Professional Documents

Culture Documents

List of Lab Equipments: Annexure - "B"

Uploaded by

manish upadhyayOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

List of Lab Equipments: Annexure - "B"

Uploaded by

manish upadhyayCopyright:

Available Formats

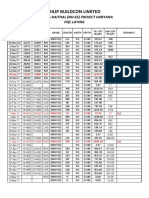

Project :- Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.

860 (Pehowa) with paved shoulder

(length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"B"

LIST OF LAB EQUIPMENTS

Sl.No Sub. NO. Description Quantity Due Date of Remark

Calibration

1 (A) FOR SOIL

(i) Liquid limit device with casagrande and ASTM grooving tools as per IS :2720 (Part-5) 1 Set 1-Aug-17

(ii) Liquid limit device ( cone penetrometer ) and plastic limit device as per IS :2720 (Part-5) 1 Set 1-Aug-17

Compaction Apparatus ( Proctor Mould ) 100mm int. dia as per IS:2720 (Part-7) complete with collar, base plate

(iii) and hammer (2.6kg 2 Set 1-Aug-17

Modified (Heavy) Compaction Apparatus ( Proctor Mould ) 150mm int. dia 127.3mm ht. as per IS:2720 (Part-8)

(iv) complete with collar, base plate and hammer (4.89X457mm fall) 2 Set 1-Aug-17

100mm dia Sand Pouring Cylinder with conical funnel and tap and complete as per IS 2720 (Part-28) 1980

(v) including modified equipment 2 Set 1-Feb-17

150mm dia Sand Pouring Cylinder with conical funnel and tap and complete as per IS 2720 (Part-28) 1980

(vi) including modified equipment 2 Set 1-Feb-17

200mm dia Sand Pouring Cylinder with conical funnel and tap and complete as per IS 2720 (Part-28) 1980

(vii) including modified equipment 2 Set 1-Feb-17

(viii) Speedy Moisture Meter complete with chemicals 4 Set 1-Aug-17

Lab CBR testing equipment for cunducting CBR testing load frame with 5 ton capacity, electrically operated with

(ix) speed control as per IS 2720 (Part-16) with all accessories. 1 Set 2-Aug-17

(a) CBR mould 150mm Dia - 175 ht. 45 Nos 2-Aug-17

(b) Tripod stand for holding dial gauge holder 3 Nos 2-Aug-17

(c) CBR plunger with settlement dial gauge holder 1 Nos 2-Aug-17

(d) Surcharge weight 147mm dia 2.5 kg wt 45 Nos 2-Aug-17

(e) Perforated Plate (Brass) 45 Nos 2-Aug-17

(f) Moisture Container (Small) 100 Nos

(f) Moisture Container (Big) 100 Nos

(g) Proving Ring - 50KN 2 Nos 18-Jul-17

(g) Proving Ring - 50KN 2 Nos 18-Jul-17

(g) Proving Ring - 50KN 1 Nos 18-Jul-17

(g) Dial Indicator - 25mm*0.01 1 Nos 18-Jul-17

2 (B) For Aggregate

(i) Aggregate Impact Value Test Appratus as per IS 2386 (Part-4) 1963 1 Set 2-Aug-17

(ii) Loss Abrasion Test Appratus as per IS 2386 (Part-4) 1963 1 Set 2-Aug-17

EPC Contractor Representative Authority's Engineer Representative

Project :- Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder

(length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"B"

LIST OF LAB EQUIPMENTS

Sl.No Sub. NO. Description Quantity Due Date of Remark

Calibration

(iii) 3 ltr, 15 ltr, 30 ltr capacity cylinder for checking bulk density of aggregate with tamping rod 1 Set 2-Feb-17

(iv) Flakiness and Elongation Gauge 2 Set 1-Aug-17

(v) Riffle Box as per ASTM C-136 1 Set 2-Aug-17

(vi) Wire Basket for bulk density test 1 Set 2-Feb-17

(vii) Sand Equivalent Appratus 1 Set 1-Aug-17

3 (C) For Bitumen and Bituminous Mixes

Constant Temperature Bath for accmodating bitumen test specimen electrically operated and thermostatically

(i) controlled 50 ltr capacity temp. range ambient 80 ͦC 1 Set 2-Aug-17

Oven-Electrically Operated thermostically controlled

(ii) ( from 0 ͦC to 220 ͦC ) 1 Nos 18-Jul-17

(iii) Penetrometer automatic type, adjustable weight arrangement and needles as per IS 1203-1978 1 Set 2-Aug-17

Electrically operated solvent extraction or centrifuge type apparatus complete (AASHTO T-164) with extraction

(iv) thimbles with stocks of solvent and filter paper. 2 Set 2-Aug-17

(v) Marshal Stability test apparatus complete with all accessories. 1 Set 2-Aug-17

(vi) Acclerated Curing water bath 1 Nos 2-Aug-17

(vii) Ring and Ball Apparatus as per 1205-1978 1 Set 2-Aug-17

(viii) Core Cutting Machine with 100mm & 150mm dia. Diamond Cutting Edge Bit 1 Set 2-Aug-17

(ix) Standard tar viscometer 1 Set 2-Aug-17

(x) Saybolt Viscometer 1 Set 2-Aug-17

(xi) Vaccum Pump and 2ltr. Capacity Glass flask 1 Set 2-Aug-17

(xii) Hot Plate 3 Nos 2-Aug-17

(xiii) Asphalt Mixer 1 Nos

4 (D) For Cement, Concrete and Materials

(i) Vicat Needle Apparatus for Setting time with plunger as per IS 269-1967 1 Nos 2-Aug-17

(ii) Soundness testing apparatus for cement, Le Chatlier moulds 2 Set 2-Aug-17

(iii) High Frequency mortor cube vibrator for cement testing 1 Set 2-Aug-17

(iv) Slump Cone with Rod 6 Set 2-Feb-17

EPC Contractor Representative Authority's Engineer Representative

Project :- Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder

(length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"B"

LIST OF LAB EQUIPMENTS

Sl.No Sub. NO. Description Quantity Due Date of Remark

Calibration

(v) Vibrating (DLC) Hammer (AIMIL TYPE) 1 Set 2-Feb-17

(vi) Compression Testing Machine 2000KN capacity 1 Nos 1-Aug-17

(vii) Concrete Cubes Moulds (150X150X150)mm 150 Nos 2-Feb-17

(viii) Concrete Cubes Moulds (100X100X100)mm 15 Nos 2-Feb-17

(ix) Concrete Cubes Moulds (70.6X70.6X70.6)mm 12 Nos 2-Feb-17

(x) Concrete Cubes Moulds (50X50X50)mm 12 Nos 2-Feb-17

(xi) Concrete Beam Moulds (150X150X700)mm 30 Nos 2-Feb-17

(xii) Flexural Testing Machine 1 Set 1-Aug-17

5 (E) General

1 Rain Gauge with rain measuring cylinder 1 Nos 2-Aug-17

2 Weight Balance

(i) 50kg capacity semi-self indicating Electronic Balance - Accuracy 5.0 gm 3 Nos 18-Jul-17

(ii) 30kg capacity semi-self indicating Electronic Balance - Accuracy 1.0 gm 3 Nos 18-Jul-17

(iii) 5kg capacity semi-self indicating Electronic Balance - Accuracy 0.1 gm 2 Nos 18-Jul-17

(iv) 600gm capacity semi-self indicating Electronic Balance - Accuracy 0.01 gm 1 Nos 18-Jul-17

