Professional Documents

Culture Documents

Storage of Renewable Energy Using Phase Change Materials (PCMS)

Uploaded by

Luis Felipe Gutierrez MarcantoniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Storage of Renewable Energy Using Phase Change Materials (PCMS)

Uploaded by

Luis Felipe Gutierrez MarcantoniCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/333080832

Storage of Renewable Energy Using Phase Change Materials (PCMs)

Conference Paper · November 2012

CITATIONS READS

0 105

2 authors:

Samit Jain Nidhi Agrawal

Pluss Advanced Technologies Pvt Ltd Pluss Advanced Technologies Pvt. Ltd. Gurgaon

52 PUBLICATIONS 30 CITATIONS 7 PUBLICATIONS 0 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Phase Change Material Applications View project

Specialty Polymers View project

All content following this page was uploaded by Samit Jain on 14 May 2019.

The user has requested enhancement of the downloaded file.

PLUSS®

Storage of Renewable Energy Using Phase Change Materials (PCMs)

Authors:

Nidhi Agrawal; Pluss Polymers Pvt. Ltd., nidhi@pluss.co.in

Suman Kumari; Pluss Polymers Pvt. Ltd., suman@pluss.co.in

Devendra Jain; Pluss Polymers Pvt. Ltd., djain@pluss.co.in

Abstract

Renewable energy from natural resources such as solar, wind, and geothermal accounted for as much as 16.7% of

the total energy consumption in the world (2010). It is expected to increase exponentially in the coming years. Solar

Energy in India is expected to touch 20000 MW of electricity generation by 2022 under the Jawaharlal Nehru National

Solar Mission. Use of renewable energy, benefits the environment, strengthens our energy security, and helps improve

our economy. The challenge today is not of renewable energy generation but energy storage. As an attempt to store

and utilize renewable energy, Phase Change Materials (PCMs) play a major role. These materials work on the basic

principle of storing energy while changing phases between the three states of matter. Of the three states, liquid-solid

transition is widely utilized. The thermal energy is stored as latent heat of fusion/solidification. A wide range of PCMs

ranging from -30oC to +90oC have been indigenously developed for the first time in India. In addition to the

commercialization of PCMs of different temperature range, research and development for enhancing the properties of

the end commercial product is also being carried out. A few of the properties of PCMs being researched on to improve

their commercial acceptance are: increasing the heat transfer rate and simplifying the process of charging for heating

applications. This includes the use of Microwaves, which are used worldwide for heating and cooking. PCMs have

also posed a problem due to leakage of encapsulations during the life time of a

product. To address this, successful research has been carried out to develop form stable PCM where the PCM does

not lose its shape during phase transition. The presentation will elaborate on the above and specifically provide the

current state of the art of PCMs, their future in India and comparison with rest of the world. The paper stresses on

commercial applications of the developed PCMs to enable low cost thermal energy storage solutions for the

developing world.

1 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

Why conserve renewable energy?

In India there are a number of factors which contribute to the current situation of energy crisis. There has

been a sharp rise in the consumption of energy since the last decade of 20th century. Hydroelectricity is a

cheap source of energy but is inflexible in terms of location. Other renewable energy resources such as solar

power, geo-thermal, tidal power are in a nascent stage of development and are commercially unviable.

Non-renewable energy is the major resource of total energy resources of the country; For example, coal, oil

or gas fired power stations produce electricity. Petroleum derivatives are used in the transportation sector.

Major problem here is that India has to import most of these non renewable petroleum products. The need

for environmental durability in everything we do and produce has become one of the most critical issues

today. How we create, use and recycle various forms of energy is an important factor.

Phase Change Materials (PCMs): A Method of conserving renewable and non renewable energy

What are PCMs?

PCMs are energy storage materials that have considerably higher thermal energy storage densities compared

to sensible heat storage materials. They absorb or release large quantities of energy at a constant

temperature by undergoing a change of phase.

There are three states of matter – solid, liquid and gas. A phase change is a change between two of these

states. For example, in a boiling saucepan, water becomes steam – it changes from its liquid state to its

gas state. The ‘magic’ of these phase changes is that it takes a lot of energy to pass through them.

Studies conducted to compare phase change and sensible heat storages have shown that a significant

reduction in storage volume can be achieved using PCM compared to sensible heat storage [1]. For example,

to store the same amount of energy from a unit solar collector area, rock (sensible heat storage material)

requires more than seven times the storage mass of paraffin wax, five times the storage mass of medicinal

paraffin and more than eight times the storage mass of Na2SO4.10H2O. [2, 3]

A latent heat thermal storage system has following three main components:

1. A PCM suitable for the desired temperature range;

2. A container for the PCM (encapsulations of PCMs);

3. A heat exchange surface for transferring the heat from heat source to PCM and from PCM to the

heat sink. [4]

Applications: How does PCM conserve Energy?

