Professional Documents

Culture Documents

Commissioning the S-Series Turbine

Uploaded by

Vilas m ChinkeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Commissioning the S-Series Turbine

Uploaded by

Vilas m ChinkeCopyright:

Available Formats

SKINNER

S-Series

Page 8

COMMISSIONING

4.0 COMMISSIONING 2) Check that the Trico constant level oiler mount-

ing adaptors and bottles are set to the correct

This section applies to a new turbine or to any turbine height. Check that the vents are clear of for-

that is to be operated again after a period of disuse. eign matter. Refer to Technical Data

Section 8.

Before commencing the commissioning operation, iso-

late the turbine from the steam supply and the driven 3) Fill each bearing housing to the correct level,

unit. using any of the recommended oils specified

(see Technical Data Section 8).

4.1 CLEANING CAUTION:

A) DO NOT OVERFILL THE HOUSINGS

1) Wipe off all preserving compound, dust, and

B) REFER TO THE WOODWARD GOVER-

debris from the entire unit and driven machine.

NOR MANUAL IN SECTION 10 FOR ANY

Make sure that all moving linkage and parts

LUBRICATION INSTRUCTIONS.

are clean. Also clear the immediate area

around the turbine and driven machine of all 4) Fill the Trico oiler bottles approximately three-

debris and loose tools not required. quarters full and refit to their mounting

2) Flush out the bearings liberally using paraffin/ adaptors.

kerosene. Also flush any oil piping, gear cases CAUTION:

or oil reser voirs. Allow the flushings to NEVER LET THE OILER BOTTLES BECOME

completely drain then refit all drain plugs. EMPTY.

4.2 LUBRICATING/COOLING 5) If the turbine utilizes a pump driven force feed

oil lubrication system:

The bearings are provided with either ring oiled

Fill the system with a recommended lubricant,

lubrication or a force feed system. In addition to

then run the system to circulate the oil into the

the sleeve type radial bearings at both the cou-

bearing housings BEFORE starting the turbine.

pling and governor end, there is a deep groove

ball thrust bearing at the outboard end of the NOTE:

governor end bearing. a) Circulate the oil until its temperature has

reached 100° F (40° C).

1) Ring lubrication bearing housings are provided b) Refer to manufacturer’s instructions in

with water cooled jackets. The amount of wa- Section 10.

ter circulated through each jacket should be

adjusted so as to maintain a bearing oil tem- 6) Check that the following items are lubricated

perature of 120° to 175° F (50° to 80° C). with one of the recommended high tempera-

ture greases specified in Technical Data

NOTE: Section 8.

The cooling water pressure at inlet should

preferably be 25-30 psig (1.8-2.1 kg/cm2g), a) The governor valve stem and guide

and in no case should exceed 75 p s ig b) Emergency trip linkage

(5.3 kg/cm2g). c) Governor linkage.

It is recommended that the water outlet from

the jackets be passed through an open

collector to the drain, so that water circulation

can be checked.

You might also like

- Gmi 404470935806Document5 pagesGmi 404470935806b8505887No ratings yet

- TR Filter TDS FlowerDocument7 pagesTR Filter TDS FlowerBinod KafleNo ratings yet

- Oil Flushing Procedures For Steam Turbine & Generator Sets 1Document8 pagesOil Flushing Procedures For Steam Turbine & Generator Sets 1atul singhNo ratings yet

- Bomba HydracellDocument9 pagesBomba HydracellHelison MendesNo ratings yet

- Overseas Locomotive Shipment Preparation GuideDocument6 pagesOverseas Locomotive Shipment Preparation Guideamir barekatiNo ratings yet

- Storage Procedure - WAD002 Issue 10Document2 pagesStorage Procedure - WAD002 Issue 10NikkikumarNo ratings yet

- Tfe 7315Document7 pagesTfe 7315mohd faizNo ratings yet

- APDD 339A Sierra Long Term StorageDocument4 pagesAPDD 339A Sierra Long Term StorageCesar HernandezNo ratings yet

- Lister Cs Manual PDFDocument16 pagesLister Cs Manual PDFMASSERONNo ratings yet

- Hyundai Exel 89 1.5l.mantenimientoDocument18 pagesHyundai Exel 89 1.5l.mantenimientoAlexander cesar neyra sotoNo ratings yet

- Marine Engine Installation GuideDocument22 pagesMarine Engine Installation GuideAungthuyaThuyaNo ratings yet

- Руководство По Ремонту Brp CanDocument513 pagesРуководство По Ремонту Brp CanvaleriyNo ratings yet

- Manual Ato 7227 FX 2019 IngDocument10 pagesManual Ato 7227 FX 2019 IngAlvaro PadillaNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7Document12 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 7anony8103No ratings yet