(v) Platform Balance 250 kg Capacity 1 Nos 2-Aug-17

(vi) Dial gauge of 0.25mm 4 Nos 2-Aug-17

(vii) Spacer Disc 2 Nos 2-Feb-17

3 Enamel Trays

(i) 240mm X 180mm X 50mm 6 Nos 2-Feb-17

(ii) 180mm X 120mm X 40mm 6 Nos 2-Feb-17

(iii) 120mm X 100mm X 40mm 6 Nos 2-Feb-17

(iv) Circular plates of 250mm dia 15 Nos 2-Feb-17

4 Sieve as per IS-460-1962

EPC Contractor Representative Authority's Engineer Representative

Project :- Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder

(length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"B"

LIST OF LAB EQUIPMENTS

Sl.No Sub. NO. Description Quantity Due Date of Remark

Calibration

Set of IS Sieves 450mm internal dia. 75mm, 63mm, 50mm, 45mm, 40mm, 37.5mm, 31.5mm, 26.5mm, 25mm,

(i) 22.4mm, 20mm, 19mm, 16mm, 13.2mm, 12.5mm, 11.2mm, 10mm, 9.5mm, 6.3mm, 5.6mm, 4.75mm, 2.36mm 1 Set 2-Aug-17

complete with lid and pan

Set of IS Sieves 200mm internal dia. (brass frame and steel or brass wire cloth mesh) 4.75mm, 2.8mm, 2.36mm,

(ii) 2.0mm, 1.40mm, 1.0mm, 1.18mm, 900micron, 850micron, 710micron, 600micron, 425micron, 355micron, 1 Set 18-Jul-17

300micron, 180micron, 150micron, 90micron, 75micron, 45micron complete with lid and pan

5 Thermometer

(i) Glass Thermometer range 0 to 300 ͦC 3 Nos 2-Feb-17

(ii) Digital Thermometer range -50 to +300 ͦC 3 Nos 2-Feb-17

(iii) Digital Hygrometer range -50 ͦC to +100 ͦC (for Max. & Min. Temprature & Humidity Recording) 2 Nos 2-Feb-17

6 (F) Glasswares

(i) Glass Beaker 250ml capacity, Borosil 4 Nos 2-Aug-17

(ii) Glass Beaker 500ml capacity, Borosil 2 Nos 2-Aug-17

(iii) Glass Beaker 1000ml capacity, Borosil 1 Nos 2-Aug-17

(iv) Glass Measuring Cylinder, 100ml Capacity Borosil 40 Nos 2-Aug-17

(v) Glass Measuring Cylinder, 250ml Capacity Borosil 6 Nos 2-Aug-17

(vi) Glass Measuring Cylinder, 500ml Capacity Borosil 4 Nos 2-Aug-17

(vii) Glass Measuring Cylinder, 1000ml Capacity Borosil 2 Nos 2-Aug-17

(viii) Glass Pycknometer 1000ml. Capacity Borosil 3 Nos 2-Aug-17

(ix) Glass Pycknometer 500ml. Capacity Borosil 3 Nos 2-Aug-17

(x) Sp. Gravity Bottle 50ml capacity Borosil 1 Nos 2-Aug-17

(xi) Gmm Flask 2000ml Capacity Borosil 1 Nos 2-Aug-17

(xii) Sampling Pipettes fitted with pressure and suction inlets, 10ml capacity 2 Nos 2-Aug-17

(xiii) Grain Size Analysis Pipette Method, 10ml capacity complete with sedimentation tube and stand 1 Nos 2-Aug-17

