Professional Documents

Culture Documents

Saline Water Conversion Corporation (SWCC) : Design of Grade Slab (380 Gis Floor) Design of Slab For Wheel Loading

Uploaded by

MadhubalaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saline Water Conversion Corporation (SWCC) : Design of Grade Slab (380 Gis Floor) Design of Slab For Wheel Loading

Uploaded by

MadhubalaCopyright:

Available Formats

CERT'D

Saline Water Conversion Corporation

(SWCC)

APP'D

M.SAEED

CHEK'D

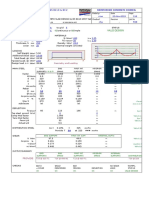

DESIGN OF GRADE SLAB (380 GIS FLOOR)

DESIGN OF SLAB FOR WHEEL LOADING :-

Note : Though no vehicle movement is envisaged in GIS room,

for the purpose of design forklift movement is considered.

Grade of concrete fc' = 28 N/mm2

fc' = 4000 Psi

REVISED AS PER ILF COMMENTS

Vehicle Specification FORK LIFT

DESIGN OF GRADE SLAB

Total Depth of Slab h = 300 mm 11.81 Inches

DESCRIPTION

Unit weight of concrete gc = 24.000 kN/m3

gc = 152.872 Pcf

Modulus of concrete Ec = 33 x gc1.50 x Sqrt (fc') In Psi

= 33 x (152.872)^1.50 x Sqrt (4000)

= 3.945E+06 Psi

Modulus of sub grade kc = 6000 kN / m2 / m As per soil report

= 870.00 Pounds / In / In2

Maximum wheel load Ww = 2500 Kg 24.5KN

= 5513 Lbs

Dimensions of wheel base in mm (l x b) = 300 x 300

Distance between c/c of wheels = 1030 mm

= 40.55 Inches

Wheel contact area = 90000 mm2 0.09m2

DAR

DAR

BY

Equivalent loaded diameter = 338.51 mm = 13.33 Inches

Relationship between slab stifness D/K = 8.2 E+05 inch4 Fig A2.2.1 of

14.07.13

22.08.13

DATE

and subgrade modulus ACI 360

Unit moment per 1000 Lbs load = 200 lbs-inch/inch Fig A2.2.2 of

NO.

(From wheel loading design chart) ACI 360

A

REVISIONS Additional unit moment per 1000 lbs load = 30 lbs-inch/inch Fig A2.2.2 of

DESIGNED Total unit moment per 1000 lbs load = 230 lbs-inch/inch ACI 360

BY:- HMA

DATE:- 22.08.13 Moment on the slab for max. wheel load = 1267.875 lbs-inch/inch

CHECKED = 1267.875 lbs-ft/ft

BY:- AAQ Actual tensile stress = 50 psi Fig A2.2.3

DATE:- 22.08.13

OPRG. DEPT Factor of safety for stresses FOS = 2.00 Table 4.9.2 of

BY Allowable tensile stress = 7.50 * sqrt (fc') ACI 360

DATE:- = 474.342 psi

ENG'G. DEPT. Hence the actual tensile stress is less than allowable tensile stress, the grade Slab is safe

BY:- Note

DATE:- Maximum wheel load/wheel contact area = 24.5/.09 = 272 KN/m2 > 10 KN/m2 (vendor LL in GIS hall)

CERTIFIED.

BY:-

DATE:- AS BUILT BY DATE

DOCUMENT TITLE INDEX PLANT DOCUMENT NO. SHEET NO. REV.

