 HM100 HM150 HM200 HM250 HM300

MOMENT OF INERTIA (kg. m2)

SEMI OPEN 0.069

CLOSED — 0.108 0.242 0.904 4.490 9.00 18.225

INDUCED FLOW 0.046 0.046 0.170 0.612 2.188 6.05 13.141

MAX. PASS SPHERE THROUGH

IMPELLER

SEMI OPEN 20

CLOSED 28 36 50 69 95 105

INDUCED FLOW 34 34 31 37 66 41 68

MAX PASS SPHERE AT CUT WATER

SEMI OPEN 35

CLOSED 17 20 26 39 60 79

INDUCED FLOW 35 17 20 26 39 60 79

4.0 JLN 09-W23 Edition 8 Page 17/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.2 HM Technical information - CASING DATA

PUMP SIZE HM50 HM75 HM100 HM150 HM200 HM250 HM300

FRAME SIZE 250 250 300 400 500 600 750

Inlet Diameter (mm) 50 75 100 150 200 250 300

Outlet Diameter (mm) 32 50 75 100 150 200 250

Inlet flange 50/2” 80/3” 100/4” 150/6” 200/8” 250/10” 300/12”

DIN/ANSI

Outlet flange 32/1 ¼” 50/2” 80/3” 100/4” 150/6” 200/8” 250/10”

DIN/ANSI

Outlet Position

Top vertical

Top horizontal

Bottom horizontal

Side 45°

Top 45°

Bottom 45°

Bottom vertical

Side 36° and 72°

Top and bottom 36° and 72°

STANDARD MATERIAL HIGH HIGH HIGH HIGH HIGH HIGH HIGH

CHROME CHROME CHROME CHROME CHROME CHROME CHROME

Other Material options Yes Yes Yes Yes Yes Yes Yes

CASING MIN THICKNESS 16 20 24 27 35 40 40

Max. working pressure 18.6 18.6 15.9 15.6 15.6 15.6 15.6

(bar)

Maximum test pressure 28 28 24 23 23.5 23.5 23.5

(bar)

4.0 JLN 09-W23 Edition 8 Page 18/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Moments of Inertia (kg / m2)

This is for the shaft / expeller grease retainers, impeller and expeller basically all moving parts in the bare shaft pump.

HM Impeller

OPEN CLOSED

50 0.101

75 ---- 0.143

100 ---- 0.778

150 ---- 1.010

200 ---- 5.08

250 ---- 10.3

300 ---- 21

4.0 JLN 09-W23 Edition 8 Page 19/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.3 General arrangement

Drawing No. Drawing No.

