Professional Documents

Culture Documents

Strainer Guide - Part19 PDF

Uploaded by

Sri SubektiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strainer Guide - Part19 PDF

Uploaded by

Sri SubektiCopyright:

Available Formats

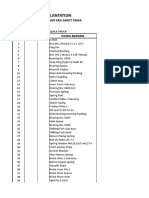

Table Three: Wedge Wire

Percent

Opening Micron

Open Area

0.003” 75

0.005” 127 7.7

0.010” 254 14.3

0.015” 381 20

0.020” 500 25

0.031” 775 34

0.034” 864 20

0.062” 1550 50

0.063” 1600 51

0.094” 2350 61

0.125” 3175 67

0.156” 3962 71

CHAPTER 6

Capacity

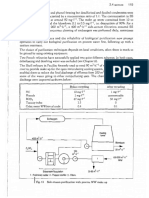

The capacity ratio or open area ratio (OAR) of a strainer influences such operating

characteristics as the length of time it can operate without cleaning and the created pressure

loss. The OAR is the relationship between internal cross sectional area (flow area) of the

pipe and the open flow area of the material which makes up the straining element. The

nominal pipe size should be used to calculate OAR for threaded strainers.

A 100% OAR, or 1-to-1 ratio, would give an unrestricted flow area equal to that of the pipe

while the element was clean. However, as clogging occurs flow would be inhibited. A

200% OAR, or 2-to-1 ratio would provide full flow, after the element became 50% clogged.

However, larger OAR’s would be appropriate for flow in which much debris is expected to

be strained or where very viscous fluids are being handled.

When considering the OAR of a straining element, there are two accepted methods of

analysis used by various specifying agencies and manufacturers. One method maintains

“line of sight” reasoning and uses the multiple of the open areas for elements in series. In

this method, a 60% open area material in series with a 40% open area material has a resultant

combined open area of 24% (i.e. as in accordance with Military Standards). An alternative

method allows the open area of the more restrictive element in series to be used. This

alternative method is allowable because fluid does not always flow straight through the mesh

in a “line of sight” flow path – it can actually flow sideways between the weaves of the mesh

which reduces the restrictions. There is also typically some space between the mesh and the

perforated plate for lateral flow.

This would be 40% for the example above (i.e. as in accordance with Underwriter

Laboratories’ Standards). The method used influences the estimated operating pressure drop,

as well as design decisions such as sizing.

19

You might also like

- Core Sampling of The Filter Bed: Appendix 11Document3 pagesCore Sampling of The Filter Bed: Appendix 11Ahmed ShawkyNo ratings yet

- A Relationship Between Screen Opening and Mesh Size For Standard SievesDocument3 pagesA Relationship Between Screen Opening and Mesh Size For Standard SievesShubham RathoreNo ratings yet

- JOB No. 8: Load Penetration Test ExperimentDocument6 pagesJOB No. 8: Load Penetration Test ExperimentEman ArshadNo ratings yet

- Wire Fill Table CalculatorDocument6 pagesWire Fill Table CalculatorAhmed SayedNo ratings yet

- A Relationship Between Screen Opening and Mesh Size For Standard SievesDocument3 pagesA Relationship Between Screen Opening and Mesh Size For Standard SievesMuhammadAmdadulHoqueNo ratings yet

- Test Name: Determination of Tensile Properties of Geotextile Using Wide Strip ScopeDocument3 pagesTest Name: Determination of Tensile Properties of Geotextile Using Wide Strip ScopeSwapan PaulNo ratings yet

- Problem 2-3 Red Reservoir, Average Relative Permeability CharacteristicsDocument6 pagesProblem 2-3 Red Reservoir, Average Relative Permeability CharacteristicsDion AndriNo ratings yet

- SHKR School AsdrubalDocument25 pagesSHKR School AsdrubalArmando Pulgar BenavidesNo ratings yet

- Comparison of An External Gear Pump Wear Model With Test DataDocument8 pagesComparison of An External Gear Pump Wear Model With Test Data김동하No ratings yet

- Computational Fluid Dynamics CourseworkDocument5 pagesComputational Fluid Dynamics CourseworkArjun NehruNo ratings yet

- Additive AravinthDocument15 pagesAdditive AravinthAravinth subramanianNo ratings yet

- Sieve Hyd-ClassDocument2 pagesSieve Hyd-ClassMuh UmaNo ratings yet

- Excel PraktikumDocument11 pagesExcel PraktikumAndi Azzahra RatuNo ratings yet

- Tutorial 1Document12 pagesTutorial 1MAHLATSE MULALANo ratings yet

- Sewage Slope and Depth of FlowDocument1 pageSewage Slope and Depth of Flowchootymalli9760No ratings yet

