Professional Documents

Culture Documents

Power and Control Cables For Extreme Application According To

Uploaded by

Rachid SmailiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power and Control Cables For Extreme Application According To

Uploaded by

Rachid SmailiCopyright:

Available Formats

Power and control cables for extreme application according to VDE 0250 PART.

814

MAIN APPLICATION

Extra heavy duty power and control cables. For application with high mechanical stresses (i.e.: tensile

and torsion simoultaneously applied). These cables have a tensile load of minimum 2000 N (standard for

control cables) and are indicated to be used on equipment such as container crane spreader reels, rack and

pinion elevators using shave guided cables, pendant station, all tenders etc.

CONSTRUCTION

Conductor: Tinned copper conductor, extraflexible cl.6 IEC 60228 up to 6 mm2, flexible cl.5

IEC 60228 from 10 mm2

Both the class of conductors are specially designed for mobile application

Insulation: EPR compound better than 3GI3

special compound with improved electrical and mechanical characteristics

Cores identification: Colours according to according to DIN VDE 0293 part 308 / HD 308 S2

Standard colours:

- 4 cores: green/yellow, brown, black, grey

- 5 cores: green/yellow, blue, brown, black, grey

- ≥ 6 cores: black with printed numbers, green/yellow in the outer layer

Central strainer (if any): Made of aramidic yarns

To be used as support element

Laying-up: Short lay length for better flexibilty

≤ 6,5 times the laying-up cores diameter in maximum 3 layer (for control cables)

Separation (if any): Tape(s)

Inner sheath: Polychloroprene rubber based compound

Better than 5GM2

Antitwisting protection: Textile braid of synthetic yarns

Firmly vulcanized bonded between inner and outer sheath

Outer sheath: Yellow polychloroprene rubber compound

Oil and chemical resistant, 5GM3/5GM5 abrasion and notch resistant

Marking: U.T.V. CAVI manufactured BY PALAZZO - PANZERFLEX-L VS 0,6/1 kV n. of cores x cross section

PARAMETERS

Electrical Rated voltage Uo/U= 0,6/1 kV

Maximum permissible operating voltage in AC systems Um = 1,2 kV

AC test voltage over 5 minutes 3,5 kV

Current Carrying Capacity According to DIN VDE 0298 part 4

Thermal Fully flexible operation - 25 °C

Fixed installation - 40 °C

Maximum permissible operating temperature of the conductor 90 °C

Short-circuit temperature of the conductor 250 °C

Mechanical Tensile load Up to 20 N/mm2

PANZERFLEX-L with a minimum of 2000 N

VS 0.6/1 kV Minimum bending radii According to DIN VDE 0298 part 3

NSHTÖU-J/ -O; Reeling operation No restriction. Consult the manufacturer

if speed exceeds 180 m/min

NSHTÖU -JZ / OZ

Chemical Resistance to oil According to VDE / IEC standard

Weather resistance Unrestricted use outdoor and indoor,

tugh rubber UV resistant, moisture resistant.

sheathed cable

24 Panzerflex and Tunnelflex Cables

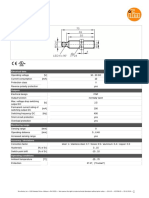

TABLE 1 - PANZERFLEX-L VS 0.6/1 kV - NSHTÖU-J/ -O; NSHTÖU -JZ / OZ tough rubber sheathed cable

Vertical Application and High Tensile Load

N. of cores Conductor Overall diameter Net weight Maximum Current carrying capacity at 30 °C* Short circuit

and nominal D.C. resist. approx. permissible current

tensile force Laid Suspended Spiral or 80 ° to 200

section at 20 °C nom. diam. min. max. kg/km N straight in free air 1 layer 2 layer 3 layer °C