HM50 HM200

SA502535 SA502549

201-321B 99-W40 Ed4 205-321B 99-W40 Ed4

201-331B 99-W40 Ed4 205-331B 99-W40 Ed4

201-341B 99-W40 Ed4 205-341B 99-W40 Ed4

HM75 HM250

SA502536 SA502553

202-321B 99-W40 Ed4 206-321B 99-W40 Ed4

202-331B 99-W40 Ed4 206-331B 99-W40 Ed4

202-341B 99-W40 Ed4 206-341C 00-W30 Ed5

HM100 HM300

SA502541 SA502558

203-321B 99-W40 Ed4

203-331B 99-W40 Ed4

203-341B 99-W40 Ed4

HM150

SA502545

204-321B 99-W40 Ed4

204-331B 99-W40 Ed4

204-341B 99-W40 Ed4

4.0 JLN 09-W23 Edition 8 Page 21/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Single adjustment

HM50-S SA501302 HM200-S SA501248

HM75-S SA501303 HM250-S SA501401

HM100-S SA501242 HM300-S SA501405

HM150-S SA501244

Single adjustment overhead mounted Motor

HM50-SSA502080 04-W38 Ed B HM300-S SA502157 04-W38 Ed B

SA502122 04-W38 Ed B SA502158 04-09 Rev A

SA502126 04-W38 Ed B SA502162 04-W38 Ed B

SA502163 04-09 Rev A

HM75-S SA501889 04-W38 Ed B

HG100-S 303-311B 99-W41 Ed4

SA501888 04-W38 Ed B

303-312B 99-W41 Ed4

SA502127 04-W38 Ed B

303-321B 99-W41 Ed4

303-331B 99-W41 Ed4

HM100-S SA501815 04-W38 Ed B

303-341B 99-W41 Ed4

SA501890 04-W38 Ed D

SA502322 04-W38 Ed B

HG150-S 304-311B 99-W40 Ed4

304-312B 99-W40 Ed4

HM150-S SA502138 04-W38 Ed B

304-321B 99-W40 Ed4

SA502141 04-W38 Ed B

304-331B 99-W40 Ed4

304-341B 99-W40 Ed4

HM200-S SA502144 04-W38 Ed B

SA502148 04-W38 Ed B

HG200-S 305-311B 99-W40 Ed4

305-312B 99-W40 Ed4

HM250-S SA502152 04-W38 Ed B

305-321B 99-W40 Ed4

305-331B 99-W40 Ed4

305-341B 99-W40 Ed4

4.0 JLN 09-W23 Edition 8 Page 22/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

Singel adjustment side mounted

Frame Pump Left side Right side

250 HM 50 SA505624 SA506053

HM 75 SA505625 SA506054

300 HM 100 SA505630 SA506059

400 HM 150 SA505734 SA506064

500 HG 150 SA505738 SA506068

HM 200 SA505739 SA506069

600 HG 200 SA505743 SA506073

HM 250 SA505744 SA506074

750 HM 300 SA505750 SA506080

4.0 JLN 09-W23 Edition 8 Page 23/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.4. Tombstone charts

ft m

100

300 90

80

250

HM 50 HM 75 HM 100 HM 150 HM 200 HM 250 HM 300

70

200 60

50

150

40

100 30

20

50

10

10 40 60 80 100 200 400 600 800 1000 2000 m 3/hr

50 150 200 300 500 1000 2000 4000 5000 10000 USGPM

4.0 JLN 09-W23 Edition 8 Page 24/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.5 Performance curves

SI-versions Curve No.

HM50 O4 11AAAAHCHCO4si_4

HM50 W9 11AAAAHCHCW9si_1

HM75 C4 12AAAAHCHCC4si_3

HM75 W9 12AAAAHCHCW9si_1

HM100 C5 13AAAAHCHCC5si_3

HM100 W9 13AAAAHCHCW9si_1

HM150 C5 14AAAAHCHCC5si_3

HM150 W9 14AAAAHCHCW9si_2

HM200 C5 15AAAAHCHCC5si_5

HM200 W9 15AAAAHCHCW9si_2

HM250 C5 16AAAAHCHCC5si_4

HM250 W9 16AAAAHCHCW9si_2

HM300 C5 17AAAAHCHCO5si_6

US-versions Curve No.