1. Conservation of Solar energy

Various applications in India, like crop drying, solar water heating, solar cooking is dependent on

sun’s heating rays. Solar energy usage sounds very effective and economic, but in actual use the

energy is available only one third the times in 24hours. Remaining number of hours is left in dark and

more specifically heat deficient. Hence to use the solar energy effectively and efficiently, the

requirement is to save it, when it is in abundance and use it when there is scarcity, i.e., at night. Many

research papers prove the concept but the utilization of the concept has not been done to its full extent

2 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

[5-12]. The papers referred here, use oil and stone to conserve solar energy. Results show that the

backup time obtained here is not sufficient for the actual application. The reason behind this lies in

the fact that the energy stored during the daytime gets conserved in the form of specific heat which

does not last long.

Figure 1

PCMs present a solution to this problem. The energy in PCMs during the daytime gets stored in the

form of latent/sensible heat. This heat is stored at a temperature corresponding to the transition

temperature of the product. savE® OM48, savE® OM53, savE® HS58 are being explored for this

purpose. Here, either of the mentioned products absorbs heat during the day time and releases the heat

later in the day thereby maintaining the constant temperature for the application before the next

sunshine. These PCMs find application in applications such as solar drying and solar water heating.

HS89 is useful in solar cooking. The line and bar graph below shows the temperature profile and

enthalpy distribution of savE® OM53 (Organic based) respectively.

Figure 2: T-History and enthalpy graph of savE® OM53

Solar dryers with thermal storage

The thermal storage with a solar air heater allows continuous drying during partial clouds and/or

evening/night hours, increasing the utility and reliability of the solar dryers.

Most parts of India receive mean daily solar radiation in the range of 5-7 kWh/m2, and have more than

275 sunny days in a year. Hence, solar drying has a high potential of diffusion in the country, and offers a

viable option in the domestic and small farm sector. It is identified as an appropriate technology for

Indian masses, and has numerous advantages such as

3 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

1. No recurring cost,

2. Potential to reduce drudgery,

3. High nutritional value of food,

4. High durability, and

5. No thermal shocks.

Figure 3 depicts of a solar drying system as proposed by Pluss.

Figure 3: Proposed set up for solar dryer

There is need to focus on hybrid solar drying with latent heat storage materials. The experimental work

done by researchers has limited the use of latent heat to paraffin wax only. Paraffin wax itself suffers

from a drawback of low thermal conductivity. Hence the target should be to employ the materials which

can utilize the latent heat thereby using its steady and moderate temperature maintenance properties. The

thermal conductivity problems can also be resolved by using various thermal conductivity enhancement

techniques; like introducing fins, adding high conductivity particles, inserting metallic foams, metal fibers

etc.

Another application for storing solar energy is in Concentrated Solar Power generation. Concentrated

solar power (CSP) systems use mirrors or lenses to concentrate a large area of sunlight, or solar thermal

energy onto a small area. Electrical power is produced when the concentrated radiation is converted to

heat, which drives a heat engine connected to an electrical power generator. But the dependence on solar

energy only inhibits the performance of the power plant and hence generation of electricity. Use of higher

temperature PCMs allows the continuous generation of electricity. To increase the efficiency of solar

plant, Michels and Pitz-Paal used a cascade of multiple phase change materials (PCM) which include:

sodium nitrate (NaNO3), an eutectic mixture of potassium nitrate and potassium chloride (KNO3/KCl) and

potassium nitrate (KNO3) [14].

Use of proper design of heat exchanger and high thermal conductivity of the PCM allows the solar plant

to generate electricity continuously.

2. Space Heating/cooling

Plaster board has been in constant development since 1980s. Microencapsulated paraffin capsules

available from BASF and others have been incorporated in gypsum during manufacturing of the

board. The boards may be installed on the inside or outside of the building. Boards, when installed

4 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

inside allow utilization of 90-95% of the theoretical Thermal Energy Storage (TES) capacity against

10-15% if on the outside wall (outside the insulation). Use of such boards has been limited due to the

high cost and consequently a long payback period of 8-12 years. UPM, Spain have developed and

patented a board, based on use of 45% paraffin microcapsules compared to 26% normally used. With

this a payback period of one to two years is achieved. It reduces up to 40% of the energy consumption

of the building [13].

Phase Change Material can be used for space / floor heating applications in different forms. One of

them is keeping the PCM filled panels or blister packs under the floor with suitable arrangements. In

this application the PCM can also be used as an energy bank in bulk containers like tank and suitable

fluid flow is provided through the tank to get back the stored energy. In general solar energy is being

used to store in the form of heat into the PCMs and the stored energy is used in the cold times (evening).

