Professional Documents

Culture Documents

Preparation and Dry Out Process

Uploaded by

anwar sadatOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

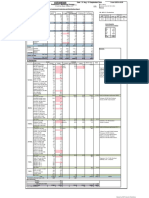

Preparation and Dry Out Process

Uploaded by

anwar sadatCopyright:

Available Formats

Preparation

• All instruments and the furnace fuel controllers have been checked

• The blinds should still be in place

• Isolate the compressors K-3001

• The reaction section is open, Remove the blinds on the "start-up" lines or intermittent use

lines (reactors by-pass lines).

• Start the reactor effluent air cooler.

• The reactor effluent trim cooler is online.

• Introduce nitrogen upstream of compressor K-3001and open the discharge.

Dry out

Start the recycle compressor K-3001 at 6-7 bar suction and circulate the nitrogen at

maximum rate through the reaction section.

Start F-3001 (reactor feed heater).

Start free water draining at all the low points and the V-3002 separator drum water

boot. While the system is heating up, check for leaks. If required, perform hot bolting

to tighten.

Raise reactor R-3001 inlet temperature up to 300deg. C maximum at 15deg. C/hr.

Hold this temperature for 24 hours. During this operation flames inside H-3001

should be observed to detect any wrong pattern and specially flame impingement.

Continue free water draining at all the low points and the V-3002 separator drum

water boot. The system is considered as dry when the amount of water drained at all

the low points is less than 1.0 ltr/h for two consecutive hours.

Decrease R-3001 reactor inlet temperature down to 150deg. C at 50deg. C/hr.

Shutdown the F-3001 heater and continue the circulation of nitrogen in reaction

section loop until R-3001 reactor temperature reaches K-3001 recycle compressor

discharge temperature.

Shutdown and isolate K-3001 recycle compressor. Depressurize the reaction section

loop and start the preparation of R-301 catalyst loading.

You might also like

- Operation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleDocument31 pagesOperation and Protection of 210 MW Turbine Condensation Extracton Pump and Condensation CycleAshish Lanjewar100% (1)

- BIT Lab Manual for Refrigeration & Air ConditioningDocument29 pagesBIT Lab Manual for Refrigeration & Air ConditioningdeepaknayanNo ratings yet

- Ac Basics 51412Document12 pagesAc Basics 51412guerrezNo ratings yet

- Cal U Mechanical Engineering Lab Experiment on Refrigeration CyclesDocument12 pagesCal U Mechanical Engineering Lab Experiment on Refrigeration CyclesMohamad FaizNo ratings yet

- Guide Spec DX Air Outdoor Condensing Unit 2 2017Document5 pagesGuide Spec DX Air Outdoor Condensing Unit 2 2017JamesNo ratings yet

- Section 1.4 - Processing Control EquipmentDocument35 pagesSection 1.4 - Processing Control EquipmentLakshman Kumar JulapalliNo ratings yet

- 4.condenser & Feed Water SystemsDocument62 pages4.condenser & Feed Water SystemsAjit Kumar100% (1)

- Fresh Water GeneratorDocument13 pagesFresh Water GeneratorPrem Cesc NathNo ratings yet

- Lab 10Document4 pagesLab 10Nashit AhmedNo ratings yet

- 803 Rac (Me-803) Exp. ManualDocument47 pages803 Rac (Me-803) Exp. ManualAnonymous z3RsdPToNo ratings yet

- CFBC Refractory Dryout Along With Atmospheric Boilout FinalDocument7 pagesCFBC Refractory Dryout Along With Atmospheric Boilout FinalpurvgargNo ratings yet

- Study performance water chillerDocument12 pagesStudy performance water chillerபிரேம் ஆனந்த்No ratings yet

- Refrigeration - Test - Rig Lab ManualDocument6 pagesRefrigeration - Test - Rig Lab ManualSandeep SainiNo ratings yet

- Maintenance Tips For Heat ExchangerDocument4 pagesMaintenance Tips For Heat ExchangerMONANo ratings yet

- Ice - Plant - Test - Rig Lab ManualDocument5 pagesIce - Plant - Test - Rig Lab ManualSandeep SainiNo ratings yet

- Commisioning Activity ReportDocument27 pagesCommisioning Activity ReportbmohmedyasinNo ratings yet

- Lab 10Document3 pagesLab 10AhmedNo ratings yet

- Condenser Performance Analysis and Its ImprovementDocument23 pagesCondenser Performance Analysis and Its Improvementanup_nair100% (1)

- CONDENSER SchemeDocument47 pagesCONDENSER SchemeAbhishek SinhaNo ratings yet

- Deaerator MDT SeriesDocument9 pagesDeaerator MDT Seriesz3kh4No ratings yet

- MAM I Revision Class PDFDocument19 pagesMAM I Revision Class PDFMalik ForbesNo ratings yet

- 3 Theoretical Basis of Cold ProductionDocument6 pages3 Theoretical Basis of Cold ProductionAnastasia FlamehostNo ratings yet