(n∙mm2) Ohm/km mm mm mm A A A A A kA

7G1.5 13,7 1,6 16,9

19,0 460 2000 23 24 18 14 11 0,19

12G1.5 13,7 1,6 23 25,1 805 2000 23 24 18 14 11 0,19

18G1.5 13,7 1,6 23,1

25,2 855 2000 23 24 18 14 11 0,19

24G1.5 13,7 1,6 26,5

28,6 1100 2000 23 24 18 14 11 0,19

30G1.5 13,7 1,6 29,6

32,8 1420 2000 23 24 18 14 11 0,19

36G1.5 13,7 1,6 29,8

32,8 1460 2000 23 24 18 14 11 0,19

7G2.5 8,21 2,1 18,6

20,7 590 2000 30 32 24 18 15 0,32

12G2.5 8,21 2,1 25,5

27,6 1050 2000 30 32 24 18 15 0,32

18G2.5 8,21 2,1 25,7

27,8 1130 2000 30 32 24 18 15 0,32

24G2.5 8,21 2,1 29,8

33,0 1560 2000 30 32 24 18 15 0,32

30G2.5 8,21 2,1 34,0

37,2 2000 2000 30 32 24 18 15 0,32

36G2.5 8,21 2,1 34,2

37,4 2070 2000 30 32 24 18 15 0,32

7G4 5,09 2,7 21,4

23,5 820 2000 41 43 33 25 20 0,51

12G4 5,09 2,7 29,8

33,0 1550 2000 41 43 33 25 20 0,51

18G4 5,09 2,7 30,0

33,2 1680 2000 41 43 33 25 20 0,51

20G6 - - 39,0

42,5 2800 2400 - - - - - -

4G10 1,95 4,2 21,7 23,8 905 2000 74 78 59 45 36 1,3

4G16 1,24 5,4 25,4 27,5 1310 2000 99 104 79 60 49 2,0

4G25 0,795 6,6 29,6 32,8 1870 2000 131 138 105 80 64 3,2

4G35 0,565 8,0 32,6 35,8 2470 2800 162 170 130 99 79 4,5

4G50 0,393 9,3 37,8 41,0 3280 4000 202 212 162 123 99 6,4

4G70 0,277 11,2 43,2 46,2 3410 5600 250 263 200 153 123 9,0

4G95 0,210 13,0 48,0 52,5 5630 7600 301 316 241 184 147 12,2

*Tabulated values are valid up to three loaded conductors with or without earth.

Derating factor shall be used for multicore cables depending on loaded conductors. See page 45.

www.utvcavi.com 25

You might also like

- Panzerflex L 2Document2 pagesPanzerflex L 2Nino BallatanNo ratings yet

- Cable NshtouDocument1 pageCable NshtouEugenioNo ratings yet

- Schede Tecniche Panzerflex VsDocument1 pageSchede Tecniche Panzerflex Vslek888No ratings yet

- Cable - Datasheet - (Eng) S07RC4N8-F, Pirelli - 2002-04-01 - Screened-Submersible-SensorcableDocument2 pagesCable - Datasheet - (Eng) S07RC4N8-F, Pirelli - 2002-04-01 - Screened-Submersible-SensorcableA. Muhsin Pamungkas100% (1)

- EU Data Sheet Chainflex CF890Document8 pagesEU Data Sheet Chainflex CF890gaconlonton410No ratings yet

- D 025 Topflex Motor 109Document2 pagesD 025 Topflex Motor 109MarcosNo ratings yet

- EU Data Sheet Chainflex CF896Document6 pagesEU Data Sheet Chainflex CF896vfernandezNo ratings yet

- Elettrotek Kabel GAALFLEXDocument2 pagesElettrotek Kabel GAALFLEXIvan NikodijevicNo ratings yet

- Foundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureDocument1 pageFoundation Fieldbus: Dataguard™ - Iec61158-2 - Isa/Sp50 - Type A - Extended TemperatureJosé CallisayaNo ratings yet

- Apdcl TSDocument18 pagesApdcl TSBhavesh KeraliaNo ratings yet

- Windfarm Cables DatasheetsDocument10 pagesWindfarm Cables DatasheetsMarkos AntoniosNo ratings yet

- 4x2.5GV+Sch and 7x2.5GV+SchDocument1 page4x2.5GV+Sch and 7x2.5GV+SchalaNo ratings yet

- BASKETHEAVYFLEXDocument2 pagesBASKETHEAVYFLEXGustavo RodriguezNo ratings yet

- Belden P/N 50106F: Industrial CAT 6 F/UTPDocument2 pagesBelden P/N 50106F: Industrial CAT 6 F/UTPAsep heriyanaNo ratings yet

- Prysmian - TECSUN XPVXDocument5 pagesPrysmian - TECSUN XPVXsydneyaus2005No ratings yet

- GTP For 1CX300sqmmDocument4 pagesGTP For 1CX300sqmmpriyanka236No ratings yet

- DB1136752ENDocument1 pageDB1136752ENIng. Mario A. Samudio IbarraNo ratings yet

- Far East 07Bn8-F: Power Cables EN 50525-2-21Document7 pagesFar East 07Bn8-F: Power Cables EN 50525-2-21dachinicuNo ratings yet

- Cordaflex (SMK) (N) ShtoeuDocument3 pagesCordaflex (SMK) (N) Shtoeufikri abu kassimNo ratings yet

- Instrumentation Cable: ApplicationDocument2 pagesInstrumentation Cable: Applicationbakien-canNo ratings yet