- ARIavCAD Step-By-Step Tutorial 1.8.07Document45 pagesARIavCAD Step-By-Step Tutorial 1.8.07neoeuripides1No ratings yet

- Table 3: Voltage Drop: ExampleDocument1 pageTable 3: Voltage Drop: Exampletaufiqishak09No ratings yet

- Lab 7 Laminar & Turbular FlowDocument16 pagesLab 7 Laminar & Turbular FlowLandel SmithNo ratings yet

- A Note On Saaty'S Random Indexes: CI RIDocument3 pagesA Note On Saaty'S Random Indexes: CI RIcovid19 bebasNo ratings yet

- P3 Sieve AnalysisDocument2 pagesP3 Sieve AnalysisvaleidshafikNo ratings yet

- Appendix E PARTICLE SIZE-U.S. SIEVE SIZEDocument3 pagesAppendix E PARTICLE SIZE-U.S. SIEVE SIZEVeronica CorreaNo ratings yet

- Water OelDocument5 pagesWater Oelalizabano9fNo ratings yet

- Capability Analysis: Cycle Specified Pos. Actual Pos. Difference 1Document1 pageCapability Analysis: Cycle Specified Pos. Actual Pos. Difference 1bhavesh_balasNo ratings yet

- Grafik Hubungan Ketinggian Cairan Terhadap DebitDocument3 pagesGrafik Hubungan Ketinggian Cairan Terhadap DebitROMANo ratings yet

- Horizontal Tank Chart 2Document4 pagesHorizontal Tank Chart 2גרבר פליקסNo ratings yet

- Pipe Dia 0.75 (M/S) Around 2.5 (M/S) Around 1.5 (M/S) Rise (MM) Slope (Minimum) (%) Slope (Maximum) (%) Slope (Maximum) (%)Document2 pagesPipe Dia 0.75 (M/S) Around 2.5 (M/S) Around 1.5 (M/S) Rise (MM) Slope (Minimum) (%) Slope (Maximum) (%) Slope (Maximum) (%)mazzam75No ratings yet

- Vapor-Liquid Equilibrium Binary Systems: RelationsDocument2 pagesVapor-Liquid Equilibrium Binary Systems: RelationsGrinder Hernan Rojas UrcohuarangaNo ratings yet

- Construction of Main Canal and Associated Structures (CH 10+000 - 41+678) On Welkayit Sugar Development Irrigation ProjectDocument12 pagesConstruction of Main Canal and Associated Structures (CH 10+000 - 41+678) On Welkayit Sugar Development Irrigation ProjectgirumNo ratings yet

- Combine CalculationDocument3 pagesCombine CalculationKamran JUTTNo ratings yet

- Particle Size US Sieve Series and Tyler Mesh Size EquivalentsDocument3 pagesParticle Size US Sieve Series and Tyler Mesh Size EquivalentsAiman HakimNo ratings yet

- Laboratory 4 - Group 3Document8 pagesLaboratory 4 - Group 3Joanne Bernadette IcaroNo ratings yet

- Milling AluminiumDocument4 pagesMilling AluminiumRufusGartzNo ratings yet

- Design of Airfoils For Wind Turbine BladesDocument7 pagesDesign of Airfoils For Wind Turbine BladesAzinoNo ratings yet

- Experiment No. 3a Particle Size Distribution Sieve Analysis of SoilDocument8 pagesExperiment No. 3a Particle Size Distribution Sieve Analysis of Soilhey cuteNo ratings yet

- Lab 8 ReportDocument3 pagesLab 8 ReportQusaiNo ratings yet

- Orifice and Free Jet Flow ResultDocument13 pagesOrifice and Free Jet Flow Resultmartian mingNo ratings yet

- Beam ProgramDocument10 pagesBeam ProgramAnirudh SabooNo ratings yet

- Laboratory Consolidation TestDocument10 pagesLaboratory Consolidation Testنور عليNo ratings yet

- Harmonic #: A1 A2 A3 A4 DC Amplitude PhaseDocument3 pagesHarmonic #: A1 A2 A3 A4 DC Amplitude PhaseZokiNo ratings yet

- Distortion AnalysisDocument4 pagesDistortion AnalysisMd Rahul HossainNo ratings yet

- Annexure 4 - Stability - Case IVDocument4 pagesAnnexure 4 - Stability - Case IVMd Ghani HaiderNo ratings yet

- Simulation of Flow Over Airfoil: International Research Journal of Engineering and Technology (IRJET)Document9 pagesSimulation of Flow Over Airfoil: International Research Journal of Engineering and Technology (IRJET)Santhosh KumarNo ratings yet

- Mass BalanceDocument4 pagesMass BalancealvinchuanNo ratings yet

- Mehran University of Engineering and Technology, JamshoroDocument6 pagesMehran University of Engineering and Technology, JamshoroMuhammad Fahad AliNo ratings yet