- AFA Alco Series ValveDocument3 pagesAFA Alco Series ValveRay RavelNo ratings yet

- PPT-1 For RAC Lect - GD SirDocument55 pagesPPT-1 For RAC Lect - GD SirKamal Kumar AgrawalNo ratings yet

- Refrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearDocument9 pagesRefrigeration and Air Conditioning Lab: Mansoura University Faculty of Engineering Mechanical Power Department 4 YearKhaled HakimNo ratings yet

- CONDENSEr GLDocument37 pagesCONDENSEr GLharisankar100% (1)

- hp26 Eng HandbookDocument58 pageshp26 Eng HandbookxbinfluxNo ratings yet

- Operation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.Document132 pagesOperation - Manual Sondex A/S SFD 6: Customer: Newbuilding No: Order No.: Sondex Order No.: Encl.AlexDor100% (1)

- Operating Instructions Refrigerated Air Dryers Models D-300 Through D-7500Document13 pagesOperating Instructions Refrigerated Air Dryers Models D-300 Through D-7500janessa ilaganNo ratings yet

- Airtek Dryer SC & CT40-3000 ManualDocument41 pagesAirtek Dryer SC & CT40-3000 ManualReimund_Krohn100% (8)

- 2d - Guidance On Safe Use of TelehandlersDocument5 pages2d - Guidance On Safe Use of TelehandlersmohammudpNo ratings yet

- Condensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaDocument36 pagesCondensadora Vertical Lennox 13acx de 1.5 A 5 Ton R410a 13 Seer MonofasicaJorgee RossaNo ratings yet

- Study of Single Stage Air CompressorDocument28 pagesStudy of Single Stage Air CompressorRealKimJongUnNo ratings yet

- Oxygen PlantDocument10 pagesOxygen Plantshoaib705No ratings yet

- PREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014Document6 pagesPREPARATION AND REGENERATION PROCEDURE OF REFORMER CATALYST 121211 REv 1 6 1-2014dragofloresNo ratings yet

- 5 - Condensor, GSC and Ejector in Thermal Power PlantDocument36 pages5 - Condensor, GSC and Ejector in Thermal Power PlantEshwar Pawar100% (1)

- Split AC StartupDocument5 pagesSplit AC StartupreshmaNo ratings yet

- Evans HDC Install Procedure Mack E7 Rev 02feb12Document5 pagesEvans HDC Install Procedure Mack E7 Rev 02feb12juanNo ratings yet

- Rac Lab ManualDocument69 pagesRac Lab ManualHrshita SinghNo ratings yet

- Compressor Stage-2Document24 pagesCompressor Stage-2pranay26No ratings yet

- A Report On Boiler Feed WaterDocument11 pagesA Report On Boiler Feed WaterAustin UdofiaNo ratings yet

- Internship Report MGCLDocument34 pagesInternship Report MGCLKhalil RazaNo ratings yet

- Procool Marine Air Conditioner User ManualDocument9 pagesProcool Marine Air Conditioner User ManualGabriel Alejandro Dominguez PetullaNo ratings yet

- Mine ClimateDocument16 pagesMine ClimateRehal JandialNo ratings yet

- HVAC System Operation DescriptionDocument10 pagesHVAC System Operation DescriptionMohamed Khaled Fadl DahabNo ratings yet

- Pipe Elements 1Document310 pagesPipe Elements 1Ryan Llona FernandezNo ratings yet

- Generator Hydrogen CoolingDocument31 pagesGenerator Hydrogen CoolingAshwani Dogra67% (3)

- Operation Of Boilers: Key Phases And Water Treatment StepsDocument50 pagesOperation Of Boilers: Key Phases And Water Treatment Stepstsrinivasan5083100% (1)

- Refrigeration System Components"The provided title "TITLE Refrigeration System ComponentsDocument14 pagesRefrigeration System Components"The provided title "TITLE Refrigeration System ComponentsRizwan SaeedNo ratings yet

- ME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneDocument6 pagesME-495 Laboratory Exercise Number 3 ME Dept, SDSU - KassegneJasmine_lai00No ratings yet

- DEAERATORDocument14 pagesDEAERATORHassan Faraz0% (1)

- INA3-6 HRSG Final ReportDocument30 pagesINA3-6 HRSG Final ReportgpowerpNo ratings yet

- Boiler CommissioningDocument35 pagesBoiler CommissioningNikhil MalhotraNo ratings yet

- Refrigeration Test RigDocument10 pagesRefrigeration Test Rigakshayarora1909No ratings yet

- Caleffi: Anti-Condensation ValveDocument4 pagesCaleffi: Anti-Condensation Valvedamian_m_ovidiu_7896No ratings yet

- Exp 2 Performance of A Steam Plant PDFDocument8 pagesExp 2 Performance of A Steam Plant PDFfaris_hamir33% (3)

- Aad PrasadestaDocument244 pagesAad PrasadestaIlyas Rangga Ramadhan100% (1)

