Professional Documents

Culture Documents

Spe-97886-Pa Reologia

Uploaded by

manuel cabarcasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spe-97886-Pa Reologia

Uploaded by

manuel cabarcasCopyright:

Available Formats

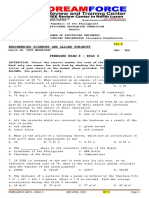

Rheology of Heavy-Oil Emulsions

Hussein Alboudwarej, Moin Muhammad, and Ardi Shahraki, Schlumberger; Sheila Dubey and Loek Vreenegoor,

Shell Global Solutions (US) Inc.; and Jamal Saleh, Shell International E&P

Summary In addition to formation blockage and general difficulty in the

Water is invariably produced with crude oil. If there is enough separation of oil and water in production facilities, one of the main

shear force when crude oil and produced water flow through the drawbacks of emulsion formation is an increase in the apparent

production path, stable emulsions may be formed. This scenario viscosity of the oil. Viscosity of water-in-oil emulsions increases

may particularly be present during the production of heavy oils, as the water cut increases before the so-called emulsion inversion

where steam is used to reduce the viscosity of heavy oil, or in cases point, beyond which the continuous phase changes to water (i.e.,

in which submersible pumps are used to artificially lift the pro- water-in-oil emulsion switches to oil-in-water emulsion). It has

duced fluids. To efficiently design and operate heavy-oil produc- been shown that the viscosity of the water-in-oil emulsion may

tion systems, knowledge of the realistic viscosities of the emulsi- increase as much as one order of magnitude or even higher over

fied heavy oil, under the actual production conditions, is necessary. the viscosity of the dry oil (Singh et al. 2004). In oil-in-water

This study is an attempt to investigate the effect of water content, emulsions, viscosity decreases with an increase in water content.

pressure, and temperature (i.e., operating conditions on the viscos- Therefore, the maximum apparent viscosity of emulsions occurs at

ity of live heavy-oil emulsions). the emulsion inversion point (Szelag and Pauzder 2003).

Two heavy oil samples from South America were used for this One of the field implications of emulsion inversion and emul-

study. The stock tank oil (STO) samples were recombined with the sion viscosity is the transportation of heavy oil-in-water emulsions.

corresponding flash gases to reconstitute the original reservoir oil It has been shown that under certain conditions, the viscosity of

compositions. Live oil/water emulsions were prepared in a con- the heavy oil-in-water emulsion is considerably lower than the

centric cylinder shear cell using synthetic formation water, under heavy oil (Nunez et al. 2000). Because water production is gen-

predetermined pressure, temperature, and shear conditions. The erally increasing with the life span of the oil production field, it

stability of live emulsions was investigated using a fully visual is also very important to have an accurate measure of the emul-

pressure/volume/temperature (PVT) cell, while viscosities were sion inversion point and viscosity for optimum pipeline and facil-

measured using a precalibrated, high-pressure capillary viscom- ity design.

eter. Viscosities were measured at least in three different flow rates The majority of experimental work on the emulsion stability

at the testing conditions. In addition to live-oil emulsion studies, and viscosity measurements is performed for STO samples. How-

the stability and droplet size distribution of STO emulsions were ever, dissolved gases affect the viscosity of oil and the correspond-

also determined. ing emulsions. For optimum design and operation of the oilfield

Experimental results indicated that the inversion point for the production facilities, knowledge of live-oil emulsion properties is

STO emulsions was approximately 60% water cut (volume), and required. In the present work, stability and viscosity of two South

the average droplet size was increasing with water content. For all American live heavy-oil emulsions were studied. Live-oil emul-

measured cases, viscosities varied with temperature according to sions were prepared in a shear cell and analyzed in a visual PVT

an Arrhenius relation, while viscosities did not indicate any varia- cell for stability and in a capillary viscometer for viscosity mea-

tion with flow rate (shear) within the range of tested flow rates. surement. The information from this study may be used for both

Measured viscosities also increased as pressure decreased below facility-pipeline and artificial lift system design.

the bubblepoint of the sample as lighter hydrocarbon components The study of the performance of ESP systems indicates that

evolved. The measured viscosities increased as much as 500% under these conditions, a given system will not be able to provide

because of the presence of emulsions before a sharp drop in vis- optimum performance if the water cut increases from 0 to 50%.

cosity beyond the inversion point. The variation of viscosity with For a system operating on unchanging parameters, the rate of

water content for live emulsion samples indicated that the inver- production will decrease drastically because of the scale of in-

sion point for live emulsions is similar to that of STO samples. crease in emulsion viscosity with water cut.

The experimental results are also used to analyze and evaluate

Experimental

the performance of an ESP system when water cut increases and

causes emulsion in a well. Two South American live-oil samples were used for this study.

The STO samples were recombined with 5-component synthetic

gas mixtures to reconstitute the reservoir fluid compositions. The

Introduction recombined samples were conditioned at reservoir pressure and

As an oilfield ages, the rate of water production increases. With temperature for a period of 5 days. The recombined samples were

enough shear force (e.g., flow through a downhole pump or a flow then analyzed for composition and physical properties, as shown in

restriction such as a choke valve or orifice), a stable emulsion can Tables 1 and 2 for Oil A and Oil B, respectively.

be formed. Presence of inorganic solids such as sand, clay, and To prepare emulsions, water samples with similar compositions

corrosion products, together with surface-active materials such as to reservoir waters were used. Compositions of formation water

asphaltenes and naphthenic acids, also enhance the stability of samples are provided in Table 3. Note that Water A and B cor-

emulsions (Kokal 2005). Because of the presence of these ele- respond to Oil A and Oil B, respectively. A high-pressure shear

ments, the occurrence of tight emulsions in the production facili- cell was used to prepare live emulsions. The device is a Taylor-

ties is quite common. In some cases, emulsions may also form in Couette flow device in which the annulus between the two con-

the near-wellbore region, leading to emulsion blockage of porous centric cylinders is used to provide the shear environment for the

media (Kokal et al. 2002). fluid. It is rated to pressures up to 7,000 psia, temperatures up to

390°F, and rotational frequencies (through a magnetic coupling)

up to 100 Hz. The operation of the shear cell is controlled auto-

matically to maintain operating conditions. To form emulsions, the

Copyright © 2007 Society of Petroleum Engineers

shear cell is first filled with a water sample, and then pressurized

This paper (SPE 97886) was accepted for presentation at the 2005 SPE/PS-CIM/CHOA and heated up to the desired set points. Water is then displaced

International Thermal Operations and Heavy Oil Symposium, Alberta, 1–3 November. Origi-

nal manuscript received for review 26 August 2005. Revised manuscript received 3 January

under live conditions with the oil sample until desired water/oil

2007. Paper peer approved 8 February 2007. volume ratio is achieved. The rotational speed in the cell then

August 2007 SPE Production & Operations 285

emulsifies the water under provided shear condition. After shear-

ing the mixture for the desired period of time, the cell content is

displaced with an inert gas isothermally and isobarically to a

sample cylinder equipped with an internal mixing ring. The emul-

sion cylinder is maintained under the same pressure and tempera-

ture and a continuous rocking condition. Emulsion samples are

transferred to a visual PVT cell for stability analysis and to a

capillary viscometer for viscosity measurement as needed. Table 4

summarizes the conditions under which different emulsions were

prepared. Note that the water cut (%vol) is defined as the volume

of water over the total volume expressed as percentage.