- MMBZXXVXL, SZMMBZXXVXL Series 40 Watt Peak Power Zener Transient Voltage SuppressorsDocument5 pagesMMBZXXVXL, SZMMBZXXVXL Series 40 Watt Peak Power Zener Transient Voltage SuppressorsEsquisofNo ratings yet

- Topflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingDocument2 pagesTopflex - Emv-2Yslcy-J: For Power Supply Connections To Frequency Converters, Double Screened, 0,6/1kV, Meter MarkingMarcosNo ratings yet

- Janitza Datasheet-UMG96RM enDocument7 pagesJanitza Datasheet-UMG96RM enNelutu BreazuNo ratings yet

- Crane CablesDocument2 pagesCrane CablesTimuçin KARABULUTLARNo ratings yet

- Servo Cables: Technical Data: ConstructionDocument1 pageServo Cables: Technical Data: ConstructionRajiv ChaudhariNo ratings yet

- DatasheetDocument1 pageDatasheetramkumar85No ratings yet

- 1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsDocument8 pages1SMB5.0AT3 Series 600 Watt Peak Power Zener Transient Voltage SuppressorsedgardoNo ratings yet

- 120 Ω Modbus/CAN Bus RS-485 Technical DataDocument1 page120 Ω Modbus/CAN Bus RS-485 Technical DataJoel Marchena GrandaNo ratings yet

- Kerpen 10px1 5 Is-Os En50288-7Document3 pagesKerpen 10px1 5 Is-Os En50288-7Rijo RajanNo ratings yet

- Tecsun (PV) Pv1 F Cable For Photovoltaics: EnergyDocument5 pagesTecsun (PV) Pv1 F Cable For Photovoltaics: Energyrommy_boy330No ratings yet

- RE 2X (ST) YSWAY FL PDFDocument3 pagesRE 2X (ST) YSWAY FL PDFAnas AzzedineNo ratings yet

- RE 2X (ST) YSWAY FLDocument3 pagesRE 2X (ST) YSWAY FLandy175No ratings yet

- TOPCABLE - RH5Z1-OL Al Eng - Rev7Document4 pagesTOPCABLE - RH5Z1-OL Al Eng - Rev7apranaguptaNo ratings yet

- 1 5smcxxat3 OnDocument9 pages1 5smcxxat3 Onmukesh sharmaNo ratings yet

- Multispeed 500Document1 pageMultispeed 500Luis AguilarNo ratings yet

- 12x18 AWG TC 600V Overall Shielded Control Cable - 8KMP112109 - V - 1 - R - 3Document2 pages12x18 AWG TC 600V Overall Shielded Control Cable - 8KMP112109 - V - 1 - R - 3omarNo ratings yet

- Cordaflex (SMK) - V (N) Shtoeu EnglDocument3 pagesCordaflex (SMK) - V (N) Shtoeu EnglrachidNo ratings yet

- Servo Motor Cables: Technical Data: ConstructionDocument1 pageServo Motor Cables: Technical Data: ConstructionHafiani HichamNo ratings yet

- 2 - 7714-U0gy8-HaDocument1 page2 - 7714-U0gy8-HaMohd Sami UddinNo ratings yet

- Evc 135Document4 pagesEvc 135Leewwon LeeNo ratings yet

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionDocument10 pagesServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineNo ratings yet

- IID 4167 En-Ta200541-Uk8pr0321iDocument4 pagesIID 4167 En-Ta200541-Uk8pr0321iapusica.wwhNo ratings yet

- Datasheet 6281-Ev 120127 EngDocument6 pagesDatasheet 6281-Ev 120127 EngsalimiyounessNo ratings yet

- Leaflet Zvar CapacitorsDocument5 pagesLeaflet Zvar CapacitorsGagak 2304No ratings yet

- DatasheetDocument5 pagesDatasheetStuxnetNo ratings yet

- MV CONNEX Technical Data Surge Arrester Size 2 and DrawingDocument6 pagesMV CONNEX Technical Data Surge Arrester Size 2 and DrawingFelipe Mafioletti SchuartzNo ratings yet

- Opgw-12b1-48 (62.7 12.7)Document9 pagesOpgw-12b1-48 (62.7 12.7)Palle YulianNo ratings yet

- Lapp Pro586469enDocument5 pagesLapp Pro586469enshakti jhaNo ratings yet

- Power and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVDocument3 pagesPower and Control Cable IEC 60502-1: Flame Retardant, Sunlight Resistant 90 °C / U /U 0,6/1 KVShashank SaxenaNo ratings yet

- 2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11Document2 pages2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11Daniel ArgumedoNo ratings yet