HM50 O4 11AAAAHCHCO4us_4

HM50 W9 11AAAAHCHCW9us_1

HM75 C4 12AAAAHCHCC4us_3

HM75 W9 12AAAAHCHCW9us_1

HM100 C5 13AAAAHCHCC5us_3

HM100 W9 13AAAAHCHCW9us_1

HM150 C5 14AAAAHCHCC5us_3

HM150 W9 14AAAAHCHCW9us_2

HM200 C5 15AAAAHCHCC5us_5

HM200 W9 15AAAAHCHCW9us_2

HM250 C5 16AAAAHCHCC5us_4

HM250 W9 16AAAAHCHCW9us_2

HM300 C5 17AAAAHCHCO5us_6

4.0 JLN 09-W23 Edition 8 Page 25/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.6 Spare Parts Double adjustment

HM50 Frame 250 SA 502233 Full Flow

SA 50223302 Low Flow

SA 50223303 Expeller

SA 50223306 ANSI Flanges Full Flow

SA 50223307 ANSI Flanges Low Flow

SA 50223308 ANSI Expeller

HM75 Frame 250 SA 502234 Full Flow

SA 50223402 Low Flow

SA 50223403 Expeller

SA 50223406 ANSI Flanges Full Flow

SA 50223407 ANSI Flanges Low Flow

SA 50223408 ANSI Expeller

HM100 Frame 300 SA 502239 Full Flow

SA 50223902 Low Flow

SA 50223903 Expeller

SA 50223906 ANSI Flanges Full Flow

SA 50223907 ANSI Flanges Low Flow

SA 50223908 ANSI Expeller

HM150 Frame 400 SA 502244 Full Flow

SA 50224402 Low Flow

SA 50224403 Expeller

SA 50224406 ANSI Flanges Full Flow

SA 50224407 ANSI Flanges Low Flow

SA 50224408 ANSI Expeller

HM200 Frame 500 SA 502249 Full Flow

SA 50224902 Low Flow

SA 50224903 Expeller

SA 50224906 ANSI Flanges Full Flow

SA 50224907 ANSI Flanges Low Flow

SA 50224908 ANSI Expeller

HM250 Frame 600 SA 502255 Full Flow

SA 50225502 Low Flow

SA 50225503 Expeller

SA 50225506 ANSI Flanges Full Flow

SA 50225507 ANSI Flanges Low Flow

SA 50225508 ANSI Expeller

HM 300 Frame 750 SA502260 Full Flow

SA50226002 Low Flow

SA50226003 Expeller

SA50226006 ANSI Flanges Full Flow

SA50226007 ANSI Flanges Low Flow

SA50226008 ANSI Expeller

4.0 JLN 09-W23 Edition 8 Page 26/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

4.2.7 Spare Parts Single Adjustment

HM50 FHC-S SA501296 PDWC1x222

LHC-S SA50129602 PDWC1x212

EHC-S SA50129603 PDWC1x412

FHC-S ANSI SA50129604 PDWC1x224

LHC-S ANSI SA50129605 PDWC1x214

EHC-S ANSI SA50129606 PDWC1x414

HM75 FHC-S SA501297 PDWC2x222

LHC-S SA50129702 PDWC2x212

EHC-S SA50129703 PDWC2x412

FHC-S ANSI SA50129704 PDWC2x224

LHC-S ANSI SA50129705 PDWC2x214

EHC-S ANSI SA50129706 PDWC2x414

MHC-S SA50129707 PDWC2x132

MHC-S SA50129708 PDWC2x134

MHC-S SA50129709 PDWC2x122

MHC-S ANSI SA50129710 PDWC2x124

HM100 FHC-S SA501235 PDWC3x222

LHC-S SA50123502 PDWC3x212

EHC-S SA50123503 PDWC3x412

FHC-S ANSI SA50123504 PDWC3x224

LHC-S ANSI SA50123505 PDWC3x214

EHC-S ANSI SA50123506 PDWC3x414

MHC-S SA50123507 PDWC3x122

MHC-S ANSI SA50123508 PDWC3x124

MHC-S SA50123509 PDWC3x132

MHC-S ANSI SA50123510 PDWC3x134

HM150 FHC-S SA501237 PDWC4x222 Rev E 08-06-25

LHC-S SA50123702 PDWC4x212 Rev E 08-06-25

EHC-S SA50123703 PDWC4x412 Rev E 08-06-25

FHC-S ANSI SA50123704 PDWC4x224 Rev C 08-06-25

LHC-S ANSI SA50123705 PDWC4x214 Rev C 08-06-25

EHC-S ANSI SA50123706 PDWC4x414 Rev C 08-06-25

HM200 FHC-S SA501241 PDWC5x222 Rev E 08-06-25

LHC-S SA50124102 PDWC5x212 Rev E 08-06-25

EHC-S SA50124103 PDWC5x412 Rev E 08-06-25

FHC-S ANSI SA50124104 PDWC5x224 Rev C 08-06-25

LHC-S ANSI SA50124105 PDWC5x214 Rev C 08-06-25

EHC-S ANSI SA50124106 PDWC5x414 Rev C 08-06-25

4.0 JLN 09-W23 Edition 8 Page 27/28

Slurry Pumps Heavy Duty Slurry

Pumps Ranges

HM250 FHC-S SA501394 PDWC6x222 Rev D

LHC-S SA50139402 PDWC6x212 Rev D

EHC-S SA50139403 PDWC6x412 Rev D

FHC-S ANSI SA50139404 PDWC6x224 Rev C

LHC-S ANSI SA50139405 PDWC6x214 Rev C

EHC-S ANSI SA50139406 PDWC6x414 Rev B

HM300 FHC-S SA501398 PDWC7x222 Rev B

LHC-S SA50139802 PDWC7x212 Rev B

EHC-S SA50139803 PDWC7x412 Rev B

FHC-S ANSI SA50139804 PDWC7x224 Rev B

LHC-S ANSI SA50139805 PDWC7x214 Rev B

EHC-S ANSI SA50139806 PDWC7x414 Rev B

4.0 JLN 09-W23 Edition 8 Page 28/28

You might also like

- TC Pump: The Total Slurry SolutionDocument4 pagesTC Pump: The Total Slurry SolutionDiego Mejia100% (1)