Stability analyses for STO samples were performed using

bottle tests; however, for live emulsion samples, a fully visual PVT

cell was used. Live emulsion samples were transferred from a

sample cylinder (with mixing ring) to the PVT cell. The magnetic

coupling in the PVT cell was turned off to eliminate any further

shearing of the sample. For live emulsion samples, only stability of

85% water-cut samples were tested.

A capillary viscometer rated to 10,000 psia and 374°F was used

for viscosity measurements. The capillary viscometer consists of

two, high-pressure cylinders (32 ml each) connected to a 10-ft-

long and 0.03-in. diameter capillary coil. A differential pressure

transducer is used to monitor the pressure drop across the capillary

coil. The fluid sample is pumped from one cylinder to the other

through the capillary coil by an opposed pump. From the measured

fluid-flow rate and pressure drop, the viscosity can be determined

using the Hagen-Poiseuille relationship for laminar flow in tubes,

namely

=

⌬p

Q

冉 冊 r4

8L

=

⌬p

Q

k, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (1)

where is the fluid apparent viscosity; ⌬p is the pressure drop

across the capillary tube of length, L, and an internal radius r; and

Q is the volumetric flow rate. The tube constant k is determined by

calibrating the viscometer using standards of known viscosity at

test pressures and temperature. Note that the maximum Reynolds

number for this study corresponding to the highest flow rate and

the lowest viscosity was approximately 25, indicating a fully lami-

nar flow. Shear stress at the wall can be calculated as

⌬p D

= , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (2)

4L

in which D is the internal diameter of the capillary tube, L is the

length of capillary tube, and ⌬p is the pressure drop across the

capillary tube. Shear rate at the wall may be calculated as

␥= , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (3)

in which and are wall shear stress and fluid apparent viscosity.

Results and Discussion

STO Emulsion Preparation and Stability Analysis. STO emul-

sions were prepared for both Oil A and Oil B samples to determine

the emulsion inversion points. The significance of the inversion

point is that generally, emulsions show the maximum viscosity at

or near the inversion point. Also, the STO inversion points may

give an idea about the corresponding live-oil emulsion inversion

286 August 2007 SPE Production & Operations

points. STO emulsions were prepared by simply adding proper speed is higher. A combination of lower rotational speed (i.e.,

volume ratio of oil and formation water, and hand-shaking the decoupling at higher rotational speed than 70 Hz) and higher vis-

mixture intermittently for at least half an hour. In all cases, both oil cosity leads to a lower shear rate environment for the case of 50%

and water had been equilibrated at 130 °F before mixing. No volume water content emulsion sample. Stability analysis was only

estimate of applied shear rate is available. The samples were kept performed on 85% water cut emulsions for both Oil A and Oil B

at the same temperature for at least 18 to 20 hours before any samples. Water separation could be observed as soon as the emul-

photomicrographs were taken. For the cases of 85% volume water sion sample was transferred from shear cell to the visual PVT cell

cuts, both Oil A and Oil B sample emulsions were unstable, and oil (in less than 15 minutes). Fig. 3 shows the segregated water and oil

and water started segregating instantaneously. in a visual PVT cell under the same conditions. Note that for the

Fig. 1 shows the results of stability bottle tests for STO Oil A case of Oil B, oil is partially adhered to the glass surface and does

emulsion samples with water cuts of 10, 50, 62, and 85% volume, not allow clear observation. The 85% water-cut emulsions were

respectively. The 50% water-cut emulsion was stable at least for unstable even in the presence of shear from PVT cell magnetic

18 to 24 hours, whereas the 62% volume water-cut emulsion stirrer. No image analysis was performed on the 85% water-cut

showed signs of oil/water segregation after a few hours. The in- emulsions, because both STO and live emulsions were unstable

version point for STO Oil A emulsions samples is estimated to be and could not be used for viscosity testing. No stability analysis

60±5% volume water cut. Fig. 2 shows the stability results for was performed on other live emulsions.

STO Oil B emulsion samples with water cuts of 50, 70, and 85% To investigate water droplet size distribution in emulsions, a

volume, respectively. Both 70 and 85% volume water cuts showed subsample of the live emulsions was flashed from the correspond-

instantaneous segregation of oil and water, indicating unstable ing emulsion cylinders to ambient conditions. The samples were

emulsions. The inversion point for STO Oil B emulsion samples is then analyzed under a microscope, and photomicrographs for each

estimated to be 65±5% volume water cut. emulsion were analyzed using image analysis software. Figs. 4

and 6 show the photomicrographs of emulsions for the Oil A and

Live Emulsion Preparation and Stability Analysis. Table 4 Oil B samples, respectively. Figs. 5 and 7 depict the correspond-

shows the conditions at which live emulsions were prepared in the ing droplet size distribution for the same images. Note that the

shear cell. The difference in the applied shear rates for the Oil A resolution of the images is approximately 1 micron, and number

emulsion samples is caused by the viscosity of the samples and the frequency for droplets smaller than 1 micron is merely a calculated

rotational speed. For 10 and 85% volume water contents, viscosity number and may not represent the actual droplets. For Oil A emul-

is lower than the case of 50% volume water content, and rotational sions, the droplet size distribution for both 10 and 50% water cut

Fig. 1—Stability of Oil A (STO) at 130°F. Fig. 2—Stability of Oil B (STO) at 130°F.

August 2007 SPE Production & Operations 287

Fig. 3—Stability of live 85% water-cut live emulsions of Oil A

and Oil B.

are very similar, and only the number frequency in the 50% water

cut is slightly higher. For Oil B, there is a slight shift in the droplet

size distribution of 50 and 60% emulsions compared to the 15%

emulsion. Comparing the 50 and 60% emulsions of Oil B, it seems

that 50% emulsion has a higher-number frequency of smaller drop-

lets, while the 60% emulsion has a higher number of larger drop-

lets. Note also that for 60% water cut, droplet size distribution

suggests the existence of another size mode, thus a near bimodal

distribution [e.g., partially unstable emulsions (Salager et al.