EPC Contractor Representative Authority's Engineer Representative

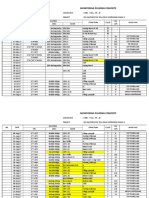

ANNEXURE - "C" -MPR FOR QUALITY CONTROL

QUALITY ASSURANCE & QUALITY CONTROL TEST REPORT WITNESSED BY AUTHORITY'S ENGINEER FOR UP TO THE MONTH OF 11 JANUARY 2016

TESTS CONDUCTED DURING CURRENT TOTAL TESTS CONDUCTED BY AE TOTAL TESTS CONDUCTED BY AE UP

NO. OF TEST TOTAL TEST UPTO PREVIOUS MONTH MONTH TOTAL TESTS UPTO THIS MONTH DURING CURRENT MONTH TO THIS MONTH

Sl. No. DESCRIPTION FREQUENCY OF TEST REQUIRED IN REMARK

CURRENT MONTH

TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED

1.0 TESTS ON BORROW AREAS FOR EMBANKMENT AND SUBGRADE/FLY ASH

1.1 FSI 1 test / 1500 mᶟ 234 234 0 0 0 0 234 234 0 0 0 0 234 234 0

1.2 GSA 1 test / 1500 mᶟ 234 234 0 0 0 0 234 234 0 0 0 0 234 234 0

1.3 LL / PL / PI 1 test / 1500 mᶟ 375 375 0 0 0 0 375 375 0 0 0 0 375 375 0

1.4 MDD / OMC 1 test / 1500 mᶟ 375 375 0 0 0 0 375 375 0 0 0 0 375 375 0

1.5 CBR Test 1 test / 3000 mᶟ 181 181 0 0 0 0 181 181 0 0 0 0 181 181 0

1.6 FDD (Emb. Layer) 1 set / 3000 m² 4805 4782 23 2430 2424 6 7235 7206 29 2430 2424 6 7235 7206 29

1.7 FDD (Sub. Layer) 1 test / 2000 m² 3044 3027 17 2180 2174 6 5224 5201 23 2180 2174 6 5224 5201 23

2.0 TESTS ON OGL SAMPLES (MCW&SR)

2.1 FSI 1 test / 250m 208 208 0 0 0 0 208 208 0 0 0 0 208 208 0

2.2 GSA 1 test / 250m 208 208 0 0 0 0 208 208 0 0 0 0 208 208 0

2.3 LL / PL / PI 1 test / 250m 206 206 0 0 0 0 206 206 0 0 0 0 206 206 0

2.4 MDD / OMC 1 test / 250m 206 206 0 0 0 0 206 206 0 0 0 0 206 206 0

2.5 CBR Test As Required 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

2.6 FDD (OGL) Min. 6 Pit 742 726 16 72 72 0 814 798 16 72 72 0 814 798 16

3.0 TESTS ON EXCAVATED SOIL

3.1 FSI 1 test / 1500 mᶟ 14 14 0 0 0 0 14 14 0 0 0 0 14 14 0

3.2 GSA 1 test / 1500 mᶟ 14 14 0 0 0 0 14 14 0 0 0 0 14 14 0

3.3 LL / PL / PI 1 test / 1500 mᶟ 14 14 0 0 0 0 14 14 0 0 0 0 14 14 0

3.4 MDD / OMC 1 test / 1500 mᶟ 14 14 0 0 0 0 14 14 0 0 0 0 14 14 0

3.5 CBR Test As Required 7 7 0 0 0 0 7 7 0 0 0 0 7 7 0

4.0 TEST ON GRANULAR SUB BASE COURSE (GSB)

4.1 GRADATION 1 test / 400 mᶟ 170 170 0 114 114 0 284 284 0 114 114 0 284 284 0

4.2 LL / PL / PI 1 test / 400 mᶟ 170 170 0 114 114 0 284 284 0 114 114 0 284 284 0

4.3 MDD / OMC 1 tset / source 12 12 0 0 0 0 12 12 0 0 0 0 12 12 0

4.4 CBR Test 1 tset / source 12 12 0 0 0 0 12 12 0 0 0 0 12 12 0

4.5 AIV As Required 15 15 0 0 0 0 15 15 0 0 0 0 15 15 0

4.6 FDD (GSB) 1 test / 1000 m² 396 396 0 312 312 0 708 708 0 312 312 0 708 708 0

5.0 TEST ON AGGREGATE BASE COURSE (WMM)

5.1 Mix Aggregate Gradation 1 test / 200 mᶟ 170 170 0 104 104 0 274 274 0 104 104 0 274 274 0

5.2 Plasticity Index 1 test / 200 mᶟ 144 144 0 104 104 0 248 248 0 104 104 0 248 248 0

5.3 AIV 1 test / 1000 mᶟ 45 45 0 35 35 0 80 80 0 35 35 0 80 80 0

5.4 MDD / OMC 1 tset / source 6 6 0 0 0 0 6 6 0 0 0 0 6 6 0

5.5 Water Absorption 1 tset / source 6 6 0 0 0 0 6 6 0 0 0 0 6 6 0

5.6 FI & EI 1 test / 500 mᶟ 77 77 0 58 58 0 135 135 0 58 58 0 135 135 0

EPC Contractor Representative Authority's Engineer Representative

ANNEXURE - "C" -MPR FOR QUALITY CONTROL

QUALITY ASSURANCE & QUALITY CONTROL TEST REPORT WITNESSED BY AUTHORITY'S ENGINEER FOR UP TO THE MONTH OF 11 JANUARY 2016

TESTS CONDUCTED DURING CURRENT TOTAL TESTS CONDUCTED BY AE TOTAL TESTS CONDUCTED BY AE UP

NO. OF TEST TOTAL TEST UPTO PREVIOUS MONTH MONTH TOTAL TESTS UPTO THIS MONTH DURING CURRENT MONTH TO THIS MONTH

Sl. No. DESCRIPTION FREQUENCY OF TEST REQUIRED IN REMARK

CURRENT MONTH

TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED

5.7 FDD (WMM) 1 test of 3 test / 1000 mᶟ 678 670 8 548 548 0 1226 1218 8 548 548 0 1226 1218 8

5.8 FDD (DLC) 1 test of 3 test / 2000 mᶟ 310 310 0 310 310 0 620 620 0 310 310 0 620 620 0

5.9 FDD (SHOULDER) 1 test / 2000 m² 234 234 0 234 234 0 468 468 0 234 234 0 468 468 0

5.10 FDD (MEDIAN) 1 test / 2000 m² 151 151 0 151 151 0 302 302 0 151 151 0 302 302 0

5.11 FDD (BACKFILLING) MIn. 3 Pit 24 24 0 24 24 0 48 48 0 24 24 0 48 48 0

6.0 FINE AGGREGATE (SAND FOR CONCRETE)

6.1 Sieve Analysis / Gradation On Daily Basis 0 0 0 32 32 0 0 0 0 32 32 0 39 39 0

6.2 Specific Gravity (SSD) As Required 0 0 0 0 0 0 0 0 0 0 0 0 34 34 0

6.3 Water Absorption / Moisture Content On Daily Basis 0 0 0 32 32 0 0 0 0 32 32 0 34 34 0

6.4 Silt Content Once in a week 0 0 0 32 32 0 0 0 0 32 32 0 24 24 0

7.0 COARSE AGGREGATE (FOR CONCRETE)

7.1 Sieve Analysis / Gradation of 10mm On Daily Basis 189 187 2 32 32 0 221 219 2 32 32 0 221 219 2

7.2 Sieve Analysis / Gradation of 20mm On Daily Basis 185 183 2 32 32 0 217 215 2 32 32 0 217 215 2

7.3 Sieve Analysis / Gradation of All in Aggregate On Daily Basis 71 71 0 32 32 0 103 103 0 32 32 0 103 103 0

7.4 Specific Gravity (3test = 1 set) As Required 34 34 0 0 0 0 34 34 0 0 0 0 34 34 0

7.5 AIV 3 test / week 79 79 0 15 15 0 94 94 0 15 15 0 94 94 0

7.6 FI & EI 3 test / week 64 64 0 15 15 0 79 79 0 15 15 0 79 79 0

7.7 Water Absorption / Moisture Content On Daily Basis 86 86 0 32 32 0 118 118 0 32 32 0 118 118 0

8.0 CEMENT

Physical Tests

8.1 Standard Consistency Test 1 test per lot 10 10 0 4 4 0 14 14 0 4 4 0 14 14 0

8.2 Soundness Test 1 test per lot 10 10 0 4 4 0 14 14 0 4 4 0 14 14 0

8.3 Intial & Final Setting Time Test 1 test per lot 10 10 0 4 4 0 14 14 0 4 4 0 14 14 0

8.4 Compressive Strength Test 1 test per lot

(i) 3 Days (Set) 18 18 0 12 12 0 30 30 0 12 12 0 30 30 0

(ii) 7 Days (Set) 18 18 0 12 12 0 30 30 0 12 12 0 30 30 0

(iii) 28 Days (Set) 18 18 0 12 12 0 30 30 0 12 12 0 30 30 0

9.0 PRIME COAT / TACK COAT

9.1 Rate of Spray (Prime Coat) 1 test / lot 36 36 0 36 36 0 72 72 0 36 36 0 72 72 0

9.2 Rate of Spray (Tack Coat) 3 test / Day 36 36 0 36 36 0 72 72 0 36 36 0 72 72 0

10.0 DENSE BITUMEN MACADAM (DBM)

10.1 Sieve Analysis 1 test for each 34 34 0 34 34 0 68 68 0 34 34 0 68 68 0

400 ton of mix & Min. 2

10.2 Bitumen Extraction & Gradation Test test / day

48 48 0 48 48 0 96 96 0 48 48 0 96 96 0

10.3 Aggregate Impact Value 1 test / 350 mᶟ 28 28 0 28 28 0 56 56 0 28 28 0 56 56 0

10.4 Comb. Flakiness & Elongation Index 1 test / 350 mᶟ 28 28 0 28 28 0 56 56 0 28 28 0 56 56 0

EPC Contractor Representative Authority's Engineer Representative

ANNEXURE - "C" -MPR FOR QUALITY CONTROL

QUALITY ASSURANCE & QUALITY CONTROL TEST REPORT WITNESSED BY AUTHORITY'S ENGINEER FOR UP TO THE MONTH OF 11 JANUARY 2016

TESTS CONDUCTED DURING CURRENT TOTAL TESTS CONDUCTED BY AE TOTAL TESTS CONDUCTED BY AE UP

NO. OF TEST TOTAL TEST UPTO PREVIOUS MONTH MONTH TOTAL TESTS UPTO THIS MONTH DURING CURRENT MONTH TO THIS MONTH

Sl. No. DESCRIPTION FREQUENCY OF TEST REQUIRED IN REMARK

CURRENT MONTH

TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED

10.5 GMM 1 test / day 14 14 0 14 14 0 28 28 0 14 14 0 28 28 0

10.6 Marshall Stability, Flow, VMA, VFB, & Air Voids 1set / 3mould 144 144 0 144 144 0 288 288 0 144 144 0 288 288 0

10.7 Drilled Core Density 1test / 700 m² 89 89 0 89 89 0 178 178 0 89 89 0 178 178 0

10.8 Sp. Gravity & Water Absorption As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.0 BITUMINOUS CONCRETE (BC)

11.1 Sieve Analysis 1 test for each 400 MT 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

400 ton of mix & Min. 2

11.2 Bitumen Extraction & Gradation Test test / day

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.3 Aggregate Impact Value 1 test / 50 mᶟ 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.4 Comb. Flakiness & Elongation Index 1 test / 50 mᶟ 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.5 Stripping Value Test 1 test / source 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.6 Marshall Stability, Flow, VMA, VFB, & Air Voids 1set / 3mould 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.7 Drilled Core Density 1test / 250 m² 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