- 2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11Document2 pages2x16 AWG TC 600V Overall Shielded Control Cable - 8KDP102109 - V - 1 - R - 11jairo mahechaNo ratings yet

- DB3022673ENDocument1 pageDB3022673ENChristoper SepulvedaNo ratings yet

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pages(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniNo ratings yet

- Flexidrum T 210Document2 pagesFlexidrum T 210Bruno TumbacoNo ratings yet

- Pressure Transmitters: PXT-K SeriesDocument2 pagesPressure Transmitters: PXT-K Serieskarim karimNo ratings yet

- Technical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDocument9 pagesTechnical Specification For 18 (30) KV Cold-Shrinkable Cable AccessoriesDkalestNo ratings yet

- Technical Specification AL-59 Conductor 893Document18 pagesTechnical Specification AL-59 Conductor 893pramjitNo ratings yet

- Cable Instrumentacion 1Document1 pageCable Instrumentacion 1Misi KeiterNo ratings yet

- 6XV18300PH10 Datasheet enDocument2 pages6XV18300PH10 Datasheet enRonaldo CesarNo ratings yet

- 14DG96000040零部件图册Document697 pages14DG96000040零部件图册Rachid Smaili100% (1)

- Operating ManualDocument466 pagesOperating ManualRachid SmailiNo ratings yet

- Planetary Plug-In Gearboxes by LiebherrDocument12 pagesPlanetary Plug-In Gearboxes by LiebherrRachid Smaili100% (1)

- Data Logger BasicsDocument17 pagesData Logger BasicsRachid SmailiNo ratings yet

- FSG Angular Position Transducers EDocument11 pagesFSG Angular Position Transducers ERachid SmailiNo ratings yet

- Sany Sdcy90Document528 pagesSany Sdcy90Rachid SmailiNo ratings yet

- Part Manual For DG4502Y90029Document665 pagesPart Manual For DG4502Y90029Rachid SmailiNo ratings yet

- Terex Franna Pick Carry Cranes Spec 1bdb74Document39 pagesTerex Franna Pick Carry Cranes Spec 1bdb74Rachid SmailiNo ratings yet

- Liebherr Lrs 545 31 Reachstacker Container Handling Toplift Datasheet EnglisDocument3 pagesLiebherr Lrs 545 31 Reachstacker Container Handling Toplift Datasheet EnglisRachid SmailiNo ratings yet

- MEDITOOL Parts For Oil Field Transportation Equipment (2020.10.01) - Sos StackerDocument8 pagesMEDITOOL Parts For Oil Field Transportation Equipment (2020.10.01) - Sos StackerRachid SmailiNo ratings yet

- TAD1342VE: Volvo Penta Industrial DieselDocument2 pagesTAD1342VE: Volvo Penta Industrial DieselRachid SmailiNo ratings yet

- Cable Harnessing: Special Cables Temperature Measurement HarnessingDocument4 pagesCable Harnessing: Special Cables Temperature Measurement HarnessingRachid SmailiNo ratings yet

- Technical Data - Tad1342veDocument9 pagesTechnical Data - Tad1342veRachid SmailiNo ratings yet

- Pieces de Rechange KONECRANESDocument11 pagesPieces de Rechange KONECRANESRachid SmailiNo ratings yet

- TAD1140-1142VE: Low Cost of OwnershipDocument2 pagesTAD1140-1142VE: Low Cost of OwnershipRachid Smaili100% (1)

- Spare Parts CatalogueDocument1 pageSpare Parts CatalogueRachid SmailiNo ratings yet

- Encodeur Vitesse Rotation IncrementalDocument4 pagesEncodeur Vitesse Rotation IncrementalRachid SmailiNo ratings yet

- TUP 18 20 en PDFDocument2 pagesTUP 18 20 en PDFRachid SmailiNo ratings yet

- Ig5788 03 - en UsDocument3 pagesIg5788 03 - en UsRachid SmailiNo ratings yet

- TUP 20-1200 TUP 18-1200: Forklift For General Loads 18, 20 TonnesDocument2 pagesTUP 20-1200 TUP 18-1200: Forklift For General Loads 18, 20 TonnesRachid SmailiNo ratings yet

- Elme Spreader Donnees TechniquesDocument15 pagesElme Spreader Donnees TechniquesRachid Smaili100% (3)

- 2) FOGMAKER Installation Fire Suppression SystemDocument1 page2) FOGMAKER Installation Fire Suppression SystemRachid SmailiNo ratings yet

- 4tnv94l NCKM - PDF YanmarDocument27 pages4tnv94l NCKM - PDF YanmarRachid Smaili100% (2)