2000)]. The viscosity measurements for the same oil at 60% water

cut also shows a partially unstable system. Fig. 4—Photomicrographs of Oil A live emulsions (sample

flashed to ambient conditions).

Viscosity Measurements. The viscosities of the neat Oil A and

Oil B samples, together with their corresponding emulsions, were

determined using a capillary viscometer. Measured viscosities for

both dry Oil A and Oil B samples, at various pressures, are shown

in Fig. 8. Data follow an Arrhenius-type temperature trend, at least

for the measured range of temperature. Also, the neat oil viscosi-

ties decrease as the amount of solution gas increases with increas-

ing pressure. The viscosity of each sample was measured at least

at three different volumetric flow rates (shear rates), and the re-

ported viscosity values are the arithmetic average of measured

viscosities for each sample. There was no significant variation of

viscosity with shear rate. Tables 5 and 6 show the range of applied

shear rates (s−1) for each measured viscosity point. The standard

deviation of viscosity with shear rate varied between 0.1 and 1.4%

for Oil A and between 0.02 and 1.4% for Oil B. The overall

average standard deviations of measured viscosities over the range

of shear rate were 0.5 and 0.4% for Oil A and Oil B, respectively.

In all cases, reducing pressure below the bubblepoint (and sepa-

ration of lighter hydrocarbon components) increased the measured

viscosities for both neat oils and emulsions, as expected. At the

same time, an increase in water content of emulsions (up to and

near inversion point) increased the viscosities (Fig. 9). For the case

Fig. 5—Droplet size distribution of Oil A live emulsions (sample Fig. 6—Photomicrographs of Oil B live emulsions (sample

flashed to ambient conditions). flashed to ambient conditions).

288 August 2007 SPE Production & Operations

Fig. 7—Droplet size distribution of Oil B live emulsions (sample

flashed to ambient conditions).

Fig. 8—Viscosities of Oil A and Oil B (no water). Triangles for

100 psia, circles for 1,000 psia, diamonds for 2,000 psia, and

squares for 3,000 psia.

of the Oil A sample, viscosities increased up to 30% for 50%

water-cut emulsions at 40°F, and viscosity variation was more

sensitive to pressure than to water content. In comparison, the Case Study

viscosity of Oil B emulsions showed higher variation with water

content than with pressure. For the case of Oil B emulsions, vis- An ESP system performance analysis under these experimental

cosities increased more than 5 times at 50% water cut and 40°F. results was conducted. For this analysis, the measured data for Oil

For Oil B at 60% water cut, the viscosity dropped drastically B at 2,000 psia and 70°F is used. The measured data under the

compared to the 50% water cut. This behavior might be an indi- conditions was used to calibrate the calculated viscosity. The in-

cation that the emulsions were beyond the inversion point. formation and data for the reservoir and the well are presented in

Table 7 and Fig. 12.

Comparison of Emulsion Viscosity Correlations. Four single- Fig. 13 displays the well performance curves for oil (with no

parameter correlations were chosen for the comparison. Taylor’s emulsion). For this case, the flowing bottomhole pressure (FBHP)

(1932) and Vand’s (1948) correlations were used as the pioneer was 511 psia. For the flow rate, a pressure of 1,076 psia is required

and most commonly referred correlations. The correlations of Ron- to lift the fluid to the surface. This difference in pressure clearly

ningsen (1995) and Yaron and Gal-Or (1972) were chosen based indicates that the well requires artificial lift to produce 950 B/D of

on two separate performance studies (Johnsen and Ronningsen liquid, and an ESP system is the most suitable candidate for this

2003; Pal 2001). Although multiple-parameter correlations are situation. To achieve this flow rate, an additional 565 psi of pres-

available for more accurate prediction of emulsion viscosities, the sure is required. The pressure profile (pressure gradient) plot, seen

single-parameter equations were chosen for the sake of simplicity. in Fig. 14, summarizes the available and required lift pressures.

Multiple-parameter viscosity correlations need experimental data The change in water cut that changes the viscosity affects the

for tuning purposes. The emulsion viscosity data may not be avail- whole system twofold.

able a priori. Details of the correlations are provided in the Ap- First, increase in viscosity drastically changes the tubing per-

pendix. formance. Achieving the same rate requires much higher pressure

Figs. 10 and 11 depict the results of such a comparison for Oil to lift the fluid to the surface when water cut is increased. The

A and Oil B, respectively. The emulsion viscosities for Oil A were change in profile is shown in Fig. 14, and the friction component

best predicted with Taylor’s correlation with an absolute average that bears the effect of the viscosity is shown in Fig. 15.

error of 13%; Oil B emulsion viscosities were best predicted by the Second, the viscosity affects the performance of the pump. As

correlation of Yaron and Gal-Or with an average absolute error of the viscosity increases, the efficiency of the pump decreases and

21%. Note that only emulsion viscosity data were considered in the requires more stages to produce the same flow rate. Table 8 shows

error analysis. For Oil A, single-parameter correlations tend to that the number of stages, and required power increases drastically

overpredict the viscosity of emulsions, while for Oil B, no par- as water cut increases. The table also shows that the head factor for

ticular trend could be distinguished. This comparison between the each stage decreases and the power factor increases. The lower the

selected correlations, although limited to single-parameter corre- head correction factor, the less head or lift will be provided. On the

lations, shows that the predicted viscosity of emulsions with no a other hand, the higher the power factor, the more power will be

priori measurement may be largely inaccurate. required by the pump to operate and lift the same rate (these

factors are 1.0 for water). Therefore, the pump provides less head

or lift and requires more power (e.g., a larger motor) as emulsion

viscosity increases. This increase indicates that if the increase in

water cut is expected, the system should be designed for approxi-

mately the inversion point that causes the highest viscosity. As

emulsion viscosity increases with the water cut, more lift is re-

quired to move the fluid to the surface, and also the increase in

viscosity reduces the efficiency of the pump. In Table 9, the best

efficiency rate of the pump decreases as the viscosity increases.

In this analysis, the number of stages required to continue

producing the same rate was determined. In actual practice, if the

number of stages is set, then the production rate will decrease as

water cut increases, as expected.