11.8 Sp. Gravity & Water Absorption As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

12.0 BITUMEN VG-30

12.1 Penetration Grade at 25 Degree 1 test / lot 33 33 0 33 33 0 66 66 0 33 33 0 66 66 0

12.2 Softening Point 1 test / lot 33 33 0 33 33 0 66 66 0 33 33 0 66 66 0

12.3 Dutility at 27 Degree 1 test / lot 33 33 0 33 33 0 66 66 0 33 33 0 66 66 0

12.4 Viscosity 1 test / lot 33 33 0 33 33 0 66 66 0 33 33 0 66 66 0

12.5 Specific Gravity 1 test / lot 33 33 0 33 33 0 66 66 0 33 33 0 66 66 0

13.0 CONCRETE CUBE TESTING (SITE)

13.1 7 Days

(i) M-15 PCC (SET) MORT&H - Section 1700 48 48 0 16 16 0 64 64 0 16 16 0 64 64 0

(ii) M-20 PCC (SET) MORT&H - Section 1700 82 82 0 17 17 0 99 99 0 17 17 0 99 99 0

(iii) M-25 RCC (SET) MORT&H - Section 1700 7 7 0 1 1 0 8 8 0 1 1 0 8 8 0

(iv) M-30 RCC (SET) MORT&H - Section 1700 67 67 0 67 67 0 134 134 0 67 67 0 134 134 0

(v) M-35 RCC (SET) MORT&H - Section 1700 7 7 0 7 7 0 14 14 0 7 7 0 14 14 0

(vi) M-35 PILE (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(vii) M-40 RCC (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(viii) M-45 RCC (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(ix) M-20 KERB (SET) MORT&H - Section 1700 10 10 0 10 10 0 20 20 0 10 10 0 20 20 0

(x) DLC MORT&H - Section 600 104 104 0 104 104 0 208 208 0 104 104 0 208 208 0

(xI) PQC MORT&H - Section 600 198 198 0 198 198 0 396 396 0 198 198 0 396 396 0

13.2 28 Days

(i) M-15 PCC (SET) MORT&H - Section 1700 24 24 0 22 22 0 46 46 0 22 22 0 46 46 0

EPC Contractor Representative Authority's Engineer Representative

ANNEXURE - "C" -MPR FOR QUALITY CONTROL

QUALITY ASSURANCE & QUALITY CONTROL TEST REPORT WITNESSED BY AUTHORITY'S ENGINEER FOR UP TO THE MONTH OF 11 JANUARY 2016

TESTS CONDUCTED DURING CURRENT TOTAL TESTS CONDUCTED BY AE TOTAL TESTS CONDUCTED BY AE UP

NO. OF TEST TOTAL TEST UPTO PREVIOUS MONTH MONTH TOTAL TESTS UPTO THIS MONTH DURING CURRENT MONTH TO THIS MONTH

Sl. No. DESCRIPTION FREQUENCY OF TEST REQUIRED IN REMARK

CURRENT MONTH

TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED

(ii) M-20 PCC (SET) MORT&H - Section 1700 30 30 0 26 26 0 56 56 0 26 26 0 56 56 0

(iii) M-25 RCC (SET) MORT&H - Section 1700 2 2 0 2 2 0 4 4 0 2 2 0 4 4 0

(iv) M-30 RCC (SET) MORT&H - Section 1700 100 100 0 100 100 0 200 200 0 100 100 0 200 200 0

(v) M-35 RCC (SET) MORT&H - Section 1700 10 10 0 10 10 0 20 20 0 10 10 0 20 20 0

(vi) M-35 PILE (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(vii) M-40 RCC (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(viii) M-45 RCC (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(ix) M-20 KERB (SET) MORT&H - Section 1700 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(x) PQC MORT&H - Section 600 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

14.0 CONCRETE CUBE/BEAM TESTING (MIX DESIGN TRIALS)

14.1 7 Days

(i) M-15 PCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(ii) M-20 PCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(iii) M-25 RCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(iv) M-30 RCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(v) M-35 RCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(vi) M-35 PILE (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(vii) M-40 RCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(viii) M-45 RCC (SET) MORT&H - Section 1700 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

(ix) DLC MORT&H - Section 600 6 6 0 0 0 0 6 6 0 0 0 0 6 6 0

(x) PQC MORT&H - Section 600 6 6 0 0 0 0 6 6 0 0 0 0 6 6 0

14.2 28 Days

(i) M-15 PCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(ii) M-20 PCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(iii) M-25 RCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(iv) M-30 RCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(v) M-35 RCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(vi) M-35 PILE (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(vii) M-40 RCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(viii) M-45 RCC (SET) MORT&H - Section 1700 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

15.0 THIRD PARTY TESTING

12.1 Soil Testing

(i) FSI As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(ii) GSA (Silt & Clay) As Required 6 6 0 0 0 0 6 6 0 0 0 0 6 6 0

(iii) LL / PL / PI As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

EPC Contractor Representative Authority's Engineer Representative

ANNEXURE - "C" -MPR FOR QUALITY CONTROL

QUALITY ASSURANCE & QUALITY CONTROL TEST REPORT WITNESSED BY AUTHORITY'S ENGINEER FOR UP TO THE MONTH OF 11 JANUARY 2016

TESTS CONDUCTED DURING CURRENT TOTAL TESTS CONDUCTED BY AE TOTAL TESTS CONDUCTED BY AE UP

NO. OF TEST TOTAL TEST UPTO PREVIOUS MONTH MONTH TOTAL TESTS UPTO THIS MONTH DURING CURRENT MONTH TO THIS MONTH

Sl. No. DESCRIPTION FREQUENCY OF TEST REQUIRED IN REMARK

CURRENT MONTH

TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED TESTED PASSED FAILED

(iv) MDD / OMC As Required 12 12 0 6 6 0 18 18 0 6 6 0 18 18 0

(v) CBR Test As Required 12 12 0 6 6 0 18 18 0 6 6 0 18 18 0

(vi) Shrinkage Limit As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(vii) Soluble Sulphate Test As Required 8 8 0 0 0 0 8 8 0 0 0 0 8 8 0

(viii) Soil Bearing Capacity (Plate Load Test) As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

15.2 Steel

(i) 8mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(ii) 10mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(iii) 12mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(iv) 16mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(v) 20mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(vi) 25mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(vii) 32mm (3pc = 1 set) 1 test / lot 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

15.3 Aggregate

(i) Fine Aggregate As Required 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(ii) Coarse Aggregate (10mm) As Required 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(iii) Coarse Aggregate (20mm) As Required 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(iv) Coarse Aggregate (40mm) As Required 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

(v) GSB As Required 2 2 0 0 0 0 2 2 0 0 0 0 2 2 0

15.4 Cement

(i) Ultratech (OPC-43) 1 test / 500 MT 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

(ii) Shree (OPC-43) 1 test / 500 MT 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

15.5 Water As Required

15.6 Hume pipe Testing(1200mm dia) As Required 8 8 0 0 0 0 8 8 0 0 0 0 8 8 0

15.7 Hume pipe Testing(600mm dia) As Required 8 8 0 0 0 0 8 8 0 0 0 0 8 8 0

15.8 Admixture As Required 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

16.0 CALIBRATION IN-HOUSE

16.1 Batching Plant CP-30 6 Month 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

16.2 Batching Plant CP-2.50 6 Month 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

16.3 Hot Mix Plant 6 Month 1 1 0 0 0 0 1 1 0 0 0 0 1 1 0

EPC Contractor Representative Authority's Engineer Representative

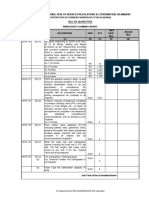

Project :- Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder (length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC

Basis.