If any waste heat sources are available, these can also be used.

In solar energy storage method, both air and water can be used as the heat transfer fluid to collect the

heat energy from solar radiation. The heated fluid is passed through the PCM and thus the heat energy

is transferred (stored) in the PCM during the day time. The excess heat from the solar energy gets stored

in the PCM and the room temperature is maintained at comfortable condition. During evening / night,

the fluid is passed between the room / floor. The energy stored in the PCM is utilized by the passing

fluid. Thus the temperature of the room is always maintained in a comfortable range throughout the

day.

Further, apart from the above methods, inside walls of the building can be lined with the panels filled

with PCM. Here, electrical load is used to charge the PCM. Depending on the environment, suitable

temperature Phase Change Material is selected. Phase Change Material such as savE® HS22, savE®

HS24, savE® HS29, savE® OM32, etc from Pluss Polymers are suitable for above applications.

Figure 4: T-History and enthalpy graph of savE® HS22

Pluss is also working on use of form stable PCM for use of these applications which will allow a very

high PCM content in the wall panels. Initial trials indicate up to 80% content is possible.

3. Cold chain

PCM finds large scale application in refrigerators. Many places in India face long hours of power cut.

During this period, temperature of the cooling unit shoots up at a very high rate. Technically the problem

seems to be irresolvable, as the functioning of the refrigerator is dependent on availability of

5 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

electricity. PCM works as boost to the cold chain industries where such problems become a barrier to

further growth. Variety of PCMs can be useful for such applications, depending on the temperature,

manufacturer/user wants to maintain inside the unit. Figure 5 shows the two applications where PCM

is installed for transportation.

(a) (b)

Figure 5(a): Transportation in vehicles. An alternative way of transporting at constant temperature

Figure 5(b): Polystyrene foam box incorporating PCM for pharmaceutical transportation

Range of PCMs commercially available from Pluss Polymers include FROST®, savE® HS7N, savE®

HS10N, savE® HS15N, savE® HS23N are commercially available. All the above mentioned PCMs are

hydrated salt (Inorganic) based. Specialty of these products is that they come with a high latent heat

so as to provide the minimum of 4-6 hours of back up time during black out. A domestic refrigerator

where the inside temperature of the freezer ranges from -22oC to -5oC, savE® HS7N stores the cold

energy and utilizes it during black out. Similar to this application, is for the freezers on wheel where

the ice cream needs to be kept at a temperature below -19oC, savE® HS 23N serves the purpose. Because

of the high latent available with the product, it maintains a temperature below -19oC for 12 hours or

more. Figure below shows the temperature profile of savE® HS7N during melting and freezing.

The bar graph along with it shows the enthalpy distribution of savE® HS7N between 5 degree

above and below the transition temperature. To interpret, each bar represents the enthalpy available in

savE® HS7N at each degree as the PCM passes the temperature difference of 10oC.

Figure 6: T-History and enthalpy graph of savE® HS7N

4. Conserving non-renewable resources

A few applications in India are fuel dependent which cause to environmental issues and do not make

it cost effective. Use of PCM in such applications reduces the cost involved with fuel consumption

and hence reducing the emission of harmful gases. For example in transportation of vaccines and

6 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

other food products where the temperature is to be maintained in the range of 4-8oC, air conditioning

in AC operated vans can be replaced by PCMs panels. The panels filled with suitable PCMs like

FROST® is lined along the walls of the vehicle. Amount can be varied according to the backup hours

required. FROST® panels are charged by regular freezers before installing the panels in van. Similarly

savE® HS29 is used to maintain the temperature inside telecom shelters whenever there is a power

cut. Panels can be arranged dependent on the space available. While the electricity is available, panels

get charged, i.e. PCM gets frozen below its freezing point and the stored cold energy is utilized

whenever temperature rises above 29oC, thereby maintaining the constant temperature without

dissipating harmful gases in the atmosphere, which would otherwise result from use of DG sets.

Application development

Conventional method of using any PCM is to fill in pouches and panels. These method leads to utilization

of 100% latent heat as against the PCMs which can be converted to be. However, the conventional

method suffers with the drawback of leakage. Encapsulation, if punctured due to mishandling or

packaging may lead to leakage of the PCMs at application site. Hence the requirement is to develop a PCM,

which remains solid even at 10 degree above the transition temperature. Form stable is not new in the field

of thermal storage but the techniques described in the literature are either complicated or suffer from the

drawback of low latent heat. Work has been done by Pluss Polymers to overcome the mentioned detriment.