- 5000 Series Vertical: Centrifugal Slurry PumpsDocument4 pages5000 Series Vertical: Centrifugal Slurry PumpsROY RIVERA100% (1)

- Installation, Operation and Maintenance Manual: JANUARY 31, 2018Document31 pagesInstallation, Operation and Maintenance Manual: JANUARY 31, 2018DANIEL NICOLAS GONZALEZ SANCHEZNo ratings yet

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDocument17 pagesWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia Ranaivoarimanana100% (2)

- Bomba - Weir - Warman Horizontal Pumps PDFDocument8 pagesBomba - Weir - Warman Horizontal Pumps PDFWanderson Alcantara100% (1)

- 11.1.06 Warman Pump Shaft SealsDocument12 pages11.1.06 Warman Pump Shaft SealsMartin Calderon100% (1)

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDocument19 pagesWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Ahlstar IOM 20031215 English (Links)Document121 pagesAhlstar IOM 20031215 English (Links)Drese Chahaize100% (4)

- Catalogo Goulds PumpsDocument1,249 pagesCatalogo Goulds Pumpsleslie80% (5)

- KSB Pump Movi ManualDocument12 pagesKSB Pump Movi ManualVenkat Dora100% (3)

- Goulds 3700Document9 pagesGoulds 3700JackNo ratings yet

- Bomba Warman 3x2Document44 pagesBomba Warman 3x2Alex ContrerasNo ratings yet

- Technical Bulletin 5Document14 pagesTechnical Bulletin 5RANAIVOARIMANANANo ratings yet

- Bombas Hidrociclones ResumenDocument289 pagesBombas Hidrociclones ResumenJesus vera alvarado100% (1)

- 1-Pump Selection Guide by Goulds - Rev - PSG PDFDocument24 pages1-Pump Selection Guide by Goulds - Rev - PSG PDFMelvin MagbanuaNo ratings yet

- Sulzer MBNDocument108 pagesSulzer MBNHazem Hasan100% (2)

- Warman Slurry Pumping Manual - Jun1999 PDFDocument357 pagesWarman Slurry Pumping Manual - Jun1999 PDFHazwan HairollahNo ratings yet

- Resources Mechanical AESSEAL Guides OEMDocument147 pagesResources Mechanical AESSEAL Guides OEMhufuents-1100% (2)

- RP2 Operation Manual Version ADocument78 pagesRP2 Operation Manual Version AAndrés Rodríguez100% (1)

- Krebs Products For The Coal IndustryDocument20 pagesKrebs Products For The Coal IndustryANo ratings yet

- KSB Etanorm SYA PumpDocument24 pagesKSB Etanorm SYA Pumpsuperdave643100% (2)

- Pump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishDocument25 pagesPump Iso13709 Api610 bb3 Multistage DVMX Marelli Maintenance Manual EnglishJuan Pablo Chumba Lara100% (1)

- Heavy Duty Oil & Gas Pump SolutionsDocument6 pagesHeavy Duty Oil & Gas Pump Solutionsvrider81No ratings yet

- WI - 7 5 022 Warman Pump Tolerances - r7Document2 pagesWI - 7 5 022 Warman Pump Tolerances - r7munhNo ratings yet

- Centrifugal Pump - ACP - Manual-V2.2 - enDocument144 pagesCentrifugal Pump - ACP - Manual-V2.2 - enValter Nagamati50% (4)

- Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Document1 pageWpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1 Wpa108a05/1Gabriel Alejandro Marino EstayNo ratings yet

- Pump Performance Curve Index: 1.5/1 AH 2/1.5 AHDocument9 pagesPump Performance Curve Index: 1.5/1 AH 2/1.5 AHMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- Technical Bulletin 3Document17 pagesTechnical Bulletin 3RANAIVOARIMANANANo ratings yet

- Mechanical Seal Face MaterialsDocument19 pagesMechanical Seal Face MaterialsKamlesh Kamlesh Etwaro100% (1)

- PDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressDocument4 pagesPDF 5000 Series Vertical Pumps Elastomer Lined or All Metal Abrasion Corrosion Resistant - CompressPepe CarrNo ratings yet