THIS DRAWING IS NOT

TO BE USED FOR DESIGN CALCULATIONS FOR 380 KV GIS BUILDING

CONSTRUCTION OF

FOR ORDERING J 302-QC-20-J-0051 B

MATERIALS UNTIL YANBU PS-2

CERTIFIED AND

DATED

AL-MUSAYJEED SAUDI ARABIA JOB ORDER NO. DOC.CON.SHT 425-QP40-L-0002

CERT'D

Saline Water Conversion Corporation

(SWCC)

APP'D

M.SAEED

CHEK'D

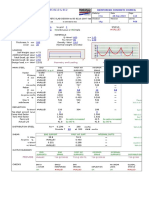

Reinforcement Steel for Grade Slab :- (Using sub grade drag formula)

Area required As = F x L x w/(2 x fs) Cl.6.3 of ACI 360

Where As = Cross sectional area in Sq.inches

fs = Allowable stress in reinforcement in Psi

F= Slab subgrade friction co-oefficient

L= Distance between joints (Distance between the free ends of the slab that move due to

shrinkage contraction or thermal expansion) in inches

REVISED AS PER ILF COMMENTS

w= Dead weight of slab (Assumed to be 12.50 Psf per inch of slab thickness)

DESIGN OF GRADE SLAB

Applying the above formula

DESCRIPTION

F= 1.5 L= 38 feet w= 147.638 psf

fs = 60000 psi

Area of steel required As = 1.5 x 38 x 147.638/(2 x 60000)

= 0.0701 inch² per foot

= 141 mm² per m

Provide 12 mm diameter bar with a spacing of 200 m c/c. bothways.

DAR

DAR

BY

14.07.13

22.08.13

DATE

NO.

REVISIONS

DESIGNED

BY:- HMA

DATE:- 22.08.13

CHECKED

BY:- AAQ

DATE:- 22.08.13

OPRG. DEPT

BY

DATE:-

ENG'G. DEPT.

BY:-

DATE:-

CERTIFIED.

BY:-

DATE:- AS BUILT BY DATE

DOCUMENT TITLE INDEX PLANT DOCUMENT NO. SHEET NO. REV.

THIS DRAWING IS NOT

TO BE USED FOR

CONSTRUCTION OF DESIGN CALCULATIONS FOR 380 KV GIS BUILDING

FOR ORDERING

MATERIALS UNTIL

J 302-QC-20-J-0051 B

CERTIFIED AND

YANBU PS-2

DATED

AL-MUSAYJEED SAUDI ARABIA JOB ORDER NO. DOC.CON.SHT 425-QP40-L-0002

CERT'D

Saline Water Conversion Corporation

(SWCC)

APP'D

M.SAEED

CHEK'D

DESIGN OF GRADE SLAB (STORE ROOM)

Note : Though no vehicle movement is envisaged in GIS room,

for the purpose of design forklift movement is considered.

Grade of concrete fc' = 28 N/mm2

fc' = 4000 Psi

REVISED AS PER ILF COMMENTS

Vehicle Specification FORK LIFT

DESIGN OF GRADE SLAB

Total Depth of Slab h = 150 mm 5.91 Inches

DESCRIPTION

Unit weight of concrete gc = 24.000 kN/m3

gc = 152.872 Pcf

Modulus of concrete Ec = 33 x gc1.50 x Sqrt (fc') In Psi

= 33 x (152.872)^1.50 x Sqrt (4000)

= 3.945E+06 Psi

Modulus of sub grade kc = 6000 kN / m2 / m As per soil report

= 870.00 Pounds / In / In2

Maximum wheel load Ww = 2500 Kg 24.5KN

= 5513 Lbs

Dimensions of wheel base in mm (l x b) = 300 x 300

Distance between c/c of wheels = 1030 mm

= 40.55 Inches

Wheel contact area = 90000 mm2 0.09m2

DAR

DAR

BY

Equivalent loaded diameter = 338.51 mm = 13.33 Inches

Relationship between slab stifness D/K = 1.6 E+05 inch4 Fig A2.2.1 of

14.07.13

22.08.13

DATE

and subgrade modulus ACI 360

Unit moment per 1000 Lbs load = 200 lbs-inch/inch Fig A2.2.2 of

NO.