August 2007 SPE Production & Operations 289

Conclusions Nomenclature

Viscosities of live recombined Oil A and Oil B samples and their D ⳱ internal diameter of capillary tube

different water-cut emulsions were measured using a capillary vis- k1–k4 ⳱ constants in Eq. A-4

cometer. Experimental results indicated that for all measured K ⳱ dispersed-phase viscosity/continuous-phase viscosity

cases, viscosities varied with temperature according to an Arrhe- L ⳱ length of capillary tube

nius relation, while viscosities did not indicate any variation within Q ⳱ volumetric flow rate

the range of tested flow rates, suggesting that fluids are Newto-

r ⳱ internal radius of capillary tube

nian. Measured viscosities also increased as pressure decreased

below the bubblepoint of the sample, inline with the amount of T ⳱ temperature

dissolved gases. Viscosity measurements for dry oil and emulsions ␥ ⳱ shear rate

of Oil A samples indicated that emulsion viscosities have in- ⌬p ⳱ differential pressure

creased by 30%, while for the case of Oil B samples, the increase ⳱ volume% water cut in Eq. A-4

in the emulsion viscosities was as high as 500%. ⳱ apparent emulsion viscosity

Regarding emulsion stabilities, the bench top bottle tests indi- c ⳱ continuous phase viscosity

cated that the inversion point for STO Oil A emulsions was ap- r ⳱ relative viscosity defined in Eq. A-1

proximately 60±5% volume water cut, and, for STO Oil B emul- ⳱ shear stress

sions, was approximately 65±5% volume water cut. For live-oil ⳱ volume fraction of dispersed phase

samples, the stability of only 85% volume water cut for both Oil

A and Oil B samples was tested, and both emulsion samples were

unstable. A systematic study to determine the inversion point of Acknowledgment

live-oil emulsions was not performed. However, the viscosity mea- The authors wish to thank Schlumberger and Shell Global Solu-

surements for the Oil A sample suggest that the inversion point tions (U.S.) Inc. for permission to publish this work. The authors

may be approximately 55±5% volume water cut at the tested con- would also like to thank Craig Borman, Trevor Lockyer, Rob

ditions (10% volume water cut lower than that of the STO sample). Fisher, and Abdulai Dawodu for performing experimental work.

A more definitive experimental scope of work is required to de-

termine the inversion point for the live emulsion samples. References

Comparison between four emulsion viscosity single-parameter Johnsen, E.E. and Ronningsen, H.P. 2003. Viscosity of ‘Live’ Water-in-Oil

correlations and measured viscosities indicated that the absolute Emulsions: Experimental Work and Validation of Correlations. Jour-

average error in the predicted emulsions viscosities could be as nal of Petroleum Science and Engineering 38: 23–36.

high as 200% for the tested fluids, as shown in Table 9. Single- Kokal, S. 2005. Crude-Oil Emulsions: A State-of-the-Art Review. SPEPF

parameter emulsion viscosity correlations should only be used 20 (1): 5–13. SPE-77497-PA. DOI: 10.2118/77497-PA.

with an expectation of large errors.

If higher water cut is expected during the lifespan of the ESP

system operation, the performance of the ESP should be consid-

ered very carefully. As the results show, either the system should

be designed for the worst-case scenario, which is the inversion

point, or change in the ESP system should be considered at dif-

ferent stages of the well’s life as water cut increases. But these

evaluations require reliable data for the emulsion viscosity of the

fluid.

Fig. 9—Viscosities of Oil A and Oil B and correspond-

ing emulsions.

290 August 2007 SPE Production & Operations

Fig. 10—Comparison between measured and calculated emul- Fig. 11—Comparison between measured and calculated emul-

sion viscosities for Oil A. sion viscosities for Oil B.

Kokal, S. et al. 2002. Productivity Decline in Oil Wells Related to As- Appendix

phaltene Precipitation and Emulsion Blocks. Paper SPE 77767 pre- In the following equations, the relative viscosity is defined as:

sented at the SPE Annual Technical Conference and Exhibition, San

Antonio, Texas, 29 September–2 October. DOI: 10.2118/77767-MS.

r = , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (A-1)

Nunez, G.A., Sanchez, G., Gutierrez, X., Silva, F., Dalas, C., and Rivas, H. c

2000. Rheological behavior of concentrated bitumen in water emul-

sions. Langmuir 16 (16): 6497–6502. in which r is the relative viscosity, is the emulsion apparent

viscosity, and c is the continuous-phase viscosity.

Pal, R. 2001. Single-Parameter and Two-Parameter Rheological Equations

The celebrated Taylor equation for the relative viscosity of very

of State for Nondilute Emulsions. Industrial and Engineering Chem-

dilute emulsions of nearly spherical noncolloidal droplets is:

istry Research 40: 5666–5674.

Ronningsen, H.P. 1995. Correlations for Predicting Viscosity of W/O

Emulsions Based on North Sea Crude Oils. Paper SPE 28968 presented

at the SPE International Symposium on Oilfield Chemistry, San An-

r = 1 + 冉 5K + 2

2K + 2 冊

, . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (A-2)

tonio, Texas, 14–17 February. DOI: 10.2118/28968-MS. in which K is the viscosity ratio of dispersed phase to continuous

Salager, J-L., Marquez, L., Pena, A.A., Rondon, M., Silva, F., and Tyrode, phase, and is the dispersed-phase volume fraction.

E. 2000. Current Phenomenological Know-How and Modeling of Vand’s correlation is a theoretically based exponential function

Emulsion Inversion. Industrial and Engineering Chemistry Research in the form of

冉 冊

39: 2665–2676.

2.5

Singh, P., Thomason, W.H., Gharfeh, S., Nathanson, L.D., and Blumer, r = exp , . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (A-3)

D.J. 2004. Flow Properties of Alaskan Heavy-Oil Emulsions. Paper 1 − 0.609

SPE 90627 presented at the SPE Annual Technical Conference and

in which is the volumetric concentration of dispersed phase.

Exhibition, Houston, 26–29 September. DOI: 10.2118/90627-MS.

Variations of Vand’s equation have been used. The most common

Szelag, H. and Pauzder, B. 2003. Rheological properties of emulsions modification is to replace 0.609 with a constant that can be deter-

stabilized by acylglycerol emulsifiers modified with sodium carboxy- mined by fitting experimental data.

lates. Colloids And Surfaces A—Physicochemical And Engineering As- Ronningsen correlation is represented as

pects 219 (1–3): 87–95.

Taylor, G.I. 1932. The Viscosity of Fluid Containing Small Drops of ln r = k1 + k2T + k3 + k4T, . . . . . . . . . . . . . . . . . . . . . . . (A-4)

Another Fluid. Proceedings of Royal Society A 138: 41–48.

Vand, V. 1948. Journal of Physics and Colloidal Chemistry 52: 217.

Yaron, I. and Gal-Or, B. 1972. On Viscous Flow and Effective Viscosity

of Concentrated Suspensions and Emulsions. Rheologica Acta 11:

241–252.

Fig. 12—Well trajectory.

August 2007 SPE Production & Operations 291

Fig. 14—Pressure profile for different water cuts, at 950 B/D.

Fig. 13—Inflow and outflow curves for 0% water cut.