Latent heat obtained from the composite of form stable PCM is above 200 kJ/kg, and is the most

desirable property for any PCM in any application. Form Stable PCMs are blends of polymers with the

PCM material which are then converted into polymeric sheets or pelletized. Figure 7 below shows the

application of form stable PCM in Jackets.

Figure 7: Jackets designed with pockets to carry PCM

Any raw PCM when in solid state causes discomfort to the user while working. Using form stable PCM

enables the user to bend and do any kind of work with complete flexibility. Moreover, the user always

remains protected from any kind of leakage due to puncturing of pouches.

PCM application: World Market Scenario

Building and construction application is the largest market for PCMs in terms of revenue. In 2010, it was

approximately $86.9 million and is expected to grow with a CAGR of 37.6% from the year 2010 to 2015.

Companies are mainly focusing on increasing awareness about the advantages of PCM in buildings. The

textile applications of PCMs are expected to grow at a CAGR of 38.5% from the year 2010 to 2015 [15].

The key players in this application market are Outlast Technologies, and Glacier Tek. These companies

are also partnering with branded textile and apparel companies such as Nike, Bison, Achidatex, KMA,

7 WAITRO, 5-6th November 2012, New Delhi

PLUSS®

Logistics and textiles B.V. for increasing awareness about the PCM integrated materials. Other key

players in the field which are actively working are BASF, Rubitherm, Climator, EPS and Entropy

solutions. They are focusing on introducing novel products to increase the thermal efficiency of the PCM

products. They are undergoing collaborations with the application/commercial users to increase the

awareness of thermal storage. PCM is in its initial stage of commercialization, and the prices of these

materials are higher than the other insulating materials like wood. Therefore, it becomes important on part

of PCM companies to establish strong marketing relationships with the end-users to convince them of the

advantages of using PCM products.

The prices are expected to reduce as the level of awareness increases, volumes grow and the products are

used in more and more applications. In practice cost of manufacturing of PCM is low but large sum of

money is spent on the Research and development, marketing and advertising, which then inflates the cost

of PCM products. In near future, with the adoption of this technology on large scale, manufacturing

expenses of PCM products will come down.

References

1. F. Agyenim, N. Hewitt, P. Eames, M. Smyth; A review of materials, heat transfer and phase change problem

formulation for latent heat thermal energy storage systems (LHTESS); Renewable and Sustainable Energy

Reviews 2010; 14: 615-628.

2. Morrison, Abdel-Khalik; Effects of phase change energy storage on the performance of air based and liquid

based solar heating systems; Solar Energy 1978; 20:57-67.

3. A.A. Ghoneim; Comparison of theoretical models of phase change and sensible heat storage for air and water

based solar heating systems; Solar Energy 1989; 42(3):209-220.

4. A.F. Regin, S.C. Solanki, J.S. Saini; Heat transfer characteristics of thermal energy storage system using PCM

capsules: A Review; Renewable and Sustainable Energy Reviews 2008; 12: 2438-2458.

5. J.L. Butler, J.M. Troeger; Drying peanuts using solar energy stored in a rockbed. Agricultural energy vol. I,

Solar Energy, selected papers and abstracts. ASAE publication, St. Joseph, Michigan 1980.

6. H.P. Garg, V.K. Sharma, R.B. Mahajan, A.K. Bhargave. Experimental study of an inexpensive solar collector

cum storage system for agriculture uses. Solar Energy 1985; 35(4): 321-331.

7. G.N. Tiwari, A.K. Singh, P.S. Bhatia. Experimental simulation of a grain drying system. Energy Conservation

and Management 1994; 35(5): 453-458.

8. Ayensu, V. Asiedu-Bondzie. Solar drying with convective self flow and energy storage. Solar Wind and

Technology 1986; 3(4): 273-279.

9. P.M. Chouhan, C. Choudhary, H.P. Garg. Comparative performance of coriander dryer coupled to solar air

heater and solar air-heater-cum-rockbed-storage. Applied Thermal Engineering 1996; 16(6): 475-486.

10. Ayensu. Dehydration of food crops using a solar dryer with convective heat flow. Solar Energy 1997; 59(4-6):

121-126.

11. S. Devahastin, S. Pitaksuriyarat. Use of latent heat storage to conserve energy during drying and its effect on

drying kinetics of a food product. Applied thermal Engineering 2006; 26: 1705-1713.

12. P.A. Potdhuke, S.B. Thombre. Development of a new type of solar dryer: its mathematical modeling and

experimental evaluation. International Journal of Energy Research 2008; 32: 765-782.

13. http://phys.org/wire.news/105457166/new-energy-efficient-building-material.html, August 2012.

14. H. Michels, R. Pitz-Paal, Cascaded latent heat storage for parabolic trough solar power plants; Solar Energy

(2007); 81: 829-837.