- NEHS07740001Document4 pagesNEHS07740001mahmodNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- Bomba Myers D35-20DVDocument12 pagesBomba Myers D35-20DVdiroperacionesNo ratings yet

- User S Guide KDDocument22 pagesUser S Guide KDEmil KochanekNo ratings yet

- Operation & Maintenance Manual: Thrustmaster Outboard Propulsion Unit Section 5 Maintenance ProceduresDocument9 pagesOperation & Maintenance Manual: Thrustmaster Outboard Propulsion Unit Section 5 Maintenance ProceduresMohammed BasionyNo ratings yet

- Rcrit 14V647 9581Document43 pagesRcrit 14V647 9581Eko PurwantoNo ratings yet

- Caution: CCN: 80440142 Rev. ADocument5 pagesCaution: CCN: 80440142 Rev. AGustavo HuertasNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddydioneslealNo ratings yet

- Caip-II Apu & Engine Storage by Aviator-ArifDocument25 pagesCaip-II Apu & Engine Storage by Aviator-ArifAparna RNo ratings yet

- Basic MaintenanceDocument23 pagesBasic MaintenancePedro Lucas Rodrigues QueirozNo ratings yet

- Manual and Parts List: SubmersibleDocument12 pagesManual and Parts List: SubmersibleWalter Ruiz AstoNo ratings yet

- Main Pump - Test - Measurement of Case Drain Oil: Shutdown SISDocument4 pagesMain Pump - Test - Measurement of Case Drain Oil: Shutdown SISR I SantosoNo ratings yet

- Group 3 Tests and Adjustments Group 3 Tests and AdjustmentsDocument15 pagesGroup 3 Tests and Adjustments Group 3 Tests and AdjustmentsGlaitonNo ratings yet

- Fuel Module in Tank Unit Replacement InstructionsDocument3 pagesFuel Module in Tank Unit Replacement InstructionsForesight MisrNo ratings yet

- Instruction - Flushing Gas Turbine Lubricant Oil SystemDocument5 pagesInstruction - Flushing Gas Turbine Lubricant Oil SystemRicky Hendra Silalahi100% (1)

- EKM Engineering Knowledge MotorDocument22 pagesEKM Engineering Knowledge MotorMc Den Al BakryNo ratings yet

- .Archivetempsection 15 - StorageDocument6 pages.Archivetempsection 15 - StorageFernando MirandaNo ratings yet

- Lubrication and MaintenanceDocument18 pagesLubrication and MaintenanceRamon AcostaNo ratings yet

- Imai Ek General Q ADocument88 pagesImai Ek General Q APranjyoti SaikiaNo ratings yet

- Technical Information Bulletins Ajax # 010717Document28 pagesTechnical Information Bulletins Ajax # 010717harley florezNo ratings yet

- Service Manual Susuki Baleno Sy418Document395 pagesService Manual Susuki Baleno Sy418juanmahepa75% (4)

- IAMI Revision Answers Motor and GeneralDocument26 pagesIAMI Revision Answers Motor and GeneralStewart LongNo ratings yet

- Caterpillar 988 Wheel Loader Operators Manual SN 87aDocument6 pagesCaterpillar 988 Wheel Loader Operators Manual SN 87aCarlos Cetina100% (1)

- Manual de Taller de Motor Completo Suzuki Gran Viatara 2.5Document93 pagesManual de Taller de Motor Completo Suzuki Gran Viatara 2.5Toni diestreNo ratings yet

- Boiler Do's & Don'tsDocument7 pagesBoiler Do's & Don'tsMithilesh YadavNo ratings yet

- Caterpillar Crawler Operators Manual CT o d9Document7 pagesCaterpillar Crawler Operators Manual CT o d9Tommy JunNo ratings yet

- Pbs Turbo LTD./ 595 01 - Velka Bites, Czech RepublikDocument23 pagesPbs Turbo LTD./ 595 01 - Velka Bites, Czech Republikslava50% (2)

- 500 TF ManualDocument13 pages500 TF ManualJawad AmjadNo ratings yet

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- Service Letter: Hartzell Propeller IncDocument6 pagesService Letter: Hartzell Propeller IncLuis AbelleiraNo ratings yet

- FLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eDocument2 pagesFLUCHING LUB SYSTEM NOHAB W25 W25SG W25DF 9197400200eLIVIANo ratings yet

- System maintenance proceduresDocument13 pagesSystem maintenance proceduresMTK2016No ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Service and Training Manual for 99AX Reciprocating Booster AssemblyDocument34 pagesService and Training Manual for 99AX Reciprocating Booster AssemblyFernando NunezNo ratings yet

- Propeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Document7 pagesPropeller Maintenance Manual 132A: Page 7-56 Rev. 22 Dec/20Alexis Kidema0% (1)

- GMI2148840355689Document9 pagesGMI2148840355689Govind kumar DhnakaNo ratings yet