National Iranian Oil Company (NIOC) at both onshore and

in which k1 to k4 are constants that have been determined at dif- offshore production fields as a process/production engineer.

ferent shear rates (30, 100, and 500 s−1) and based on a set of North He holds PhD and an MSc degrees from the University of Cal-

Sea oil database, T is temperature (°C), and is the volume per- gary, and a BS degree from the Abadan Institute of Technol-

cent water cut. The constants for 500 s−1 are: k1⳱−0.06671, ogy, all in chemical engineering. Moin Muhammad is Manager

k2⳱−0.000775, k3⳱0.03484, k4⳱0.00005. At constant tempera- of the DBR Technology Center with Schlumberger in Edmon-

ton, Canada. He has more than 12 years of operational, re-

ture, Eq. A-3 reduces to a single-parameter equation.

search, and management experience in reservoir fluid prop-

Yaron and Gal-Or’s analysis gives the following correlation for erties, flow assurance, and business development-related po-

the relative viscosity of concentrated emulsions: sitions (Canada and U.S.). Moin holds an MS degree from the

University of Alberta, Canada and a BS degree from Punjab

r = 1 University, Pakistan, both in chemical engineering. Ardeshir

+ 再 5.5关47 Ⲑ 3 + 10 − 共84 Ⲑ 11兲2 Ⲑ 3 + 共4 Ⲑ K兲共1 − 7 Ⲑ 3兲兴

10共1 − 10 Ⲑ 3兲 − 25共1 − 4 Ⲑ 3兲 + 共10 Ⲑ K兲共1 − 兲共1 − 7 Ⲑ 3兲

冎 ,

(Ardi) Shahraki is a senior production engineer with Schlum-

berger in the Artificial Lift segment at Schlumberger Reservoir

Completions campus in Rosharon, Texas. He has been with

Schlumberger since 2002. He previously worked for IHS Energy

. . . . . . . . . . . . . . . . . . . . . . . . (A-5) as a principal engineer/project manager. His interests include

multiphase fluid flow, well-system analysis, and modeling and

in which K is the viscosity ratio of dispersed phase to continuous predicting the performance of artificial lift systems for the de-

phase, and is the dispersed-phase volume fraction. sign and diagnostics of systems. He holds BS and MS degrees in

petroleum engineering from the University of Louisiana at

Lafayette, and a PhD degree in petroleum engineering from

Hussein Alboudwarej is a senior research project engineer with New Mexico Tech. Sheila Dubey is a senior staff research en-

Schlumberger at DBR Technology Center, Edmonton. The fo- gineer at Shell Global Solutions (U.S.) Inc. at the Westhollow

cus of his research is on wax and asphaltene flow assurance Technology Center in Houston and has been with Shell Oil

and the rheology of waxy and heavy crude oils. His research Company for 27 years. She is currently the U.S. team lead for

interests also include development of experimental tech- Scale Emulsions Rheology Foam (SERF) in Flow Assurance. She

niques and tools for complex phase behavior and flow assur- brings significant experience to these areas of flow assurance

ance studies. Before his graduate studies, he worked for the because of her background in physical organic chemistry,

analytical chemistry, chemical engineering, and strong prac-

tical laboratory skills in the areas of E&P, chemicals, and refin-

ing. Her interests also include EOR and asphaltenes. She holds

an MS degree from MUN in Newfoundland and a PhD degree

from the University of Calgary, both in chemistry, as well as an

MS degree in chemical engineering from the University of Tulsa.

Loek Vreenegoor joined Shell in 1990, working at the Shell Re-

search and Technology Center Amsterdam (SRTCA) in The

Netherlands with a focus on R&D and Technical Services. He

started in the area of polymer processing, then becoming in-

volved in modeling and computational fluid dynamics (CFD)

of viscoelastic flows. After a 1-year assignment at Westhollow

Technology Center (WTC) in Houston, where he worked on 3D

CFD of degrading polymers and multiphase flow, he returned

to SRTCA as the team leader in multiphase flow and became

Fig. 15—Friction component of pressure profile for 15 and 50%

water cut and 950 B/D.

292 August 2007 SPE Production & Operations

involved in three-phase flow modeling and slug mitigation. He Delft University of Technology, and he completed his PhD thesis

then joined the Flow Assurance group, working out of Amster- on the mathematical modeling of two-phase bubbly flows on

dam and Houston. Managerial responsibilities were combined the same faculty. Jamal Saleh has been a senior process/flow

with providing technical support, both in the design and op- assurance engineer with Shell International Exploration & Pro-

erational phase of upstream projects, varying from the Ormen duction since 2002. Before joining Shell, Jamal worked as a

Lange deepwater gas/condensate development in Norway senior flow assurance engineer at Intec Engineering for 2 years

to plugged flow lines in the Gulf of Mexico to heavy oil devel- and a process simulation engineer at Epcon International for 4

opments off the coast of Brazil. Vreenegoor holds a cum laude years. He holds a PhD degree in chemical engineering from

degree obtained at the Applied Mathematics Faculty of the Lamar University.

August 2007 SPE Production & Operations 293

You might also like

- Practice Examples Chapter 7 Thermochemistry Petrucci 10th EdDocument7 pagesPractice Examples Chapter 7 Thermochemistry Petrucci 10th EdHaggai NidarNo ratings yet

- Introduction To Electrical EngineeringDocument221 pagesIntroduction To Electrical EngineeringMarwin DacallosNo ratings yet

- 8 - PB 8 ESAS 3 Set BDocument12 pages8 - PB 8 ESAS 3 Set BBLACK MAMBA0% (2)

- Emulsiones Experiencias Spe-93386-PaDocument7 pagesEmulsiones Experiencias Spe-93386-PaEdison GarciaNo ratings yet

- Asfaltenso y Resinas 1 Ef060465wDocument10 pagesAsfaltenso y Resinas 1 Ef060465wChristian PaterninaNo ratings yet

- Viscosity Model for Water-in-Oil Emulsions in Porous MediaDocument11 pagesViscosity Model for Water-in-Oil Emulsions in Porous MediaAnand aashishNo ratings yet

- (Audrey Drelich 2010) Evolution of Water-In-Oil Emulsions Stabilized With Solid Particles Influence of Added EmulsifierDocument7 pages(Audrey Drelich 2010) Evolution of Water-In-Oil Emulsions Stabilized With Solid Particles Influence of Added EmulsifierJesus Ivan RomeroNo ratings yet

- VISCOSITY OF CRUDE OIL EMULSIONSDocument6 pagesVISCOSITY OF CRUDE OIL EMULSIONSferchosb12No ratings yet

- Emulsion 002Document30 pagesEmulsion 002Manus AgereNo ratings yet

- EMULSIONES EN CAPILARES 1-S2.0-S0301932209000366-MainDocument9 pagesEMULSIONES EN CAPILARES 1-S2.0-S0301932209000366-MainEdison GarciaNo ratings yet