- A7 PumpDocument14 pagesA7 PumpIr Go JarNo ratings yet

- PUMPDocument28 pagesPUMPRenalyn TorioNo ratings yet

- Gland PackingDocument141 pagesGland PackingAndreas SimatupangNo ratings yet

- WKF ManualDocument14 pagesWKF ManualBASK_123No ratings yet

- 1 Goulds Pumps 3196 1.5x3-8STXDocument7 pages1 Goulds Pumps 3196 1.5x3-8STXPaola moreno100% (1)

- GPS Vertical Sump Pump: Centrifugal Slurry PumpsDocument2 pagesGPS Vertical Sump Pump: Centrifugal Slurry PumpsJOKO WIKARNANo ratings yet

- Manual de Partes Bomba Vertical de Pulpa Serie Sala VASA 180-336-150-SADocument13 pagesManual de Partes Bomba Vertical de Pulpa Serie Sala VASA 180-336-150-SAIvàn Varas100% (1)

- Warman Pumps: Assembly, Operating and Maintenance InstructionsDocument20 pagesWarman Pumps: Assembly, Operating and Maintenance InstructionsMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 06-MBN Installation, operation and maintenance instruction(英文)Document92 pages06-MBN Installation, operation and maintenance instruction(英文)Muchammad Shidieq Munadzar50% (2)

- Warman Submersible Slurry Pumps GuideDocument4 pagesWarman Submersible Slurry Pumps GuideCristobal JM CreativNo ratings yet

- Centrifugal Pumps Product IntroductionDocument1 pageCentrifugal Pumps Product IntroductionFrancis Michael0% (1)

- Et PN Iso Pump Instruction Manual-OrgDocument60 pagesEt PN Iso Pump Instruction Manual-OrgSd Ver67% (12)

- Coti GIW Rep 26x28LSA PDFDocument3 pagesCoti GIW Rep 26x28LSA PDFjohan diazNo ratings yet

- Catalogo Transportadores WAMDocument202 pagesCatalogo Transportadores WAMCarlos Lourenço100% (1)

- MANUAL Slurry MAX PUMP RM150 KM04579Document61 pagesMANUAL Slurry MAX PUMP RM150 KM04579Rimbert100% (1)

- Original Spare Parts Manual ReferenceDocument104 pagesOriginal Spare Parts Manual ReferenceJorge Rivera100% (1)

- Base Plate Gould PumpDocument1 pageBase Plate Gould PumpErnestoNo ratings yet

- 5p0102ab - KSB Megachem - O&m Manual PDFDocument12 pages5p0102ab - KSB Megachem - O&m Manual PDFRishabh VermaNo ratings yet

- Warman WRT BrochureDocument8 pagesWarman WRT BrochurePaul Ticla PuenteNo ratings yet

- St Ives Gold Mine millMAX Pump Installation and Wear AnalysisDocument11 pagesSt Ives Gold Mine millMAX Pump Installation and Wear Analysissinter-musicNo ratings yet

- Sulzer Pump Operating ManualDocument65 pagesSulzer Pump Operating ManualLuisfer Mendieta100% (9)

- High-pressure multistage centrifugal pumpsDocument8 pagesHigh-pressure multistage centrifugal pumpsgaryiandersonNo ratings yet

- Hda Operational ManualDocument48 pagesHda Operational ManualDouglas DuarteNo ratings yet

- LPH 40106 - 60527 InstructionsDocument52 pagesLPH 40106 - 60527 InstructionsPítty Jonathan Jaramillo100% (1)

- Shaft Sealing OptionsDocument1 pageShaft Sealing OptionsMartin CalderonNo ratings yet

- Warman Pump Curves PDFDocument16 pagesWarman Pump Curves PDFkudanyamu100% (7)

- Unidad Hidraulica MPDocument77 pagesUnidad Hidraulica MPGustavo Nina100% (2)

- KSB Omega PumpsDocument68 pagesKSB Omega PumpsNataliaBostan50% (2)

- Bomba Weir AHDocument6 pagesBomba Weir AHDaniel BorgesNo ratings yet

- ZHONGJIA PUMP BrochureDocument36 pagesZHONGJIA PUMP BrochurePablo HurtubiaNo ratings yet

- R/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlDocument1 pageR/F - Pn16 Rating Cast Compact 'Y'-Type Strainer: Sdd/Ycp/Pn16/StlGỗ MộcNo ratings yet