ANNEXURE -"D"

BORROW AREA SUMMARY

FREE GSA ATTERBERGS LIMITS PROCTOR TEST

SWELL CBR AT

INDEX MDD 97 % OF

GRAVEL SAND SILT & LL PL PI OMC MDD

Sl.No BA NO. VILLAGE LOCATION SIDE CLAY USED FOR APPROVED BY AE

(%) (%) (%) (%) (%) (%) (%) (gm/cc) (%) (%)

BA No. 01 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/154 Dated

1 Fujalpur 19+250 LHS 11.98 2.15 53.45 44.4 23.09 N.P. N.P. 1.997 9.99 12.75 EMBANKMENT & SUB GRADE on 04.10.2016

( Part Quan.I )

BA No. 01 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/170 Dated

2 Fujalpur 19+250 LHS 12.75 2.15 53.12 44.74 23.88 N.P. N.P. 1.998 10.28 12.95 EMBANKMENT & SUB GRADE on 20.10.2016

( Part Quan.II )

BA No. 01 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/197 Dated

3 Fujalpur 19+250 LHS 13.62 1.12 42.45 56.43 29.10 N.P. N.P. 1.932 11.14 13.15 EMBANKMENT & SUB GRADE

( Part Quan.III ) on 21.11.2016

4 BA No. 08 Baroli 23+200 LHS 14.15 0.13 48.07 51.80 23.43 N.P. N.P. 1.947 10.43 13.73 EMBANKMENT & SUB GRADE MSV/ PRJ/ 168/ NHAI/A-K /2OL6/199 Dated

on 22.11.2016

MSV/ PRJ/ 168/ NHAI/A-K /2OL6/200 Dated

5 BA No. 09 Untsar (PB) 06+000 RHS 12.55 0.56 39.63 59.81 32.63 22.78 9.84 1.811 11.90 12.50 EMBANKMENT & SUB GRADE on 22.11.2016

MSV/ PRJ/ 168/ NHAI/A-K /2OL6/202 Dated

6 BA No. 10 Baroli 23+200 LHS 5.82 0.00 84.78 15.22 35.97 N.P. N.P. 1.675 13.32 EMBANKMENT on 23.11.2016

BA No. 11 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/188 Dated

7 Jhansa (Thol) 30+600 LHS 13.12 10.82 39.58 49.60 31.53 22.69 8.83 1.966 10.74 EMBANKMENT & SUB GRADE on 09.11.2016

( Part Quan.I )

BA No. 11 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/201 Dated

8 Jhansa (Thol) 30+600 LHS 13.19 10.33 38.66 51.01 31.43 22.37 9.06 1.962 10.70 EMBANKMENT & SUB GRADE on 22.11.2016

( Part Quan.II )

9 BA No. 12 Naise 39+600 RHS 12.48 0.72 20.92 78.36 33.64 21.47 12.18 1.884 11.39 12.5 EMBANKMENT & SUB GRADE MSV/ PRJ/ 168/ NHAI/A-K /2OL6/204 Dated

on 28.11.2016

MSV/ PRJ/ 168/ NHAI/A-K /2OL6/203 Dated

10 BA No. 13 Jalberha 43+000 LHS 13.99 0.64 29.22 70.14 33.24 23.08 10.16 1.906 11.65 9.98 EMBANKMENT & SUB GRADE on 24.11.2016

BA No. 16 MSV/ PRJ/ 168/ NHAI/A-K /2OL6/205 Dated

11 Untsar (PB) 06+000 RHS 22.54 0.00 15.22 84.78 36.80 20.74 16.07 1.861 12.26 9.90 EMBANKMENT & SUB GRADE on 28.11.2016

( Part Quan.II )

EPC Contractor Representative Authority's Engineer Representative

NATIONAL HIGHWAYS AUTHORITY OF INDIA

Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder (length 50.860 km) in the State of Haryana under NHDP Phase-III on EPC

Basis.

ANNEXURE -"E"

:

CLIENT NATIONAL HIGHWAYS AUTHORITY OF INDIA

:

AUTHORITY'S ENGINEER MSV INTERNATIONAL INC.

M/s DILIP BUILDCON LIMITED

: M/s VARAHA INFRA LIMITED (JV)

EPC CONTRACTOR

SUMMARY OF CONCRETE MIX DESIGN

Source of Coarse Aggregate :- DBL Stock (Handesra/Narayangarh) Brand of Cement :- Shree / Ultratech

Source of Fine Aggregate :- DBL Stock (Handesra/Narayangarh) Grade of Cement :- OPC-43

Source of Water :- Borewell No.1 @ Base Camp Brand of Admixture :- KUNAL Kunacon 37SS

Compressive Strength

SSD WT. kg/m³ SLUMP (mm) (N/mm²)

Sl. Date of Grade of CA : CA CA : FA Water Admixture Cement Fly-Ash Water

No. Casting Concrete

(20mm : 10mm)

% Cement (kg) (kg) (kg) (kg) Remarks

% Ratio 20mm Aggragate 10mm Aggregate Fine Aggregate

(kg) (kg) (kg) Initial 30 min. 60 min. 90 min. 7 Days 28 Days

1 1/9/2016 M:15 PCC 60:40 62:38 0.50 2.28 285 0 142.5 723 482 753 120 100 80 65 16.09 27.09 Approved

2 20/09/2016 M:20 PCC 60:40 60:40 0.50 1.95 300 0 150.0 712 474 742 120 95 80 60 21.5 33.05 Approved

3 1/9/2016 M:25 RCC 60:40 57:43 0.44 1.63 340 0 149.0 643 429 827 Collaps 190 160 100 26.06 40.00 Approved

4 15/09/2016 M:30 RCC 60:40 58:42 0.39 2.04 370 0 144.3 651 434 802 Collaps 200 170 110 30.25 43.1 Approved

5 16/09/2016 M:35 RCC 60:40 57:43 0.38 2.09 380 0 144.4 637 425 817 Collaps 200 180 120 35.5 48.2 Approved

6 17/09/2016 M:35 PILE 60:40 57:43 0.38 2.60 400 0 152.0 624 416 800 Collaps Collaps 200 160 34.09 47.21 Approved

7 13/12/2016 M:35 RE 65:35 65:35 0.40 2.66 380 0 152.0 675 547 660 Collaps 150 100 80 34.07 Approved

PANNEL

8 15/10/2016 M:40 RCC 60:40 60:40 0.36 2.48 400 0 144.0 665 443 754 180 150 120 100 40.95 53.25 Approved

9 15/10/2016 M:45 RCC 60:40 60:40 0.34 2.55 425 0 144.5 657 438 745 Collaps 180 150 120 40.6 60.12 Approved

10 20/12/2016 M:20 KERB 60:40 55:45 0.45 1.55 310 0 139.5 545 543 875 30 20 15 10 24.37 Approved

11 16/10/2016 DLC 60:40 - - - 120 30 132.0 456 788 846 - - - - 13.07 - Approved

12 16/10/2016 PQC 60:40 60:40 0.34 320 80 136.0 555 552 751 50 35 25 20 31.67 44.12 Approved

EPC Contractor Representative Authority's Engineer Representative

EPC Contractor Representative Authority's Engineer Representative

NATIONAL HIGHWAYS AUTHORITY OF INDIA

Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder (length

50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"F"

CLIENT : NATIONAL HIGHWAYS AUTHORITY OF INDIA

AUTHORITY'S ENGINEER : MSV INTERNATIONAL INC.