(From wheel loading design chart) ACI 360

A

REVISIONS Additional unit moment per 1000 lbs load = 30 lbs-inch/inch Fig A2.2.2 of

DESIGNED Total unit moment per 1000 lbs load = 230 lbs-inch/inch ACI 360

BY:- HMA

DATE:- 14.07.13 Moment on the slab for max. wheel load = 1267.875 lbs-inch/inch

CHECKED = 1267.875 lbs-ft/ft

BY:- AAQ Actual tensile stress = 50 psi Fig A2.2.3

DATE:- 14.07.13

OPRG. DEPT Factor of safety for stresses FOS = 2.00 Table 4.9.2 of

BY Allowable tensile stress = 7.50 * sqrt (fc') ACI 360

DATE:- = 474.342 psi

ENG'G. DEPT. Hence the actual tensile stress is less than allowable tensile stress, the grade Slab is safe

BY:- Note

DATE:- Maximum wheel load/wheel contact area = 24.5/.09 = 272 KN/m2 > 10 KN/m2 (vendor LL in GIS hall)

CERTIFIED.

BY:-

DATE:- AS BUILT BY DATE

DOCUMENT TITLE INDEX PLANT DOCUMENT NO. SHEET NO. REV.

THIS DRAWING IS NOT

TO BE USED FOR DESIGN CALCULATIONS FOR 380 KV GIS BUILDING

CONSTRUCTION OF

FOR ORDERING J 302-QC-20-J-0051 B

MATERIALS UNTIL YANBU PS-2

CERTIFIED AND

DATED

AL-MUSAYJEED SAUDI ARABIA JOB ORDER NO. DOC.CON.SHT 425-QP40-L-0002

CERT'D

Saline Water Conversion Corporation

(SWCC)

APP'D

M.SAEED

CHEK'D

Reinforcement Steel for Grade Slab :- (Using sub grade drag formula)

Area required As = F x L x w/(2 x fs) Cl.6.3 of ACI 360

Where As = Cross sectional area in Sq.inches

fs = Allowable stress in reinforcement in Psi

F= Slab subgrade friction co-oefficient

L= Distance between joints (Distance between the free ends of the slab that move due to

shrinkage contraction or thermal expansion) in inches

REVISED AS PER ILF COMMENTS

w= Dead weight of slab (Assumed to be 12.50 Psf per inch of slab thickness)

DESIGN OF GRADE SLAB

Applying the above formula

DESCRIPTION

F= 1.5 L= 22 feet w= 73.819 psf

fs = 60000 psi

Area of steel required As = 1.5 x 22 x 73.819/(2 x 60000)

= 0.0203 inch² per foot

= 141 mm² per m

Provide 12 mm diameter bar with a spacing of 200 m c/c. bothways.

DAR

DAR

BY

14.07.13

22.08.13

DATE

NO.

REVISIONS

DESIGNED

BY:- HMA

DATE:- 14.07.13

CHECKED

BY:- AAQ

DATE:- 14.07.13

OPRG. DEPT

BY

DATE:-

ENG'G. DEPT.

BY:-

DATE:-

CERTIFIED.

BY:-

DATE:- AS BUILT BY DATE

DOCUMENT TITLE INDEX PLANT DOCUMENT NO. SHEET NO. REV.

THIS DRAWING IS NOT

TO BE USED FOR

CONSTRUCTION OF DESIGN CALCULATIONS FOR 380 KV GIS BUILDING

FOR ORDERING

MATERIALS UNTIL

J 302-QC-20-J-0051 B

CERTIFIED AND

YANBU PS-2

DATED

AL-MUSAYJEED SAUDI ARABIA JOB ORDER NO. DOC.CON.SHT 425-QP40-L-0002

You might also like

- TCC62 Retaining WallDocument9 pagesTCC62 Retaining Wallshafiq_05No ratings yet

- Design Calculation of Elevated Service Reservoir: (India) PVT LTDDocument38 pagesDesign Calculation of Elevated Service Reservoir: (India) PVT LTDjuliyet strucNo ratings yet

- Pressure Table-Nvk Portion IsolatedDocument42 pagesPressure Table-Nvk Portion IsolatedVasanthakumarNo ratings yet

- Attachment 1 - Bi-Axial Bending CheckDocument2 pagesAttachment 1 - Bi-Axial Bending CheckYang W OngNo ratings yet