- 06-Mechanisms of Crude Oil DemulsificationDocument10 pages06-Mechanisms of Crude Oil DemulsificationajostosNo ratings yet

- Alkaline FloodingDocument8 pagesAlkaline FloodingrifffaelfNo ratings yet

- 2008 Effect of Salinity and PH On Pickering Emulsion StabilityDocument17 pages2008 Effect of Salinity and PH On Pickering Emulsion StabilityLuis Carlos Patiño LagosNo ratings yet

- Simulation of O/W Emulsion Flow in Alkaline/Surfactant FloodDocument7 pagesSimulation of O/W Emulsion Flow in Alkaline/Surfactant FloodWilmer CuicasNo ratings yet

- A Case History of Heavy-Oil Separation in Northern Alberta: A Singular Challenge of Demulsifier Optimization and ApplicationDocument6 pagesA Case History of Heavy-Oil Separation in Northern Alberta: A Singular Challenge of Demulsifier Optimization and Applicationmanuel cabarcasNo ratings yet

- Spe 159979 MSDocument12 pagesSpe 159979 MSAfifahNo ratings yet

- A. A.S. D.G.: K. L. Mittal Et Al. (Eds.), Surfactants in Solution © Plenum Press, New York 1986Document2 pagesA. A.S. D.G.: K. L. Mittal Et Al. (Eds.), Surfactants in Solution © Plenum Press, New York 1986Ahlul Hafizan ReshaNo ratings yet

- SPE-176465-MS Experimental Investigation of Crude Oil Emulsion Physicochemical Properties and Demulsifier Dosage PredictionDocument24 pagesSPE-176465-MS Experimental Investigation of Crude Oil Emulsion Physicochemical Properties and Demulsifier Dosage PredictionGabriel EduardoNo ratings yet

- Simulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil RecoveryDocument13 pagesSimulation of O/W Emulsion Flow in Alkaline/Surfactant Flood For Heavy Oil Recoverylulalala8888No ratings yet

- Emulsification of Heavy Crude Oil in Water For Pipeline Transportation PDFDocument7 pagesEmulsification of Heavy Crude Oil in Water For Pipeline Transportation PDFJesus AlbertoNo ratings yet

- Demulsification of W/O emulsion at petroleum field and reservoir conditions using some demulsifiers based on polyethylene and propylene oxidesDocument11 pagesDemulsification of W/O emulsion at petroleum field and reservoir conditions using some demulsifiers based on polyethylene and propylene oxidesLluísNo ratings yet

- Experimental Investigation of Stability of Water in Oil Emulsions at ReservoirDocument13 pagesExperimental Investigation of Stability of Water in Oil Emulsions at ReservoirNour SwamNo ratings yet

- Paper Emulsiones. ViscosidadDocument13 pagesPaper Emulsiones. ViscosidadCesar MedinaNo ratings yet

- Al-Wahaibi2015 Article ExperimentalInvestigationOfTheDocument7 pagesAl-Wahaibi2015 Article ExperimentalInvestigationOfTheJesus AlbertoNo ratings yet

- Droplet Size Dependent Solubilization and Crystallization of Lipids in Oil-In-Water EmulsionDocument11 pagesDroplet Size Dependent Solubilization and Crystallization of Lipids in Oil-In-Water EmulsionCynthia Cano SarmientoNo ratings yet

- Emulsion Stability of Cosmetic Creams Based On Water-In-Oil High Internal Phase EmulsionsDocument7 pagesEmulsion Stability of Cosmetic Creams Based On Water-In-Oil High Internal Phase EmulsionsjosareforNo ratings yet

- Spe-123866-Ms A New Eor MethodDocument10 pagesSpe-123866-Ms A New Eor MethodyovaNo ratings yet

- Treatment of EmulsionDocument7 pagesTreatment of EmulsionSaurab DevanandanNo ratings yet

- Controlling The Emulsion Stability of Cosmetics Through Shear Mixing ProcessDocument7 pagesControlling The Emulsion Stability of Cosmetics Through Shear Mixing ProcessPark JiminNo ratings yet

- SPE-63165-MS Emulsion Index PDFDocument12 pagesSPE-63165-MS Emulsion Index PDFGabriel EduardoNo ratings yet

- Integrated Solution For Emulsion Diagnosis in Horizontal Production LogsDocument15 pagesIntegrated Solution For Emulsion Diagnosis in Horizontal Production LogsmbwassefNo ratings yet

- Characterization of Oil-Water Emulsion and Its UseDocument7 pagesCharacterization of Oil-Water Emulsion and Its UseCamilo Bocanegra ChaparroNo ratings yet

- Juntarasakul 2018 IOP Conf. Ser. - Earth Environ. Sci. 140 012024Document7 pagesJuntarasakul 2018 IOP Conf. Ser. - Earth Environ. Sci. 140 012024Ahmed HosniNo ratings yet

- SPE 102564 The Effect of Wettability On Oil Recovery of Alkaline/Surfactant/P Olymer FloodingDocument8 pagesSPE 102564 The Effect of Wettability On Oil Recovery of Alkaline/Surfactant/P Olymer FloodingClyde San VicenteNo ratings yet

- Factors Affecting Emulsion StabilityDocument2 pagesFactors Affecting Emulsion StabilityYusran YunusNo ratings yet

- Breaking of Water-in-Crude-Oil Emulsions. 2. Influence of Asphaltene Concentration and Diluent Nature On Demulsifier..Document7 pagesBreaking of Water-in-Crude-Oil Emulsions. 2. Influence of Asphaltene Concentration and Diluent Nature On Demulsifier..Jesus Alejandro RangelNo ratings yet

- OTC-29732-MS Recent Updates On Smart Water EOR in LimestoneDocument11 pagesOTC-29732-MS Recent Updates On Smart Water EOR in LimestonesaeedNo ratings yet

- Wang 2006Document9 pagesWang 2006Javier E. Guerrero ArrietaNo ratings yet

- Baldygin, Nobesm Mitra, 2014Document7 pagesBaldygin, Nobesm Mitra, 2014andrea.cipagautaNo ratings yet

- The Key To Predicting Emulsion Stability - Solid ContentDocument8 pagesThe Key To Predicting Emulsion Stability - Solid ContentLAURA CATALINA CARDENAS RODRIGUEZNo ratings yet

- Rate Effects On Water-Oil Relative PermeabilityDocument12 pagesRate Effects On Water-Oil Relative Permeabilityari_si100% (2)

- 2011-Alkaline Steam Foam-Cocepts and Experimental Results - RepairedDocument14 pages2011-Alkaline Steam Foam-Cocepts and Experimental Results - Repairedfernando aguilarNo ratings yet