15. Advanced Phase Change Material (PCM) market: Global forecast (2010-2015): By Markets and Markets.

8 WAITRO, 5-6th November 2012, New Delhi

View publication stats

You might also like

- Phase Change Materials (PCM) For Solar Energy Usages and Storage: An OverviewDocument20 pagesPhase Change Materials (PCM) For Solar Energy Usages and Storage: An Overviewmailsk123No ratings yet

- 4 Ways of Storing Hydrogen From Renewable Energy - Spectra - June 2020Document9 pages4 Ways of Storing Hydrogen From Renewable Energy - Spectra - June 2020F SedighiNo ratings yet

- Jatinpatel2016 2 JapanDocument10 pagesJatinpatel2016 2 JapanIsmael El ShamyNo ratings yet

- Benefits of Using Electricity From Renewable Energy SourcesDocument45 pagesBenefits of Using Electricity From Renewable Energy SourcesDjurdjina Petkovic100% (1)

- Study On Behaviour of Thermal Energy Storage Materials Under Conventional and Solar Heating SystemsDocument7 pagesStudy On Behaviour of Thermal Energy Storage Materials Under Conventional and Solar Heating SystemsMukul SainNo ratings yet

- Colectores SolaresDocument36 pagesColectores SolaresJavier Ignacio TrepianaNo ratings yet

- Hello!: Eduard CasalmeDocument16 pagesHello!: Eduard CasalmePhilip ArpiaNo ratings yet

- Earth Sci Week 4 SagotDocument2 pagesEarth Sci Week 4 SagotKyla Francine TiglaoNo ratings yet

- Materials Today: Proceedings: C.M. Vivek, P. Ramkumar, P.K. Srividhya, M. SivasubramanianDocument5 pagesMaterials Today: Proceedings: C.M. Vivek, P. Ramkumar, P.K. Srividhya, M. SivasubramanianMuhammadAsimNo ratings yet

- RER Mod3@AzDOCUMENTS - inDocument17 pagesRER Mod3@AzDOCUMENTS - inrahulNo ratings yet

- Phy (Project)Document12 pagesPhy (Project)AvinashNo ratings yet

- A Review On Applications of Phase Change Materials in Solar DistillationDocument15 pagesA Review On Applications of Phase Change Materials in Solar DistillationAlberto LepelNo ratings yet

- Design On RefrigerationDocument4 pagesDesign On RefrigerationShubham SharmaNo ratings yet

- Energy Conservation Techniques For Manufacturing IndustriesDocument11 pagesEnergy Conservation Techniques For Manufacturing IndustriesIJRASETPublicationsNo ratings yet

- Benefits of Using Electricity From Renewable Energy SourcesDocument44 pagesBenefits of Using Electricity From Renewable Energy SourcesDjurdjina PetkovicNo ratings yet

- Untitled DocumentDocument13 pagesUntitled DocumentKokki KumarNo ratings yet

- Seminar FinaleDocument27 pagesSeminar FinaleDevam KengeNo ratings yet

- Energy Storage Technology-23.04-Rev1Document51 pagesEnergy Storage Technology-23.04-Rev1huanran zhouNo ratings yet

- Renewable Energy and The Development of Dendropower in India and SE AsiaDocument24 pagesRenewable Energy and The Development of Dendropower in India and SE AsiaweaeaNo ratings yet

- Blossoming Sources of EnergyDocument6 pagesBlossoming Sources of EnergyRaghavendra RaghavNo ratings yet

- 1 s2.0 S2213138823002916 MainDocument14 pages1 s2.0 S2213138823002916 MainMB NeoFluxNo ratings yet

- The Relation of Collector and Storage Tank Size in Solar Heating SystemsDocument7 pagesThe Relation of Collector and Storage Tank Size in Solar Heating SystemsSpidy PoudelNo ratings yet

- Solar Energy As Renewable Energy Source: SWOT Analysis: January 2019Document6 pagesSolar Energy As Renewable Energy Source: SWOT Analysis: January 2019Quicksilver 1975No ratings yet

- Solar Training at ONGC, DehradhunDocument54 pagesSolar Training at ONGC, DehradhunParveen ChoudharyNo ratings yet

- Energy Conservation in IndustriesDocument31 pagesEnergy Conservation in IndustriesAmit AnandNo ratings yet

- Hydrogen Storage in Porous Silicon - A ReviewDocument12 pagesHydrogen Storage in Porous Silicon - A Reviewgabriela plaiasuNo ratings yet

- American International University-Bangladesh (AIUB) Faculty of Engineering (EEE)Document4 pagesAmerican International University-Bangladesh (AIUB) Faculty of Engineering (EEE)Mahatab UddinNo ratings yet