- Caisson Design Based On 2018 IBC & 2016 CBCDocument2 pagesCaisson Design Based On 2018 IBC & 2016 CBCNelson VegaNo ratings yet

- Caisson Design AnalysisDocument2 pagesCaisson Design Analysisjklo12No ratings yet

- Caisson Design AnalysisDocument2 pagesCaisson Design AnalysisIsprotec IngenieriaNo ratings yet

- Caisson design for Jembatan Sungai Tolinggula IIDocument1 pageCaisson design for Jembatan Sungai Tolinggula IIBamz ImpazztNo ratings yet

- Crane Gurder Model Desidn 10.0 M Span and 90 T CapacityDocument25 pagesCrane Gurder Model Desidn 10.0 M Span and 90 T Capacitymayankjain333No ratings yet

- 2-Col Bent On Bored PilesDocument17 pages2-Col Bent On Bored PilesabdurehimNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116Document1 pageSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 16-Aug-2014 116mathewsujith31No ratings yet

- Caisson Design Based On 2021 IBC & 2019 CBCDocument2 pagesCaisson Design Based On 2021 IBC & 2019 CBCLuis Alfredo Atencia VillarealNo ratings yet

- Anx 1_ULS.xlsDocument197 pagesAnx 1_ULS.xlsGANGA PROJECTNo ratings yet

- Spreadsheets To BS 8110: FlightDocument4 pagesSpreadsheets To BS 8110: FlightNezza AriffNo ratings yet

- PC Pile CALDocument1 pagePC Pile CALReab SimanthNo ratings yet

- Detailed design of a 2-column bridge bent pier on bored pilesDocument17 pagesDetailed design of a 2-column bridge bent pier on bored pileszxcNo ratings yet

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Design of Isolated Footing For CheckingDocument3 pagesDesign of Isolated Footing For CheckingNizar AhamedNo ratings yet

- Design calculations for 11m span crane gantry girderDocument20 pagesDesign calculations for 11m span crane gantry girderkushaljp8989No ratings yet

- Design of eccentric footing for Kuantum Paper ProjectDocument18 pagesDesign of eccentric footing for Kuantum Paper ProjectAamir SuhailNo ratings yet

- Basement WallDocument4 pagesBasement WallMohamad RammelNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document7 pagesRCC91 One-Way Solid Slabs (Tables)ery achjariNo ratings yet

- Flexural beam design calculationDocument17 pagesFlexural beam design calculationReceb AgaNo ratings yet

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- Spreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CDocument7 pagesSpreadsheets To BS 8110 & EC2: Advisory Group 8rd Floor Slab RMW 20-Nov-2019 116 CHG - R68 A F CKhan EngrNo ratings yet

- 3.design of BracketDocument39 pages3.design of BracketmahalakshmiNo ratings yet

- RCC91 One-Way Solid Slabs (Tables)Document8 pagesRCC91 One-Way Solid Slabs (Tables)Murthy GunaNo ratings yet

- Reliance: Mangalore ST 12-May-2020 1 - 4068Document4 pagesReliance: Mangalore ST 12-May-2020 1 - 4068Anilkumar VidelaNo ratings yet

- Gantry CraneDocument31 pagesGantry Cranekushaljp8989No ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- PILE ANALYSISDocument4 pagesPILE ANALYSISRuemu Godwin InikoriNo ratings yet

- Project: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamDocument4 pagesProject: Beam Number: Engineer: Date:: Design Doubly Reinforcement Rectangular BeamAnonymous e2wolbeFsNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12asuncionNo ratings yet

- Slab400 2Document1 pageSlab400 2Aek JanNo ratings yet

- Slab DesignDocument9 pagesSlab Designsuleiman.ahNo ratings yet

- L&T Water Treatment DesignDocument2 pagesL&T Water Treatment DesignPowerhouse ShaftNo ratings yet

- Slab Transfor1Document1 pageSlab Transfor1Aek JanNo ratings yet

- Design of Pile and Pile Cap BeamDocument4 pagesDesign of Pile and Pile Cap Beamshivendra kumarNo ratings yet

- 1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationDocument17 pages1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationSurya PratapNo ratings yet