- Lesson 3.4Document7 pagesLesson 3.4MitzlNo ratings yet

- Underground Pipeline Crossing Application Information and Specifications (Non-Flammable Substances Only)Document4 pagesUnderground Pipeline Crossing Application Information and Specifications (Non-Flammable Substances Only)Ilyes kNo ratings yet

- Sysmod - System Models: Population Service Rate Queue SizeDocument11 pagesSysmod - System Models: Population Service Rate Queue Sizecp3y2000-scribdNo ratings yet

- 7 Relative Permeability ExDocument2 pages7 Relative Permeability ExTripoli ManoNo ratings yet

- Section 12 Method DevelopmentDocument21 pagesSection 12 Method DevelopmentNtombizodwa VincenthNo ratings yet

- Category OverviewDocument20 pagesCategory Overviewshru6sanviNo ratings yet

- Surface Roughness Value ConversionsDocument2 pagesSurface Roughness Value Conversionsnick10686No ratings yet

- Conductivity ExperimentDocument6 pagesConductivity ExperimentDon Amaru SarmaNo ratings yet

- Tonmoy Kumar Saha - WSUV ID 011578904: L WT RDocument9 pagesTonmoy Kumar Saha - WSUV ID 011578904: L WT RRiheen AhsanNo ratings yet

- Laying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex EDocument2 pagesLaying Conditions: 40 ºC 30 ºC 1.5 K M/W 0.8 M. Annex Elk RentalNo ratings yet

- Total: Tamices % Ret Parcial % Que Pasa Astm Abertura en MM Peso Retenido (G) % Ret AcumuladoDocument1 pageTotal: Tamices % Ret Parcial % Que Pasa Astm Abertura en MM Peso Retenido (G) % Ret AcumuladoKimyhiro Saguma CastilloNo ratings yet

- HY-8 Culvert Analysis ReportDocument9 pagesHY-8 Culvert Analysis ReportVYOINGENIERIA SASNo ratings yet

- Anilox RollsDocument14 pagesAnilox RollsMilos Papic100% (1)

- Documentación Adicional. Tema 1. Parte 1. Disipador de Impacto Tipo VIDocument4 pagesDocumentación Adicional. Tema 1. Parte 1. Disipador de Impacto Tipo VIFabricio OrtegaNo ratings yet

- Contact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftFrom EverandContact Lens Design Tables: Tables for the Determination of Surface Radii of Curvature of Hard Contact Lenses to Give a Required Axial Edge LiftNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Point of Use Reverse Osmosis - Part11 PDFDocument1 pagePoint of Use Reverse Osmosis - Part11 PDFSri SubektiNo ratings yet

- PHP Series Dosing Pump - Part36Document1 pagePHP Series Dosing Pump - Part36Sri SubektiNo ratings yet

- PHP Series Dosing Pump - Part32Document1 pagePHP Series Dosing Pump - Part32Sri SubektiNo ratings yet

- Non Destructive Examination of Pumps - Part1 PDFDocument1 pageNon Destructive Examination of Pumps - Part1 PDFSri SubektiNo ratings yet

- PHP Series Dosing Pump - Part35Document1 pagePHP Series Dosing Pump - Part35Sri SubektiNo ratings yet

- PHP Series Dosing Pump - Part34Document1 pagePHP Series Dosing Pump - Part34Sri SubektiNo ratings yet

- PHP Series Dosing Pump - Part33Document1 pagePHP Series Dosing Pump - Part33Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part133Document1 pageIndustrial Waste Water Treatment - Part133Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part132Document1 pageIndustrial Waste Water Treatment - Part132Sri SubektiNo ratings yet

- PHP Series Dosing Pump - Part31Document1 pagePHP Series Dosing Pump - Part31Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part131Document1 pageIndustrial Waste Water Treatment - Part131Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part134Document1 pageIndustrial Waste Water Treatment - Part134Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part130Document1 pageIndustrial Waste Water Treatment - Part130Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part129Document1 pageIndustrial Waste Water Treatment - Part129Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part124Document1 pageIndustrial Waste Water Treatment - Part124Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part116Document1 pageIndustrial Waste Water Treatment - Part116Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part126Document1 pageIndustrial Waste Water Treatment - Part126Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part121Document1 pageIndustrial Waste Water Treatment - Part121Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part123Document1 pageIndustrial Waste Water Treatment - Part123Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part122Document1 pageIndustrial Waste Water Treatment - Part122Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part125Document1 pageIndustrial Waste Water Treatment - Part125Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part118Document1 pageIndustrial Waste Water Treatment - Part118Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part119Document1 pageIndustrial Waste Water Treatment - Part119Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part115Document1 pageIndustrial Waste Water Treatment - Part115Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part120Document1 pageIndustrial Waste Water Treatment - Part120Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part114Document1 pageIndustrial Waste Water Treatment - Part114Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part113Document1 pageIndustrial Waste Water Treatment - Part113Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part117Document1 pageIndustrial Waste Water Treatment - Part117Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part112Document1 pageIndustrial Waste Water Treatment - Part112Sri SubektiNo ratings yet