- Master Thesis Renewable Energy PDFDocument6 pagesMaster Thesis Renewable Energy PDFKathryn Patel100% (2)

- Sustainable Energy Review July-September 2016Document16 pagesSustainable Energy Review July-September 2016Har HamNo ratings yet

- Performance Analysis of A Solar Grape Dryer With Thermal Energy Storage by PCMDocument7 pagesPerformance Analysis of A Solar Grape Dryer With Thermal Energy Storage by PCMAVES HUSAINYNo ratings yet

- Est MDocument13 pagesEst MshubhaMNo ratings yet

- Murali 2019Document35 pagesMurali 201911751175No ratings yet

- Economic and Eco-Friendly Analysis of Solar Power Refrigeration SystemDocument5 pagesEconomic and Eco-Friendly Analysis of Solar Power Refrigeration SystemSiddh BhattNo ratings yet

- Renewable Energy Thesis ProposalDocument4 pagesRenewable Energy Thesis Proposalangelagibbsdurham100% (2)

- ES - E NotesDocument117 pagesES - E NotesMuzammil Ali SyedNo ratings yet

- Improving Solar Cooker Performance Using Phase Change Materials: A Comprehensive ReviewDocument26 pagesImproving Solar Cooker Performance Using Phase Change Materials: A Comprehensive ReviewCARPE NOCTEMNo ratings yet

- Development and Performance Evaluation of A Solar Energy Based Portable Micro Cold StorageDocument11 pagesDevelopment and Performance Evaluation of A Solar Energy Based Portable Micro Cold Storagegorka.aldayaNo ratings yet

- Energy Conservation Research Paper PDFDocument5 pagesEnergy Conservation Research Paper PDFgw2xyzw9100% (1)

- Renewable Energy Dissertation PDFDocument8 pagesRenewable Energy Dissertation PDFDoMyPaperAlbuquerque100% (1)

- Ijetae Icertsd 0213 48Document5 pagesIjetae Icertsd 0213 48Cristina DumitruNo ratings yet

- Green SinergyDocument14 pagesGreen SinergyditaNo ratings yet

- Wjet 2023071211334484Document22 pagesWjet 2023071211334484hammadbedo00No ratings yet

- Journal Homepage: - : IntroductionDocument5 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- 2-Background of The StudyDocument3 pages2-Background of The StudysharmaineNo ratings yet

- Technical ReportDocument5 pagesTechnical Reportapi-721867833No ratings yet

- 1) It's .Renewable!Document5 pages1) It's .Renewable!Huyền ĐinhNo ratings yet

- Case StudyDocument60 pagesCase Studyj4leschelNo ratings yet

- Han Solar and The Green Supply Chain: O R - H S R C LDocument12 pagesHan Solar and The Green Supply Chain: O R - H S R C LVkNo ratings yet

- Designing and Fabrication of Double Pass Solar Air Heater Integrated With Thermal StorageDocument7 pagesDesigning and Fabrication of Double Pass Solar Air Heater Integrated With Thermal StorageM. RazaNo ratings yet

- Thesis Topics For Renewable EnergyDocument4 pagesThesis Topics For Renewable Energyheatherleeseattle100% (2)

- Zero To Green Final ReportDocument36 pagesZero To Green Final ReportSriram Ranganathan100% (1)

- Research Paper On Energy ConservationDocument4 pagesResearch Paper On Energy Conservationkkxtkqund100% (1)

- Energy Dissertation TopicsDocument4 pagesEnergy Dissertation TopicsThesisPapersForSaleSingapore100% (1)

- International Journal of Engineering Research and Development (IJERD)Document7 pagesInternational Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- ShubhankarDocument13 pagesShubhankarShubhankar KhandaiNo ratings yet

- Solar Refrigeration ReportDocument64 pagesSolar Refrigeration ReportSakshi JoshiNo ratings yet

- Electricity Storage System A Gravity Battery IEEEDocument5 pagesElectricity Storage System A Gravity Battery IEEEThoriq HilmuddinNo ratings yet

- Thesis Alternative EnergyDocument8 pagesThesis Alternative Energyjessicaoatisneworleans100% (2)

- Unit 5 World Energy ScenarioDocument43 pagesUnit 5 World Energy ScenarioRitvikNo ratings yet

- Uncertainties and CFD Code Validation: H. W. ColemanDocument9 pagesUncertainties and CFD Code Validation: H. W. ColemanLuis Felipe Gutierrez MarcantoniNo ratings yet

- Modelling Liquid-Solid Phase Changes With Melt ConvectionDocument17 pagesModelling Liquid-Solid Phase Changes With Melt ConvectionLuis Felipe Gutierrez MarcantoniNo ratings yet