- Design of MACH Deck Panel - Slab (300mm THK)Document7 pagesDesign of MACH Deck Panel - Slab (300mm THK)Sankar AnandNo ratings yet

- 2-Col Bent On Bored PilesDocument29 pages2-Col Bent On Bored PilesHenry DiyokeNo ratings yet

- SVP010053 - Bih-C-Des - 131Document56 pagesSVP010053 - Bih-C-Des - 131AJAY SHINDENo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- Strut Design Sheet PDFDocument84 pagesStrut Design Sheet PDFPrakashNo ratings yet

- Abutment - 28+545 Re01Document217 pagesAbutment - 28+545 Re01mayank007aggarwalNo ratings yet

- Check For SBC P/A M /Z M /Z: Provided Area Is OkayDocument2 pagesCheck For SBC P/A M /Z M /Z: Provided Area Is OkayVikunj TilvaNo ratings yet

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument3 pagesPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesYHK3001No ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- Creep Effects on North Luzon Expressway BridgeDocument2 pagesCreep Effects on North Luzon Expressway BridgeDan PeckleyNo ratings yet

- Delhi Metro MC1B: Design DataDocument9 pagesDelhi Metro MC1B: Design DataRamachandra SahuNo ratings yet

- FOOTING-DESIGN for RCDocument1 pageFOOTING-DESIGN for RCRalph Richard NipitNo ratings yet

- Design of two-way reinforced concrete slabDocument15 pagesDesign of two-way reinforced concrete slabMohammed Saleem Syed KhaderNo ratings yet

- Larsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PierDocument3 pagesLarsen & Toubro Limited Ecc Division: Transformer Transportation On Solding Khad Bridge Design Review of PiervibishnanNo ratings yet

- 2 (AutoRecovered)Document9 pages2 (AutoRecovered)epe civil1No ratings yet

- Foundation Design for Air Compressor Shed ColumnsDocument7 pagesFoundation Design for Air Compressor Shed Columnsmvap2856No ratings yet

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Bined Footing DesignDocument3 pagesBined Footing DesignMadhubalaNo ratings yet

- 5.design of Isolated FootingDocument4 pages5.design of Isolated FootingMadhubalaNo ratings yet

- MLDocument2 pagesMLMadhubalaNo ratings yet

- The Lab Manual Rev 5 PDFDocument219 pagesThe Lab Manual Rev 5 PDFJesrey Salazar MacaseroNo ratings yet

- MLDocument2 pagesMLMadhubalaNo ratings yet

- MLDocument2 pagesMLMadhubalaNo ratings yet

- Madhu Me Syllabus PDFDocument4 pagesMadhu Me Syllabus PDFMadhubalaNo ratings yet

- Presentation 2Document21 pagesPresentation 2MadhubalaNo ratings yet

- MATLAB code for free space and Okumura path loss modelsDocument4 pagesMATLAB code for free space and Okumura path loss modelskomakal yalni kNo ratings yet

- ManetDocument106 pagesManetarulrajiv1No ratings yet

- zSAP-BOE-2016 14 ML Watson IoT Platform PDFDocument20 pageszSAP-BOE-2016 14 ML Watson IoT Platform PDFMadhubalaNo ratings yet

- Sensing PDFDocument8 pagesSensing PDFSaiKishoreNo ratings yet

- Media KitDocument22 pagesMedia KitEmilyNo ratings yet

- Luxand FaceSDK DocumentationDocument117 pagesLuxand FaceSDK DocumentationrdhartzNo ratings yet

- Epoxy HRDocument5 pagesEpoxy HRMuthuKumarNo ratings yet

- Sublime Union: A Womans Sexual Odyssey Guided by Mary Magdalene (Book Two of The Magdalene Teachings) Download Free BookDocument4 pagesSublime Union: A Womans Sexual Odyssey Guided by Mary Magdalene (Book Two of The Magdalene Teachings) Download Free Bookflavia cascarinoNo ratings yet

- TN Govt RecruitmentDocument12 pagesTN Govt RecruitmentPriyanka ShankarNo ratings yet