- Impact of A Novel Scale Inhibitor System On The Wettability of Paleozoic Unayzah Sandstone Reservoir, Saudi ArabiaDocument6 pagesImpact of A Novel Scale Inhibitor System On The Wettability of Paleozoic Unayzah Sandstone Reservoir, Saudi ArabiaRosa K Chang HNo ratings yet

- Evaluation of Stability For Flowing Water-In-Oil Emulsion in Transportation PipelineDocument15 pagesEvaluation of Stability For Flowing Water-In-Oil Emulsion in Transportation PipelineTrung Dinh DucNo ratings yet

- Spe 123097Document18 pagesSpe 123097Jose Gregorio Fariñas GagoNo ratings yet

- Comparison of Three Methods of Relative Permeability MeasurementDocument16 pagesComparison of Three Methods of Relative Permeability MeasurementRosa K Chang HNo ratings yet

- Integrated - Solution of Emulsion Evaluatio by LogsDocument12 pagesIntegrated - Solution of Emulsion Evaluatio by Logsjlbarretoa0% (1)

- Ghosh2015 - Estabilidad SedimentacionDocument11 pagesGhosh2015 - Estabilidad SedimentacionAlbaMariaLotoNo ratings yet

- Acceptable Water-Oil and Gas-Oil Relative Permeability Measurements For Use in Reservoir Simulation ModelsDocument12 pagesAcceptable Water-Oil and Gas-Oil Relative Permeability Measurements For Use in Reservoir Simulation Modelsari_si100% (4)

- Mechanistic Study of Improved Heavy Oil Recovery by Alkaline FloodDocument12 pagesMechanistic Study of Improved Heavy Oil Recovery by Alkaline FloodRosa K Chang HNo ratings yet

- ASTMDocument10 pagesASTMGabriel EduardoNo ratings yet

- 4JOFCOLLINTSCIDocument11 pages4JOFCOLLINTSCIRouzseNo ratings yet

- SPE 102828 Field Success in Carbonate Acid Diversion, Utilizing Laboratory Data Generated by Parallel Flow TestingDocument14 pagesSPE 102828 Field Success in Carbonate Acid Diversion, Utilizing Laboratory Data Generated by Parallel Flow TestingzachNo ratings yet

- SPE 99757 Comparison of Secondary and Tertiary Recovery With Change in Injection Brine Composition For Crude Oil/Sandstone CombinationsDocument14 pagesSPE 99757 Comparison of Secondary and Tertiary Recovery With Change in Injection Brine Composition For Crude Oil/Sandstone CombinationsMuhammad Umair AliNo ratings yet

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocument13 pagesColloids and Surfaces A: Physicochemical and Engineering AspectsMarceta BrankicaNo ratings yet

- Spe 143161 MSDocument8 pagesSpe 143161 MSIbrahim SalahudinNo ratings yet

- OTCbservationDocument9 pagesOTCbservationlulalala8888No ratings yet

- OTC-28132-MS Subsea Demulsifier Injection To Reduce Emulsion Viscosity and Enhance Crude Oil ProductionDocument9 pagesOTC-28132-MS Subsea Demulsifier Injection To Reduce Emulsion Viscosity and Enhance Crude Oil ProductionRajarshiPanigrahiNo ratings yet

- Spe113510 PDFDocument10 pagesSpe113510 PDFعبدالغفار بيزانNo ratings yet

- Hsieh 1977Document12 pagesHsieh 1977Ruben Cruces LiraNo ratings yet

- Interaction of Paraffin Wax Gels With Ethylene/Vinyl Acetate Co-PolymersDocument7 pagesInteraction of Paraffin Wax Gels With Ethylene/Vinyl Acetate Co-Polymersazzrizalz1470No ratings yet

- Cipc 2009-053Document11 pagesCipc 2009-053Ralf JonesNo ratings yet

- Spe 186362 MSDocument12 pagesSpe 186362 MSyunusjanNo ratings yet

- SOLUCIÓN 5 - CARGA DE LIQUIDOSDocument7 pagesSOLUCIÓN 5 - CARGA DE LIQUIDOSmanuel cabarcasNo ratings yet

- Art 1Document10 pagesArt 1manuel cabarcasNo ratings yet

- SOLUCIÓN 1 - CARGA DE LIQUIDOSDocument13 pagesSOLUCIÓN 1 - CARGA DE LIQUIDOSmanuel cabarcasNo ratings yet

- Art - Tablas Claves Del Hazop IIDocument16 pagesArt - Tablas Claves Del Hazop IImanuel cabarcasNo ratings yet

- Supervisión Tremendo - PCPDocument17 pagesSupervisión Tremendo - PCPmanuel cabarcasNo ratings yet

- SPE 107290 Monitoring and Controlling Paraffin Deposition by A Direct Assessment TechniqueDocument9 pagesSPE 107290 Monitoring and Controlling Paraffin Deposition by A Direct Assessment Techniquemanuel cabarcasNo ratings yet

- IPTC-21827-MS Progressive Cavity Pump Self Optimising System Argentina FieldDocument8 pagesIPTC-21827-MS Progressive Cavity Pump Self Optimising System Argentina Fieldmanuel cabarcasNo ratings yet

- Supervisión Tremendo Ii - PCPDocument12 pagesSupervisión Tremendo Ii - PCPmanuel cabarcasNo ratings yet

- REDA Continuum: Improve Lift, Efficiency, and Reliability in Unconventional and Conventional Oil WellsDocument2 pagesREDA Continuum: Improve Lift, Efficiency, and Reliability in Unconventional and Conventional Oil Wellsmanuel cabarcasNo ratings yet

- SPE 136690 Improving Progressing Cavity Pump Performance Through Automation and SurveillanceDocument9 pagesSPE 136690 Improving Progressing Cavity Pump Performance Through Automation and Surveillancemanuel cabarcasNo ratings yet

- SPE 165666 Case Study: Achieving Maximum PCP Run-Life and Production in South America With Real-Time Digital Downhole MonitoringDocument5 pagesSPE 165666 Case Study: Achieving Maximum PCP Run-Life and Production in South America With Real-Time Digital Downhole Monitoringmanuel cabarcasNo ratings yet

- Journal of Natural Gas Science and Engineering: Priyabrata Pal, Ahmad Abukashabeh, Sameer Al-Asheh, Fawzi BanatDocument8 pagesJournal of Natural Gas Science and Engineering: Priyabrata Pal, Ahmad Abukashabeh, Sameer Al-Asheh, Fawzi Banatmanuel cabarcasNo ratings yet

- SPE 101846 Data Acquisition in Pumping WellsDocument18 pagesSPE 101846 Data Acquisition in Pumping Wellsmanuel cabarcasNo ratings yet

- Motores de Imanes Permanentes VS InducciónDocument15 pagesMotores de Imanes Permanentes VS Inducciónmanuel cabarcasNo ratings yet