- Energies: An Optimum Enthalpy Approach For Melting and Solidification With Volume ChangeDocument21 pagesEnergies: An Optimum Enthalpy Approach For Melting and Solidification With Volume ChangeLuis Felipe Gutierrez MarcantoniNo ratings yet

- Report CAPPELLIDocument81 pagesReport CAPPELLILuis Felipe Gutierrez MarcantoniNo ratings yet

- Fulltext01 PDFDocument164 pagesFulltext01 PDFLuis Felipe Gutierrez MarcantoniNo ratings yet

- Grid Convergence Error Analysis For Mixed-Order Numerical SchemesDocument48 pagesGrid Convergence Error Analysis For Mixed-Order Numerical SchemesLuis Felipe Gutierrez MarcantoniNo ratings yet

- Verification and Validation in Computational Fluid DynamicsDocument64 pagesVerification and Validation in Computational Fluid Dynamicssanthiyaj100% (1)

- Numerical Solution of The Compressible Laminar Boundary Layer Equations - CuriosityFluidsDocument10 pagesNumerical Solution of The Compressible Laminar Boundary Layer Equations - CuriosityFluidsLuis Felipe Gutierrez Marcantoni100% (1)

- Non NewtonianDocument14 pagesNon NewtonianLuis Felipe Gutierrez MarcantoniNo ratings yet

- D.J.Tritton - Physical Fluid Dynamics (2007, OUP) PDFDocument536 pagesD.J.Tritton - Physical Fluid Dynamics (2007, OUP) PDFlfgmarcantoni100% (1)

- Fluid Mechanics, 4: Edition, by Frank M. WhiteDocument8 pagesFluid Mechanics, 4: Edition, by Frank M. WhiteLuis Felipe Gutierrez MarcantoniNo ratings yet

- William C. Gardiner Jr. (Auth.), William C. Gardiner Jr. (Eds.) - Combustion Chemistry-Springer-Verlag New York (1984)Document514 pagesWilliam C. Gardiner Jr. (Auth.), William C. Gardiner Jr. (Eds.) - Combustion Chemistry-Springer-Verlag New York (1984)Luis Felipe Gutierrez Marcantoni100% (1)

- John H. S. Lee-The Gas Dynamics of Explosions-Cambridge University Press (2016)Document218 pagesJohn H. S. Lee-The Gas Dynamics of Explosions-Cambridge University Press (2016)Luis Felipe Gutierrez MarcantoniNo ratings yet

- Spherical VesselDocument26 pagesSpherical VesselLuis Felipe Gutierrez MarcantoniNo ratings yet

- K Omega SST DES ReportDocument65 pagesK Omega SST DES ReportLuis Felipe Gutierrez Marcantoni100% (1)

- Towards - The - Ultimate - Conservative - Difference - Scheme-I: The Quest of Monotonicity PDFDocument6 pagesTowards - The - Ultimate - Conservative - Difference - Scheme-I: The Quest of Monotonicity PDFLuis Felipe Gutierrez MarcantoniNo ratings yet

- A Practical General Two State HLL Riemann Solver For Hyperbolic Conservation LawsDocument12 pagesA Practical General Two State HLL Riemann Solver For Hyperbolic Conservation LawsLuis Felipe Gutierrez MarcantoniNo ratings yet

- Rankine HugoniotDocument21 pagesRankine HugoniotSaurabh KhandelwalNo ratings yet

- Shock Waves Amp Explosions Chapman and HallDocument280 pagesShock Waves Amp Explosions Chapman and HallLuis Felipe Gutierrez MarcantoniNo ratings yet

- CA Aa214b Ch5Document54 pagesCA Aa214b Ch5Luis Felipe Gutierrez MarcantoniNo ratings yet

- CFD TutorialsDocument56 pagesCFD TutorialsOsama A GhaniNo ratings yet

- Godunov-Type Methods For Gas Dynamics PDFDocument25 pagesGodunov-Type Methods For Gas Dynamics PDFLuis Felipe Gutierrez MarcantoniNo ratings yet

- AIAA 2010-0351 Detonation Turbulence InteractionDocument12 pagesAIAA 2010-0351 Detonation Turbulence InteractionLuis Felipe Gutierrez MarcantoniNo ratings yet

- FluxNumerical MethodsDocument16 pagesFluxNumerical MethodsLuis Felipe Gutierrez MarcantoniNo ratings yet

- FluxNumerical MethodsDocument16 pagesFluxNumerical MethodsLuis Felipe Gutierrez MarcantoniNo ratings yet

- Elements of Computational Fluid Dynamics: P. WesselingDocument147 pagesElements of Computational Fluid Dynamics: P. WesselingLuis Felipe Gutierrez MarcantoniNo ratings yet