- An Improvement in Endodontic Therapy You Will AppreciateDocument2 pagesAn Improvement in Endodontic Therapy You Will AppreciateIs MNo ratings yet

- Bajaj Internship ReportDocument69 pagesBajaj Internship ReportCoordinator ABS100% (2)

- Risus License Information PDFDocument1 pageRisus License Information PDFSam CorbenNo ratings yet

- Project On Honda Two WheelersDocument46 pagesProject On Honda Two WheelersC SHIVASANKARNo ratings yet

- Feedback Control of Dynamic Systems Franklin 7th Edition Solutions ManualDocument36 pagesFeedback Control of Dynamic Systems Franklin 7th Edition Solutions Manualkilter.murk0nj3mx100% (31)

- Readings On The History and System of The Common Law - Roscoe PoundDocument646 pagesReadings On The History and System of The Common Law - Roscoe PoundpajorocNo ratings yet

- Mfi in GuyanaDocument19 pagesMfi in Guyanadale2741830No ratings yet

- Engine Rear Oil Seal PDFDocument3 pagesEngine Rear Oil Seal PDFDIEGONo ratings yet

- (Leon 2021) Pengaruh Financial Distress, Laverage Terhadap Konservatisme Akuntansi Pada Perusahaan Manfaktur Sektor Konsumsi 2016-2019Document24 pages(Leon 2021) Pengaruh Financial Distress, Laverage Terhadap Konservatisme Akuntansi Pada Perusahaan Manfaktur Sektor Konsumsi 2016-2019PUTRI AYU HASTUTINo ratings yet

- Viennot - 1979 - Spontaneous Reasoning in Elementary DynamicsDocument18 pagesViennot - 1979 - Spontaneous Reasoning in Elementary Dynamicsjumonteiro2000No ratings yet

- 1 MergedDocument93 pages1 MergedAditiNo ratings yet

- Portable USB ChargerDocument13 pagesPortable USB ChargerParmar KundanNo ratings yet

- DOCS-#165539-v8-Technical Manual FOB4 TS Section 5 - MaintenanceDocument108 pagesDOCS-#165539-v8-Technical Manual FOB4 TS Section 5 - MaintenanceBME AOHNo ratings yet

- Arnica The Miracle Remedy - Case RecordsDocument4 pagesArnica The Miracle Remedy - Case Recordskaravi schiniasNo ratings yet

- Hyundai 14 - 16 - 20 - 25BRJ-9Document8 pagesHyundai 14 - 16 - 20 - 25BRJ-9NayanajithNo ratings yet

- NAFTA CertificateDocument2 pagesNAFTA Certificateapi-522706100% (4)

- Continuous Improvement Strategies in TQMDocument28 pagesContinuous Improvement Strategies in TQMSimantoPreeomNo ratings yet

- GFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportDocument21 pagesGFEI International Comparison of Light-Duty Vehicle Fuel Economy - Evolution Over Eight Years From 2005 To 2013 - TransportRayane LimaNo ratings yet

- A Review of High School Economics Textbooks: February 2003Document27 pagesA Review of High School Economics Textbooks: February 2003Adam NowickiNo ratings yet

- The Guide To Modern Event PlanningDocument31 pagesThe Guide To Modern Event Planningsilversurfer123No ratings yet

- Gorsey Bank Primary School: Mission Statement Mission StatementDocument17 pagesGorsey Bank Primary School: Mission Statement Mission StatementCreative BlogsNo ratings yet

- RCD-GillesaniaDocument468 pagesRCD-GillesaniaJomarie Alcano100% (2)

- USA Gas TurbineDocument4 pagesUSA Gas TurbineJustin MercadoNo ratings yet

- Teaching Methods in The PhilippinesDocument2 pagesTeaching Methods in The PhilippinesTonee Marie Gabriel60% (5)

- Pertanyaan Dan Jawaban Interview Dengan Bahasa InggrisDocument2 pagesPertanyaan Dan Jawaban Interview Dengan Bahasa Inggrissan_idrus_sip99No ratings yet