EPC CONTRACTOR : M/s DILIP BUILDCON LIMITED

M/s VARAHA INFRA LIMITED (JV)

DAILY WEATHER REPORT

Month : DECEMBER Year : 2016

Location of Weather Station: DBL Base Camp

TEMPARATURE HUMIDITY RAINFALL

DATE STATUS REMARK

Max. ͦC Min. ͦC Max. Min. 24hrs (mm)

1-Dec-2016 23.9 14.6 95 63 - CL S = Sunny

2-Dec-2016 24.7 15.5 86 54 - CL CL = Cloudily

3-Dec-2016 22.7 12.5 94 61 - CL R = Rainy

4-Dec-2016 22.5 11.9 90 49 - CL

5-Dec-2016 23.0 11.3 89 53 - S/CL

6-Dec-2016 21.8 11.2 90 70 - S/CL

7-Dec-2016 20.0 11.0 90 75 - S/CL

8-Dec-2016 20.0 11.1 92 77 - S/CL

9-Dec-2016 20.3 12.1 92 73 - S/CL

10-Dec-2016 20.5 13.5 90 76 - S/CL

11-Dec-2016 23.4 15.1 92 71 - CL

12-Dec-2016 22.7 14.1 92 72 - CL

13-Dec-2016 19.9 14.0 87 74 - CL

14-Dec-2016 20.0 12.8 89 68 - CL

15-Dec-2016 20.9 10.3 87 50 - CL

16-Dec-2016 20.5 10.8 89 58 - CL

17-Dec-2016 21.8 10.5 90 50 - CL

18-Dec-2016 21.6 12.1 88 44 - S/CL

19-Dec-2016 22.1 12.2 82 54 - S/CL

20-Dec-2016 22.7 10.2 85 42 - S/CL

21-Dec-2016 22.4 8.1 83 47 - S/CL

22-Dec-2016 21.2 9.8 89 63 - S/CL

23-Dec-2016 22.8 10.4 90 60 - CL

24-Dec-2016 21.9 12.2 89 65 - CL

25-Dec-2016 19.9 11.4 82 62 - S/CL

26-Dec-2016 21.1 10.2 86 52 - CL

27-Dec-2016 21.5 10.7 84 50 - S/CL

28-Dec-2016 21.9 12.7 85 55 - CL

29-Dec-2016 20.1 13.5 85 69 - S/CL

30-Dec-2016 21.4 13.1 81 59 CL

31-Dec-2016 21.2 17.7 85 61 - CL

Summary (Rain Fall In mm)

Till Previous Month (mm) During the Month (mm) Commulative (mm)

191 0 62.00

EPC Contractor's Representative Authority Engineer Representative.

NATIONAL HIGHWAYS AUTHORITY OF INDIA

Four-laning of Ambala - Kaithal Section of NH-65 from Km 0.000 (Ambala) to Km 50.860 (Pehowa) with paved shoulder (length

50.860 km) in the State of Haryana under NHDP Phase-III on EPC Basis.

ANNEXURE -"F"

CLIENT : NATIONAL HIGHWAYS AUTHORITY OF INDIA

AUTHORITY'S ENGINEER : MSV INTERNATIONAL INC.

EPC CONTRACTOR : M/s DILIP BUILDCON LIMITED

M/s VARAHA INFRA LIMITED (JV)

DAILY WEATHER REPORT

Month : JANUARY Year : 2017

Location of Weather Station: DBL Base Camp

TEMPARATURE HUMIDITY RAINFALL

DATE STATUS REMARK

Max. ͦC Min. ͦC Max. Min. 24hrs (mm)

1-Jan-2017 22.9 11.4 89 56 - CL S = Sunny

2-Jan-2017 23.1 10.9 82 51 - CL CL = Cloudily

3-Jan-2017 23.1 10.8 81 50 - CL R = Rainy

4-Jan-2017 23.3 11.1 85 59 - CL

5-Jan-2017 23.2 11.0 84 59 - S/CL

6-Jan-2017 20.5 13.5 84 71 - S/CL

7-Jan-2017 16.0 10.0 90 74 - S/CL

8-Jan-2017 19.8 10.1 90 65 - S/CL

9-Jan-2017 19.5 7.9 83 60 - S/CL

10-Jan-2017 17.4 6.7 79 47 - S/CL

11-Jan-2017 17.4 7.0 77 49 - CL

12-Jan-2017 18.1 6.8 77 52 - CL

13-Jan-2017 18.2 7.5 80 50 - CL

14-Jan-2017 18.5 7.6 81 54 - CL

15-Jan-2017 18.7 8.0 80 57 - CL

16-Jan-2017 18.2 9.0 83 64 - CL

17-Jan-2017 14.5 7.9 90 72 - CL

18-Jan-2017 17.2 7.0 85 67 - S/CL

19-Jan-2017 18.6 7.5 86 62 - S/CL

20-Jan-2017 17.9 8.0 82 66 - S/CL

21-Jan-2017 17.8 10.5 85 72 - S/CL

22-Jan-2017 21.8 11.2 83 68 - S/CL

23-Jan-2017 21.9 10.9 87 56 - CL

24-Jan-2017 20.0 12.5 86 68 - CL

25-Jan-2017 20.8 15.5 84 68 - S/CL

26-Jan-2017 16.8 13.5 88 79 - CL

27-Jan-2017 20.8 12.6 90 82 - S/CL

28-Jan-2017 18.8 12.8 88 76 - CL

29-Jan-2017 - S/CL

30-Jan-2017 CL

31-Jan-2017 - CL

Summary (Rain Fall In mm)

Till Previous Month (mm) During the Month (mm) Commulative (mm)

191 0 62.00

EPC Contractor's Representative Authority Engineer Representative.

You might also like

- List of Lab Equipments: Annexure - "B"Document13 pagesList of Lab Equipments: Annexure - "B"manish upadhyayNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- 7203-6311-MDC-030KL TankDocument34 pages7203-6311-MDC-030KL TankDarshJhaNo ratings yet

- FV22157 - Mechanical Ash Handling SystemDocument3 pagesFV22157 - Mechanical Ash Handling Systembashok20No ratings yet

- Air University Fire FightingDocument2 pagesAir University Fire FightingCE capital BuildersNo ratings yet

- Binder 1Document137 pagesBinder 1Anique Ur RehmanNo ratings yet

- Condensate StorageTank - R0 - 24march 2022Document44 pagesCondensate StorageTank - R0 - 24march 2022kpsahuNo ratings yet

- New 2. Sfe-Dst-Pip-1402-4102 DST For Globe ValveDocument4 pagesNew 2. Sfe-Dst-Pip-1402-4102 DST For Globe ValveSandeepNBabuNo ratings yet

- Structural Drawing For Zingama ST - 160722Document13 pagesStructural Drawing For Zingama ST - 160722Ko Kyaw NaingNo ratings yet

- Gate Valve: Piping Data SheetDocument2 pagesGate Valve: Piping Data SheetAsyadullah Al-FatihNo ratings yet

- QUO INDOTEC 20230620 Citramas SummaryDocument2 pagesQUO INDOTEC 20230620 Citramas SummaryTito FebrianNo ratings yet

- 8) Tss-Glycol Surge DrumDocument1 page8) Tss-Glycol Surge DrumKiran KumarNo ratings yet

- Hal PrintDocument1 pageHal Printhenry yuman darmawanNo ratings yet

- 200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Document3 pages200.000 Ton/Year Fractional Destillation Zone in Indonesia (Div.2)Idil FitriNo ratings yet

- .. STDocs Tender TND 088754 172251Document243 pages.. STDocs Tender TND 088754 172251Bimal DeyNo ratings yet

- Monitoring Puring Concrete LusiDocument14 pagesMonitoring Puring Concrete Lusibaihark12No ratings yet

- Appendix B Approved List of MaterialsDocument33 pagesAppendix B Approved List of MaterialsAshok Suresh0% (1)