- Ecc - New 12.131.02.980Document1 pageEcc - New 12.131.02.980Rachid SmailiNo ratings yet

- Material Price List PDFDocument2 pagesMaterial Price List PDFJp Gallardo85% (92)

- Fibres PPT 1Document19 pagesFibres PPT 1rajesh duaNo ratings yet

- Cathodic ProtectionDocument15 pagesCathodic ProtectionmiraNo ratings yet

- Ss400 Ned & Pcsir ResultsDocument1 pageSs400 Ned & Pcsir ResultsMinhas ArshadNo ratings yet

- Blaine TestDocument1 pageBlaine Testوائل شديوةNo ratings yet

- Dental Base Resins 2Document27 pagesDental Base Resins 2Nurzafirah IliasNo ratings yet

- Costar 2K: Cementitious Waterproof MembraneDocument2 pagesCostar 2K: Cementitious Waterproof MembranePearl GbolahanNo ratings yet

- Concrete Canoe Using Light Weight Aggregate: Ab Ul Saleem .K, Prashob C, Sooraj M, Mohamme NishamDocument4 pagesConcrete Canoe Using Light Weight Aggregate: Ab Ul Saleem .K, Prashob C, Sooraj M, Mohamme NishamHARISHMA RAVEENDRANNo ratings yet

- 7.1 Covalent Bonding (1C) QPDocument13 pages7.1 Covalent Bonding (1C) QPSrijita RoyNo ratings yet

- CIP 5 Plastic Shrinkage Cracking PDFDocument2 pagesCIP 5 Plastic Shrinkage Cracking PDFSwëêt Rãsçäl SëlvåNo ratings yet

- Gautam 2016Document22 pagesGautam 2016MairaMaraviChavezNo ratings yet

- Division Iii-Concrete & MasonryDocument31 pagesDivision Iii-Concrete & MasonryClive Aaron GuanzonNo ratings yet

- Kathwada Industry ListDocument14 pagesKathwada Industry Listmeet dodhiwalaNo ratings yet

- Steel PlantDocument21 pagesSteel PlantKaran Sagar KathuriaNo ratings yet

- NA2XS FL 2Y RM 18 30 KV PDFDocument2 pagesNA2XS FL 2Y RM 18 30 KV PDFSid Ali RABEHINo ratings yet

- South Africa Statistics - Land Transport Survey, March 2021Document14 pagesSouth Africa Statistics - Land Transport Survey, March 2021Deepak SamavedamNo ratings yet

- Classification and Properties of Materials: Humayun Kabir, Lecturer, Dept. of MMEDocument27 pagesClassification and Properties of Materials: Humayun Kabir, Lecturer, Dept. of MMEBiddut DasNo ratings yet

- BTCVE506A Materials, Testing & Evaluation Syllabus Dbatu UniversityDocument2 pagesBTCVE506A Materials, Testing & Evaluation Syllabus Dbatu Universityrameshwar911983020% (3)

- Arlanxeo TSR Product BrochureDocument16 pagesArlanxeo TSR Product BrochureErwin ErwinNo ratings yet

- TDS SW 901 3Document5 pagesTDS SW 901 3Frans Hendra WinartaNo ratings yet

- Rate Report 03.12.19Document13 pagesRate Report 03.12.19PP PolymerBazaarNo ratings yet

- Performance Assessment of Aged Binder Rejuvenated With Polanga OilDocument13 pagesPerformance Assessment of Aged Binder Rejuvenated With Polanga OilBesim QelajNo ratings yet

- Sector Die CatalogueDocument3 pagesSector Die CatalogueAHMED YOUSEF100% (1)

- BOQ Ato Amanuel TesfayeDocument5 pagesBOQ Ato Amanuel Tesfayedawitggg100% (1)

- Project Report On Cellular Light Weight ConcreteDocument21 pagesProject Report On Cellular Light Weight ConcreteVishal Kumar100% (1)

- Nav Precast Prestressed 02-Slab PrecastDocument24 pagesNav Precast Prestressed 02-Slab Precastmuhammad faisalNo ratings yet

- Polymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriDocument42 pagesPolymer Fiber Reinforced Concrete Pavement: by MD Mutiullah MD Faisal Mohd Abdul Quddus B. MadhuriGamer RckNo ratings yet

- Micro Alloyed Steels Voestalpine EN 30102020Document4 pagesMicro Alloyed Steels Voestalpine EN 30102020pierocarnelociNo ratings yet

- Certificate of Quality SX4040Document2 pagesCertificate of Quality SX4040SHERIF EIDNo ratings yet

- Sans 1431Document30 pagesSans 1431johndupNo ratings yet