- Parte 5 Md200Document22 pagesParte 5 Md200samuelNo ratings yet

- A Procedure For Lube Oil FlushingDocument2 pagesA Procedure For Lube Oil FlushingchrisNo ratings yet

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- WBHE ManualDocument3 pagesWBHE ManualBruno DelgadoNo ratings yet

- Light Grade Repair: Truck, Dump, Medium, Winch, Mc2 - UnimogDocument10 pagesLight Grade Repair: Truck, Dump, Medium, Winch, Mc2 - UnimogmichaelNo ratings yet

- THE POWER OF EMOTIONAL GEARBOXESDocument22 pagesTHE POWER OF EMOTIONAL GEARBOXESroberto_perraciniNo ratings yet

- Machinery Selection-Books14Document16 pagesMachinery Selection-Books14miningnova2No ratings yet

- Chiller Tech - EIL DelhiDocument9 pagesChiller Tech - EIL DelhibmanojNo ratings yet

- 73 20 02 PDFDocument12 pages73 20 02 PDFAnonymous 298xlo3uUNo ratings yet

- Briggs and Stratton 27996 9 61 Operator ManualDocument4 pagesBriggs and Stratton 27996 9 61 Operator Manualrop703406No ratings yet

- 11-4SN (G, G ) 11-4SN (G, G ) : Precision RegulatorDocument2 pages11-4SN (G, G ) 11-4SN (G, G ) : Precision RegulatorVilas m ChinkeNo ratings yet

- GD3 Activity (English)Document40 pagesGD3 Activity (English)api-3770121100% (2)

- Unbrako US Product Guide PDFDocument144 pagesUnbrako US Product Guide PDFVilas m ChinkeNo ratings yet

- Xfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsDocument6 pagesXfmea Report Sample - Design FMEA: in Addition To This Summary, This Report Includes The Following FormsVilas m ChinkeNo ratings yet

- Affinity Diagram ProcessDocument2 pagesAffinity Diagram ProcessVilas m ChinkeNo ratings yet

- Machine Foundation-1 Higher Load Not Used For ReferenceDocument5 pagesMachine Foundation-1 Higher Load Not Used For ReferenceVilas m ChinkeNo ratings yet

- 03 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - TURBINE OILSDocument5 pages03 HPCL - INDUSTRIAL - BOOKLET - JAN 2017 - Part I - TURBINE OILSVilas m ChinkeNo ratings yet

- Valve Materials ServiceDocument2 pagesValve Materials ServiceKartik MorpariyaNo ratings yet

- Product Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Document12 pagesProduct Brochure Kunkle Safety Relief Valves Product Overview Kunkle Valve en en 5198290Vilas m ChinkeNo ratings yet

- MaterialDocument1 pageMaterialVilas m ChinkeNo ratings yet

- Flexseal STG Gaskets-1Document1 pageFlexseal STG Gaskets-1Vilas m ChinkeNo ratings yet

- 21CrMoV5 7Document2 pages21CrMoV5 7zamporpsNo ratings yet

- Unbrako CatalogDocument16 pagesUnbrako CatalogAvinash BorigiNo ratings yet

- Pressure Temperature Charts ASTMDocument4 pagesPressure Temperature Charts ASTMAnonymous rdv9nb1No ratings yet

- Failure Mechanism For BaldingDocument1 pageFailure Mechanism For BaldingVilas m ChinkeNo ratings yet

- Screw Thread For UNC PDFDocument40 pagesScrew Thread For UNC PDFVilas m Chinke100% (1)

- Steam QualityDocument2 pagesSteam QualityVilas m ChinkeNo ratings yet

- Ceramic Fiber BlanketDocument1 pageCeramic Fiber BlanketVilas m ChinkeNo ratings yet

- Air Cooled CondenserDocument20 pagesAir Cooled CondenserVivek SinghNo ratings yet

- SPW Gasket TolerencesDocument1 pageSPW Gasket TolerencesVilas m ChinkeNo ratings yet

- Material ASTM A217Document1 pageMaterial ASTM A217Vilas m ChinkeNo ratings yet

- Steel Casting DrawingDocument8 pagesSteel Casting DrawingVilas m ChinkeNo ratings yet

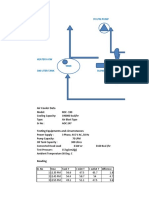

- Steam Flow Vs Power Curve for 11 TPH MaxDocument2 pagesSteam Flow Vs Power Curve for 11 TPH MaxVilas m ChinkeNo ratings yet

- Heat Exchanger Rough Rev 1Document4 pagesHeat Exchanger Rough Rev 1Vilas m ChinkeNo ratings yet

- Analysis of Air Cooled CoolerDocument6 pagesAnalysis of Air Cooled CoolerVilas m ChinkeNo ratings yet

- Thermo Compressor CalculatorDocument6 pagesThermo Compressor CalculatorVilas m ChinkeNo ratings yet