- BoQ - Permanent Pipe Line From Equalization To Make Up Water Cooling TowerDocument2 pagesBoQ - Permanent Pipe Line From Equalization To Make Up Water Cooling ToweradribmutNo ratings yet

- Brick Bats Cement Concrete Cost Estimate Excel SheetDocument4 pagesBrick Bats Cement Concrete Cost Estimate Excel SheetManash Protim GogoiNo ratings yet

- Paper 1 2015Document6 pagesPaper 1 2015pradeepNo ratings yet

- Mepl CPCLCBR Eil Qap&ds 001 2022 2023Document7 pagesMepl CPCLCBR Eil Qap&ds 001 2022 2023Mathi Vinoth PillaiNo ratings yet

- RAB Kurau-Pekanbaru (Edit)Document1 pageRAB Kurau-Pekanbaru (Edit)Anonymous 6S9tcbhNo ratings yet

- Api 579Document22 pagesApi 579dandiar1No ratings yet

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 pagesA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranNo ratings yet

- Boq For Expansion of Sohar HospitalDocument2 pagesBoq For Expansion of Sohar HospitalSundara MoorthyNo ratings yet

- WAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1Document5 pagesWAGP-1-PAR-9A-M-SAS-99-0013 Hydrocarbs 2500 ANSI F1tope odumboniNo ratings yet

- E Scope of Supply and Price Sheet: ERAL Chile Proposal Nr. 21062859-00 28.10.2021Document2 pagesE Scope of Supply and Price Sheet: ERAL Chile Proposal Nr. 21062859-00 28.10.2021Felipe CidNo ratings yet

- Dokumen - Tips - Storage Tank Piping 79720 Ps 002 Stress Analysis System Documentation CalculationsDocument25 pagesDokumen - Tips - Storage Tank Piping 79720 Ps 002 Stress Analysis System Documentation CalculationsOflodor ZazuetaNo ratings yet

- EHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2Document7 pagesEHK-IKPP-IS-DTS-005 Datasheet For Pressure Safety Valve Rev 2nathaNo ratings yet

- KSB BEV BEV LO PDFDocument36 pagesKSB BEV BEV LO PDFBernardo Salinas GonzalezNo ratings yet

- Radiographic Testing ProcedureDocument28 pagesRadiographic Testing ProcedureAbdulrahman TahaNo ratings yet

- Schedule of Requirement: List of BHEL Spares For Other Dehar MachinesDocument4 pagesSchedule of Requirement: List of BHEL Spares For Other Dehar MachinesXen Operation DPHNo ratings yet

- 180 R Inx 46000 001 - RCDocument5 pages180 R Inx 46000 001 - RCvigneshNo ratings yet

- TECVALDocument8 pagesTECVALRamaswamy Neelakantan NNo ratings yet

- BOQ FF NIH IslamabadDocument1 pageBOQ FF NIH IslamabadTariq MahmoodNo ratings yet

- Lehr Piping Equipment List 2016.5.13 @Document8 pagesLehr Piping Equipment List 2016.5.13 @hagia sophiaNo ratings yet

- Technical Clarification-Gulf Steel-1910-0318 OfferDocument4 pagesTechnical Clarification-Gulf Steel-1910-0318 OfferAnaNo ratings yet

- E4.3.1-2-3-4-5 - PTB-4-2019 PDFDocument17 pagesE4.3.1-2-3-4-5 - PTB-4-2019 PDFEdison CasallasNo ratings yet

- API 620 DesignDocument27 pagesAPI 620 Designrsubramani100% (2)

- Estimasi Piping Accessories and Bulk Material For First Firing Unit #1Document4 pagesEstimasi Piping Accessories and Bulk Material For First Firing Unit #1Arif BinorikaNo ratings yet

- Drawing List SBS - KALISARIDocument10 pagesDrawing List SBS - KALISARIDwi FajarNo ratings yet

- Mughals Company PresentationDocument30 pagesMughals Company PresentationAbid NaeemNo ratings yet

- Clarifications List: Annexure A: Client: Doc No.: Ssis/ Doc/ Anxa-Prop62A Rev0 SSIS Offer No.: SSIS-17-18-PROP-62A REV0Document3 pagesClarifications List: Annexure A: Client: Doc No.: Ssis/ Doc/ Anxa-Prop62A Rev0 SSIS Offer No.: SSIS-17-18-PROP-62A REV0Sathish RajanNo ratings yet

- Lifting Lug CalculationsDocument6 pagesLifting Lug CalculationsparhamadkNo ratings yet

- CalcsDocument7 pagesCalcskukadiya127_48673372No ratings yet

- Datasheet TankDocument1 pageDatasheet TankAnonymous lQiANQusxiNo ratings yet

- Handrails at Atrium CorridorDocument2 pagesHandrails at Atrium CorridorMariam MousaNo ratings yet

- Nov 20 2019 CORDocument16 pagesNov 20 2019 CORMarieNo ratings yet

- 1B. Vendor Offer KOSO-CV - Code2Document7 pages1B. Vendor Offer KOSO-CV - Code2vivekanandakuwaitNo ratings yet

- RT Request: Hail Surface FacilitiesDocument4 pagesRT Request: Hail Surface FacilitiesAnonymous AdofXEYAgENo ratings yet

- Vessel With Large Opening: PVE SamplesDocument25 pagesVessel With Large Opening: PVE SamplesSivateja NallamothuNo ratings yet

- Catalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)Document10 pagesCatalyst and Chemical Summary Sulfur Recovery Unit (SRU Unit #169)Jeroan AyamNo ratings yet

- Pte TG1Document28 pagesPte TG1Edson GonzalezNo ratings yet

- Revised Weld Map (23!07!2015)Document15 pagesRevised Weld Map (23!07!2015)Midhun K Chandrabose100% (1)

- Sr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCDocument3 pagesSr. No. Type Material of Construction Item Description: Pressure KG/CM G Temperature °C MOCDarshan PanchalNo ratings yet

- CompactLogix ControllersDocument72 pagesCompactLogix ControllersJulio Ce CNo ratings yet

- KCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Document9 pagesKCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Anonymous bHh1L1No ratings yet

- Hoja de Datos de Recipiente BechtelDocument3 pagesHoja de Datos de Recipiente BechtelPedro Luis Choque MamaniNo ratings yet

- Rectangular Tank Design ROARKS FORMULADocument40 pagesRectangular Tank Design ROARKS FORMULANavasOT100% (2)

- Job Opportunities at GRILDocument1 pageJob Opportunities at GRILmanish upadhyayNo ratings yet

- HRADocument1 pageHRAmanish upadhyayNo ratings yet

- IS 4031 - Part10Document5 pagesIS 4031 - Part10SourabhAdikeNo ratings yet

- CV-Abhijeet Singh 2020Document5 pagesCV-Abhijeet Singh 2020manish upadhyayNo ratings yet

- Received With Thanks ' 1,114.00 Through Payment Gateway Over The Internet FromDocument1 pageReceived With Thanks ' 1,114.00 Through Payment Gateway Over The Internet Frommanish upadhyayNo ratings yet

- Resume: Career ObjectiveDocument5 pagesResume: Career Objectivemanish upadhyayNo ratings yet

- Manish Upadhyay:, (M.P) IndiaDocument3 pagesManish Upadhyay:, (M.P) Indiamanish upadhyayNo ratings yet

- Img 0002Document1 pageImg 0002manish upadhyayNo ratings yet

- FSTM Calibration 07-07-17Document1 pageFSTM Calibration 07-07-17manish upadhyayNo ratings yet

- Calibration of CTM 07-07-2017Document1 pageCalibration of CTM 07-07-2017manish upadhyayNo ratings yet