- GMSH For Dolfyn TutorialDocument10 pagesGMSH For Dolfyn TutorialLuis Felipe Gutierrez MarcantoniNo ratings yet

- 06 BoundDocument31 pages06 BoundSubhashini RamamoorthyNo ratings yet

- Tutogmshto FoamDocument4 pagesTutogmshto FoamLuis Felipe Gutierrez MarcantoniNo ratings yet

- NEOM-NPR-GFR-Management Manual Rev 01Document24 pagesNEOM-NPR-GFR-Management Manual Rev 01MOHD ZEESHAN100% (3)

- Coolaudio V1402 DatasheetDocument8 pagesCoolaudio V1402 DatasheetlalomoneNo ratings yet

- Flydat Control Operator'S Manual: Aircraft EnginesDocument16 pagesFlydat Control Operator'S Manual: Aircraft EnginesNickNo ratings yet

- Ping20Si-DataSheet - Rev HDocument2 pagesPing20Si-DataSheet - Rev HANo ratings yet

- Linhai 600 Parts ManualDocument50 pagesLinhai 600 Parts ManualMădălina MureșanNo ratings yet

- The Innovative Solution: Performance Determines DesignDocument5 pagesThe Innovative Solution: Performance Determines DesignKristína100% (1)

- Eq List IEC 60335-2-14 (6.0) 2016-20170814Document3 pagesEq List IEC 60335-2-14 (6.0) 2016-20170814le duc huynhNo ratings yet

- Aircraft Design 30Document23 pagesAircraft Design 30Paul GernahNo ratings yet

- Knee Point Voltage Calculation of CTDocument1 pageKnee Point Voltage Calculation of CTJayam kondanNo ratings yet

- IOT BASED HEALTH MONITORING SYSTEM - DakshDocument17 pagesIOT BASED HEALTH MONITORING SYSTEM - DakshMohit MehraNo ratings yet

- ASTM C806-12 Restrained Expansion of Expansive Cement MortarDocument4 pagesASTM C806-12 Restrained Expansion of Expansive Cement MortarAlonso SojoNo ratings yet

- Smart Robotic Arm: CrustcrawlerDocument3 pagesSmart Robotic Arm: CrustcrawlerOmar FranciaNo ratings yet

- Wbcs 2022 AdmitDocument2 pagesWbcs 2022 AdmitChandra SudipNo ratings yet

- MYSWEETY GRBL Offline ControllerDocument7 pagesMYSWEETY GRBL Offline ControllerJuan José Bagur ColominasNo ratings yet

- Computer-3 1st QuarterDocument5 pagesComputer-3 1st QuarterEdmar John SajoNo ratings yet

- Introducing GUARDION Jan 2012Document44 pagesIntroducing GUARDION Jan 2012Jose SoaresNo ratings yet

- International Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonDocument13 pagesInternational Journal of Information Management: Min Yan, Raffaele Filieri, Matthew GortonmasukujjamanNo ratings yet

- About Search EnginesDocument7 pagesAbout Search EnginesMondano KentNo ratings yet

- VRZ Usa Iphone 11 128GBDocument1 pageVRZ Usa Iphone 11 128GBDamien Tucson100% (2)

- E-Mail Spam Detection Using Machine Lear PDFDocument7 pagesE-Mail Spam Detection Using Machine Lear PDFTrending this yearNo ratings yet

- ModuleDocument16 pagesModuleXzk MallaboNo ratings yet

- Introduction To MultimediaDocument217 pagesIntroduction To MultimediaMajestyNo ratings yet

- Manual IFQ Monitor en Rev 08-2022Document50 pagesManual IFQ Monitor en Rev 08-2022Gerald StiflerNo ratings yet

- Nadaraya-Watson Teoria PDFDocument9 pagesNadaraya-Watson Teoria PDFLUIS FABIAN URREGO SANCHEZNo ratings yet

- DC GeneratorDocument2 pagesDC GeneratorAravind Vinas100% (1)

- Unit4: Adapted Collider (LHC) Is The Largest Acce Erator and Collides Particle Beams On Questions ofDocument2 pagesUnit4: Adapted Collider (LHC) Is The Largest Acce Erator and Collides Particle Beams On Questions ofThắm NguyễnNo ratings yet

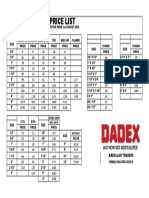

- Dadex Efast Price List 1ST August 2020Document1 pageDadex Efast Price List 1ST August 2020Jugno ShahNo ratings yet

- Online Application Help For MhadaDocument24 pagesOnline Application Help For Mhadakhanbarkat_noorNo ratings yet

- 117JJ112016Document2 pages117JJ112016DEVULAL BNo ratings yet