- Concentric AB - HistoryDocument16 pagesConcentric AB - HistoryGỗ MộcNo ratings yet

- Fisher EWN Series and EW 1 Series Valves: Scope of ManualDocument24 pagesFisher EWN Series and EW 1 Series Valves: Scope of ManualMOUWAKILNo ratings yet

- CAV4 Manual de InstruccionesDocument28 pagesCAV4 Manual de InstruccionesGỗ MộcNo ratings yet

- DONIT ISSL-09-2017 LQ 20042018 Donit Industrial Sealing SolutionsDocument44 pagesDONIT ISSL-09-2017 LQ 20042018 Donit Industrial Sealing SolutionsLuka BornaNo ratings yet

- Mounting and Operating Instructions Electrical Position ControllerDocument44 pagesMounting and Operating Instructions Electrical Position ControllerGỗ Mộc100% (1)

- iRSVP 3100 Data Sheet.Document2 pagesiRSVP 3100 Data Sheet.Gỗ MộcNo ratings yet

- Atwood & Morrill Catalogue 2Document5 pagesAtwood & Morrill Catalogue 2Gỗ MộcNo ratings yet

- 309 Erv September-2013Document8 pages309 Erv September-2013Gỗ MộcNo ratings yet

- Wp-Content Uploads Product-Documents Global Spiral Wound Gasket BrochureDocument36 pagesWp-Content Uploads Product-Documents Global Spiral Wound Gasket Brochuremuhammad khuram usmanNo ratings yet

- Large Pneumatic Cylinder Specs and DetailsDocument8 pagesLarge Pneumatic Cylinder Specs and DetailsGỗ MộcNo ratings yet

- Product Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerDocument8 pagesProduct Name / Title Paraflow Plate Heat Exchangers: ApvheatexchangerGỗ MộcNo ratings yet

- Orion 034ES N35: Head To HeadDocument1 pageOrion 034ES N35: Head To HeadGỗ MộcNo ratings yet

- BHCN 3500 123 EBV TS 20253D 0720 EnglishDocument38 pagesBHCN 3500 123 EBV TS 20253D 0720 EnglishGỗ MộcNo ratings yet

- Furnace Wall SootblowerDocument5 pagesFurnace Wall SootblowerGỗ MộcNo ratings yet

- Series 5200: Materials of ConstructionDocument1 pageSeries 5200: Materials of ConstructionGỗ MộcNo ratings yet

- Part Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialDocument5 pagesPart Number 2875 - 2820, Tapered Roller Bearings - TS (Tapered Single) ImperialGỗ MộcNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Diamond Power IR-3Z: Furnace Wall SootblowerDocument4 pagesDiamond Power IR-3Z: Furnace Wall SootblowerGỗ MộcNo ratings yet

- Product Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Document21 pagesProduct Specification Sheet: Outlet Entry Combined Pressure Reducing & Desuperheatering Valves (PRDS)Gỗ MộcNo ratings yet

- Euro Power BrochureDocument24 pagesEuro Power BrochureGỗ MộcNo ratings yet

- X31308 Y31308 TaperedRollerBearings TS (TaperedSingle) MetricDocument5 pagesX31308 Y31308 TaperedRollerBearings TS (TaperedSingle) MetricSachin JawaleNo ratings yet

- Over 10 Million GMP Cutlass Bearings Sold WorldwideDocument4 pagesOver 10 Million GMP Cutlass Bearings Sold WorldwideGỗ MộcNo ratings yet

- Severe Duty (SD) Control ValvesDocument12 pagesSevere Duty (SD) Control ValvesGỗ MộcNo ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- Bearing Tolerances Poster 2016Document1 pageBearing Tolerances Poster 2016semarasik_651536604No ratings yet

- Ó Chi PDFDocument16 pagesÓ Chi PDFGỗ MộcNo ratings yet

- CUP-CEP Brochure PDFDocument6 pagesCUP-CEP Brochure PDFGỗ MộcNo ratings yet

- AUMA Electric Actuator (DALIAN DV Valve)Document74 pagesAUMA Electric Actuator (DALIAN DV Valve)Gỗ Mộc100% (1)

- Learning Process Focus of EducationDocument2 pagesLearning Process Focus of EducationMellani Gusdian100% (1)