- Engineering Structures and Materials - Concrete Beam AnalysisDocument51 pagesEngineering Structures and Materials - Concrete Beam AnalysisVilas m ChinkeNo ratings yet

- Norman ConquestDocument35 pagesNorman Conquestapi-463690129No ratings yet

- School Form 10 SF10-SHS Senior High School Student Permanent RecordDocument3 pagesSchool Form 10 SF10-SHS Senior High School Student Permanent RecordMelben ResurreccionNo ratings yet

- User Manual: SM-R800 SM-R805F SM-R810 SM-R815FDocument154 pagesUser Manual: SM-R800 SM-R805F SM-R810 SM-R815Fbatto1No ratings yet

- Natural Law's Rise and FallDocument17 pagesNatural Law's Rise and FallNoel James100% (2)

- 15-5240 enDocument14 pages15-5240 enRafa Lopez PuigdollersNo ratings yet

- Bion W R - Complite Works Vol IIDocument272 pagesBion W R - Complite Works Vol IIjanusz100% (4)

- FPSC@FPSC - Gove.pk: Sector F-5/1, Aga Khan Road, Islamabad Email: UAN:-051-111-000-248Document9 pagesFPSC@FPSC - Gove.pk: Sector F-5/1, Aga Khan Road, Islamabad Email: UAN:-051-111-000-248Ayaz AliNo ratings yet

- How To Build A Shed With A Slanted Roof Step-by-Step GuideDocument39 pagesHow To Build A Shed With A Slanted Roof Step-by-Step GuideFederico BarberisNo ratings yet

- Employment and Skill MismatchDocument20 pagesEmployment and Skill MismatchFarah LimNo ratings yet

- Tadimalla Bala ChaitanyaDocument4 pagesTadimalla Bala ChaitanyaTADIMALLA BALA CHAITANYANo ratings yet

- Capstone PosterDocument1 pageCapstone Posterapi-538849894No ratings yet

- What is Economics? - The study of production, distribution and consumption /TITLEDocument37 pagesWhat is Economics? - The study of production, distribution and consumption /TITLEparthNo ratings yet

- Identify statements that match birthday party picturesDocument1 pageIdentify statements that match birthday party picturesprotogina100% (1)

- Saint Aquinas and Mercantilism School of ThoughtsDocument11 pagesSaint Aquinas and Mercantilism School of ThoughtsKatunga MwiyaNo ratings yet

- Case Week 2Document2 pagesCase Week 2Reta AzkaNo ratings yet

- Manure HandlingDocument14 pagesManure HandlingIvan Sampson100% (1)

- Election Summary Report November 3, 2020 - General Election Wayne County, Michigan Unofficial ResultsDocument77 pagesElection Summary Report November 3, 2020 - General Election Wayne County, Michigan Unofficial ResultsStephen BoyleNo ratings yet

- SAnet CD 9811017409 PDFDocument357 pagesSAnet CD 9811017409 PDFoeamaoesahaNo ratings yet

- Wps PrenhallDocument1 pageWps PrenhallsjchobheNo ratings yet

- UPSC EPFO Previous Year Paper 2017 Questions PDFDocument12 pagesUPSC EPFO Previous Year Paper 2017 Questions PDFPraveenNo ratings yet

- Cutaneous Abscess Furuncles and CarbuclesDocument25 pagesCutaneous Abscess Furuncles and Carbuclesazmmatgowher_1219266No ratings yet

- ĐỀ THI GIỮA KÌ 2 - E9 (TẤN)Document4 pagesĐỀ THI GIỮA KÌ 2 - E9 (TẤN)xyencoconutNo ratings yet

- Divya Shree: ObjectiveDocument2 pagesDivya Shree: Objectivekids montessoriNo ratings yet

- Exercise in Class 1 English 1 PERSONAL PRONOUNSDocument2 pagesExercise in Class 1 English 1 PERSONAL PRONOUNSDarkness jhlp100% (1)

- Data Science ArticleDocument2 pagesData Science ArticleRamendra KumarNo ratings yet

- Impact of Product Rebranding On Organization ProfitabilityDocument63 pagesImpact of Product Rebranding On Organization ProfitabilityDaniel ObasiNo ratings yet

- User's Manual: & Technical DocumentationDocument20 pagesUser's Manual: & Technical DocumentationPODOSALUD HUANCAYONo ratings yet

- Hoopvol Chapter Summaries PDFDocument29 pagesHoopvol Chapter Summaries PDFNakeisha Jesse Napallatan82% (28)

- Liming Heavy Industry Introduction NewDocument7 pagesLiming Heavy Industry Introduction NewJohnny DoeNo ratings yet

- Book Review in The Belly of The RiverDocument4 pagesBook Review in The Belly of The RiverJulian BaaNo ratings yet