- Page-1 Batching Plant (Matheri)Document1 pagePage-1 Batching Plant (Matheri)manish upadhyayNo ratings yet

- Dial Gauge CalibrationDocument2 pagesDial Gauge Calibrationmanish upadhyayNo ratings yet

- SS Calibration FormatsDocument1 pageSS Calibration Formatsmanish upadhyayNo ratings yet

- Area ChartDocument2 pagesArea Chartmanish upadhyayNo ratings yet

- National Highways Authority of India: Bitumen Extraction TestDocument2 pagesNational Highways Authority of India: Bitumen Extraction Testmanish upadhyayNo ratings yet

- Calibration of CTM 07-07-2017Document1 pageCalibration of CTM 07-07-2017manish upadhyayNo ratings yet

- Is 2720 2 1973 PDFDocument24 pagesIs 2720 2 1973 PDFTanvir HasanNo ratings yet

- Is 2720 2 1973 PDFDocument24 pagesIs 2720 2 1973 PDFTanvir HasanNo ratings yet

- List of Lab Equipments: Annexure - "B"Document16 pagesList of Lab Equipments: Annexure - "B"manish upadhyayNo ratings yet

- IS 4031 - Part10Document5 pagesIS 4031 - Part10SourabhAdikeNo ratings yet

- Dilip Buildcon Limited: Ambala-Kaithal (Nh-65) Project HaryanaDocument7 pagesDilip Buildcon Limited: Ambala-Kaithal (Nh-65) Project Haryanamanish upadhyayNo ratings yet

- Calibration Proving Ring 30 KNDocument1 pageCalibration Proving Ring 30 KNmanish upadhyayNo ratings yet

- Dilip Buildcon Limited: Ambala-Kaithal (Nh-65) Project Haryana PQC LayingDocument8 pagesDilip Buildcon Limited: Ambala-Kaithal (Nh-65) Project Haryana PQC Layingmanish upadhyayNo ratings yet

- Reinforcement Threading PlatformDocument2 pagesReinforcement Threading Platformmanish upadhyayNo ratings yet

- Combined Gradation of DBM Grade IDocument1 pageCombined Gradation of DBM Grade Imanish upadhyayNo ratings yet

- National Highways Authority of India: Bitumen Extraction TestDocument2 pagesNational Highways Authority of India: Bitumen Extraction Testmanish upadhyayNo ratings yet

- Sample Card: Vehicle NoDocument1 pageSample Card: Vehicle Nomanish upadhyayNo ratings yet

- Combined Gradation of DBM Grade IDocument1 pageCombined Gradation of DBM Grade Imanish upadhyayNo ratings yet

- Combined Gradation of BC Grade IIDocument1 pageCombined Gradation of BC Grade IImanish upadhyayNo ratings yet

- Combined Gradation of DBM Grade IIDocument2 pagesCombined Gradation of DBM Grade IImanish upadhyayNo ratings yet

- Estimations in Numbers and Measurement: Multiple-Choice QuestionsDocument5 pagesEstimations in Numbers and Measurement: Multiple-Choice QuestionsJason Lam LamNo ratings yet

- Science-9 q4 Mod5 Heat and WorkDocument20 pagesScience-9 q4 Mod5 Heat and WorkEden Cabarrubias86% (7)

- COMSATS University IslamabadDocument4 pagesCOMSATS University IslamabadMax WeberNo ratings yet

- Ten Tips Baum Perspectives Fall 2001Document3 pagesTen Tips Baum Perspectives Fall 2001HienngoNo ratings yet

- Simon E3 CatalogueDocument16 pagesSimon E3 CataloguemarketingsneNo ratings yet

- Markov Clustering AlgorithmDocument53 pagesMarkov Clustering AlgorithmAaryan GuptaNo ratings yet

- Amazon - LeetCodeDocument26 pagesAmazon - LeetCodeceline7michelle7palmNo ratings yet

- CPE 2 2 Time Scaled Event Network Exercises MacalinaoDocument6 pagesCPE 2 2 Time Scaled Event Network Exercises MacalinaoJoshua Macalinao100% (1)

- The Effect of Competence, OrganizationalDocument7 pagesThe Effect of Competence, OrganizationalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Verbal and Nonverbal CommunicationL2Document10 pagesVerbal and Nonverbal CommunicationL2margilyn ramosNo ratings yet

- F3 Math Ch1A Linear Inequalities in One UnknownDocument8 pagesF3 Math Ch1A Linear Inequalities in One Unknown何俊昇No ratings yet

- Brand Book Elena Jovanka DenisaDocument32 pagesBrand Book Elena Jovanka DenisaelenajovankadNo ratings yet

- RC MENQOL-I AU1.0 1week-Recall eng-CAoriDocument6 pagesRC MENQOL-I AU1.0 1week-Recall eng-CAoriRoviqi Bozgank AzemNo ratings yet

- Unique Meanings of The Rising Signs in Vedic AstrologyDocument55 pagesUnique Meanings of The Rising Signs in Vedic AstrologyTanishq Sahu94% (18)

- B26B26MDocument14 pagesB26B26MMMFAWZYNo ratings yet

- NGOs Role in Public Health - LectureDocument48 pagesNGOs Role in Public Health - LectureArnold Dickens JosephNo ratings yet

- Macroeconomics 6th Edition Williamson Solutions ManualDocument36 pagesMacroeconomics 6th Edition Williamson Solutions Manualfagotbouge3q7x96% (26)

- Curriculum Vitae Name: Sex: Marital Status: Date of Birth: Address: Telephone: Email Address: ObjectiveDocument2 pagesCurriculum Vitae Name: Sex: Marital Status: Date of Birth: Address: Telephone: Email Address: ObjectiveCandice LynchNo ratings yet

- Outcomes Advanced TB Review Test 2 PDFDocument3 pagesOutcomes Advanced TB Review Test 2 PDFВиктория ЛысенкоNo ratings yet

- LogDocument18 pagesLogPrawiro indro BhaktiNo ratings yet

- Chapter 15 Air: Class ViDocument24 pagesChapter 15 Air: Class ViAasthaNo ratings yet

- Department of Transport Merchant Shipping Notice No. M.1214Document5 pagesDepartment of Transport Merchant Shipping Notice No. M.1214Игорь БакановNo ratings yet

- CS-114 Fundamentals of Computer Programming: Control Statements - IIIDocument34 pagesCS-114 Fundamentals of Computer Programming: Control Statements - IIIAbdullah RiasatNo ratings yet

- Lec# 16 Breakdown in LiquidsDocument12 pagesLec# 16 Breakdown in LiquidsVishal MeghwarNo ratings yet

- Civil Engineering Laws and Ethics in The PhilippinesDocument16 pagesCivil Engineering Laws and Ethics in The PhilippinesMonde Nuylan90% (48)

- An Introduction To BS 5268 PDFDocument8 pagesAn Introduction To BS 5268 PDFSam11111No ratings yet

- Failure Mechanism-Based Reliability Assessment Framework: A Case Study in An Automotive ComponentDocument9 pagesFailure Mechanism-Based Reliability Assessment Framework: A Case Study in An Automotive ComponentmaruvadatarunNo ratings yet

- Lesson Plan in Science 3 Ranking 2020Document4 pagesLesson Plan in Science 3 Ranking 2020Karrylle Casin-Seguera Absalon100% (1)

- Running Head: Case 2.1 Hector Gaming Company 1Document4 pagesRunning Head: Case 2.1 Hector Gaming Company 1Pháp HuỳnhNo ratings yet

- The National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Document93 pagesThe National Academies Press: Space Nuclear Propulsion For Human Mars Exploration (2021)Cable KurwitzNo ratings yet