- LetterDocument5 pagesLetterSameer NaveenaNo ratings yet

- BTech - Chem Engg - Course StructureDocument6 pagesBTech - Chem Engg - Course Structureramesh dasariNo ratings yet

- Dr. Lê Xuân Đ I: Functions of Several VariablesDocument35 pagesDr. Lê Xuân Đ I: Functions of Several VariablesDuong TranNo ratings yet

- Individual Assignment 2 - Article Review - Opm530Document2 pagesIndividual Assignment 2 - Article Review - Opm530Amir HafiyNo ratings yet

- BJT Mkwi4201 Bahasa InggrisDocument3 pagesBJT Mkwi4201 Bahasa Inggrisnatalia walunNo ratings yet

- Ecotourism EssayDocument2 pagesEcotourism EssayKarenNo ratings yet

- Jeann A. Gildo Bsed-Math IiiDocument3 pagesJeann A. Gildo Bsed-Math IiiJeann GildoNo ratings yet

- An Ecological Approach For Social Work PracticeDocument11 pagesAn Ecological Approach For Social Work PracticeJona MempinNo ratings yet

- Inovasi Kurikulum Berdasarkan Komponen Kurikulum Strategi Dan Evaluasi Oleh: Sri MaryatiDocument16 pagesInovasi Kurikulum Berdasarkan Komponen Kurikulum Strategi Dan Evaluasi Oleh: Sri MaryatiFitroh NailulNo ratings yet

- ch1 2Document26 pagesch1 2Yeh Chul ShinNo ratings yet

- SSC 211 ED Activity 4.1Document4 pagesSSC 211 ED Activity 4.1bernard bulloNo ratings yet

- CPCCCA3025 Self Study GuideDocument9 pagesCPCCCA3025 Self Study GuidePranay BansalNo ratings yet

- Hph203 Lecture 03-1Document38 pagesHph203 Lecture 03-1Chengetai ManyaraNo ratings yet

- 5th Weekly Exam - Plumbing ArithmeticDocument11 pages5th Weekly Exam - Plumbing ArithmeticArchie Gomocag0% (1)

- Leadership+from+the+Inside+Out Cashman EBSDocument13 pagesLeadership+from+the+Inside+Out Cashman EBSRepublik DakasakaNo ratings yet

- Greater Noida HousingDocument42 pagesGreater Noida HousingYathaarth RastogiNo ratings yet

- Percorso Ii: The Led Roadway Lighting..Document2 pagesPercorso Ii: The Led Roadway Lighting..ChangKhenNo ratings yet

- Marketing Management Case Study AssignmentDocument19 pagesMarketing Management Case Study AssignmentSZANo ratings yet

- Research in Educ 215 - LDM Group 7Document25 pagesResearch in Educ 215 - LDM Group 7J GATUSNo ratings yet

- Full Scale Tests of Heat Strengthened Glass With Ceramic FritDocument17 pagesFull Scale Tests of Heat Strengthened Glass With Ceramic FritKároly FurusNo ratings yet

- M5 - Freedom of The Human PersonDocument8 pagesM5 - Freedom of The Human PersonMarisol OtidaNo ratings yet

- Amazon Food Review Clustering Using K-Means, Agglomerative & DBSCANDocument79 pagesAmazon Food Review Clustering Using K-Means, Agglomerative & DBSCANkrishnaNo ratings yet

- Terex Operator TrainingDocument4 pagesTerex Operator TrainingJohn100% (48)

- Automatic Bus Suspension PID Controller DesignDocument50 pagesAutomatic Bus Suspension PID Controller Designchuhuynh100% (1)

- Ultra Low Dose CT Vs Chest X Ray in Non Traumatic Emergency D 2023 EClinicaDocument14 pagesUltra Low Dose CT Vs Chest X Ray in Non Traumatic Emergency D 2023 EClinicaronaldquezada038No ratings yet

- NGS QC MetricsDocument7 pagesNGS QC MetricsAgustin BernacchiaNo ratings yet

- Perret Mahindra SeminarDocument32 pagesPerret Mahindra SeminarBeowulf StarkNo ratings yet

- DRRMQ 3 W1Document44 pagesDRRMQ 3 W1Edelmar BenosaNo ratings yet

- Overview of Medicine - Its Importance and ImpactDocument9 pagesOverview of Medicine - Its Importance and ImpactDuffosNo ratings yet