- AC Mtce PaperDocument7 pagesAC Mtce PaperSudheer KalarikkalNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Dalian Deepblue Pump Co., LTDDocument2 pagesDalian Deepblue Pump Co., LTDanwar sadatNo ratings yet

- STARTUP IDEAS Rev 03Document5 pagesSTARTUP IDEAS Rev 03anwar sadatNo ratings yet

- Alternate Start Up Biography of ARLDocument7 pagesAlternate Start Up Biography of ARLanwar sadatNo ratings yet

- STARTUP IDEAS Rev 01Document6 pagesSTARTUP IDEAS Rev 01anwar sadatNo ratings yet

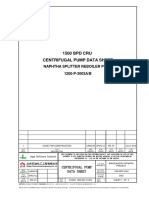

- D16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)Document3 pagesD16021.1200.RE.10-003 REV.1 Datasheet (1200-P-3003AB)anwar sadatNo ratings yet

- Offer For Aqua Refinery LTDDocument2 pagesOffer For Aqua Refinery LTDanwar sadatNo ratings yet

- DN80 DN50 20# 3 Asmeb16.5 150LB WN/RF DN100 DN50Document1 pageDN80 DN50 20# 3 Asmeb16.5 150LB WN/RF DN100 DN50anwar sadatNo ratings yet

- MLADocument2 pagesMLAanwar sadatNo ratings yet

- SE Asia TOs Technical Webinar InviteDocument1 pageSE Asia TOs Technical Webinar Inviteanwar sadatNo ratings yet

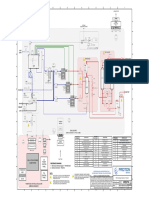

- PI For Loading System From Autower PDFDocument5 pagesPI For Loading System From Autower PDFanwar sadatNo ratings yet

- Exhaust Air Filter Options for a Gas Purification SystemDocument2 pagesExhaust Air Filter Options for a Gas Purification Systemanwar sadatNo ratings yet

- Commissioning fiber optics and accessories for outdoor multimode and single mode fiber networkDocument2 pagesCommissioning fiber optics and accessories for outdoor multimode and single mode fiber networkanwar sadatNo ratings yet

- LPG Autogas GadgetDocument15 pagesLPG Autogas GadgetShamim HadiNo ratings yet

- O&M Manual SPAC-08N-10NDocument46 pagesO&M Manual SPAC-08N-10Nanwar sadat50% (2)

- Commissioning ChecklistDocument6 pagesCommissioning Checklistanwar sadatNo ratings yet

- I. Production III. RPGCL Production Daily Gas & Condensate Production and Distribution ReportDocument1 pageI. Production III. RPGCL Production Daily Gas & Condensate Production and Distribution Reportanwar sadatNo ratings yet

- Subject: Resignation LetterDocument1 pageSubject: Resignation Letteranwar sadatNo ratings yet

- H Series 4 Installation Checklist: Read This Document Thoroughly and CarefullyDocument7 pagesH Series 4 Installation Checklist: Read This Document Thoroughly and Carefullyanwar sadatNo ratings yet

- Boosting Nitrogen purity and pressure for leak testingDocument4 pagesBoosting Nitrogen purity and pressure for leak testinganwar sadatNo ratings yet

- F56449 and F56450 Recommended Parts Per Maintenance IntervalDocument31 pagesF56449 and F56450 Recommended Parts Per Maintenance Intervalanwar sadatNo ratings yet

- " (, ,, , - )Document63 pages" (, ,, , - )OGR LegalNo ratings yet

- Parameter's Defination Regarding Life Test Report of Jiaipera CompressorDocument1 pageParameter's Defination Regarding Life Test Report of Jiaipera Compressoranwar sadatNo ratings yet

- Supplier Specification Insulation Layer: Pdmi Page 1 of 2Document2 pagesSupplier Specification Insulation Layer: Pdmi Page 1 of 2anwar sadatNo ratings yet

- Life Test Report of TT1116YLADocument8 pagesLife Test Report of TT1116YLAanwar sadatNo ratings yet

- All Links of (Posts - by Emran)Document1 pageAll Links of (Posts - by Emran)anwar sadatNo ratings yet

- Supplier Specification Hot Rolled Steel Strip: Pdmi Page 1 of 2Document2 pagesSupplier Specification Hot Rolled Steel Strip: Pdmi Page 1 of 2anwar sadatNo ratings yet

- Forwarded MessageDocument2 pagesForwarded Messageanwar sadatNo ratings yet

- GB 4706.1-2005 GB 4706.17-2010 Locked Rotor Test ReportDocument1 pageGB 4706.1-2005 GB 4706.17-2010 Locked Rotor Test Reportanwar sadatNo ratings yet

- FMDocument21 pagesFMawdhesh1213456No ratings yet

- 100 Question MechanicalDocument33 pages100 Question Mechanicalhz_hridoyNo ratings yet