- Industrial Waste Water Treatment - Part111Document1 pageIndustrial Waste Water Treatment - Part111Sri SubektiNo ratings yet

- Generator Set Technical Specification Compliance (Updated) 5.26.22Document3 pagesGenerator Set Technical Specification Compliance (Updated) 5.26.22Mark VillarosaNo ratings yet

- Api 5352Document31 pagesApi 5352NIMISHNo ratings yet

- Oman Gas PDFDocument23 pagesOman Gas PDFshyamNo ratings yet

- Process Design Package: Spent Acid Regeneration Plant (Sar)Document47 pagesProcess Design Package: Spent Acid Regeneration Plant (Sar)Rashidul Islam MasumNo ratings yet

- 5 Spec For Fume CabinetDocument5 pages5 Spec For Fume CabinetLengNo ratings yet

- Wet Room InstalationDocument11 pagesWet Room InstalationBoris PeianovNo ratings yet

- CEMS A 10 Part I APPXDocument80 pagesCEMS A 10 Part I APPXaldairlopesNo ratings yet

- Ancillary Scaffolding Components Not Covered by British StandardsDocument4 pagesAncillary Scaffolding Components Not Covered by British StandardsMatthew PowellNo ratings yet

- Pengajuan KobarDocument19 pagesPengajuan KobarmaxNo ratings yet

- Style 400 Steel Coupling: (For 12" and Larger Pipe)Document4 pagesStyle 400 Steel Coupling: (For 12" and Larger Pipe)picottNo ratings yet

- Safgard 500 600 700 Instructions 050919 WebDocument4 pagesSafgard 500 600 700 Instructions 050919 Webzidan080606No ratings yet

- SB 221Document9 pagesSB 221Siva PrasadNo ratings yet

- ShawPipe - Technical Information 6Document1 pageShawPipe - Technical Information 6AlenNo ratings yet

- Astm A 960 PDFDocument11 pagesAstm A 960 PDFEdwinMauricioMacabeoNo ratings yet

- Hydro Testing ProcedureDocument12 pagesHydro Testing ProcedureGaapchuNo ratings yet

- Method Statement For RetubingDocument4 pagesMethod Statement For RetubingJeffrey78% (9)

- Analytical Behavior of Connections To Concrete-Filled Steel Tubes - Yousef Alostaz, Stephen - JournalDocument33 pagesAnalytical Behavior of Connections To Concrete-Filled Steel Tubes - Yousef Alostaz, Stephen - JournalRMKD PrabhuNo ratings yet

- ANSI B16.5 - Steel Pipe Flanges - Maximum Pressure and Temperature Ratings - Group 1Document1 pageANSI B16.5 - Steel Pipe Flanges - Maximum Pressure and Temperature Ratings - Group 1daveNo ratings yet

- Sans 1307, Domestic Solar Water HeatersDocument5 pagesSans 1307, Domestic Solar Water HeatersShayne JonesNo ratings yet

- 2 Maaden PDFDocument29 pages2 Maaden PDFAnonymous q9eCZHMuSNo ratings yet

- CatalogDocument268 pagesCatalogAhmed SayedNo ratings yet

- Vertical Immersion Pump VTP-BBFDocument23 pagesVertical Immersion Pump VTP-BBFmourinho2No ratings yet

- Leaflet 500t Pipe TensionerDocument1 pageLeaflet 500t Pipe TensionerGhyd ArtiagaNo ratings yet

- Dxe PrtlistDocument31 pagesDxe PrtlistdevilsharmaNo ratings yet

- Caesar User Manual PDFDocument412 pagesCaesar User Manual PDFDiego BalcellsNo ratings yet

- Hamworthy Cargo Pump Manual PDFDocument140 pagesHamworthy Cargo Pump Manual PDFspamalstublieft1832No ratings yet

- ASL GX7-11 RedesignDocument54 pagesASL GX7-11 RedesignMohammed Arshad100% (2)

- IS-875-Part1 - Dead Loads For DesignDocument39 pagesIS-875-Part1 - Dead Loads For Designlokesh2325100% (7)

- API Related, Oilfield Pressure Control Equipment, Terms and Definitions, GlossaryDocument36 pagesAPI Related, Oilfield Pressure Control Equipment, Terms and Definitions, GlossaryNaveen TripuraneniNo ratings yet

- Standards SpreadsheetDocument14 pagesStandards Spreadsheetyulianus_srNo ratings yet