- Spe-17586-Ms - Analisis Nodal de Esp - ReddacionDocument7 pagesSpe-17586-Ms - Analisis Nodal de Esp - Reddacionmanuel cabarcasNo ratings yet

- SPE 110234 Overview of Beam Pump OperationsDocument11 pagesSPE 110234 Overview of Beam Pump Operationsmanuel cabarcasNo ratings yet

- 01 PhillippiDocument21 pages01 PhillippigauravNo ratings yet

- Articulo English. Proceso de Endulzamiento de Gas Natural.Document8 pagesArticulo English. Proceso de Endulzamiento de Gas Natural.Javier QuirogaNo ratings yet

- Journal of Natural Gas Science and EngineeringDocument7 pagesJournal of Natural Gas Science and Engineeringmanuel cabarcasNo ratings yet

- The Flow of Real Gases Through Porous Media: Jun/Or Member A/Me Texas A&M College Station, TexDocument13 pagesThe Flow of Real Gases Through Porous Media: Jun/Or Member A/Me Texas A&M College Station, Texherdissam1No ratings yet

- 1 s2.0 S1875510016307612 MainDocument18 pages1 s2.0 S1875510016307612 Mainmanuel cabarcasNo ratings yet

- The Key To Predicting Emulsion Stability - Solid ContentDocument8 pagesThe Key To Predicting Emulsion Stability - Solid ContentLAURA CATALINA CARDENAS RODRIGUEZNo ratings yet

- Journal of Petroleum Science and Engineering: A.R. Hasan, C.S. KabirDocument10 pagesJournal of Petroleum Science and Engineering: A.R. Hasan, C.S. Kabirmanuel cabarcasNo ratings yet

- Graficos PV - Fugas en ValvulasDocument6 pagesGraficos PV - Fugas en Valvulasmanuel cabarcasNo ratings yet

- Spe 1987 19 Peh PDocument34 pagesSpe 1987 19 Peh Pmanuel cabarcasNo ratings yet

- Oil Water EmulsionDocument38 pagesOil Water EmulsionDiego1980bNo ratings yet

- A Case History of Heavy-Oil Separation in Northern Alberta: A Singular Challenge of Demulsifier Optimization and ApplicationDocument6 pagesA Case History of Heavy-Oil Separation in Northern Alberta: A Singular Challenge of Demulsifier Optimization and Applicationmanuel cabarcasNo ratings yet

- Thermo EXAMPLE 7.1-CHAPTER 7 PDFDocument11 pagesThermo EXAMPLE 7.1-CHAPTER 7 PDFFattihiEkhmalNo ratings yet

- Anomalies of Ionization Energy in The Periodic TableDocument17 pagesAnomalies of Ionization Energy in The Periodic TableKhan AaghaNo ratings yet

- NATM TUNNEL EXCAVATIONDocument101 pagesNATM TUNNEL EXCAVATIONKate MartinezNo ratings yet

- Elements, Compounds, and MixturesDocument35 pagesElements, Compounds, and Mixturesapi-419037032No ratings yet

- Power Waves and Conjugate Matching PDFDocument5 pagesPower Waves and Conjugate Matching PDFСергей АткишкинNo ratings yet

- Downloaded Spec Details Conductive EMI GasketsDocument22 pagesDownloaded Spec Details Conductive EMI GasketsAndra AndreNo ratings yet

- EXP5-Determination of Partial Molar QuantitiesDocument2 pagesEXP5-Determination of Partial Molar QuantitiesJoseph Helir MuñozNo ratings yet

- Fluid Mechanics - McMaster MECH ENG 3O04 - Assignments 1-11 SolutionDocument54 pagesFluid Mechanics - McMaster MECH ENG 3O04 - Assignments 1-11 Solutioncttiger7135No ratings yet

- C-FC-01-Liquid Tightness Design of LNG Storage Tank Incorporating Cryogenic Temperature-Induced StressesDocument8 pagesC-FC-01-Liquid Tightness Design of LNG Storage Tank Incorporating Cryogenic Temperature-Induced StressesManoj KanadiaNo ratings yet

- Soil MDocument24 pagesSoil M123456josuaNo ratings yet

- Two Isomers of C4H8O2 NMR AnalysisDocument5 pagesTwo Isomers of C4H8O2 NMR AnalysisYudiputra SidabutarNo ratings yet

- MauriceLongBarb 2009 Chapter3AntennaParame AntennasFundamentalsDDocument32 pagesMauriceLongBarb 2009 Chapter3AntennaParame AntennasFundamentalsDchouchou chamaNo ratings yet

- (Asce) SC 1943-5576 0000367 PDFDocument5 pages(Asce) SC 1943-5576 0000367 PDFirmakNo ratings yet

- Material Properties - IIDDocument1 pageMaterial Properties - IIDAmit SharmaNo ratings yet

- MCQ DomDocument15 pagesMCQ DomprabhaakarNo ratings yet

- SCIENCE 10 2nd QUARTER MODULE 1Document27 pagesSCIENCE 10 2nd QUARTER MODULE 1Jinky Aydalla100% (2)

- MAPUA WORK ENERGY EXPERIMENTDocument7 pagesMAPUA WORK ENERGY EXPERIMENTRhon AntonioNo ratings yet

- Lab Manual PDFDocument94 pagesLab Manual PDFGabriel SavageNo ratings yet

- Analysis of Ferrocement Beams Under Shear ForceDocument9 pagesAnalysis of Ferrocement Beams Under Shear ForceSamuel LoNo ratings yet

- Tool of The Complete Optimal Control For Variable Speed Electrical DrivesDocument36 pagesTool of The Complete Optimal Control For Variable Speed Electrical DrivesrijilpoothadiNo ratings yet

- B.Tech Mech 2018R PDFDocument247 pagesB.Tech Mech 2018R PDFKKNo ratings yet

- Terminology: HumidityDocument3 pagesTerminology: HumidityAnonymous KzJcjGCJbNo ratings yet

- An Overview of Modern Permanent Magnet DesignDocument71 pagesAn Overview of Modern Permanent Magnet Designray davisNo ratings yet

- 5.3 Effective Moduli of CFRP LaminaDocument20 pages5.3 Effective Moduli of CFRP LaminaGanesh.MahendraNo ratings yet

- Analysis of Chaos in Double PendulumDocument6 pagesAnalysis of Chaos in Double PendulumBikram PaulNo ratings yet

- Electrical Conductivity and Dielectric Behaviour of Nanocrystalline NiFe2Document18 pagesElectrical Conductivity and Dielectric Behaviour of Nanocrystalline NiFe2चन्द्रभाल सिंहNo ratings yet

- 02 Atomic Structure-Solved Example-1Document24 pages02 Atomic Structure-Solved Example-1Raju SinghNo ratings yet